7© Airtec International Ltd. All Rights Reserved. No reproduction of whole or part of this Manual is allowed without written Permission of Copyright.

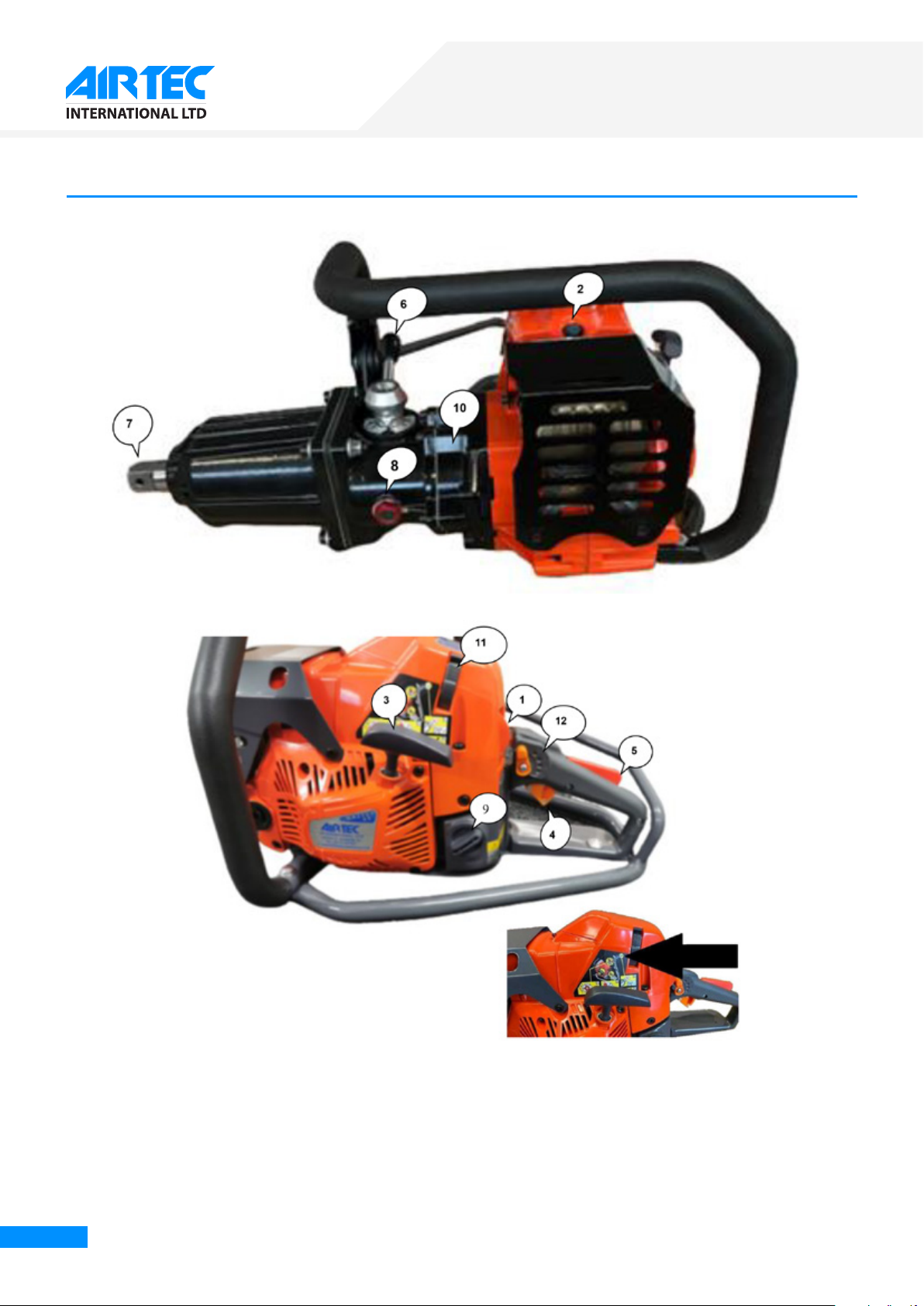

New Master35© Impact Wrench

Maintenance Manual

ROUTINE SERVICE SEE EXPLODED DIAGRAM DRAWINGS ON PAGES 10-14 AND 16-18

1. REPLACING SPARK PLUG 4003.5010

Lift two Cover Clips and lift off Filter Cover 4003.3010. Pull

off Spark Plug Cover. Unscrew Spark Plug and replace with

Champion RCJ4 or equivalent making sure the gap is set at

0.5mm (0.02”).

2. REPLACING AIR FILTER 4003.3080

Remove the Filter Cover by

lifting the Filter Cover Clips.

Loosen the two air filter

screws and remove it.

Clean with a suitable

degreaser, rinse with

water and blast dry with

compressed air. Renew the

filter if heavily clogged or

damaged.

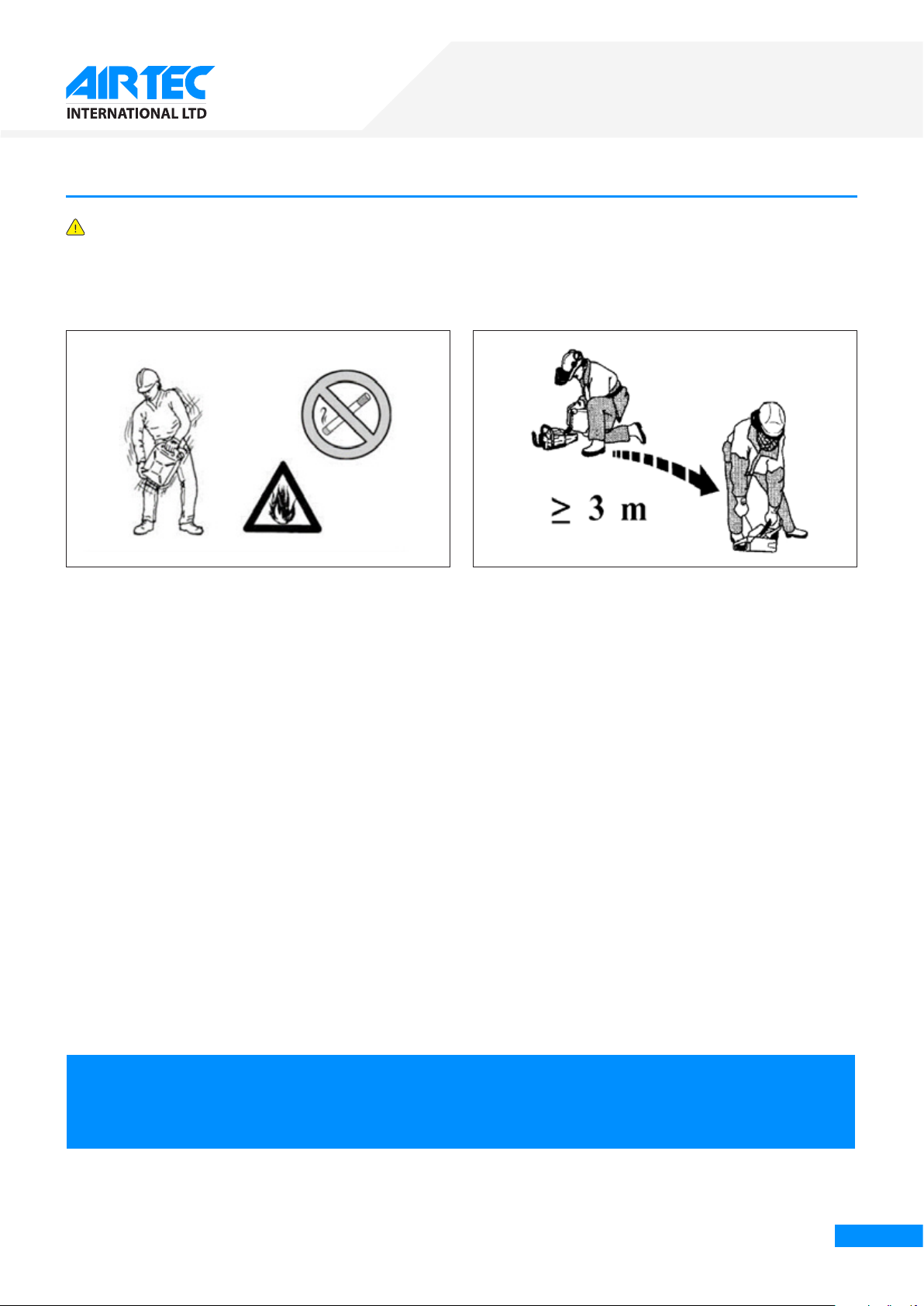

3. REPLACING FUEL FILTER 4003.1075

With the Wrench in a vertical

position open Fuel Cap

4003.6020 cautiously to release

any build-up of pressure in the

Fuel Tank. Pull out Fuel Filter and

replace if dirty.

4. REPLACING STARTER ROPE 4003.0340

Remove four Screws 4003.2070 holding Starter Assembly

4003.2190 and Screws 2300.0520 off muffler guard and

remove Starter Assembly. Hold Pulley 4003.2130 with thumb,

cut old cord and allow Pulley to turn slowly back until no

tension is left in Recoil Spring 4003.2150. Remove Centre

Screw 4003.0690 and Washer 4003.0700 and slowly lift off

Pulley. Fit new Rope through Pulley and tie a knot. Feed other

end of Rope through Starter Assembly 4003.2190 and into

Starter Handle 4003.2180 and again tie a knot. Locate Pulley

in Recoil Spring and replace Centre Screw 4003.0690 and

Washer 4003.0700. Locate Rope in the notch on outside of

pulley, turn clockwise two complete turns then release. Repeat

until the Starter Handle returns to the Housing locating hole -

Approximately six complete turns when pulled out. Re-attach

starter assembly.

5. REPLACE GEAR BOX OIL

Remove three Screws 2300.0512 in Gear Selector 2870.1000

and remove from Gear Box. Empty out old oil. Fill gearbox with

0.25 litres (½ pint) of Gazpromneft Reductor CLP68, Mobil Gerar

626, Carter EP68, Merpoa 68, Valvoline 80-90W or an equivalent

non synthetic 68 viscosity Gear Oil. Re-fit Selector and fit screws

using a suitable fastener locking fluid.

6. GREASING HAMMER AND ANVIL

Remove three nuts 2310 2061, four Screws 2300.0851 and Nose

Casing 035301. Clean out old grease and replace with 130

grammes (4 ½ ozs) of new Molybdenum Disulphate Grease

Grade 2 Ensure this is pumped into holes on the side of

Hammer Casing 2590.1000 and onto all eight striking faces.

Use of the correct quality grease will extend the life of both

Anvil and Hammer.

7. ENGINE

Clean Starter Housing and Cylinder Fins at regular intervals. Use

either a brush or compressed air. Dirt build up on the cylinder

will generate overheating which could then reduce engine

performance.

8. CARRYING AND THROTTLE HANDLE

Replace Rubber Mounts when they are ineffective or worn out.

9. ROUTINE MAINTENANCE INSTRUCTIONS

It is recommended a record of inspections and maintenance

is kept and each Wrench is given a routine maintenance

check every three months. This will reduce maintenance costs,

improve efficiency and extend its useful life. Fix a label showing

next Service date

DAILY Check all Bolts, Screws and Nuts for

tightness and gearbox oil level.

WEEKLY Clean Air Filter and Fuel Filter.

If necessary use a suitable Solvent.

MONTHLY Clean Spark Plug and check gap is 0.5 m

THREE MONTHS As above plus following:- Clean internal

Hammer and Anvil Faces thoroughly and

replace Grease.

SIX MONTHS Change Fuel Filter and check condition of

Air Filter and Spark Plug

ANNUALLY Replace Gear Box Oil

Use only GENUINE MASTER SPARE PARTS This will cost less

than using non original Spare Parts which generally don’t last

as long. Use of non-original parts reduces Wrench life cancels

Warranty