BOSS – Installation, Operation and Maintenance Manual

A l e n c o n S y s t e m s L L C - P a g e | 2

Contents

Contents ............................................................................................................................................. 2

General Information ............................................................................................................................ 4

Purpose ..................................................................................................................................... 4

Glossary..................................................................................................................................... 4

Product Warranty ....................................................................................................................... 5

Technical Support and Assistance ............................................................................................. 6

Warnings, Cautions and Notes ................................................................................................... 6

Packing List ............................................................................................................................... 7

Ordering Information .................................................................................................................. 7

IMPORTANT SAFETY INSTRUCTIONS ............................................................................................ 8

Introduction ...................................................................................................................................... 10

Energy Storage Systems Benefits ............................................................................................ 10

Energy Storage Systems Challenges ....................................................................................... 10

Potential Hazards ..................................................................................................................... 10

State-of-Charge and State-of-Health ........................................................................................ 10

BOSS Features ................................................................................................................................ 11

BOSS- Bi-Directional Optimizer for Storage Systems............................................................... 11

Galvanic Isolation ..................................................................................................................... 11

Ground Leak Detection ............................................................................................................ 12

Communication ........................................................................................................................ 12

Parallel Operation .................................................................................................................... 12

BOSS Operation............................................................................................................................... 13

BOSS Controls......................................................................................................................... 13

STATE Machine ....................................................................................................................... 14

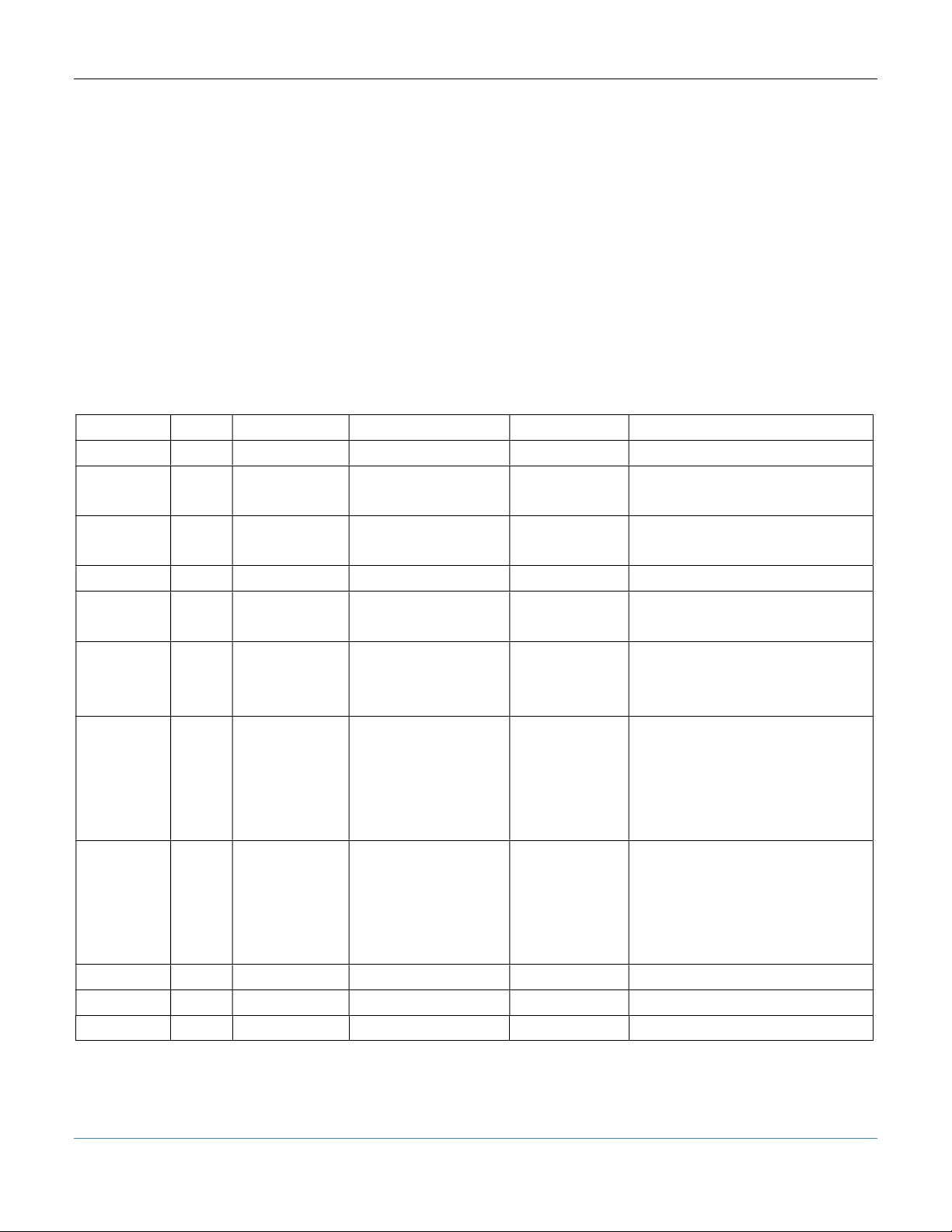

Technical Specifications ........................................................................................................... 15

Communication ................................................................................................................................ 16

BOSS Protection .............................................................................................................................. 16

BUS Protection ........................................................................................................................ 16

Under voltage ....................................................................................................................... 16

Current Limit ........................................................................................................................ 16

Short Circuit Protection ........................................................................................................ 16

Battery Protection .................................................................................................................... 16

Under voltage ....................................................................................................................... 16

Over current ......................................................................................................................... 16

Short Circuit Protection ........................................................................................................ 16

Ground Leak Protection ....................................................................................................... 16

Environmental Protection ......................................................................................................... 17

Temperature on Power Semiconductor ................................................................................ 17

Microcomputer Temperature ................................................................................................ 17

Control Board Temperature .................................................................................................. 17

Humidity ............................................................................................................................... 17

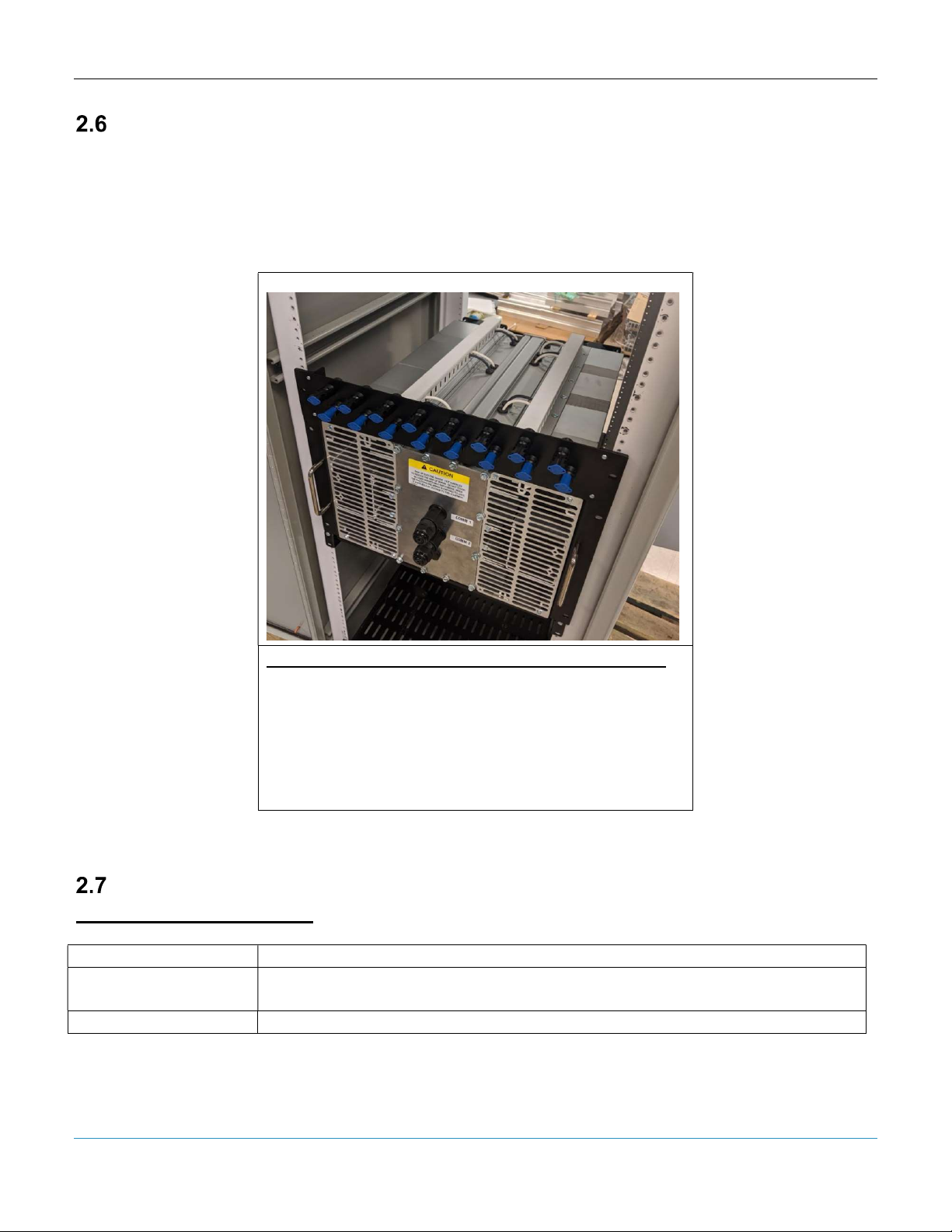

BOSS Installation ............................................................................................................................. 18

Understanding BOSS Hardware .............................................................................................. 18

BUS & Battery Cable Termination ........................................................................................ 20

Communication Ports ........................................................................................................... 21

Fusing for Input and Output Wiring........................................................................................... 22

Alencon Fused Electrical Disconnect (FEED) ....................................................................... 22

Alencon Communication Environment (ACE) Setup..................................................................... 23

PODD Installation .................................................................................................................... 23

Installation Options ........................................................................................................... 23