Allstyle AB Series User manual

AB* SERIES

AIR HANDLING UNITS INSTALLATION GUIDE

GENERAL

The AB* Series is designed for horizontal recessed

installations in a furred down area, above a suspended

ceiling or recessed in the ceiling. AB* Series models

are for electric heat, DX cooling, and for heat pump

applications. The unit can be congured for return air

ow through the integral access panel or at the end

of the unit. Installation tabs are built into the cabinet

to facilitate mounting the unit. Optional panels are

available that allow a wide range of installation

options. Electric resistance heaters are available

along with optional air conditioning and heat pump

indoor coils. Full service of all components is easily

accomplished through the access panels.

Coil Company, L.P

WARNING: Due to possible damage to equipment or personal injury, installation, service, and

maintenance should only be performed by a trained, qualied person. Consumer service is recommended

only for lter replacement.

Installation of this unit shall be made in accordance with the National Electric Code, NFPA

No. 90A and 90B, and any other local codes or utilities requirements.

WARNING: HAZARDOUS VOLTAGE - Ensure all power is disconnected before installing or

servicing this unit. More than one disconnect device may be required to de-energize the equipment.

Hazardous voltage can cause severe personal injury. Make certain all panel are in place before operating

this unit.

UNPACKING

Carefully unpack the unit and inspect the contents for

damage. If any damage is found at the time of delivery,

proper notication and claims should be made with the

carrier who delivered the unit.

Check the rating plate to assure model number and

voltage, plus any kits agree with what you ordered.

The manufacturer should be notied within 5 days of

any discrepancy or parts shortage.

LOCATION

The blower coil unit should be centrally located and

may be installed above a suspended ceiling with the

integral return panel, in a furred down area with remote

or integral return, or recessed in the ceiling.

This unit is approved for “0” clearance from any side,

front, rear, or duct work. The unit must be installed in a

level position to ensure proper condensation drainage.

Make sure the unit is level in both directions within 1/8”.

1/2018 LM20020-D

INSTALLATION GUIDE

The unit incorporates installation tabs that mount to the

framing and provide a 1/2” ange to trim to the nished

edge of a sheet rock ceiling. The access panel mounts

to the cabinet and trims the installation.

All service entrances and exits on the cabinet are

recessed to allow for 2” x 4” framing of the opening the

cabinet will be centrally located within. Any modications

to existing framing should be accomplished by the

general contractor to ensure structural strength is

maintained in the structural opening in the framing for

the ABF Series should be 47 1/4” long and 22 3/4” wide.

The unit should be positioned where the bottom edge of

the cabinet is 1/2” below the framing member.

DUCT WORK

The duct work should be installed in accordance with

the NFPA No. 90A “Installation of Air Conditioning and

Ventilating Systems” and No. 90B “Residential Type

Warm Air Heating and Air Conditioning Installed”.

The duct work should be insulated in accordance with

the applicable requirements for the particular type

installation as required by HUD, FHA, VA the applicable

building code, local utility, or other governing body.

CONDENSATE DRAIN

The AB* Series furred down air handlers are now

shipped standard with our integral drain trap built

into the drain pan. This unique design eliminates the

need for exterior condensate traps in the primary drain

line. Do not reduce the drain line size less than the

connection size on the drain pan. Condensate should

be piped to an open drain or to the outside. All drains

must pitch downward away from the unit a minimum of

1/8” per foot of line to ensure proper drainage.

REFRIGERANT PIPING

Refrigerant pipe connections are located within the

unit cabinet. Holes are provided to route refrigerant

pipes from either side of the cabinet. Refrigerant piping

external to the unit shall be sized in accordance with

the instructions of the manufacturer of the outdoor

equipment. When units are recessed mounted in the

wall, make certain that piping connections are pressure

tested prior to the wall being closed.

Manufacturer does not insulate the expansion valve

distributor tubes or liquid lines coming from

manifold. It is the sole responsibility of the contractor

to properly insulate from condensation.

(YOU MUST INSULATE THE REFRIGERANT LINES

AND TXV UP TO WHERE THE PAN CATCHES ALL

CONDENSATE DRIPS)

METERING DEVICE

All units are shipped with a check ow piston installed which

is designed for air conditioning or heat pump operation.

If your application requires a thermal expansion valve or

check expansion valve then it is necessary to remove the

piston from the distributor assembly and install the proper

metering device. Be sure to follow the instructions in the

kit to ensure proper installation.

WIRING

Consult all schematic and pictorial wiring diagrams of this

unit and the outdoor equipment to determine compatibility

of the wiring connections and to determine specic

requirements.

All eld wiring to the blower coil should be installed in

accordance with the latest edition of the National Electric

Code NFPA No. 70 and any local codes.

Check rating plates on unit for rated volts, minimum

circuit ampacity and maximum over current protection.

Supply circuit power wiring must be 75°C. (167°F)

minimum copper conductors only. Copper supply wires

shall be sized to the National Electric Code or local code

requirements, whichever is more stringent.

The unit is shipped wired for 230/240 Volt AC, 60 Hz, 1

Phase Operation. If the unit is to be operated at 208 VAC,

60 Hz, then follow the instruction on the indoor unit wiring

diagram to change the low voltage transformer to 208

VAC operation.

Be sure the unit is properly grounded.

Class 2 low voltage control wiring should not be run in

conduit with power wiring and must be separated from

power wiring, unless class 1 wire of proper voltage rating

is used. Low voltage control wiring should be 18 Awg,

color coded (105°C minimum). For lengths longer than

100 ft., 16 Awg wire should be used. Make certain that

separation of control wiring and power wiring has been

maintained.

AB* SERIES INSTALLATION GUIDE Page 2

INSTALLATION GUIDE

AB* SERIES INSTALLATION GUIDE Page 3

THERMOSTAT

Select a thermostat that is commonly referred to as a

single stage cooling with electric sub base. This stat

will energize the fan on a demand for heat or cool.

Install the thermostat on an inside wall away from

drafts, lights or other heat sources in a location that

has good air circulation from the other rooms being

controlled by the thermostat. The thermostat should

be mounted 4’ to 5’ above the oor.

SEQUENCE OF OPERATION

Cooling (cooling only or heat pump with reversing

valve energized in heat mode): When the thermostat

calls for cooling, the blower relay is energized. The

N.O. contacts will close after a time delay then the

indoor blower will operate. The circuit between R and

Y is completed which causes the contactor on the

outdoor equipment to close, and start the compressor

and the outdoor fan motor.

Cooling (heat pump with reversing valve energized

in cooling mode): When the thermostat calls for

cooling, the circuit between R and G and R and O is

complete. Circuit R and O energizes the reversing

valve to the cooling position. Circuit R and G energizes

the blower relay. The N.O. contacts will close after a

time delay then the indoor blower will operate. The

circuit between R and Y is complete. Which causes

the contactor on the outdoor equipment to close, and

start the compressor and the outdoor fan motor.

Heating (electric heat only): When the thermostat

calls for heat, the circuit between R and W is completed.

The heat sequencer is energized. A time delay will

occur, which allows the heating element(s) and the

indoor blower motor to come on.

Heating (heat pump reversing valve energized

in the heat mode): When the thermostat calls for

heat, the circuits between R and B, R and Y and R

and G are completed. Circuit R and B energize the

reversing valve switching it to the heat position. Circuit

R and Y energized the outdoor unit contactor starting

the compressor and outdoor fan. Circuit R and G

energizes the blower relay stating the blower motor.

If the indoor room temperature should continue to fall,

circuit R and W2 is by the second-stage heat bulb

on the thermostat. Circuit R-W2 energizes the heat

sequencer. The completed circuit will energize the

supplemental electric heat.

Blower Time Delay: This unit is equipped with timed

on and a timed off relay. This relay delays the start

and delays the stopping of the indoor fan motor to

maximize the efciency of the unit.

Defrost: When the unit starts the defrost cycle

supplemental heat can be provided by connecting B

on the blower coil to the defrost relay on the outdoor

heat pump. This will complete the circuit between R

and B (in the blower coil) through a set of contacts in

the defrost relay in the outdoor unit. This circuit when

it is connected, will help prevent cold air from being

discharged from the indoor unit during the defrost.

BLOWER

Units through three tons are supplied with a multi-

speed motor (high, medium, and low) with a direct

drive blower wheel which can obtain various air ows.

One and one and a half ton units are factory wired on

low speed, two ton units are factory wired on medium

speed, and two and half ton units are factory wired and

shipped with the blower connected for high speed. If

a lower blower speed is required, disconnect all power

to the unit, remove the factory wired indoor fan motor

lead from the fan relay and place an insulated cap

on the removed motor lead. Remove the insulated

cap from the desired indoor fan motor lead, place a

spade connector on the lead and connect it to the fan

relay where the original lead was connected. The

black motor lead is high speed, the red motor lead

is low speed, and the blue motor lead (if available) is

medium speed. Be sure to check the air ow and the

temperature drop across the evaporator coil to ensure

that you have sufcient air ow. For ECM option refer

to ECM wiring diagram for speed tap placement.

(ECM speed taps are 24v to energize) See page 8.

START UP

Once all connections are complete the unit should be

started up , and a check out of the completed system

should be performed. Before performing any system

test, make sure that all grilles, registers, and dampers

are open and set to the correct position. Also make

certain that the air lter is installed in the return air prior

to running the air handler.

A performance test should be conducted in the

accordance with the outdoor equipment manufacturer’s

instructions. Airow tests should be conducted in the

heating and cooling modes to ensure satisfactory

operation.

INSTALLATION GUIDE

MAINTENANCE

The system air lter(s) should be inspected, cleaned or

replaced at least monthly. If the lter is mounted internal

to unit, make sure that electrical power is disconnected

before removing the access panels. Make certain that

the access panels are replaced and secured properly

before placing the unit back in operation. This product

is designed for dependable service, however periodic

maintenance should be scheduled to be conducted by

trained professional service personnel. This service

should be conducted at least annually, and should

include testing and inspection of electrical and refrigerant

components. The heat transfer surface should be

cleaned. The blower motor is permanently lubricated for

normal operating conditions.

AB* SERIES INSTALLATION GUIDE

Warnings

Do not store or use any corrosives or

combustibles in the vicinity of this unit. All

panels must be in place and properly secured

before operating this equipment.

All electrical power servicing this unit must be

disconnected prior to removal of any panels.

Service of this unit must be accomplished

by qualied trained professional personnel

only.

Page 5

NOTE:

The condensate drain pan shown in Figure 1, has

an adjustment strap to ensure proper condensate

removal. The strap is identied by the arrow in the

gures. If it is found to be necessary, the strap may

be easily loosened and refastened to change the

pitch in the drain pan toward the drain outlets. The

drain pan pitch should not exceed 1/2 of an inch. For

proper drain line connections, follow instructions

from “CONDENSATE DRAIN” on Page 2.

WARNING

Warranty will be voided if any chemical products are used on any AllStyle coils.

AllStyle suggests water, and a soft bristled brush for cleaning.

Figure 1: Drain Pan Adjustment Strap

WIRING DIAGRAM

AB* SERIES INSTALLATION GUIDE Page 6

Revision of new relay board as of July 2016

USE COPPER CONNECTORS ONLY.

Use Conductors Suitable for 167 Deg F.

208-230VAC / 60Hz / 1Ph

EQUIPMENT GROUND USE COPPER OR

ALUMINUM WIRE.

Orange

FACTORYWIRING TABLE

HIGH VOLTAGE WIRING

LOW VOLTAGE WIRING

Single Speed Fan Control

Connect Only One Fan Lead

Not all models have 3 speeds

Black - High Speed

Blue - Medium Speed

Red - Low Speed

Air Handler with (AHF, AHK)

GND

L1

L2

M3 M4

M1 M2

Black

Red

Black

Purple

Brown

White

Black

Blue

Black

Blue

DISCONNECT POWER BEFORE

INSTALLATION OR SERVICING.

MULTIPLE POWER SOURCES

MAY BE PRESENT.

FAILURE TO DO SO MAY

CAUSE PROPERTY DAMAGE,

PERSONAL INJURY, OR DEATH.

Red

*AW1606-55361-B*

*AW1606-55361-B*

Blue

Black

Blue

Purple

Orange

Blue

Blue

Brown

White

White

Blue

ELEMENT

HEATER

NOTE 1) Wiring change is required to convert transformer to

208 Volts. Disconnect power. Disconnect orange high

voltage lead and place on terminal labeled as "208V" for 208

Volts power.

NOTE 2) Brown and White wires are used with Heat Kits

only.

FIELD

CONSULT NATIONAL CODE FOR PROPER WIRE SIZE.

3, 5kW Heating Elements

AW1606-55361-B

LIMIT

FUSE

LINK

HEATER

RELAY

2 4

65

1 3

FAN RELAY

2 4

65

1 3

G R C W

THERMOSTAT

INDOOR

MOTOR

Purple

Brown

White

TRNSF

24V

230V

208V

Com

SEE NOTE 2

Red

Blue

Black

Red

Black

Brown/White

Brown

Green

Purple

Red

24V CLASS 2 Wiring

Red Blue

SEE

NOTE 1

Blue

White

CIRCUIT NO. 1

208-230/60/1

AB* Series

WIRING DIAGRAM

Page 7AB* SERIES INSTALLATION GUIDE

24V

W G R C

THERMOSTAT

Use Conductors Suitable for 167 Deg F.

Green

Red

Purple

TRANSFORMER

USE COPPER CONNECTORS ONLY.

EQUIPMENT GROUND USE COPPER

208-230VAC / 60Hz / 1Ph

OR ALUMINUM WIRE.

230V

208V

Com

SEE

NOTE 1

NOT ALL MODELS USE FUSE LINKS

Single Speed Fan Control

Connect Only One Fan Lead

Not all models have 3 speeds

Black - High Speed

Blue - Medium Speed

Red - Low Speed

Air Handler (AHF, AHK) with

AW1606-55362-B

6, 8, 10kW Heating Elements

Red

GND

L1

L2

ELEMENT

HEATING

Brown

White

DISCONNECT POWER BEFORE

INSTALLATION OR SERVICING.

MULTIPLE POWER SOURCES

MAY BE PRESENT.

FAILURE TO DO SO MAY

CAUSE PROPERTY DAMAGE,

PERSONAL INJURY, OR DEATH.

FACTORY WIRING

NOTE 1) Wiring change is required to convert transformer to 208 Volts.

Disconnect power. Disconnect orange high voltage lead and place on

terminal labeled as "208V" for 208 Volts power.

WIRING TABLE

HIGH VOLTAGE WIRING

LOW VOLTAGE WIRING

FIELD WIRING

CONSULT NATIONAL CODE FOR PROPER WIRE SIZE.

*AW1606-55362-B*

TERMINAL BLOCK/

208-230/60/1

CIRCUIT NO.1

DISCONNECT

M4

M3

M2

M1

Black

Blue

Black

Blue

Yellow

Blue

FUSE

LIMIT

LINK

FUSE

LINK

Green

Blue

Orange

Blue Blue

Black

Black

Blue

LIMIT

ELEMENT

HEATING

White

M4

M3

M2

M1

Black

*AW1606-55362-B*

2 4

65

1 3

FAN RELAY

2 4

65

1 3

INDOOR

MOTOR

Purple

Red

Blue

Red

Black

Brown/White

Brown

Red

Green

Green

Purple

Blue

White

Black

Blue

Black

Black

Revision of new relay board as of July 2016

WIRING DIAGRAM

L1 L2 GND

W G R C Y

THERMOSTAT

Green

Red

Purple

TRANSFORMER

24V

TERMINAL

BLOCK

FACTORY WIRING

NOTE 1) Wiring change is required to convert transformer to 208 Volts.

Disconnect power. Disconnect orange high voltage lead and place on

terminal labeled as "208V" for 208 Volts power.

WIRING TABLE

HIGH VOLTAGE WIRING

LOW VOLTAGE WIRING

FIELD WIRING

USE COPPER CONNECTORS ONLY.

Use Conductors Suitable for 167 Deg F.

208-230VAC / 60Hz / 1Ph

EQUIPMENT GROUND USE COPPER OR

ALUMINUM WIRE.

DISCONNECT POWER BEFORE

INSTALLATION OR SERVICING.

MULTIPLE POWER SOURCES

MAY BE PRESENT.

FAILURE TO DO SO MAY

CAUSE PROPERTY DAMAGE,

PERSONAL INJURY, OR DEATH.

230V

208V

Com

CONSULT NATIONAL CODE FOR PROPER WIRE SIZE.

AW1509-55363-B

Air Handler - No Heat

SEE

NOTE 1

Black

Black

Black

Red

Yellow

Yellow

Purple

Green

With CTM Control

Com

L2 L1

Cool

Heat

Cool

CTM CONTROL

Heat

24V

Com

CTM

MOTOR

Orange

Blue

Black

Purple

White

Blue

Red Yellow

Red

Red

Black

G C R

FAN TIMER

COM

NC

NO

Blue

Black

Red

Blue

Blue

Red

Red

Page 8AB* SERIES INSTALLATION GUIDE

PRODUCT FEATURES

• Designed for Installation in a Furred Down Area or Dropped Ceiling Area

• Cooling Only, Cooling and Electric Heating, or Heat Pump with Electric Back Up

• Optional Factory Installed Electric Heat of Either 3, 5, 6, 8, or 10 kW

• Cooling Capacities 1, 1.5, 2.0, 2.5, or 3.0 Nominal Tons

• Orice Refrigerant Metering is Standard with ermal Expansion Valves Optional

• Standard Integral Drain Trap

• Pre-Punched Side Mounting Tabs for Easier Installations

• Copper Tube Option

• Long Life Aluminum Tubing, Fins and End Plates

• Powder Coated, Hinged Access Panels with Filter Rack

• Fully Insulated Embossed, Galvanized Steel Cabinets

AB* SERIES

FURRED DOWN

AIR HANDLER

Coil Company, L.P

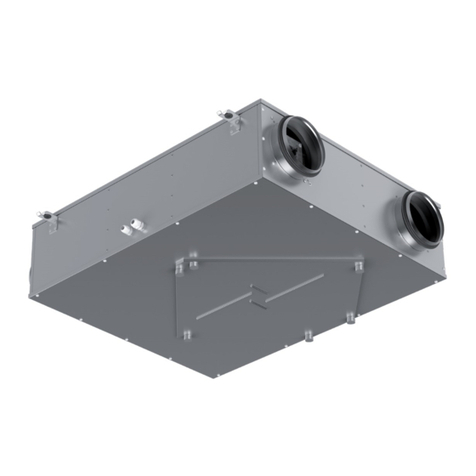

Cabinet Dimensions

Model

Nominal

Tonnage

Cabinet

Height

A

Cabinet

Length

B

Cabinet

Width

C

Plenum

Height

D

Plenum

Width

E

Optional

Return

Opening - F

Access

Grille

Width

Access

Grille

Length

ABF*

1, 1 1/2, 2, &

2 1/2 12.00” 47.00” 22.50” 8.00” 21.50” 21.00”x 8.00” 27.25” 51.25”

ABSK* 1 - 3 Tons 12.00” 57.00” 22.50” 8.00” 22.50” 21.00”x 8.00” 27.25” 61.25”

ABK* 1 - 3 Tons 12.00” 51.00” 22.50” 8.00” 21.50” 21.00”x 8.00” 27.25” 55.25”

ABTF*

1, 1 1/2, 2, &

2 1/2 16.00” 47.00” 22.50” 12.00” 21.00” 21.00”x 12.00” 27.25” 51.25”

ABTK* 3 Tons 16.00” 51.00” 22.50” 12.00” 21.00” 21.00”x 12.00” 27.25” 55.25”

ABTSK 3.5 - 4 Tons 16.00” 57.00” 22.50” 12.00” 21.00” 21.00”x 12.00” 27.25” 61.25”

ABL*

1, 1 1/2, 2, &

2 1/2 12.00” 47.00” 22.50” 8.00” 21.50” 21.00”x 8.00” 27.25” 51.25”

ABR* 3 Tons 12.00” 51.00” 22.50” 8.00” 21.50” 21.00”x 8.00” 27.25” 55.25”

Unit May Be Ordered For Either Rear Return or For Return rough Louvered Access Panel

Access Grille Length

Access Grille Width

A

E

F

C

B

D

AB* / ABT* ELECTRICAL PERFORMANCE PSC MOTOR

Model

Electric Heat

kW

Motor

AMPS

Tota l

AMPS MCA MOP BTUH

AB* / ABT*

12

0 1.5 1.5 1.7 15 0

3 1.5 14.0 16.3 20 10,257

**5 1.5 21.5 24.9 30 16,411

6 1.5 26.5 30.6 30 20,512

8 1.5 32.8 37.8 40 27,304

**10 1.5 41.5 47.9 50 32,764

AB* / ABT*

18 & 24

0 1.5 1.5 1.7 15 0

3 1.5 14.0 16.3 20 10,257

**5 1.5 21.5 24.9 30 16,411

6 1.5 26.5 30.6 30 20,512

8 1.5 32.8 37.8 40 27,304

**10 1.5 41.5 47.9 50 32,764

AB* / ABT*

30

0 1.5 1.5 1.7 15 0

3 1.5 14.0 16.3 20 10,257

**5 1.5 21.5 24.9 30 16,411

6 1.5 26.5 30.6 30 20,512

8 1.5 32.8 37.8 40 27,304

**10 1.5 41.5 47.9 50 32,764

AB* / ABT*

36

0 4 4.0 19.4 15 0

3 4 16.5 28.0 20 10,257

**5 4 24.8 33.8 30 16,411

6 4 29.0 43.3 35 20,512

8 4 35.3 40.9 45 27,304

**10 4 45.7 52.5 60 32,764

De-rate BTUH heating capacity by 25% for 208 VAC

Specications may change without notice

BLOWER PERFORMANCE FOR PSC

Model Speed

Static Pressure

0.1 0.2 0.3

AB* / ABT*

12

Low 535 460 400

Medium 700 630 540

High 800 730 620

AB* / ABT*

18

Low 740 670 610

Medium 970 850 760

High 1020 950 840

AB* / ABT*

24

Low 740 670 610

Medium 970 850 760

High 1020 950 840

AB* / ABT*

30

Low 740 670 610

Medium 970 850 760

High 1020 950 840

AB* / ABT*

36

Low 1020 950 870

Medium 1140 1100 1040

High 1250 1200 1150

AH* SERIES

FURRED DOWN

AIR HANDLER

AH* / AT* ELECTRICAL PERFORMANCE ECM MOTORS

Model

Electrical Heat

kW

Motor

AMPS

Tota l

AMPS MCA MOP BTUH

AB* / ABT*

12

0 2.8 2.8 3.2 15 0

3 2.8 15.3 17.9 20 10,257

**5 2.8 22.8 26.5 30 16,411

6 2.8 27.8 32.3 35 20,512

8 2.8 34.1 39.4 45 27,304

**10 2.8 44.5 49.5 60 32,764

AB* / ABT*

18 & 24

0 2.8 2.8 3.2 15 0

3 2.8 15.3 17.6 20 10,257

**5 2.8 22.8 27.2 30 16,411

6 2.8 27.8 32.0 35 20,512

8 2.8 34.1 39.4 45 27,304

**10 2.8 44.5 51.1 60 32,764

AB* / ABT*

30

0 4 4.0 4.6 15 0

3 4 16.5 19.4 20 10,257

**5 4 24.0 28.0 30 16,411

6 4 29.0 33.8 35 20,512

8 4 35.3 40.9 50 27,304

**10 4 44.0 51.0 60 32,764

AB* / ABT*

36

0 4 4.0 0.0 15 0

3 4 16.5 19.4 20 10,257

**5 4 24.0 28.0 30 16,411

6 4 29.0 33.8 40 20,512

8 4 35.3 40.9 50 27,304

**10 4 44.0 51.0 60 32,764

De-rate BTUH heating capacity by 25% for 208 VAC

Specications may change without notice

BLOWER PERFORMANCE ECM MOTORS

Model

Speed

Tap

Static Pressure

0.1 0.2 0.3 0.4 0.5

AB* / ABT*

18 & 24

1 0

Low (2) 650 640

Medium (3) 760 720 690 650 610

Med High (4) 860 840 790 740 680

High (5) 900 890 840 800 750

AB* SERIES

FURRED DOWN

AIR HANDLER

Coil Company, L.P

AllStyle Coil Company, L.P.

STANDARD 5 YEAR

PRODUCT LIMITED WARRANTY

January 2018

AllStyle Coil Company, L.P. makes the following standard limited warranties for products manufactured for residential applications installed in the United

States and Canada. Registered evaporator coils and air handler DX coils installed in residential applications are given a standard limited 5 year warranty.

Non-registered residential evaporator coils and air handler DX coils have a limited 1 year warrany. Hydronic coils in a residential application have a

standard limited 2 year warrany. Coils installed in commercial applications are provided a standard limited 2 year warranty (Coil Only), and a limited 1

year warranty on commercial parts. For registered multi-family applications there is a standard limited 5 year warranty for aluminum coils, and a limited

1 year warranty for parts. ese limited warranties extend to the original purchaser and any subsequent transferee, as long as the product remains at the site

of the original installation.

Limited Five (5) Year Warranty

AllStyle warrants to the purchaser of this product that should it prove defective within ve years of the date of manufacture, due to improper

workmanship and/or material under proper installation. AllStyle will repair or replace, at its option, any defective part without charge for the part.

Replacements Parts/Coils are warrantied for the remainder of the original warranty period.

is limited warranty does NOT include labor or other costs incurred for the servicing, maintenance servicing, replacing, removing, shipping or

handling. You are responsible for the cost of shipping warranty replacement coils or parts from the manufacturer to the location of your covered equipment;

the cost of shipping failed parts to the distributor, and for incidental costs incurred locally, including handling charges. AllStyle will not pay for electricity,

fuel costs, increases in electricity, or fuel costs for any reason. ese costs may be covered by a separate warranty provided by the selling dealer or contractor.

In establishing the starting date for the term of this Limited 5 Year Warranty, Purchaser must register. Register on-line at www.allstyle.com/warranty

**Note: Commercial applications will include all of the above mentioned for the standard limited two (2) year warranty.

e Above Warranties are subject to the Following Conditions:

1. You must retain your bill of sale or provide other proof of purchase.

2. is limited warranty applies only while the product remains at the site of the original installation (except for mobile home

installations), and only to products installed by licensed dealers or contractors as determined by local licensing requirements.

3. is limited warranty applies only if the product is installed and operated in accordance with AllStyle instructions and in

compliance with applicable local installation, building codes, and good trade practices.

4. AllStyle requires a yearly inspection and service of the equipment by a licensed technician.

AllStyle Does Not Cover:

Any costs of installation, disconnection, or dismantling the product, or parts used in connection with normal maintenance such as lters, and

owner-required maintenance. Consult the instructions enclosed with the product for information regarding recommended maintenance. AllStyle does not

provide any reimbursement with this warranty, i.e. lodging,wages, any expenses, including freon, etc..

is Warranty Does Not Cover Damages Caused By:

(A) Accident, negligence, or abuse; (B) Operating the product in a corrosive atmosphere containing chlorine, uorine, or any other damaging

chemicals; (C) Modication, alteration, repair or service by anyone not properly qualied to perform such service modication, alteration or repair;

(D) Improper matching or application of the product or components; (E) Failure to provide proper maintenance and service to the product according to

the manufacturer’s instructions; (F) Installation or operating of the product in manner contrary to the instructions of the manufacturer; (G) Products

installed outside the United States or its territories; (H) Failure to operate due to interruption and/or inadequate electrical service; (I) Any damage caused

by frozen or broken water pipes in the event of equipment failure; (J) AllStyle is not responsible for any water damage to property. To prevent water

damage, it is the installing contractors responsibility to install proper secondary safety pans, drain lines, and oat switches to ensure proper drainage

from over-ow; (K) Damage or repair required as a result of the use of used or recycled refrigerant; (L) Lightening, oods, res, winds, corrosive

atmosphere or any other acts of God beyond the control of AllStyle. WARNING: Warranty will be voided if ANY chemical cleaning products are

used on any AllStyle coils.

How to Obtain Warranty Service:

To obtain warranty service and/or parts replacement you must notify your selling dealer or contractor of any defect within the applicable warranty period.

ALL WARRANTIES IMPLIED BY STATE LAW, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXPRESSIVELY LIMITED TO THE DURATION OF THE LIMITED WARRANTIES SET FORTH ABOVE. Some

states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. WITH THE EXCEPTION OF ANY

WARRANTIES IMPLIED BY STATE LAW AS HEREBY LIMITED, THE FOREGOING EXPRESS WARRANTY IS EXCLUSIVE AND IN LIEU

OF ALL OTHER WARRANTIES, GUARANTEES, AGREEMENT, AND SIMILAR OBLIGATIONS OF MANUFACTURER OR SELLER WITH

RESPECT TO THE REPAIR OR REPLACEMENT OF ANY PRODUCT OR PART.

IN NO EVENT SHALL ALLSTYLE BE LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES. Some states do not allow

the exclusion of incidental or consequential damages so the above limitation may not apply to you. No person, agent, distributor, dealer, or company is

authorized to change, modify, or extend terms of these warranties in any manner whatsoever. e time within which an action must be commence to enforce

any obligation of AllStyle arising under this warranty or under any statute, or law of the United States or any states thereof, is hereby limited to one year from

the date you discover or should discovered the defect. is limitation does not apply to implied warranties arising under state law so the above provision may

not apply to you. is warranty gives you specic legal rights and you may also have other rights which vary from state to state.

Any controversy or claim arising out of or relating to this warranty, or the breach thereof, shall be settled through binding arbitration administered

by the American Arbitration Association in accordance with its Commercial Arbitration Rules, and judgment on the aware rendered by the arbitrator may

be entered in any court having jurisdiction thereof. is is the exclusive and sole remedy of Buyer, for any breach of warranty. Pursuit of any legal remedy

must occur in Harris County, Houston, Texas.

is document replaces and supersedes any and all previous warranties issued by AllStyle Coil Company, L.P.

In order to maintain the remainder of the warranty period, you must replace the failed unit with an AllStyle Coil.

©AllStyle Coil Company, L.P. January 2018

Coil Company, L.P

AllStyle Coil Company, L.P.

7037 Brittmoore Road

Houston, Texas 77041

AB* SERIES INSTALLATION GUIDE 1/2018

This manual suits for next models

10

Table of contents

Other Allstyle Air Handler manuals