EQK 18S-EHVC WD2V Series Programming manual

This manual suits for next models

3

Other EQK Air Handler manuals

Popular Air Handler manuals by other brands

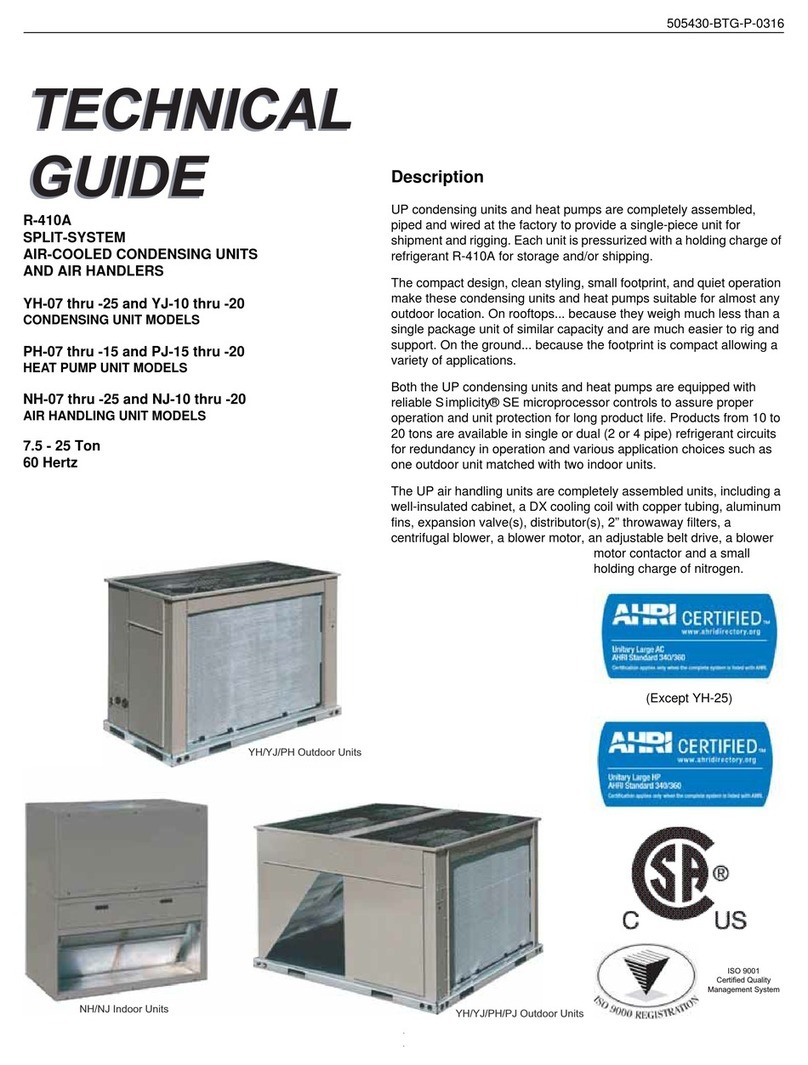

Johnson Controls Unitary Products

Johnson Controls Unitary Products YH-10 Technical guide

Salda

Salda RIS 400VE instructions

Vent-Axia

Vent-Axia Lo-Carbon PoziDry Pro 476310 Installation and wiring instructions

Trane

Trane TAMXB0A24V21DB Installation, operation and maintenance

NuAire

NuAire BPS H-ES Series installation manual

Deekax

Deekax TALTERI DIVK-C 91 CD Installation and user manual

iFlow

iFlow iFLH-14000W manual

Vent-Axia

Vent-Axia Lo-Carbon PureAir Home 479090 Installation and wiring instructions

innovair

innovair SLIM24 Installation and owner's manual

Armstrong Air

Armstrong Air BCE3M 18 installation instructions

McQuay

McQuay Skyline IM 777-2 Installation and maintenance manual

Lennox

Lennox INALTO Installation, operation and maintenance

RDZ

RDZ RNW 600 CS Instructions for installation and use

Dantherm

Dantherm TKS 60 Service manual

Alphacool

Alphacool ES Orbiter 360 TS manual

Johnson Controls

Johnson Controls AV Series installation manual

American Standard

American Standard 2/4TEC3F18A1000A Installer's guide

Amana

Amana ARUF**14 Series Installation & operating instructions