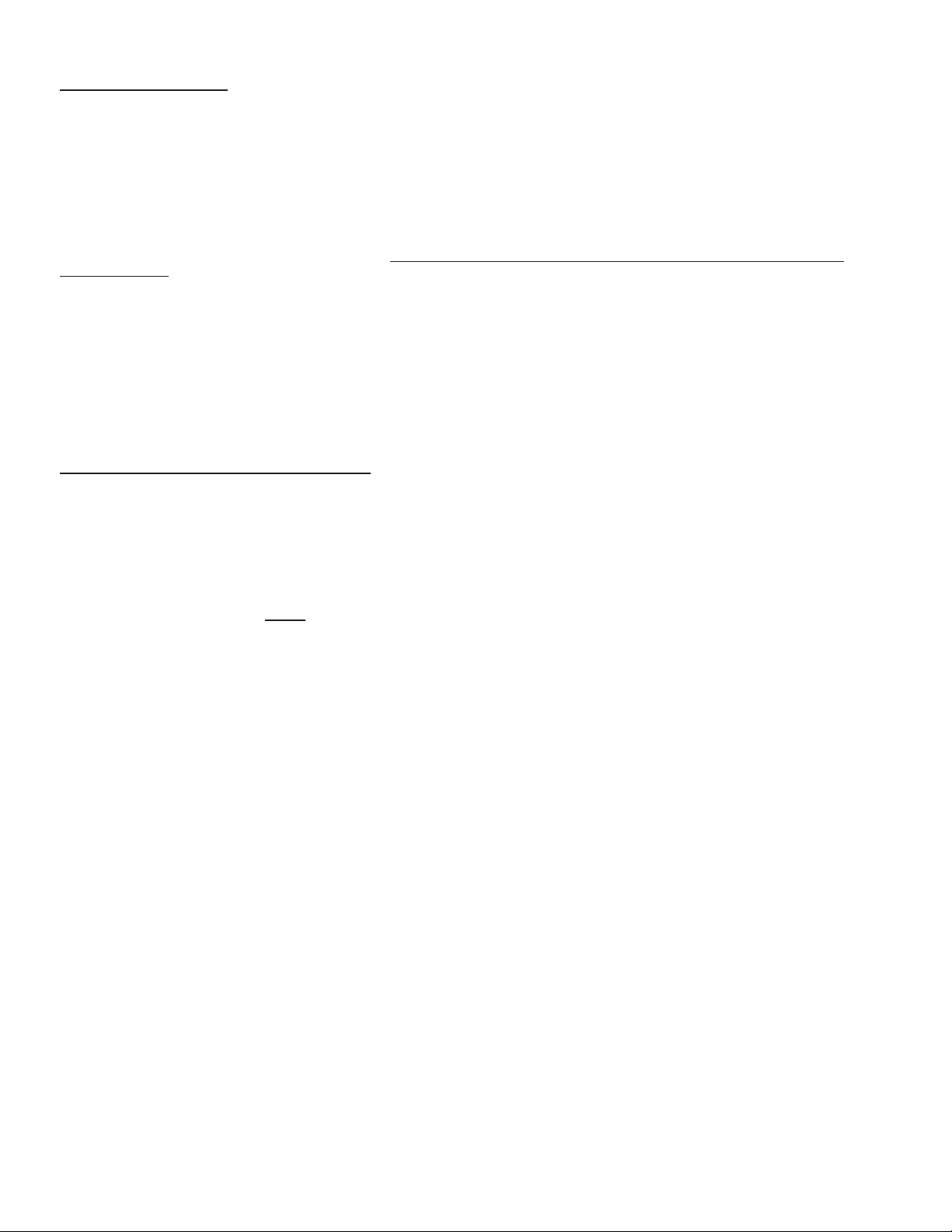

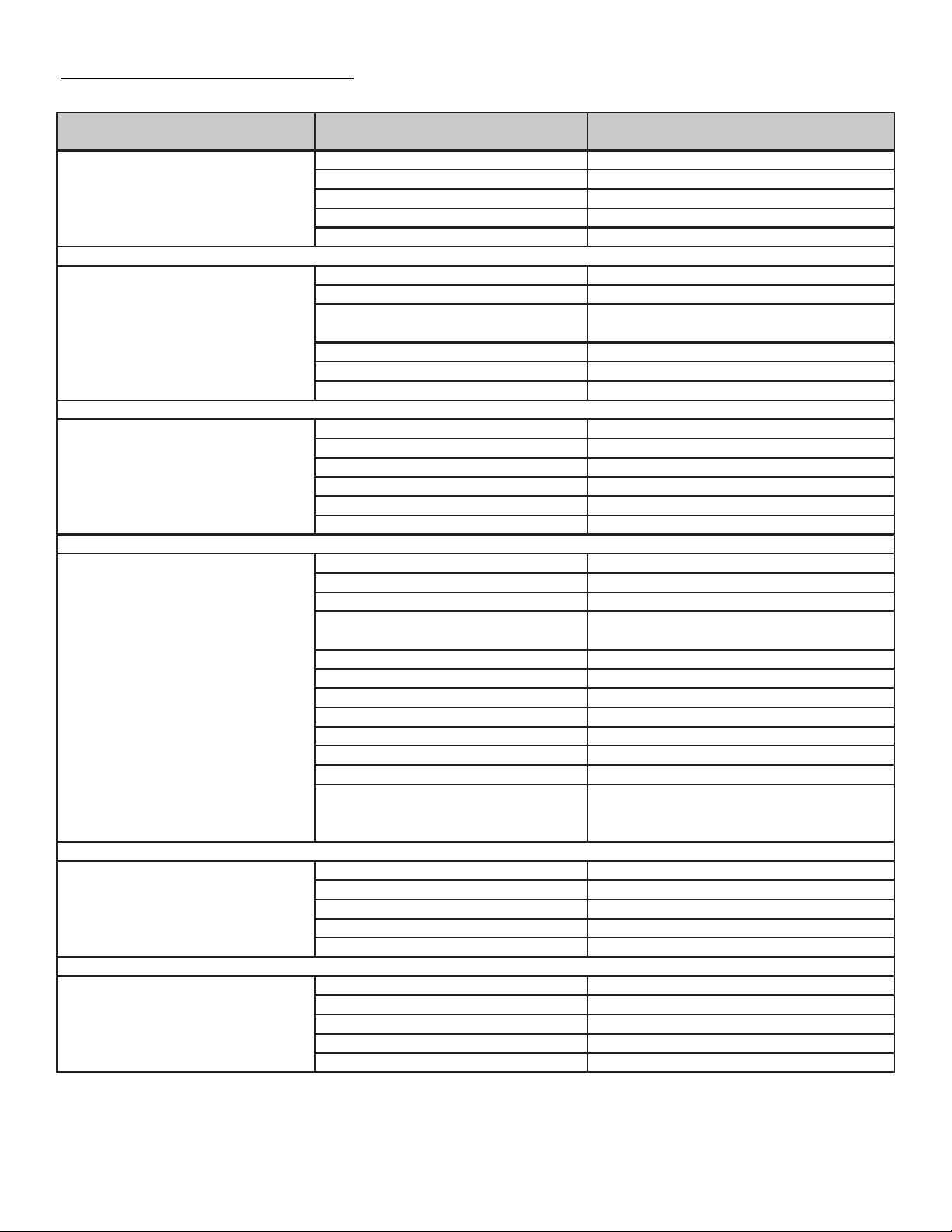

10

Problem Cause Solution

Excessive pressure loss in sys-

tem

Bypass valve not completelyopen Opencompletely

Pipe diameter to small Increasediameter

Piping system has to many tie ins Redesign pipe system

Leaks in piping system Fix leaks

In line filter element clogged Replacefilter element.

Water downstream of dryer

Bypass valve not completelyclosed Close bypass valve

Air not going through dryer Open inlet valve completely

Under high flow conditions pressure

dropssignificantly Redesign compressed air source and

check pipe diameter.

Auto drain plugged or not working. Clean drain or replace

Dryer to small for inlet air flow Replace dryer or reduce inlet flow.

No pre filter in system Install pre filter

Evaporatorpressure is to

high or to low.

Inlet air temp is to high Check air compressor after cooler

Air cooled condenser is clogged Cleancondenser

Expansion valve is defective Replace expansion valve

Refrigerantleak Find leak and fix. Add refrigerant

Pressure gauge is bad Replace with newgauge

Hot gas bypass needs adjusting Adjust valve to correct pressure.

Power is on to the dryer but the

dryer will not start

Fuse is bad Check for short, fix and replace fuse

On/Off switch defective Replaceswitch

No power going to dryer Check circuit breaker and power supply

Power going to dryer is incorrect Make sure power source and data la-

bel match.

Contactordefective Replace with a new one

Over load relaydefective Replace with a new one

Capacitordefective Replace with a new one

Start relaydefective Replace with a new one

Pressure switch defective Replace with a new one

Temp switch defective Replace with a new one

Compressordefective Replace with a new one

High Pressure switch is open

Low pressure switch is open

Thermostatopen

Find reason and reset

Find reason and reset

Find reason and reset

Evaporator Temp is to low

Hot gas bypass valve needs adjusting Adjust or replace

Evaporator pressure gauge bad Replace

Capillarytube blocked Replace

Temp or Pressure reset set to low Reset

Refrigerantleak Find leak, fix it and ad refrigerant

Evaporator Temp is to high

Ambient temp to high Improve ventilation in area

Hot Gas valve needs adjusting Adjust or replace

Condenser blocked or plugged Cleancondenser

Flow is to high going in dryer Change air compressor

Compressor valves are damaged Replacecompressor

TROUBLE SHOOTING GUIDE