TABLE OF CONTENTS

Warranty...............................................................................................................................

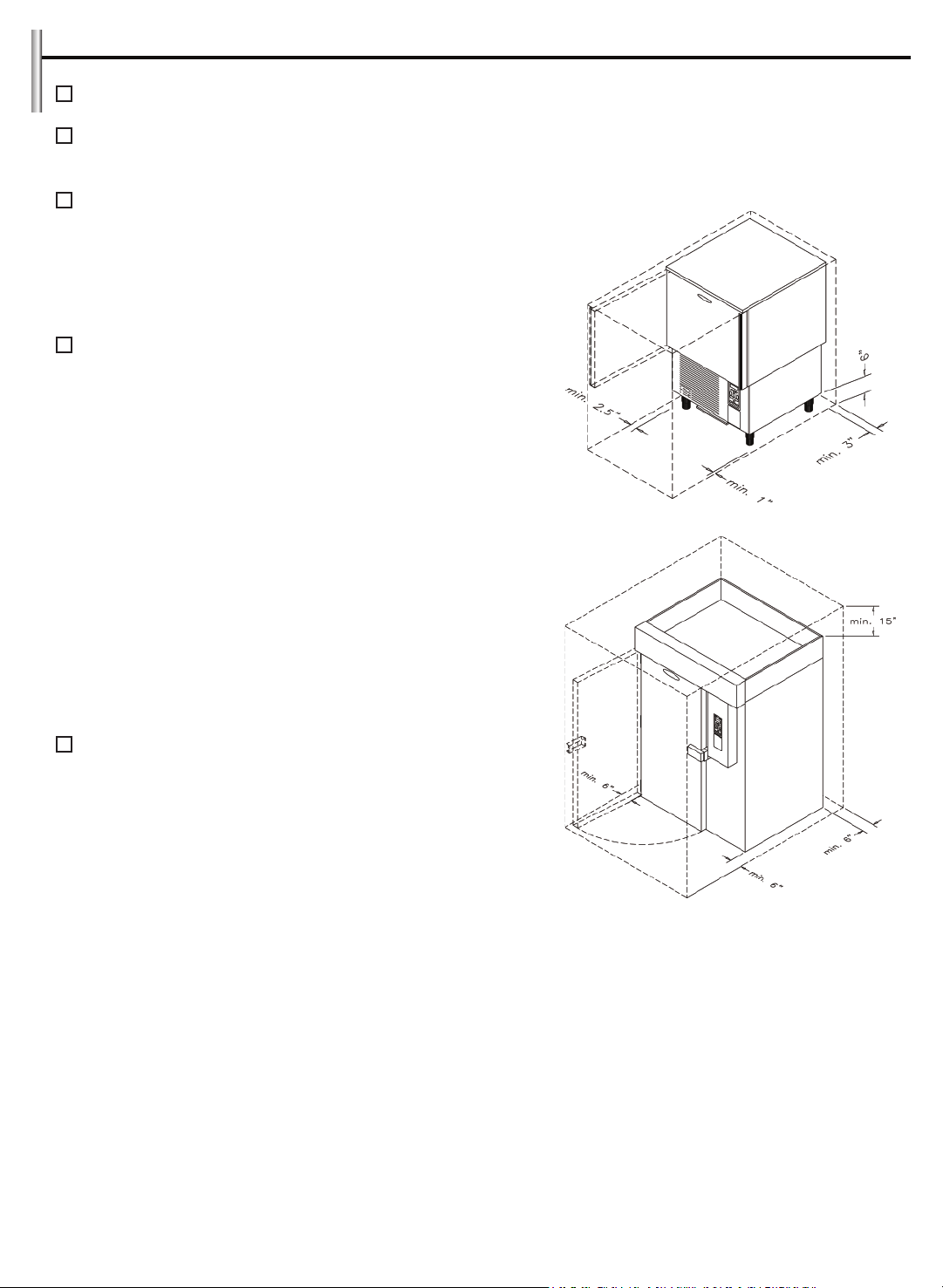

Installation............................................................................................................................

Checking for Proper Installation...........................................................................................

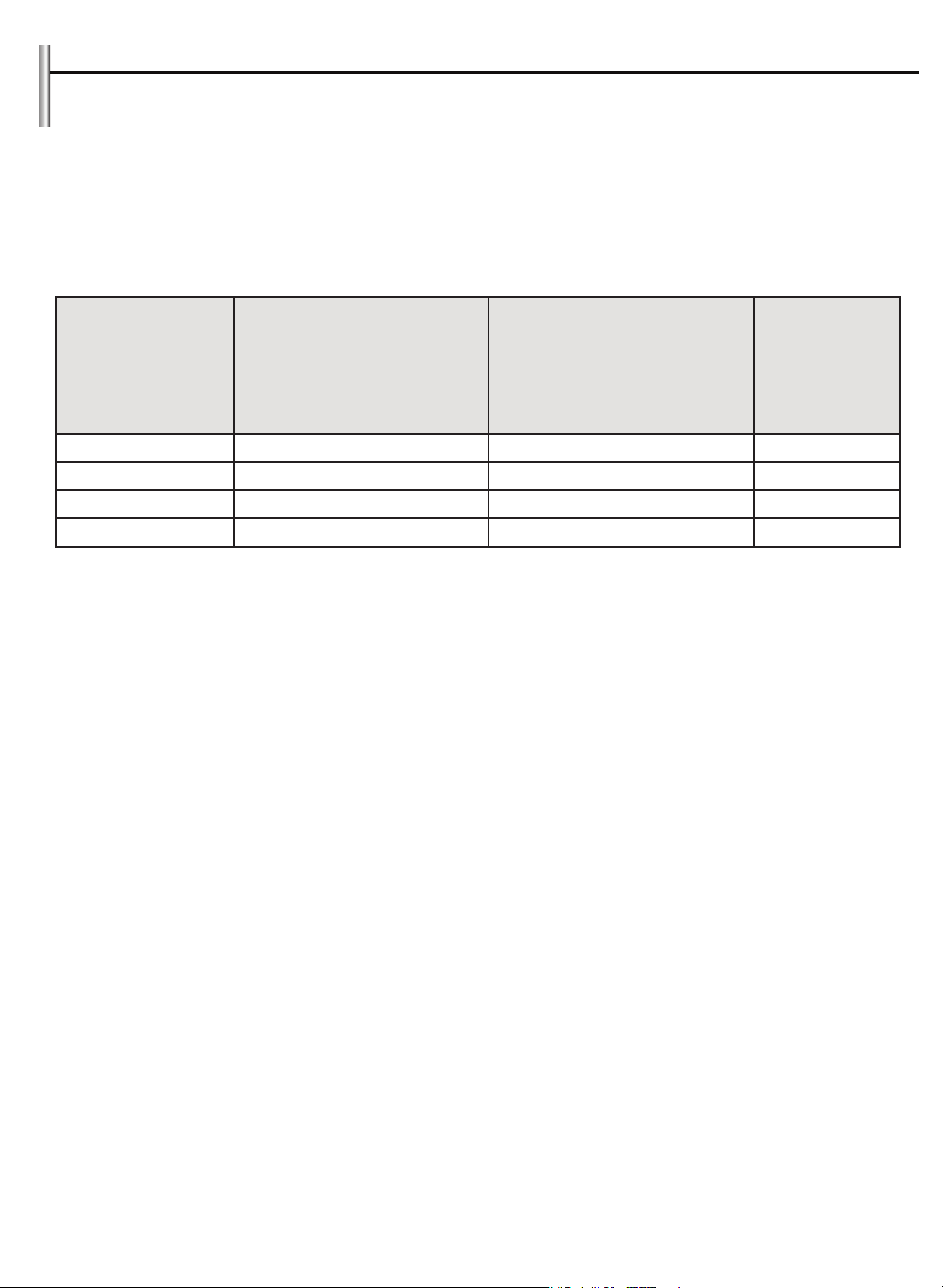

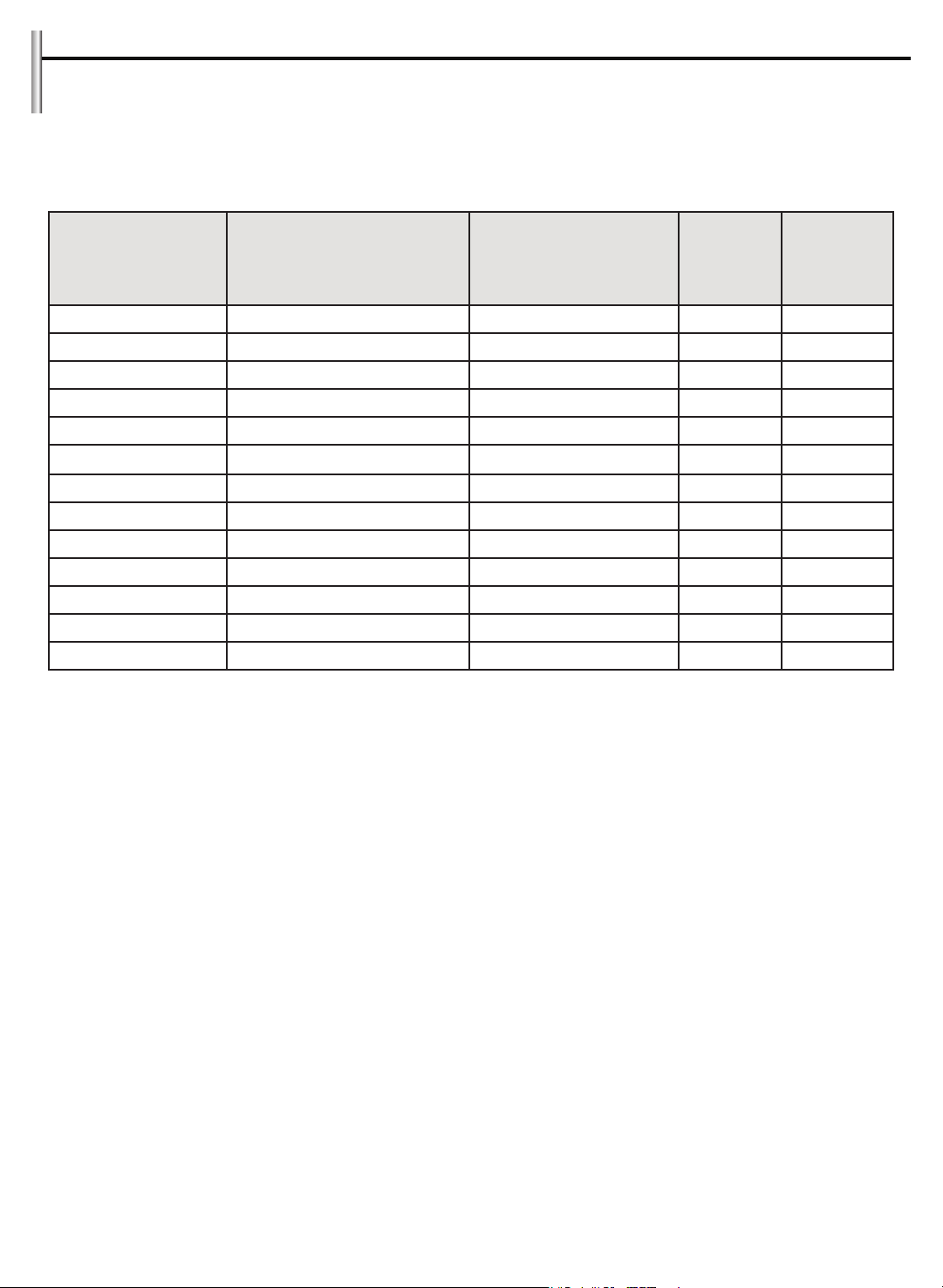

Specifications & Performance...............................................................................................

Modes Explained..................................................................................................................

Cycles Explained...................................................................................................................

- Soft Chill.................................................................................................................

- Hard Chill................................................................................................................

- Shock Freeze...........................................................................................................

- Defrost.....................................................................................................................

- Thaw........................................................................................................................

- UV Sterilization........................................................................................................

- Heated Probe..........................................................................................................

Factory Presets.....................................................................................................................

Unit Operation.....................................................................................................................

- Automatic Mode - Any Cycle................................................................................

- Manual Mode - Any Cycle.....................................................................................

- A la Carte Mode - Any Cycle.................................................................................

- Home Screen.........................................................................................................

- Automatic Mode Screen Explained.......................................................................

- Manual Mode Screen Explained............................................................................

- A la Carte Screen Explained..................................................................................

- UV Sterilization......................................................................................................

- Defrost Cycle.........................................................................................................

- Heat the Food Probe.............................................................................................

- Download HACCP Data.........................................................................................

- Run a Thaw Cycle...................................................................................................

Customizing the Cycles........................................................................................................

General Operating Instructions............................................................................................

- PC Communication Package.................................................................................

- HACCP Download (Peer-to-Peer)...........................................................................

- HACCP Download (via WiFi)..................................................................................

- WiFi Connection....................................................................................................

- Email Configuration...............................................................................................

Maintenance Instructions.....................................................................................................

Evaporator Cleaning Procedure...........................................................................................

Parts List...............................................................................................................................

1

2

3

7

8

8

8

8

9

9

9

9

9

10

11

11

12

13

14

15

16

17

18

18

18

19

19

19

19

20

21

22

23

26

27

28

29