1. INTRODUCTION

This manual contains instructions for the installation, use and maintenance of the IWK H2O. In the following manual, the

IWK H2O will be referred to as Spray-gun washer.This manual is an integral part to the product and should be kept with due

care in order to allow for its use and consultation during the life of the Spray-gun washer.

The regular operation, economy and safety of the Spray-gun washer depends on the compliance with the instructions given in this

manual. It is mandatory to follow the procedures as described in this manual.

This manual must be read and understood perfectly prior to installing, using or performing any type of

operation or maintenance on the machine. The Spray-gun washer must be used exclusively for the

washing of spray-guns or small parts, using water or water-based solvents with specific characteristics.

Use of the Spray-gun washer for processing other than the type indicated in this manual is considered

improper use and is therefore prohibited. ANEST IWATA EUROPE declines any and all responsibilities

for damages caused by the Spray-gun washer to persons, animals or property, due to use other than the

use described herein, or for damages due to negligence or failure to observe the instructions contained

in this manual.

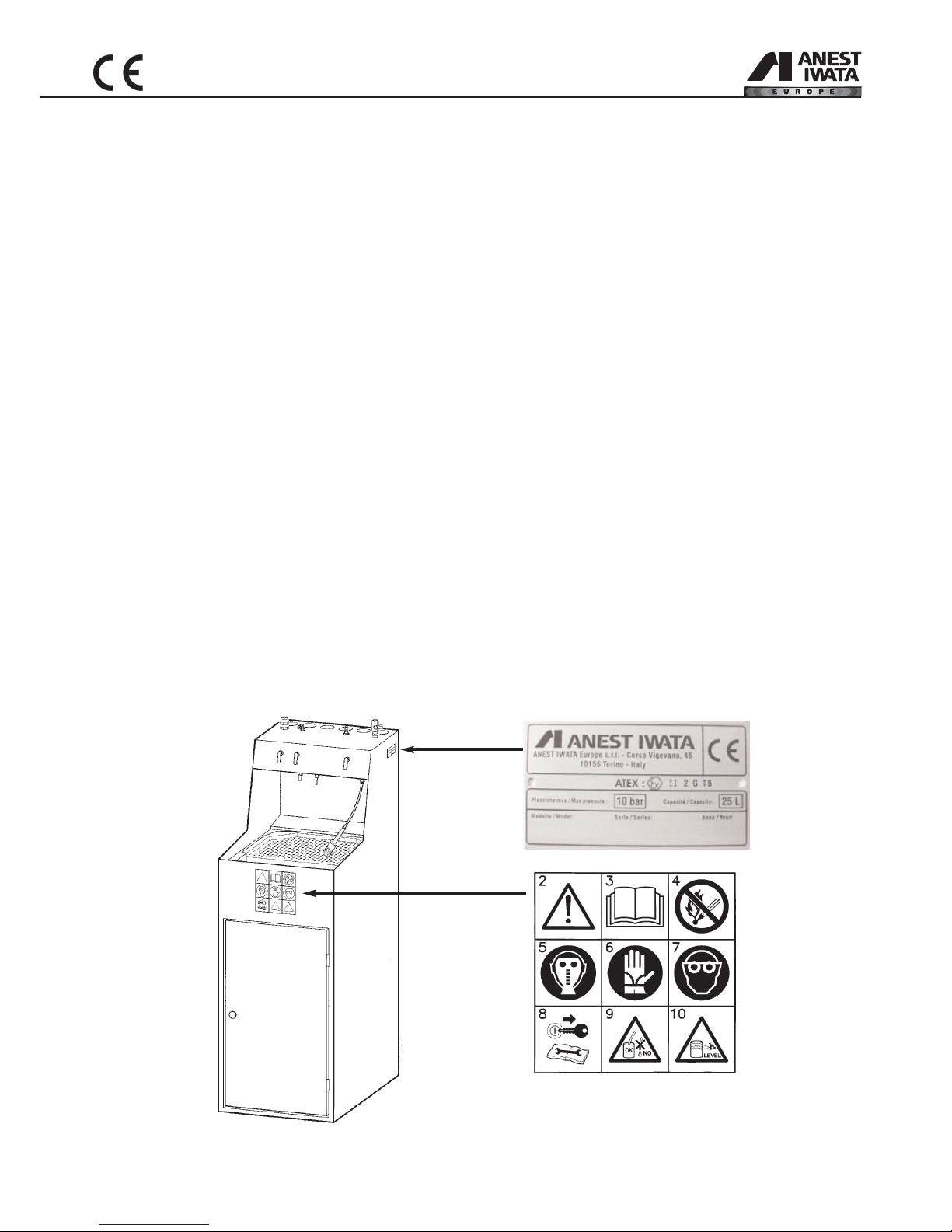

The Spray-gun washer is manufactured according to the provisions contained in the following European Directives:

- Directive 98/37/CE (Machine Safety).

- Directive 94/9/CE (Equipment to be used in potentially explosive environments).

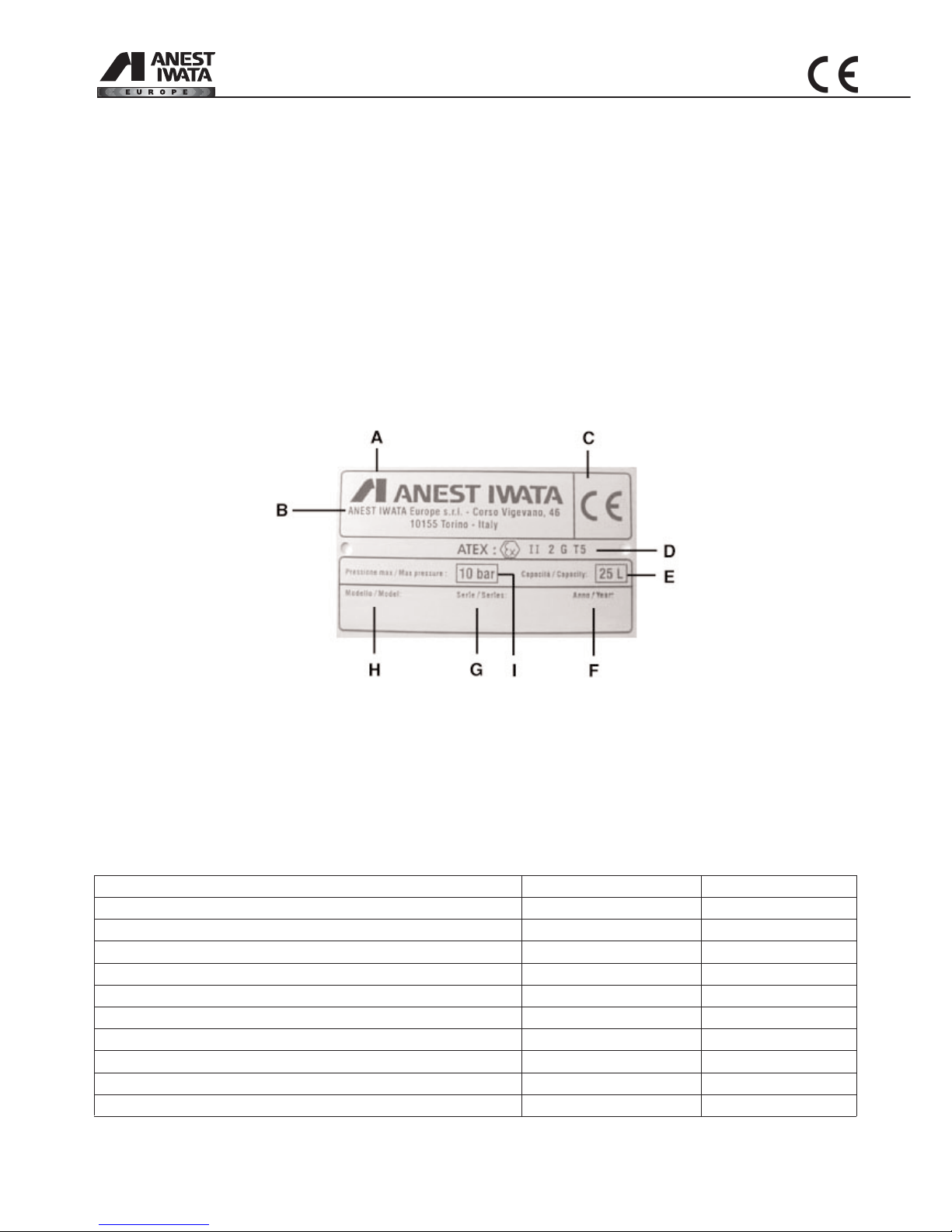

With reference to the Directive 94/9/CE (“ATEX” directive) the Spray-gun washer is a machine designed and built to work in com-

pliance with the operating parameters fixed by ANEST IWATA EUROPE and guarantees a normal level of protection in regard to

the appliances group II, category 2. The machine supplied is accompanied by the following documents:

- CE Declaration of conformity.

- CE Mark.

- Manual for use and maintenance.

1.1 GUARANTEE

Upon delivery of the Spray-gun washer, it is necessary to make sure that no damages have occurred during shipment and the sup-

ply of accessories is complete and undamaged. Claims must be filed within 8 days of delivery. The buyer is eligible for the guaran-

tee coverage only when he has complied with the guarantee conditions listed below.

ANEST IWATA EUROPE guarantees its products under the following conditions:

a) The Spray-gun washer is guaranteed for a period of two years from the date of purchase as certified by a delivery document

issued by the Dealer. When the customer requests guarantee service, he must specify the model, serial number and year of

manufacture of the appliance.

b) The guarantee covers free replacement or repair of the appliance component parts which are recognized to have manufacturing

defects without any charge for labour.

c) Guarantee services are performed at the manufacturer's factory or at authorized service centres. The appliance must be sent

already prepaid to them and shall be returned to the customer at his own expense and risk. If any intervention by technicians is

requested under guarantee coverage at the customer's installation site, then the customer shall be charged for the transfer

time, for mileage and for all board and lodging expenses according to the valid fees applied by the Service Centre. No charge

is made for the time required to repair and replace parts.

d) The manufacturer waives all liability for any damage that may directly or indirectly be caused to persons or property resulting

from failure to comply with all the provisions in the instruction manual. In particular, this regards failure to comply with warnings

about placing, installing, operating and maintaining the appliance. The present guarantee does not cover any reimbursement for

direct or indirect damage due to appliance down-time. Guarantee coverage is only valid when payments are all in due order.

e) This agreement is governed by current law in the Republic of Italy. Any controversy deriving from this agreement shall be set-

tled by the Court in Turin, Italy.

3

SPRAY-GUN WASHER IWK H2O Mod. H2O