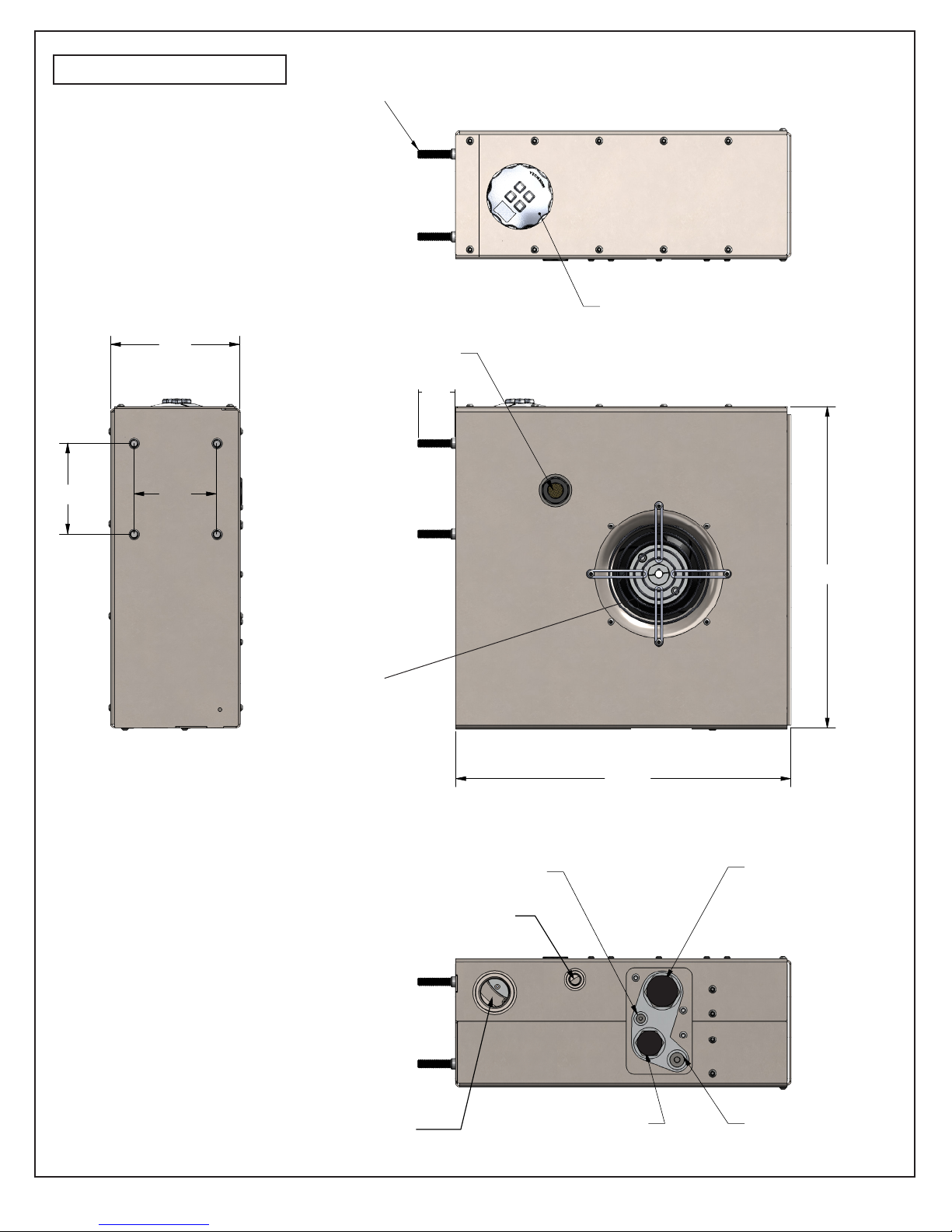

POSITIONING AND MOUNTING:

The ARC-30 is designed to fit in very tight spaces, its narrow profile allows for

behind the cab or frame rail mounting. Unit will ship with a mounting template

to aid in proper installation. (See FIG. 6) The ARC-30 requires at least 1.5” air

gap on the fan shroud side to allow for adequate air intake.

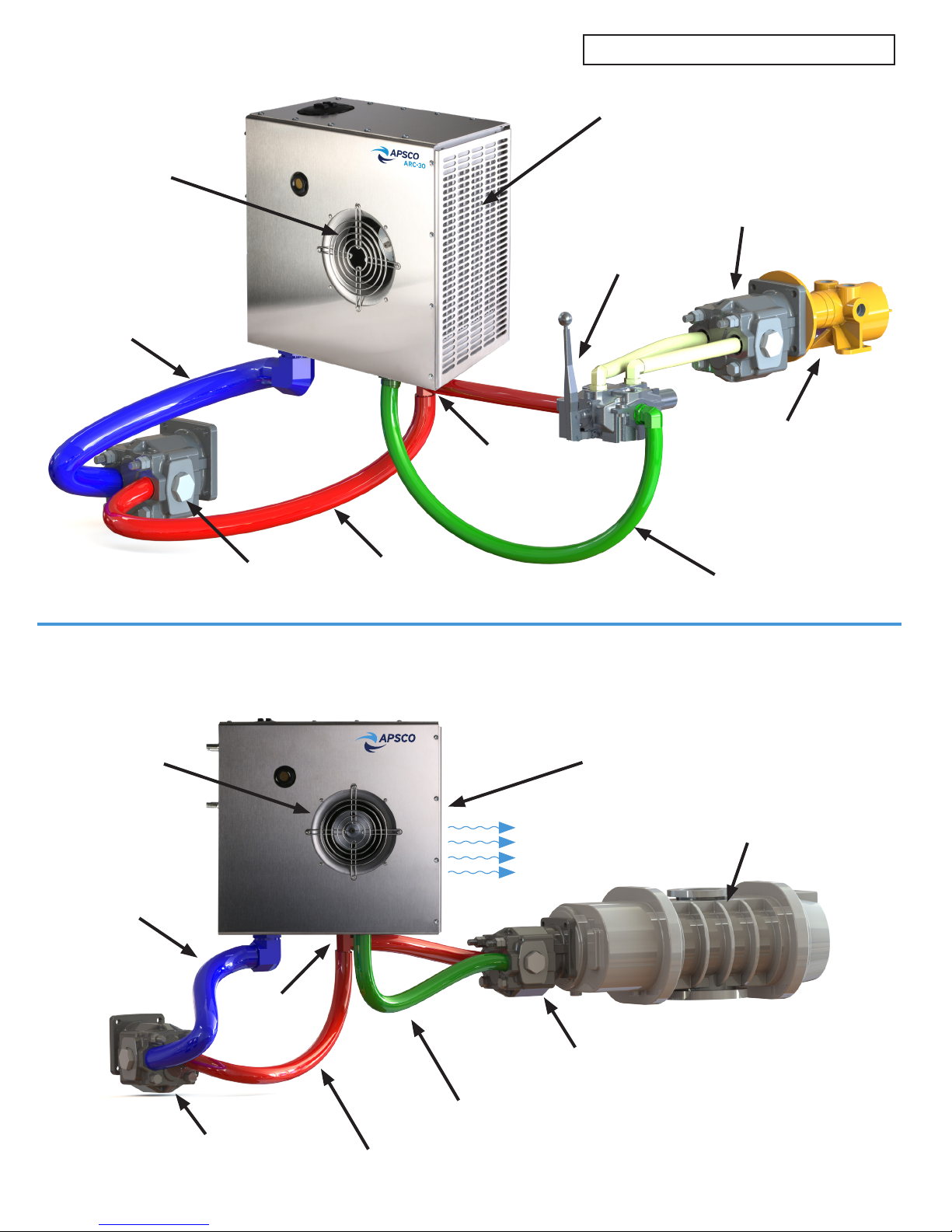

CONNECTIONS (SEE FIG.2):

Note: SAE ports do not require a thread sealant, they seal with an o-ring. Make

sure your SAE fittings have a properly sized o-ring and

are free of thread sealant.

Suction Port-24 SAE – Your hose will go from this port to the

pump inlet port. Minimum hose size – 1.5”.

Pressure Port -16 SAE – The hose from your pump output will “T” into this port.

One side of the “T” supplies the 1.2gpm to the hydraulic fan. Flow will only be

greater than 1.2gpm through this line is if the pressure relief valve setting is

exceeded. The other side of the “T” runs to the motor input or control valve

input depending on your system. Minimum hose size – 1”.

Case Drain -8 SAE – Some hydraulic pumps, motors, and control valves have a

case drain line that needs to be plumbed directly back to the cooler reservoir.

This is where you will make that connection. If your hydraulic system does not

require a case drain line simply leave the APSCO provided hex plug in this port.

Return Port -20 SAE – The hose from the outlet of your motor or control valve

should be plumbed into this port. This port takes all of the return flow from your

motor and sends it through the filter and heat exchanger built into the ARC-30.

Minimum hose size – 1.25”.

Gauge Port -4 SAE – This is a test port on the bottom of your cooler. This port

is connected to the input port of the manifold, for the purpose of connecting

diagnostic equipment like a gauge or transducer to system pressure.

Magnetic Drain Plug -8 SAE – This is where you will drain the cooler reservoir

to change the hydraulic fluid.

START UP PROCEDURE:

This Unit comes ready to install, no assembly required.

Make up all hydraulic connections.

Remove Filter cap from top of cooler, leave filter in place

and add fluid until it reaches middle of the sight glass

with the PTO disengaged. This will filter the fluid as it is

being added. Even new hydraulic fluid should be filtered.

You will need to add hydraulic fluid in slowly because the

filter is in place.

Bleed air from lines and check fluid level again. Ensure that the lines are full of

fluid and the air is bled from your system, some pumps and motors, particularly

piston will be ruined in a matter of seconds if operated without fluid.

Depending on the length and diameter of the system hoses you may need to add

fluid to the reservoir several times.

Install filter cap.

Slowly engage PTO with engine at idle speed.

Check for hydraulic leaks and repair as needed

Check for fan operation. Note that the fan will turn slowly when system

pressure is low.

Recheck reservoir fluid level. Each time you add fluid disengage PTO, if the

reservoir gets completely empty before you add fluid you will need to bleed air

from the lines again.

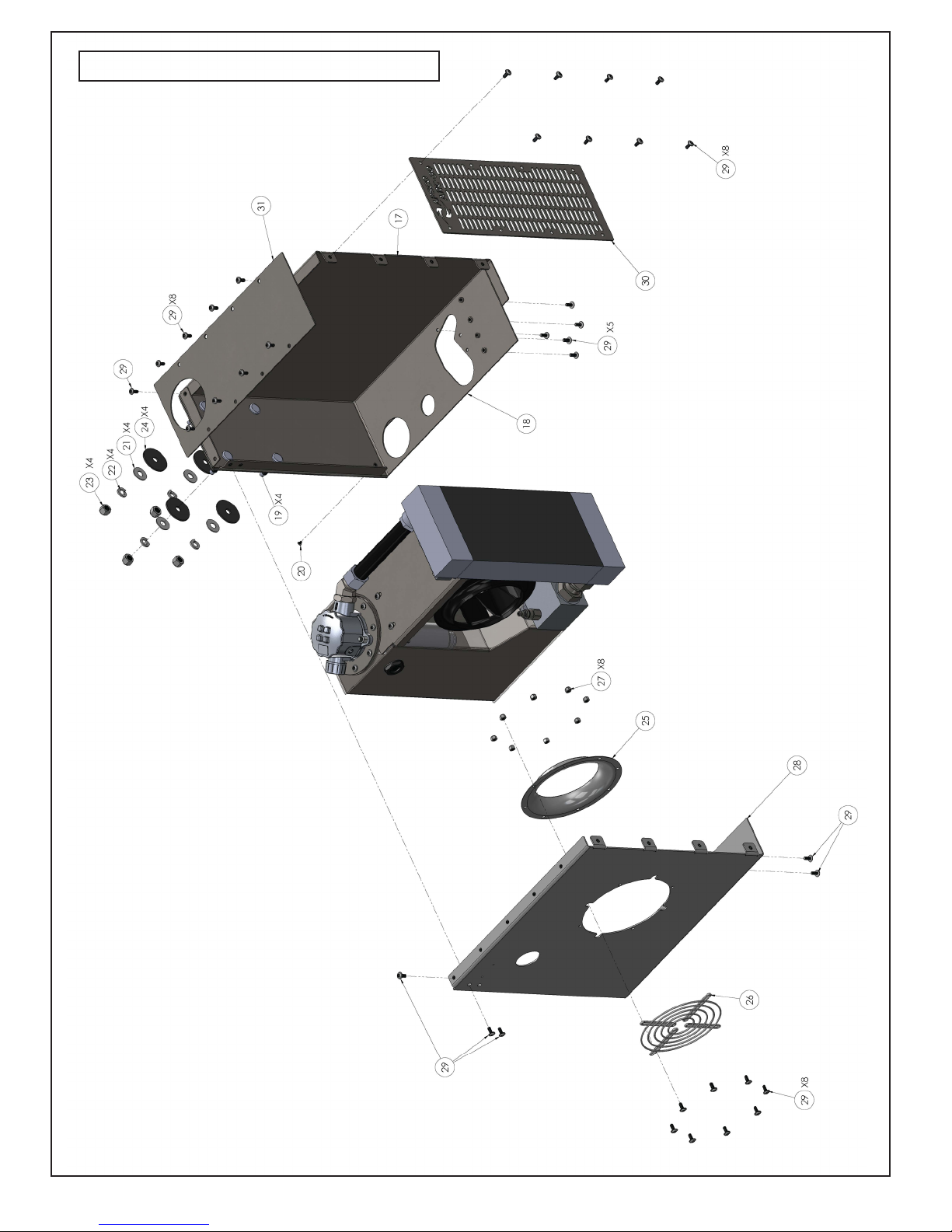

Pressure relief valve setting – The ARC-30 pressure relief valve is factory set

to 3000psi. This is a good setting if all of your other system components are

rated to at least 3000psi. Failure to set the relief valve 200psi higher than

system pressure or any other system

relief valve will result in excess build up

of heat. If you need to adjust the APSCO

pressure relief valve it can be accessed

by removing the cooler side cover and

manually adjusting with an Allen wrench.

The change in pressure is roughly 150psi/

quarter turn. Any time the side cover is

off the PTO should be off as well.

Once you verify system functionality with

no leaks and the proper fluid level your

ARC-30 is ready for operation.

SYSTEM MAINTENANCE:

Filter – Unscrew filter cap (use a screw

driver or tool with a square shank) and

replace element every three months.

Fluid – Check fluid level daily (with the

PTO off the fluid level should reach the middle of the sight glass). Drain and

replace hydraulic oil every 6 to 12 months depending on use.

Recommended Fluid – Use non foaming hydraulic fluid and see Pump and Motor

Manufacturer recommendations.

Clean Radiator – Use a mild cleaner compatible with aluminum. Be careful not

to damage fins if using a power washer to rinse cleaner off of radiator. Visually

inspect daily and clean if necessary.

INSTALLATION & OPERATION

Page 5

Warning: High Pressure oil can cause severe

injury. Turn off PTO and bleed pressure

before servicing hydraulic system.

Warning: heavy object. To avoid muscle

strain or back injury, use lifting aids and

proper lifting technique when removing or

replacing.

Warning: Rotating Fan Blade. Can cause

serious injury or cut. Keep hands clear. Turn

off and lockout unit before servicing.

Caution: Surface May be Hot. Ensure PTO is

off and unit has cooled before servicing.

ROTATE CLOCKWISE TO

INCREASE PRESSURE RELIEF

SETTING (INTERNAL HEX)

9/16” JAM NUT. LOOSEN

T0 ADJUST. TIGHTEN WHEN

PROPER RELIEF PRESSURE

HAS BEEN ACHIEVED

PRESSURE RELIEF

VALVE. FACTORY

SET AT 3000PSI