AQUA eco•wash INTRODUCTION

Dosing system for washing machines ENGLISH

ADSP7000603 rev. 1.3 09/06/2015 37/212

TABLE OF CONTENTS

1.0 INTRODUCTION …………………………………………………………………………………………………………………………… 38

1.1 Standards of reference .......................................................................................................................................... 38

1.2 Technical features ................................................................................................................................................. 38

1.3 Package content .................................................................................................................................................... 38

1.4 Installation material ................................................................................................................................................ 38

2.0 INSTALLATION ..................................................................................................................................................... 39

2.1 System assembly .................................................................................................................................................. 39

2.2 Wall mounting ..................................................................................................................................................... 39

2.3 Electric connections................................................................................................................................................ 40

2.4 Central module electric connections ....................................................................................................................... 40

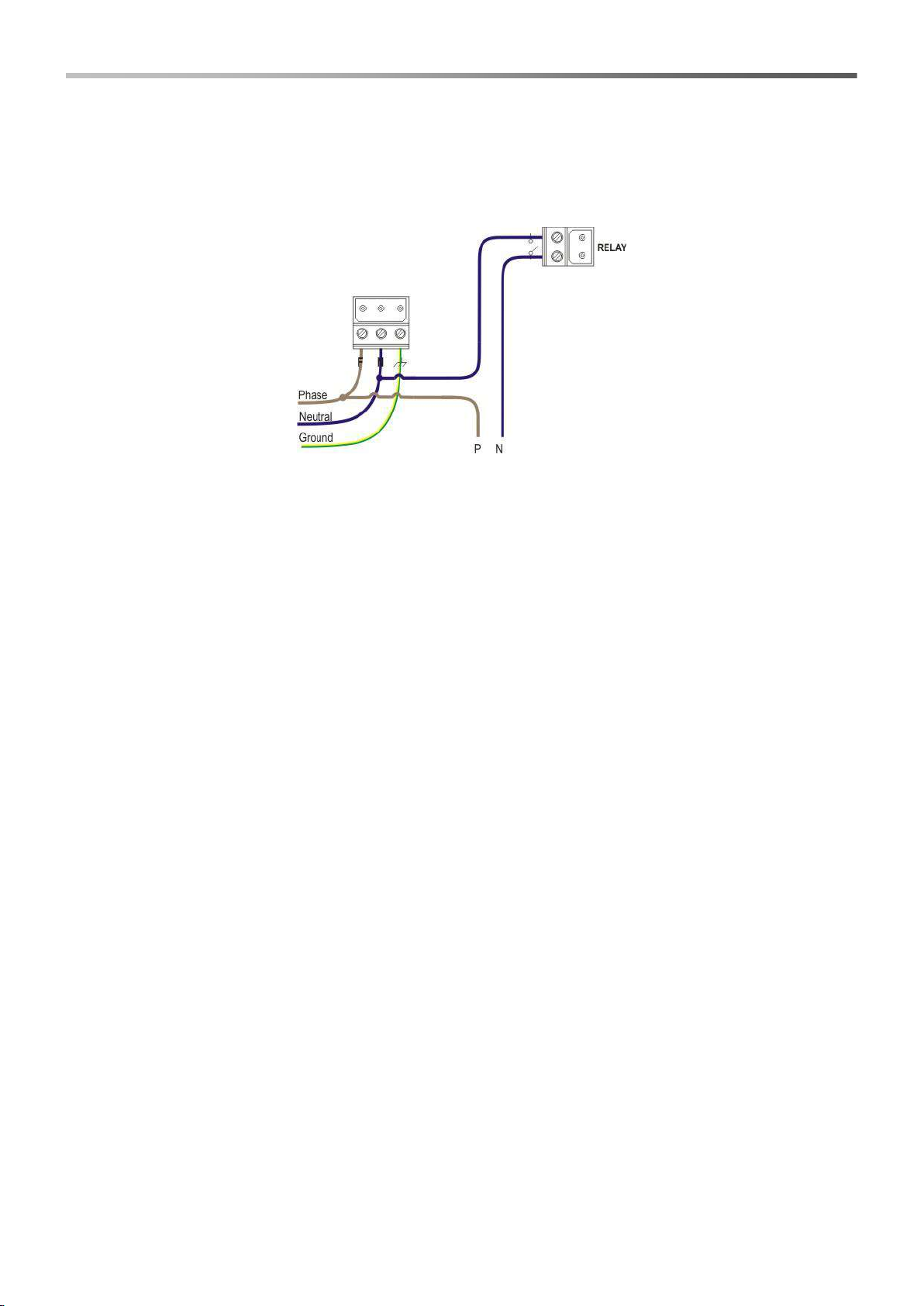

2.4.1 Power supply.......................................................................................................................................... 40

2.4.2 Flushing kit solenoid valve...................................................................................................................... 40

2.4.3 Flow sensor............................................................................................................................................ 40

2.4.4 Signals module....................................................................................................................................... 40

2.4.5 Relay output ........................................................................................................................................... 41

2.4.6 Alarms output ........................................................................................................................................ 41

2.4.7 Level probe input.................................................................................................................................... 41

2.4.8 Central module LEDS …………..…………………………………………………………………………………. 41

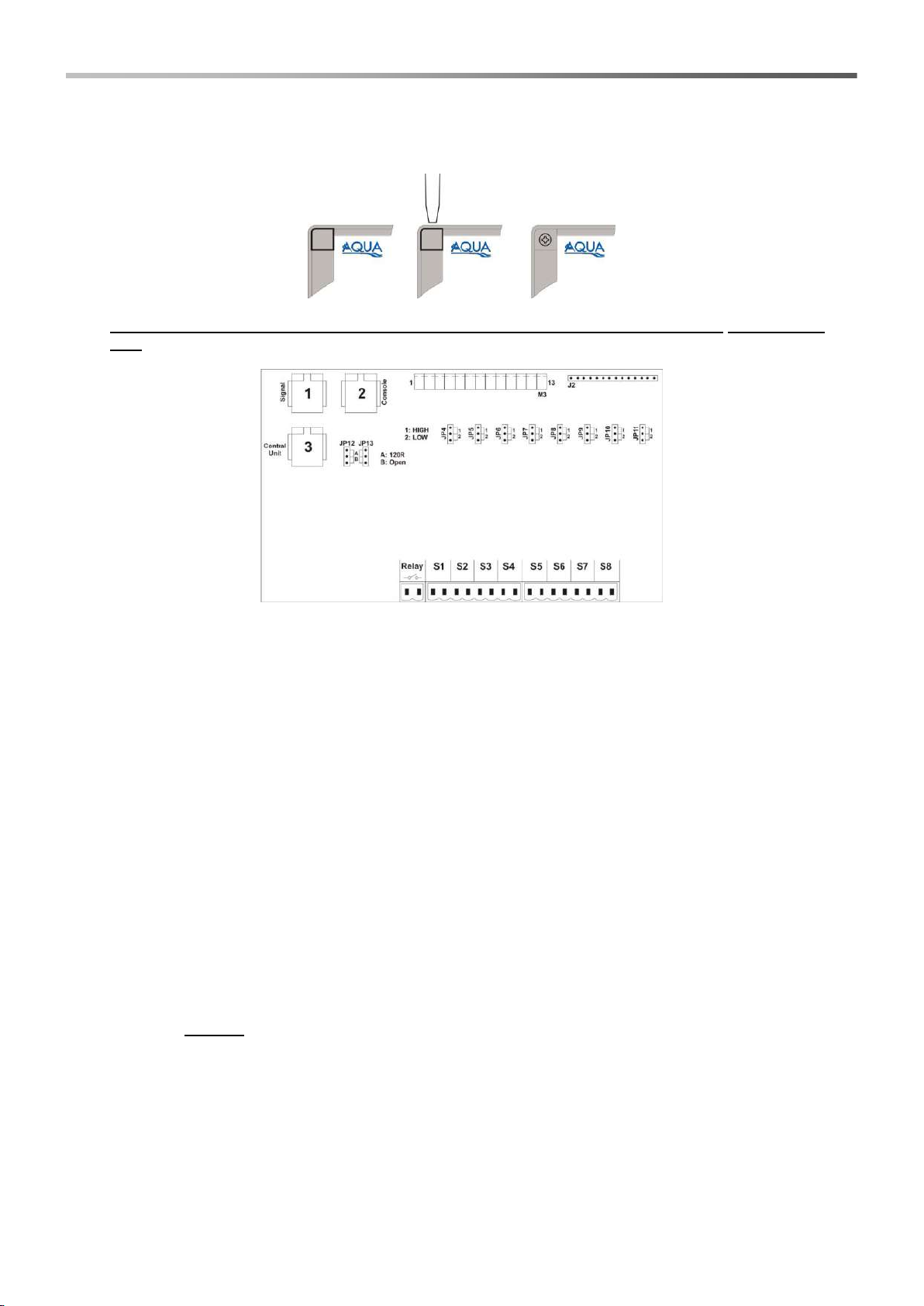

2.5 Signals module electric connections ...................................................................................................................... 42

2.5.1 Console ................................................................................................................................................ 42

2.5.2 Central module ....................................................................................................................................... 42

2.5.3 Washing machine signals ....................................................................................................................... 42

2.5.4 Signals module LEDs ……..…………………………………………………………………………. ................ 42

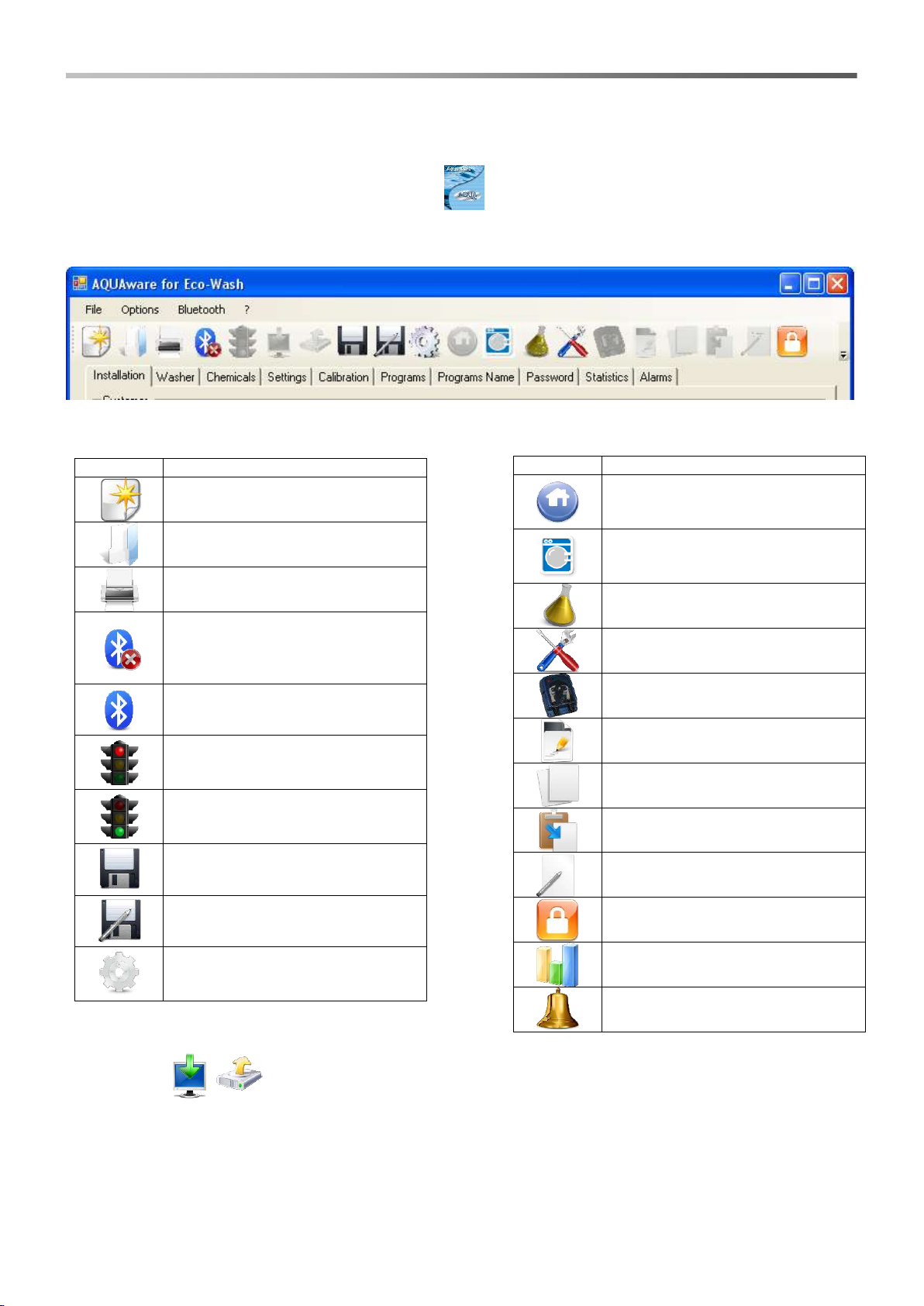

3.0 AQUAWARE CONFIGURATOR PROGRAM......................................................................................................................... 43

3.1 Step 1 –Bluetooth connection................................................................................................................................ 43

3.2 Step 2 –System configuration................................................................................................................................ 44

3.3 Step 3 –System autorecognition............................................................................................................................ 44

3.4 Step 4 –Bluetooth name setting............................................................................................................................. 44

4.0 AQUAWARE PROGRAM ..................................................................................................................................................... 45

5.0 PROGRAMMING ..................................................................................................................................................... 46

5.1 Step 1 –Bluetooth connection................................................................................................................................ 46

5.2 Step 2 –Installation................................................................................................................................................ 46

5.3 Step 3 –Washing machine..................................................................................................................................... 47

5.4 Step 4 –Chemical products.................................................................................................................................... 47

5.5 Step 5 –Settings.................................................................................................................................................... 48

5.5.1 Signals filter .......................................................................................................................................... 48

5.5.2 Drain signal............................................................................................................................................. 48

5.5.3 Flushing.................................................................................................................................................. 49

5.5.4 Autostart................................................................................................................................................. 49

5.6 Step 6 –Calibration................................................................................................................................................ 50

5.7 Step 7 –Programs.................................................................................................................................................. 51

5.7.1 Input signal instruction block................................................................................................................... 51

5.7.2 Pump instruction block............................................................................................................................ 52

5.7.3 Water instruction block............................................................................................................................ 52

5.7.4 Timer instruction block............................................................................................................................ 52

5.7.5 Meter instruction block............................................................................................................................ 52

5.7.6 END instruction block.............................................................................................................................. 52

5.7.7 Conditional instruction block ................................................................................................................. 52

5.7.8 Conditional instruction control block........................................................................................................ 53

5.7.9 RESET instruction block......................................................................................................................... 53

5.7.10 STAT instruction block............................................................................................................................ 53

5.7.11 Connection blocks .................................................................................................................................. 53

5.8 Step 8 –Program names........................................................................................................................................ 54

5.9 Step 9 –Password ................................................................................................................................................. 54

5.10 Step 10 –Statistics................................................................................................................................................. 54

5.11 Step 11 –Alarms.................................................................................................................................................... 55

5.11.1 Alarms setting......................................................................................................................................... 55

5.11.2 Pump maintenance alarm....................................................................................................................... 55

5.11.3 Calibration alarm..................................................................................................................................... 55

6.0 TROUBLESHOOTING ..................................................................................................................................................... 56

7.0 APPENDIX 1 –A few examples of invalid programs............................................................................................................... 57

8.0 APPENDIX 2 –Electric and hydraulic connections................................................................................................................. 58

9.0 APPENDIX 3 –Programming examples................................................................................................................................. 59

9.1 Example 1 ………………………………………………………………………………………………………………………. 59

9.2 Example 2 …………. .............................................................................................................................................. 60

9.3 Example 3 ……………………………………………………………………………………………................................... 61

10.0 APPENDIX 4 –Default settings ………………………………..……………………………………………………………………... 62

11.0 APPENDIX 5–Eco wash system initialization……………………………………………………………………………………………….63

12.0 APPENDIX 6–Multi-machine system ……..……………………………………………………………………………………………….64

13.0 APPENDIX 7–Continuous Washing Machine …………………………………………………………………………………… ………. 68