2

2

Contents

Notice –Warnings..............................................................................................................................................................4

Specification.......................................................................................................................................................................5

Technical Parameters of Arctic Air to Water Heat Pumps..........................................................................................5

Heating Performance Table............................................................................................................................................6

Recommended Circulation Pump (External) ..................................................................................................................8

Heat Pump Flow Pressure Drop Curves..........................................................................................................................8

Installation........................................................................................................................................................................10

Heat Pump Installation ...............................................................................................................................................10

Accessing Additional Heat Pump Parts.....................................................................................................................12

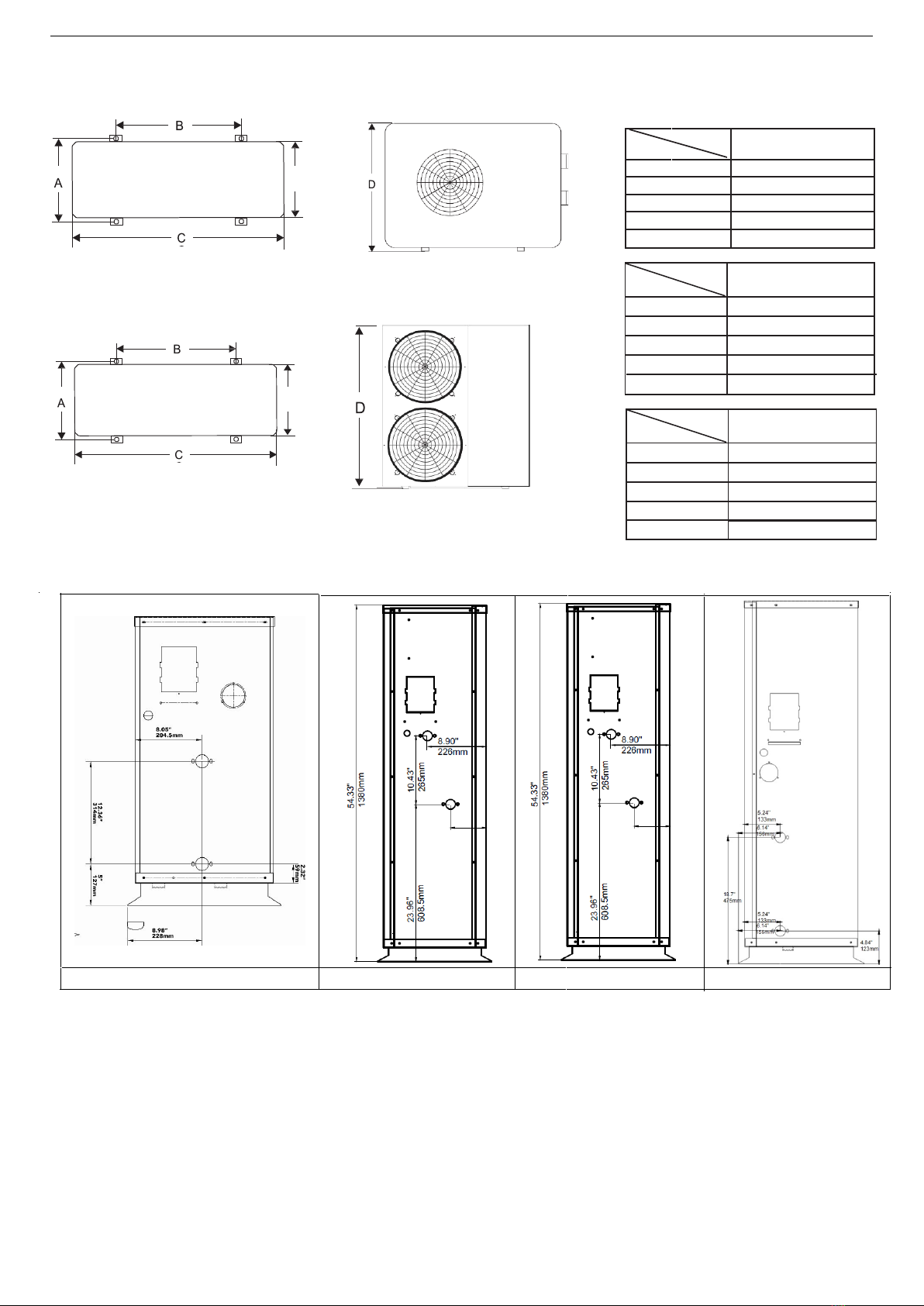

Installation Space Requirements:.................................................................................................................................13

Buffer Tank Installation...............................................................................................................................................13

Installation of Indoor Heating and Cooling Equipment ..............................................................................................14

Water Pipe Connections..............................................................................................................................................14

Installation of the Temperature Sensor.......................................................................................................................15

Electrical Wiring...........................................................................................................................................................15

Electrical Wire Selection –Warning............................................................................................................................16

What Gets Connected and Where................................................................................................................................16

Start Up.........................................................................................................................................................................19

Single Tank versus Dual Tank...........................................................................................................................................20

The Use of the Wired Controller ..................................................................................................................................21

Buttons and Display Symbols Explanation....................................................................................................................21

Wired Controller Operations .......................................................................................................................................22

Keyboard Locking / Unlocking Operation.................................................................................................................22

Turning the Unit ON/OFF..........................................................................................................................................22

Modifying the Temperature Setting ........................................................................................................................22

Mode Select Operation............................................................................................................................................22

Forced Defrost ..........................................................................................................................................................24

Clock Setting .............................................................................................................................................................24

Changing Between Celsius & Fahrenheit

...............................................................................................................24

Factory Reset

...........................................................................................................................................................24

Timer ON/OFF Settings...........................................................................................................................................24

Cancelling Timer Operation

....................................................................................................................................24

Timer Programming..................................................................................................................................................25

Selecting Energy Saving Mode, Quiet Running Mode, and Fast Heating Mode.......................................................26

Checking of State Parameters .............................................................................................................................26

MaintenanceandRepair................................................................................................................................................27

Antifreeze Protection for Cold Climates .....................................................................................................................27

Error Code Table

............................................................................................................................................................28

Wiring Diagrams...............................................................................................................................................................30