1.8

2

1.7 1.11

1.9

2.1

1.10

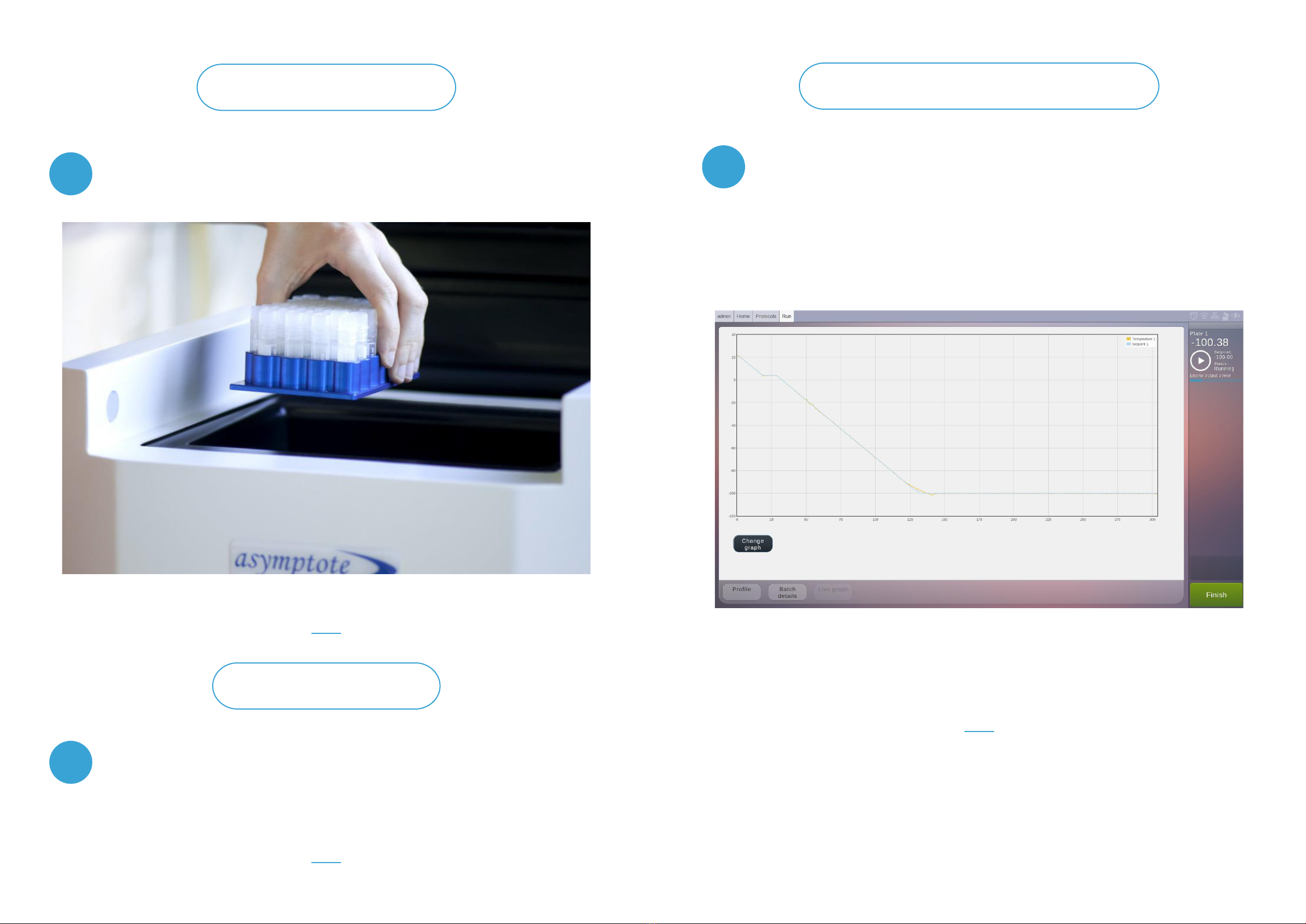

While supporting the remaining panels,

remove all screws.

Remove the remaining panels and place to

one side. Please ensure the case contains

the following:

a. VIA Freeze system

b. Mains cable

c. Correct sample loading plates

(depends on system and your

order details)

d. Manual

e. Warranty card

With scissors, carefully pierce the foil and

cut along the seam. Pull the foil packaging

away from the VIA Freeze to avoid

accidentally scratching its surfaces

Slide the foil to the base of the unit.

Lift out of foil packaging and off the crate

base. We recommend two people lift the

VIA Freeze Duo (40kg/ 88lb) and VIA Freeze

Quad (64kg/ 141lb). We also recommend

that since the bespoke packaging crate is

designed for multiple use it is kept by the

user. This in the event that the unit needs

to be shipped in the future.

In the unlikely event that something

unforeseen has happened during shipping

we recommend performing a portable

appliance test for electrical safety before

plugging the unit into the electrical supply

outlet.

Switching the unit on and

validating basic operation

Unpack the power cable and plug into the

IEC socket at the back of the unit. Ensure

the system has 15cm (6”) clearance at the

rear for the fan inlets and electronics panel.

As the system vents warm air from the cryo-

chamber through the underside of the unit,

ensure the surface the system is placed on

is a rm surface free of obstruction. Do not

place on a fabric surface.

System VIA Freeze Research VIA Freeze Duo VIA Freeze Quad

Weight 14kg (31lb) 40kg (88lb) 64kg (141lb)

Table 1 VIA Freeze System weights

The freezer should be taken out from this box and placed either on the oor or on a suitable desk,

which is strong enough to carry the freezer in a safe manner (unit weights are shown in Table 1). For

the VIA Freeze Duo and Quad, we recommend having two or more persons available when moving

the system. If required, carrying straps can be afxed to the blue carrying handles to aid lifting and

transport of the unit. The VIA Freeze Research can be safely moved by a single person.

6 7