Table of Contents i

Table of Contents

1Introduction ......................................................................................................................................... 1

Overview ............................................................................................................................................... 1

Basic System Description...................................................................................................................... 1

2Safety.................................................................................................................................................... 3

Overview ............................................................................................................................................... 3

Facility Requirements............................................................................................................................ 3

Basic Safety Precautions and Practices ............................................................................................... 4

Safety of Personnel ....................................................................................................................... 4

Preventing Cure Module and Workpiece Damage........................................................................ 4

Earthquake Precautions........................................................................................................................ 5

Personnel ...................................................................................................................................... 5

Movement...................................................................................................................................... 5

Safety Warning Labels .......................................................................................................................... 5

Emergency Shutdown ........................................................................................................................... 5

Emergency Shutdown Recovery ................................................................................................... 5

Lockout of Electrical Energy.................................................................................................................. 6

Interlock ......................................................................................................................................... 6

3Components ........................................................................................................................................ 7

Overview ............................................................................................................................................... 7

Safety First ............................................................................................................................................ 7

Standard Module Components ............................................................................................................. 7

Conveyor System .......................................................................................................................... 7

Air Exhaust .................................................................................................................................... 8

Heating System ............................................................................................................................. 8

Reinforced Cooling System........................................................................................................... 9

Software ........................................................................................................................................ 9

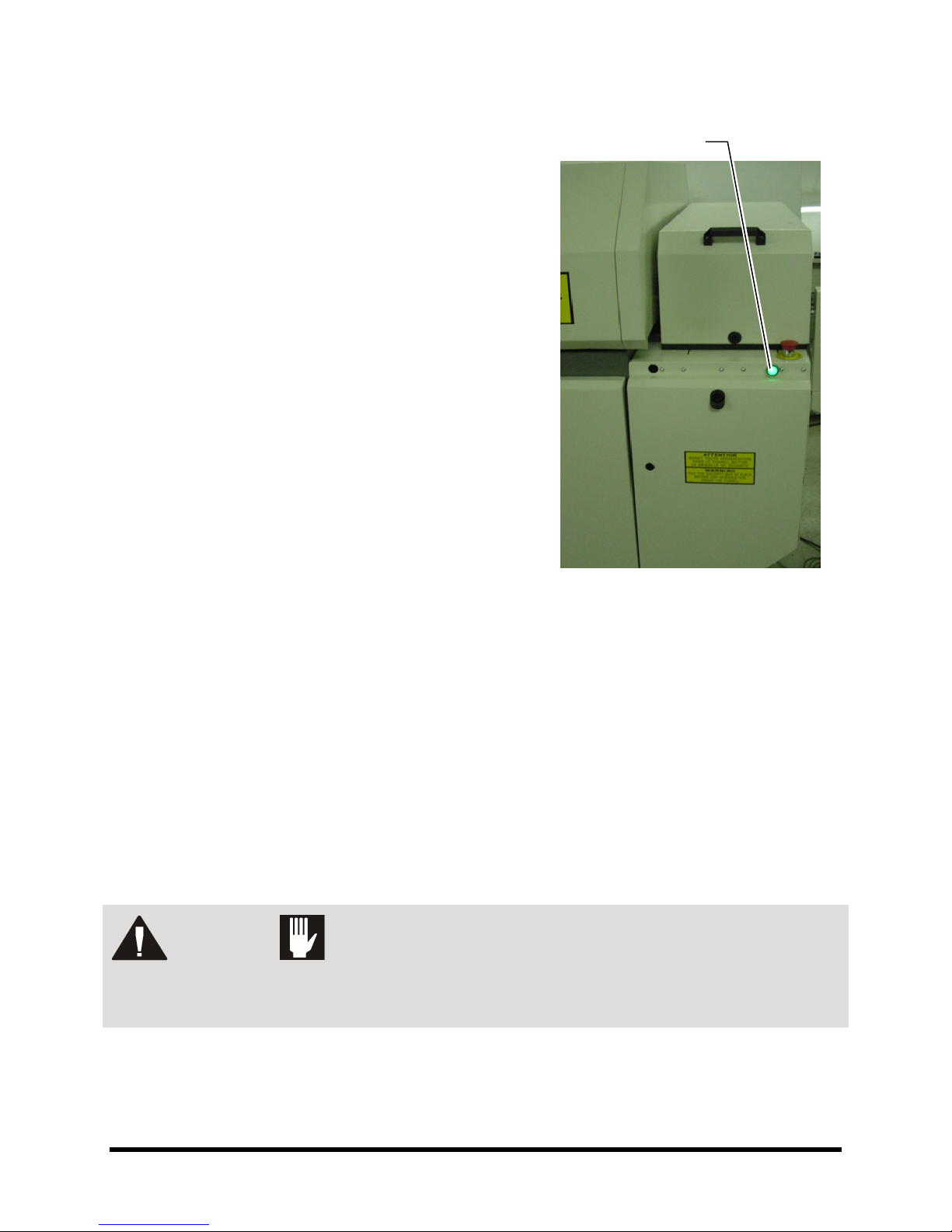

Light Beacon................................................................................................................................ 10

Optional Accessories........................................................................................................................... 13

Second Track Conveyor .............................................................................................................. 13

Heavy Duty Conveyor.................................................................................................................. 13

Automatic Conveyor Chain Lubrication ....................................................................................... 14

Dropped Board Detection Cell..................................................................................................... 14

Pin/Chain Conveyor 3 mm .......................................................................................................... 15

Board Counter Cell ...................................................................................................................... 15

Exit Jam Detection Cell ............................................................................................................... 15

4Installation ......................................................................................................................................... 17

Overview ............................................................................................................................................. 17

Safety First .......................................................................................................................................... 17

Facility Requirements.......................................................................................................................... 17

Unpacking and Placing the Cure Module............................................................................................ 17

Unpacking the Accessories ................................................................................................................. 18

Leveling the Cure Module ................................................................................................................... 19

Anchoring the Cure Module ................................................................................................................ 20

Connections ........................................................................................................................................ 20

5Operation ........................................................................................................................................... 21

Overview ............................................................................................................................................. 21

Safety First .......................................................................................................................................... 21

System Start-up................................................................................................................................... 21

System Shutdown ............................................................................................................................... 23

Hood Opening/Closing Operation ....................................................................................................... 24

Hood Opening Procedure:........................................................................................................... 24