should not be bent or pinched.

After connecting the Machine to water supply and sewerage, check the tightness of the filling hose

connections: the connection points should be dry.

Every Machine has been tested by the manufacturer, therefore, a little amount of water may remain in

the Machine. To clean the Machine from inside and remove the water that might remain after tests, perform

the fist washing cycle without any items.

Make your first washing by setting the Wash Program Selector Knob to the mark «Cotton 90 ºC».

ATTENTION! For the first washing, add 1/2 of the recommended dose of washing powder (dete-

rgent) into compartment 2 of the dispenser drawer (Fig. 14), making account of the manufacturer’s

guidelines as to the maximum items loading.

PREPARATION AND LOADING OF ITEMS

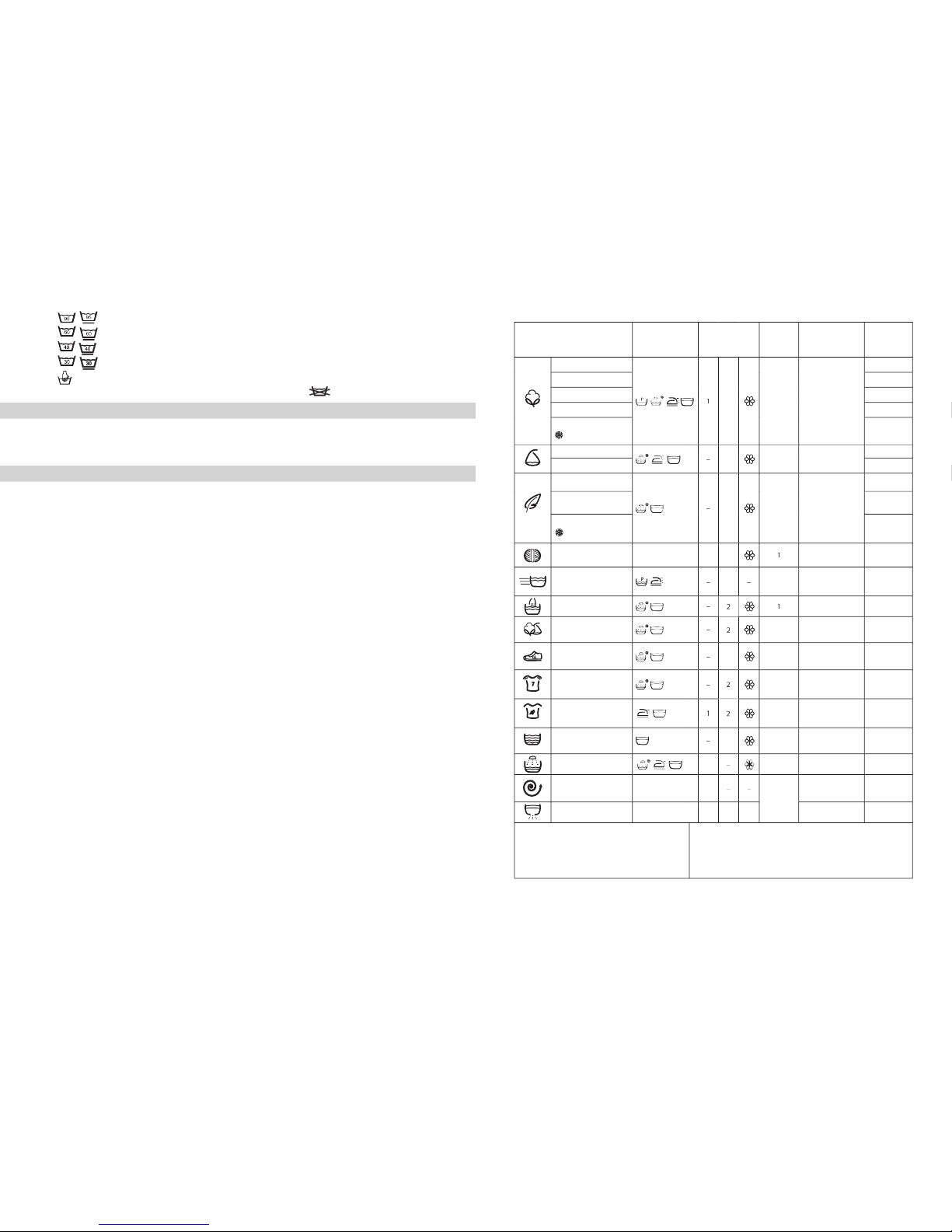

- sort out the items, having separated the coloured ones from the white ones;

- distribute the items according to the fabric care labels;

- check that the pockets of your items of clothes be empty, the damaged and torn parts be repaired,

and zippers, belts, buckles and hooks be closed or locked, and all the hard-removable spots be removed

- be sure to shake all the sand out of the clothes (pockets, cuffs);

- turn the items with applications attached inside out.

ATTENTION! Penetration into the Machine of metal objects (coins, clips) together with clothes

may be a cause of damage of the rubber gasket and plastic drum of the Machine.

Prior to washing, put small items (socks, handkerchiefs, etc.) and delicate clothes (thin tights, stockings,

etc.) into a special net or a pillowcase.

It is recommended to wash uplifts (bras) with plastic inserts (which are fit for machine-washing) in

a special bag, since inserts may get into the Machine interior through drum openings and damage the

Examine the drum for absence of foreign objects and occasional presence of domestic animals

Load your clothes items into the drum. For better results of washing and spinning, it is recommended

to wash big and small items together.

ATTENTION! At non-uniform distribution of items in the drum, the spinning speed will drop

automatically, or no spinning will take place (it would not switch on).

NEVER load the machine only with the items made of fabrics, which absorb a lot of water (terry (Turkish)

towels, gowns, mats, etc.), to avoid overloading.

ATTENTION! Close the door of the Machine until you hear a clear click of the lock (anti-closing blo-

cking should be removed). The items should not be pinched between the door and the sealing gasket.

Check for correct installation of the filling and draining hoses.

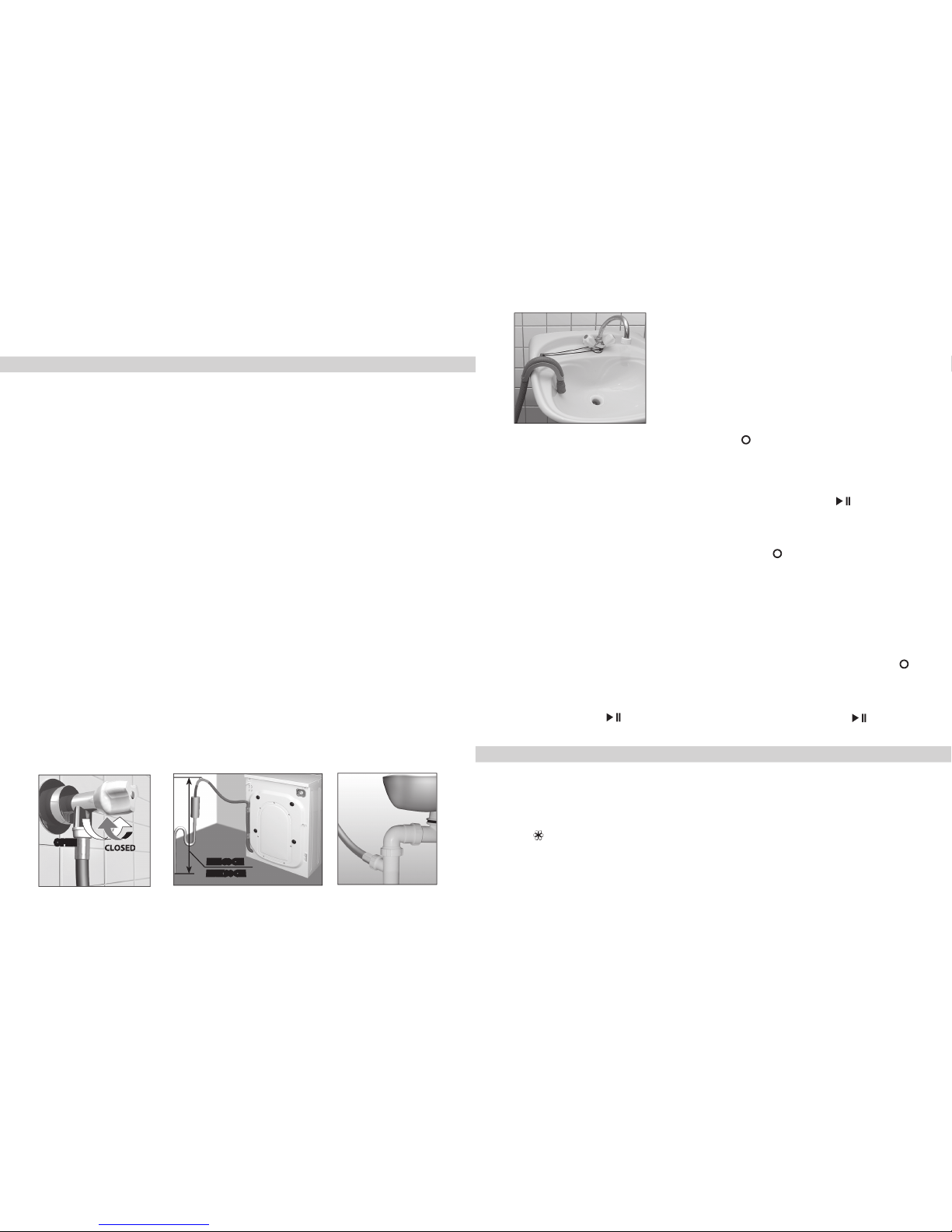

If the Machine was not in use for a long time, drain off the stag-

nant water by unscrewing the nut and disconnecting the hose from

the water supply tap. Connect the filing hose.

Open the water supply tap.

Load the respective compartments of the drawer with the washi-

ng powder intended for automatic washers, and any special treatment

substances. Close the drawer.

Insert the electric power plug into the socket (receptacle) of the

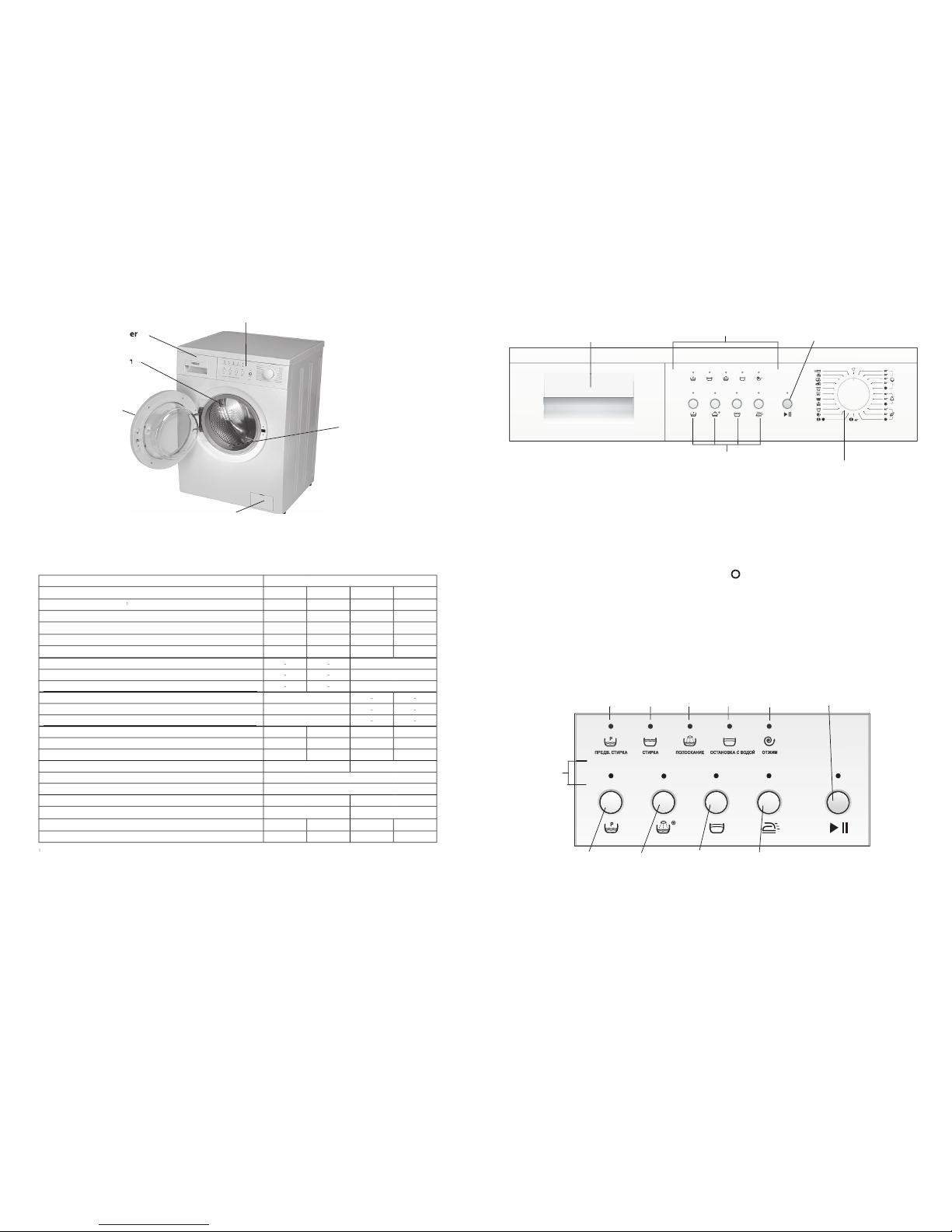

For switching the Machine on, rotate the Wash Program Selector

and set it to the mark corresponding to the

selected program). The display indication zones highlight the basic

The averaged laundry time corrected by electronic system depending on the real conditions during

If necessary, you may set optional functions, select the temperature and spinning rotation speed.

To start the Machine operation under the selected program, pres the button

illuminates on the button and sound signal is generated. The door locking device operates, and the display

starts showing the indicators of the washing program and program operations.

After the end of the last washing operation, the door blocking device will switch off – a triple sound

signal will be heard with a one-minute interval.

Upon termination of washing, set the Program Selector into the

mark – the Machine will switch off.

Take the plug out of the mains socket and close the water supply tap.

Open the door and take your items out.

Move the drawer out a little and leave the door opened a little, until the internal parts of the machine

get dry. To avoid unpleasant smell from appearing in the Machine, the door should remain open till the next

laundry. It is recommended to fix the door anti-closing blocking.

ATTENTION! A drop (interruption) of electric power supply during washing does not effect further

Machine operation: once the power is resumed, the Machine will go on with the program from the

To make changes in the earlier selected program, set the Wash Program Selector Knob into the mark

The Machine is switched off and the program underway is cancelled. Set the Knob to the setting of the

It is recommended to check the presence of the washing powder in the drawer, and to add it, if necessary.

If it is required to stop the Machine without changing the program (for example, to add items into the

pressed for 2 seconds – until blinking of the indicator in the

a sound signal, and in about 2 minutes the door blocking device will switch off.

5 RECOMMENDATIONS AND TIPS

USE OF SYNTHETIC DETERGENTS (SDs)

The machine has a drawer for loading washing powders or detergents (Fig. 14). The drawer has three

compartment marked with figures and a symbol as follows:

1 – for pre-washing and bleaching agents;

2 – for the basic washing;

- for special treatment substances (conditioners, softeners, starchers, aromatizers, etc.).

Take for your washing the SDs, bleachers and conditioners intended for automatic washers, and take

into account the manufacturer’s guidelines.

ATTENTION! In is not recommended to use gelbleachers for your washing.

Select the dosage of SDs with account of the weight of the items, their dirtiness and water hardness.

ATTENTION! SD overdosage, and use of the SDs intended for manual washing may result in exc-