Version number: 2026100811

1

Instruction Manual of ATL-991 Addressable Horn/strobe

------ Please read this Manual carefully before installing and using the product. -----

I. Product overview

The ATL-991 addressable horn/strobe(horn/strobe for short) is a kind of product manufactured by our company to be used

with bus-type fire alarm control units. Controlled by a microprocessor, the horn/strobe can realize real-time communication

with a bus-type fire alarm control unit and receive the control commands sent by it. When in a routing inspection, the red

status indicator will blink; after an accident happens, the horn/strobe will start to

operate after receiving a startup command from the bus-type fire alarm control unit.

The red status indicator will remain lit and the horn/strobe will give a flashing signal

and an audible alarm signal to notify the persons on the scene of the accident that a

fire has occurred on the site and of the necessity to take related evacuation measures,

thus preventing the fire accident from becoming a major one. The horn/strobe may be

restored to the monitoring status after the MUTE or RESET key on the bus-type fire

alarm control unit is pressed.

The horn/strobe may be used to give audible alarms and flashing alarms on the

scenes of accidents. It is suitable for places like high-rise residential buildings, public

places, hotels, amusement buildings, factories, shopping centers, hospitals, schools,

office buildings and stock exchanges, particularly places with low visibility or the

possibility of generation of smoke.

II. Product features

It can realize complete electronic coding and in situ rewriting with the help of a coder.

The audible alarm and flashing alarm may be set freely. In other words, the horn/strobe may give an audible alarm

and a flashing alarm at the same time or separately and it can be adapted to different working environments.

Designed with an upper cover and a lower cover, it can be installed, debugged and maintained conveniently.

It uses multiple super bright red LEDs as light sources for visual display, ensuring a striking display, a longer service

life and low power consumption.

III. Technical parameters

1. Executive standard: GA385- 2002

2. Operating voltage: DC24V (pulse modulation)

3. Operating current: quiescent current: ≤1mA(the current consumed by the bus); alarm current: ≤120mA@DC24V

4. Operating environment: Temperature: -10℃~+55℃; relative humidity: ≤95% (40℃, without condensation)

5. Flushing rate: one time/s

6. Alarm volume: >85dB (measured at a place 3m in front of the horn/strobe)

7. Coding method: Electronic coding

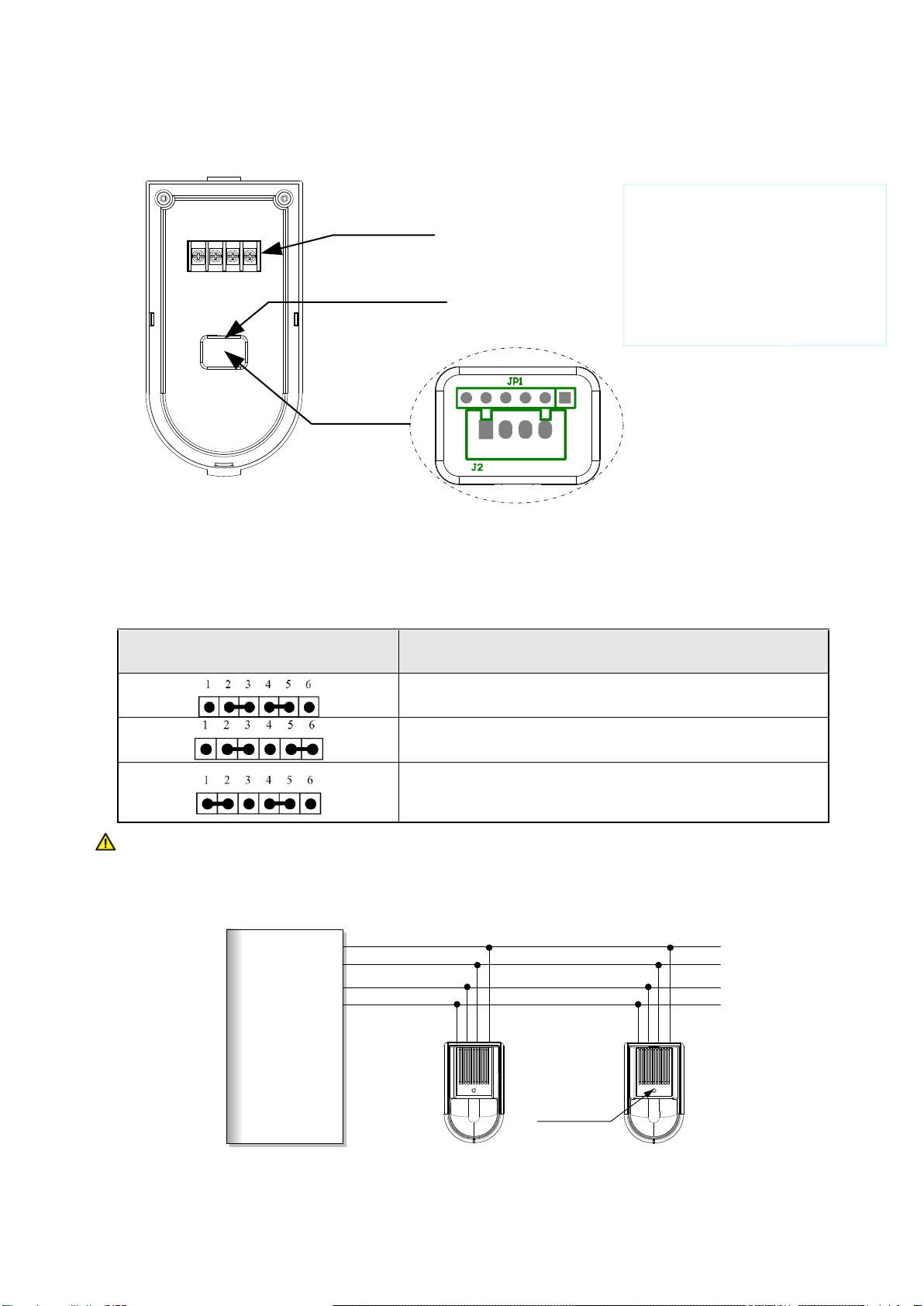

8. Wiring method: Four-wire system, non-polarity two signal buses (L1, L2) and power lines (+24V, GND)

9. Matched host machine: fire alarm control panel (such as ATL-MN300)

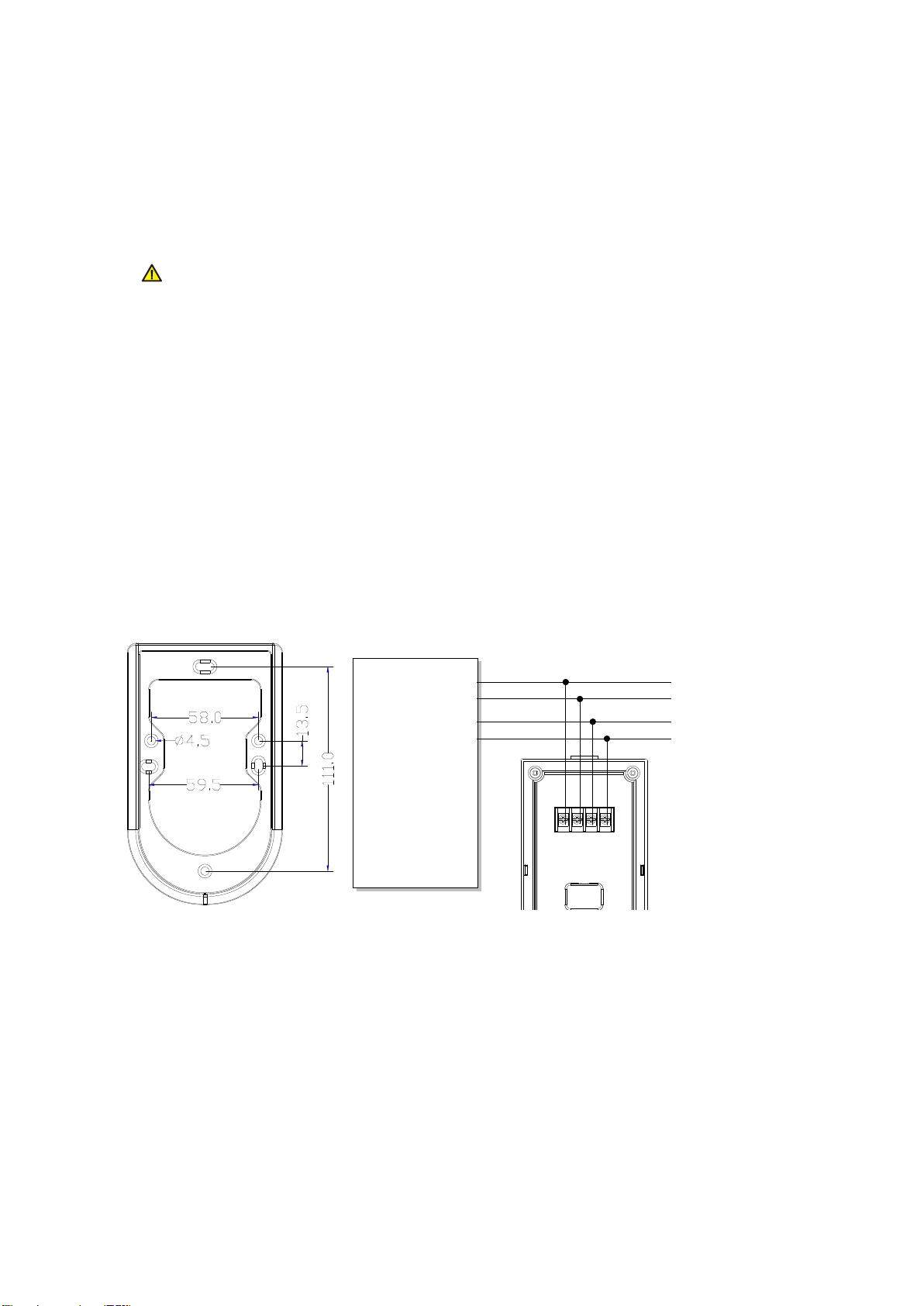

IV. Appearance and dimensions (see Fig.1)

Fig.1