ATTC LIGHTING AUTO MIG Gun Quick start guide

Fixed Automation MIG Gun

Technical Guide

MIG Technical Guide

2

LIGHTNING®

941-753-7557 • FAX:941-753-6917 • 800 342-8477 • sales@attcusa.com • www.AmericanTorchTip.com

2

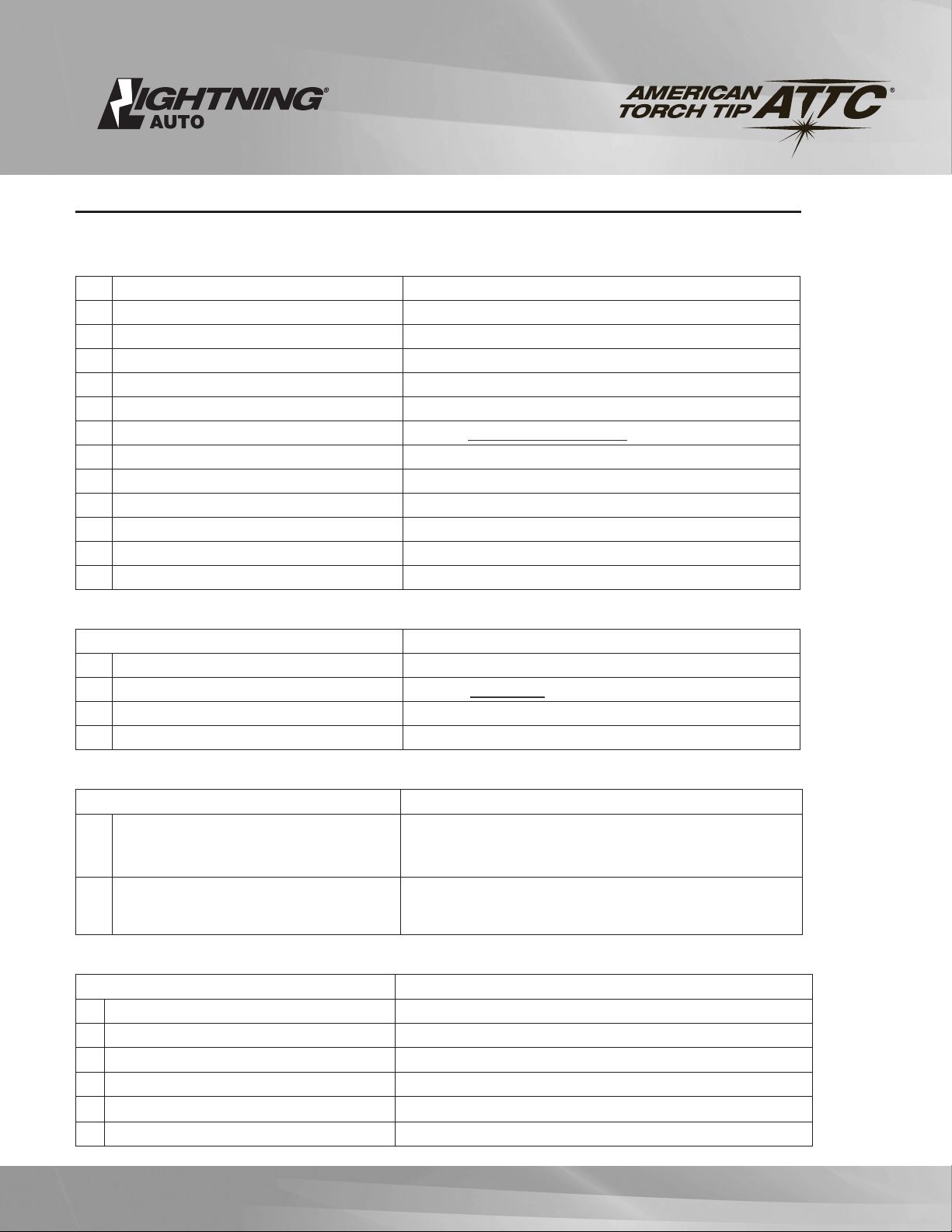

PART NUMBERING SYSTEM

Wire Size

30 .030”

35 .035”

10 1.0 mm

45 .045”

52 .052”

116 1/16”

332 3/32”

364 3/64” al

564 5/64”

Gooseneck (opt)

500 180º

522 22º

545 45º

560 60º

Cable Length

03 3 feet

3.5 3.5 feet

04 4 feet

06 6 feet

08 8 feet

10 10 feet

12 12 feet

15 15 feet

LIGHTNING HANDLE

LLightning

L E 53 04 - 45 - 560

Gun Model

53 500 amp

Power Pin

TTweco

EEuro

LN Lincoln

MMiller

100% Duty Cycle 60% Duty Cycle

Co2 Mixed Gas Co2 Mixed Gas

500 amps 350 amps 650 amps 500 amps

Amperage Ratings (duty cycle)

Reliable Automatic Welding Equipment

The Lightning®AUTO MIG gun is made to stand up to the high heat conditions typical in the

production environment. Lightning®precision consumables are designed to reduce change-out

related downtime. All gun components and consumables are made in the USA.

High Strength Cable

The outer cover is strengthened using electron beam accelerators which cross-link the polymers

and increase the tear, stretch and abrasion resistance of the cable. Hytrel inner tubing is kink and

impact resistant for smooth and reliable wire feed. The copper strand count of our premium cable

assures long life and maximum productivity.

Lightning®Contact Tips

Tapered seat designed to dissipate heat and maximize electrical conductivity.

Our dual start-point thread allows re-seating of the tip. When wire wear begins to effect

performance, simply rotate the tip 180º to a new wear-point and double the life of the contact tip.

Heavy Duty Handle

Lifetime Warranty on gun body.

Fiber reinforced resin stands up to extreme heat and impact.

Slim compact design.

3

LIGHTNING®

941-753-7557 • FAX:941-753-6917 • 800 342-8477 • sales@attcusa.com • www.AmericanTorchTip.com

3

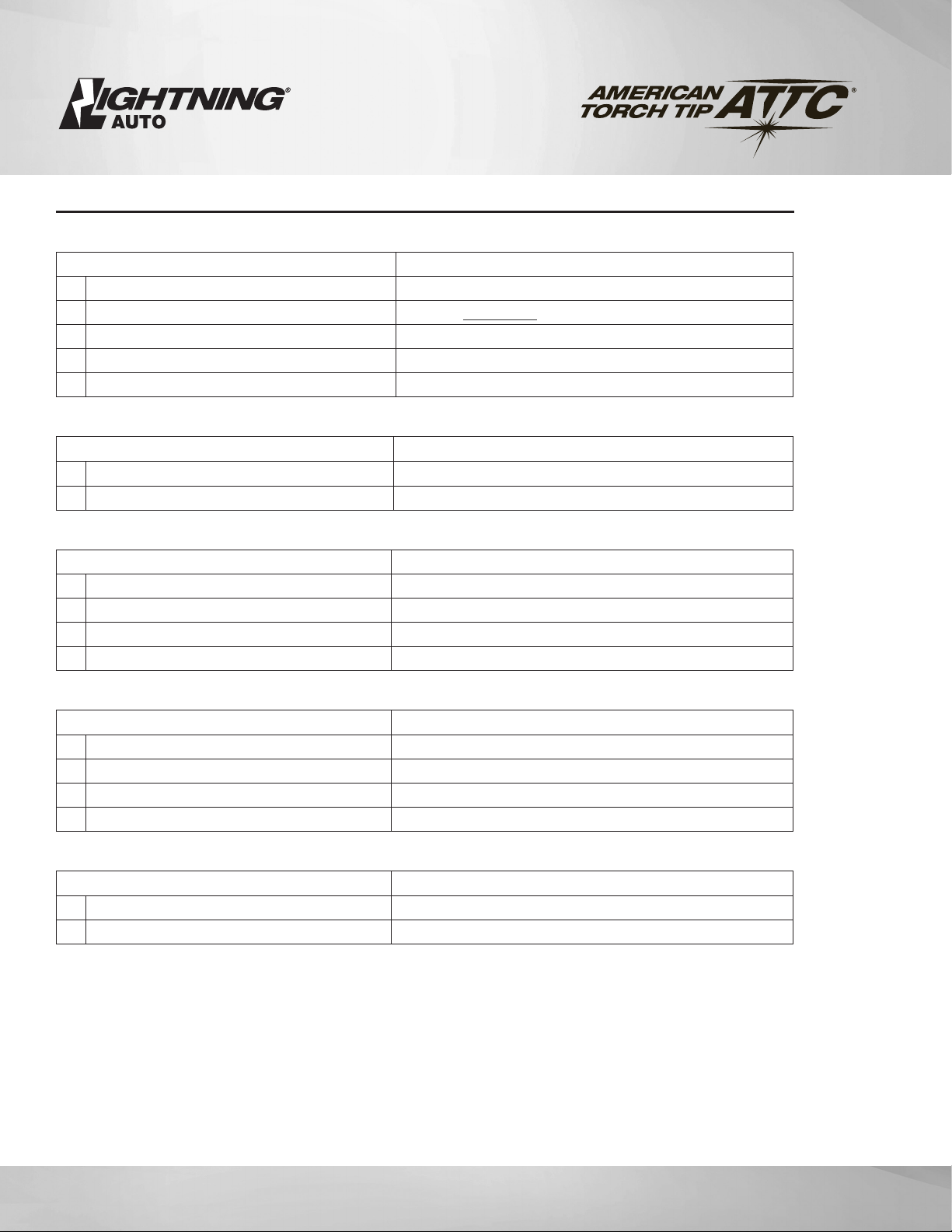

NOZZLES ID

63-2138 HD * Flush 3/8” (09.5mm)

63-2662 HD 1/8” Stick-Out 5/8” (15.9mm)

63-2150 HD 1/8” Tip Recess 1/2” (12.7mm)

63-2162 HD 1/8” Tip Recess 5/8” (15.9mm)

63-2175 HD 1/8”Tip Recess 3/4” (19.1mm)

64-2562 Extra HD Cu 1/4” Tip Rec. 5/8” (15.9mm)

64-2575 Extra HD Cu 1/4” Tip Rec. 3/4” (19.1mm)

65-2550 HD Cu 1/8” Tip Recess 1/2” (12.7mm)

65-2562 HD Cu 1/8” Tip Recess 5/8” (15.9mm)

65-2575 HD Cu 1/8” Tip Recess 3/4” (19.1mm)

64-2950 HD Bottleneck 1/8 Stick-out 1/2” (12.7mm)

63-2950 HD Bottleneck 1/8 Recess 1/2” (12.7mm)

65-2662 Extra HD 1/8 Stick-out 5/8” (15.9mm)

65-2362 Extra HD Brass 1/8 Stick-out 5/8” (15.9mm)

Threaded versions available for all nozzles.

Add “T” to part number.

CONTACT TIPS ID

63-1130 HD* .030 (0.8mm) .037

63-1135 HD .035 (0.9mm) .043

63-1140 HD .040 (1.0mm) .048

63-1145 HD .045 (1.2mm) .055

63-1152 HD .052 (1.3mm) .063

63-1178 HD 5/64 (2.0mm) .093

63-1193 HD 3/32 (2.4mm) .110

63-1162 HD 1/16” (1.6mm) .073

63-1230 HD Tapered .030 (0.8mm) .037

63-1235 HD Tapered .035 (0.9mm) .043

63-1245 HD Tapered .045 (1.2mm) .055

63-1252 HD Tapered .052 (1.3mm) .063

63-1335 HD CuCr ** .035 (0.9mm) .043

63-1345 HD CuCr .045 (1.2mm) .050

63-1352 HD CuCr .052 (1.3mm) .059

63-1362 HD CuCr 1/16” (1.6mm) .070

63-1378 HD CuCr 5/64” (2.0mm) .093

63-1394 HD CuCr 3/32” (2.4mm) .110

65-1130 Extra HD .030 .037

65-1135 Extra HD .035 .043

65-1145 Extra HD .045 .055

65-1162 Extra HD 1/16 .073

65-1178 Extra HD 5/64 .093

65-1193 Extra HD 3/32 .110

65-11120 Extra HD 7/64 .120

65-11125 Extra HD 1/8 .136

65-1235 Extra HD .035 tprd .043

65-1245 Extra HD .045 tprd .055

65-1252 Extra HD .052 tprd .063

65-1335 Extra HD CuCr .035 .040

65-1345 Extra HD CuCr .045 .050

65-1352 Extra HD CuCr .052 .060

65-1362 Extra HD CuCr 1/16 .070

GAS DIFFUSERS & RETAINER

63-3201 Diuser for HD Contact Tip

63-3104 Nozzle Retainer (for 63-3201 above)

63-3103 Diuser HD

63-3116 R/M Thread-on Diuser HD

65-3116 R/M Thread-on Extra Heavy Duty Diuser

65-3103 Diuser Extra HD

65-3103-2 Robotic Extra HD

63-3301 Gas Diuser O-Ring

SHOCK WASHERS

63-6202

63-6202HD (Heavy Duty)

LIGHTNING®GOOSENECKS

65-5100A Fixed 180º

65-5122A Fixed 22º

65-5145A Fixed 45º

65-5160A Fixed 60º

LINERS

Wire Size Length Part# OD

.023” (.6mm) 15’ 64-4115 0.150

.035” (.9mm) 15’ 62-4315 0.156

.035” (.9mm) 25’ 62-4325 0.156

.045” (1.6mm) 15’ 62-4515 0.156

.045” (1.6mm) 25’ 62-4525 0.156

.030” (.8mm) 15’ 64-4215 0.182

.035” (.9mm) 10’ 64-4310 0.175

.035” (.9mm) 15’ 64-4315 0.175

.035” (.9mm) 25’ 64-4325 0.175

.035” (.9mm) 25’ 64-4325 0.175

.035” (.9mm)al 15’ 64-4415 0.189

.045” (1.6mm) 10’ 64-4510 0.189

.045” (1.6mm) 15’ 64-4515 0.189

.045” (1.6mm) 25’ 64-4525 0.189

3/64” (1.6mm) 10’ 64-4510 0.189

3/64” (1.6mm) 15’ 64-4515 0.189

3/64” (1.6mm) 25’ 64-4525 0.189

.52” (1.6mm) 10’ 64-4510 0.189

.52” (1.6mm) 15’ 64-4515 0.189

.52” (1.6mm) 25’ 64-4525 0.189

1/16” (1.6mm) 10’ 64-4510 0.189

1/16” (1.6mm) 15’ 64-4515 0.189

1/16” (1.6mm) 25’ 64-4525 0.189

3/64-1/16al 15’ 64-4615 0.189

5/64-3/32 15’ Flat 64-4715 0.189

5/64-3/32 25’ Flat 64-4725 0.21

5/64 & 1/16” FC 10’ 64-4815 0.21

.035 – .045 15’ 64-4915 0.192

(for S.S. Wire)

NOTE: 65-11xx series tips are only to be used with 65 series Lightning® diusers.

4

LIGHTNING®

941-753-7557 • FAX:941-753-6917 • 800 342-8477 • sales@attcusa.com • www.AmericanTorchTip.com

4

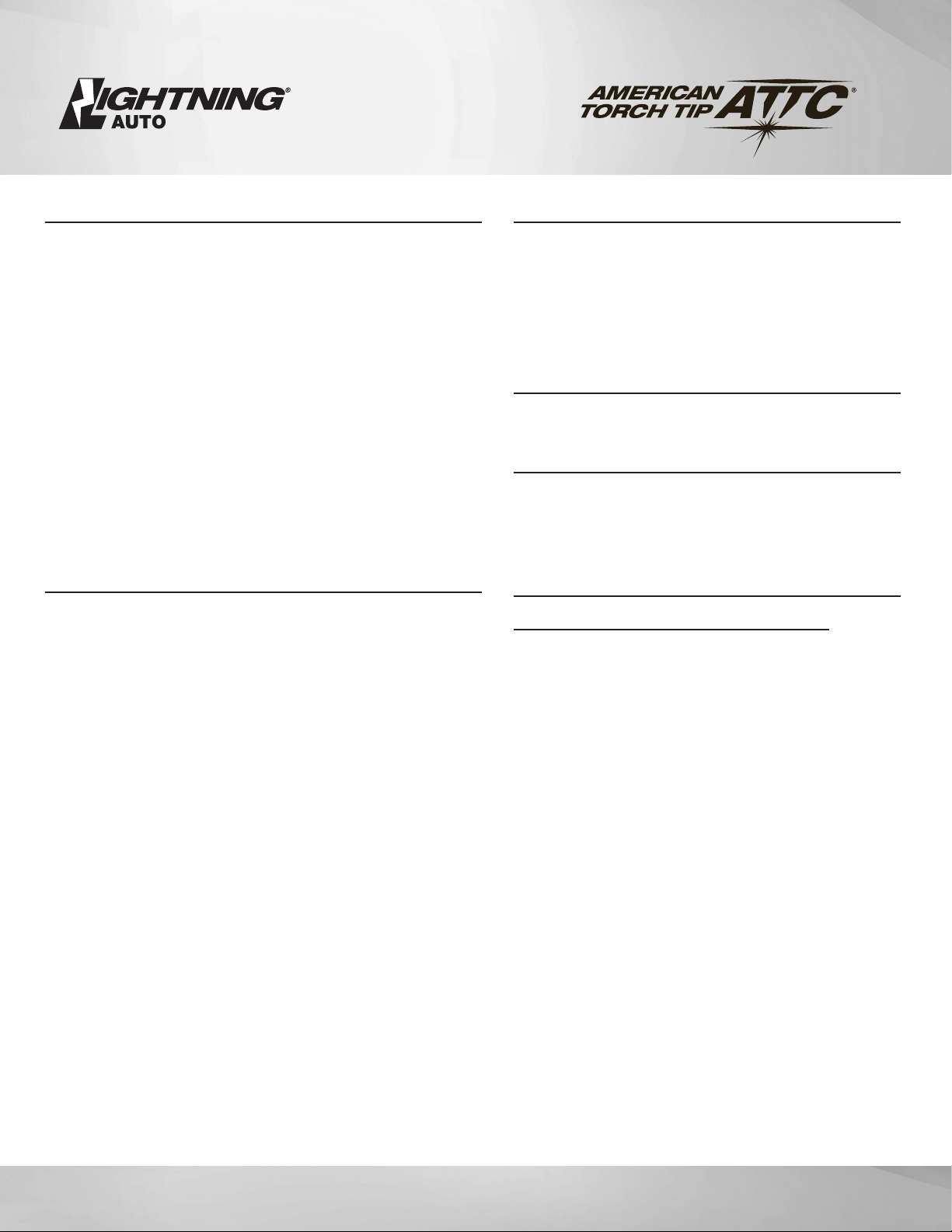

Contact Tip HD

Nozzle (Copper)

64-6301A (4/500A) 63-6302 (2/3/400A)

65-6302 (500A)

63-6502

Clamps

Front-End Housing

64-6201 65-7902 (500A)

Spring Guard

Unicable Assembly

Mounting Screw

Cone NutConnector Cone

Body Set Screw

63-6501

See Chart on page 3

See Chart on page 3

Gooseneck

See Chart on page 3

Shock Washer

Diffuser Assy. 1 Pc

63-3103

63-6202 (HD)

63-6601A

Body Assy

Front-End Assembly

64-6506

5

LIGHTNING®

941-753-7557 • FAX:941-753-6917 • 800 342-8477 • sales@attcusa.com • www.AmericanTorchTip.com

5

Connector Cone

64-6301 (4/500A)

Cone Nut

63-6302 (400A)

65-6302 (500A)

Liner O-ring

64-9001

Liner Conduit Liner

See Chart on

page 3

Power Pin O-ring

64-8202

Power Pin

Mount

64-8208

Pin (Tweco #4)

64-8211

Pin (Miller)

64-8311

Pin (Lincoln)

64-8411

Guide Cap

64-8303 (.035-1/16)

64-8304 (5/64-3/32)

Housing & Screws

63-6101LP

Unicable

See Chart on page 3

Control Plug

Connector

64-7909

Clamp

64-7907 (400A)

65-7902 (500A)

Spring Guard

63-6502 Handle

64-6106

Screws

64-6501

European Assembly

Back-End Assembly

Spring Guard - Euro

63-6504

Unicable

Euro Male Connector

64-7910

Handle

64-8107

Connector Cone

64-6301 (4/500A) Hand Nut

64-8104

Clamp

65-7902 (500A)

Cone Nut

65-6302 (500)

Euro Female

Connector

64-8102-4

Adapter Fitting (Euro)

64-8109 Included

w/64-8101

Mounting Screw

64-8106

Liner O-Ring

64-9001

Conduit Liner

See chart on page 3

Quick Connect

Power Pin Assy.

64-8101 Power Pin O-Ring

64-8103

Liner Adapter

64- 8114

Gas Nipple

63- 8113

6

LIGHTNING®

941-753-7557 • FAX:941-753-6917 • 800 342-8477 • sales@attcusa.com • www.AmericanTorchTip.com

6

NOZZLE AND CONTACT TIP SYSTEMS

IMPORTANT

Shock washer must be in place before welding to maintain insulation of

gooseneck. Be sure all parts are tightened will before welding.

When using the heavy duty retaining head make sure it is tightened with

a 11/16” wrench to prevent overheating of contact tip.

To prevent scoring on heavy duty retaining head do not use pliers.

REMOVAL AND REPLACEMENT

Pull slip-on nozzles o with a clockwise twisting motion.

When installing nozzle, exposed insulator should nest inside shock

washer to assure concentricity.

Shock washers are positioned on the end of the gooseneck with

the large insulated counterbore facing the nozzle.

Replace nozzle retainer with deep counterbore toward the gooseneck.

Tighten until retainer and shock washer are secure.

THREAD-ON (OPTIONAL FOR TWECO HD)

Thread-on nozzle system does not require nozzle retainer and

cannot be used with heavy duty head.

Shockwasher must be in place.

External gooseneck thread can be cleaned with a 9/16”-18 die.

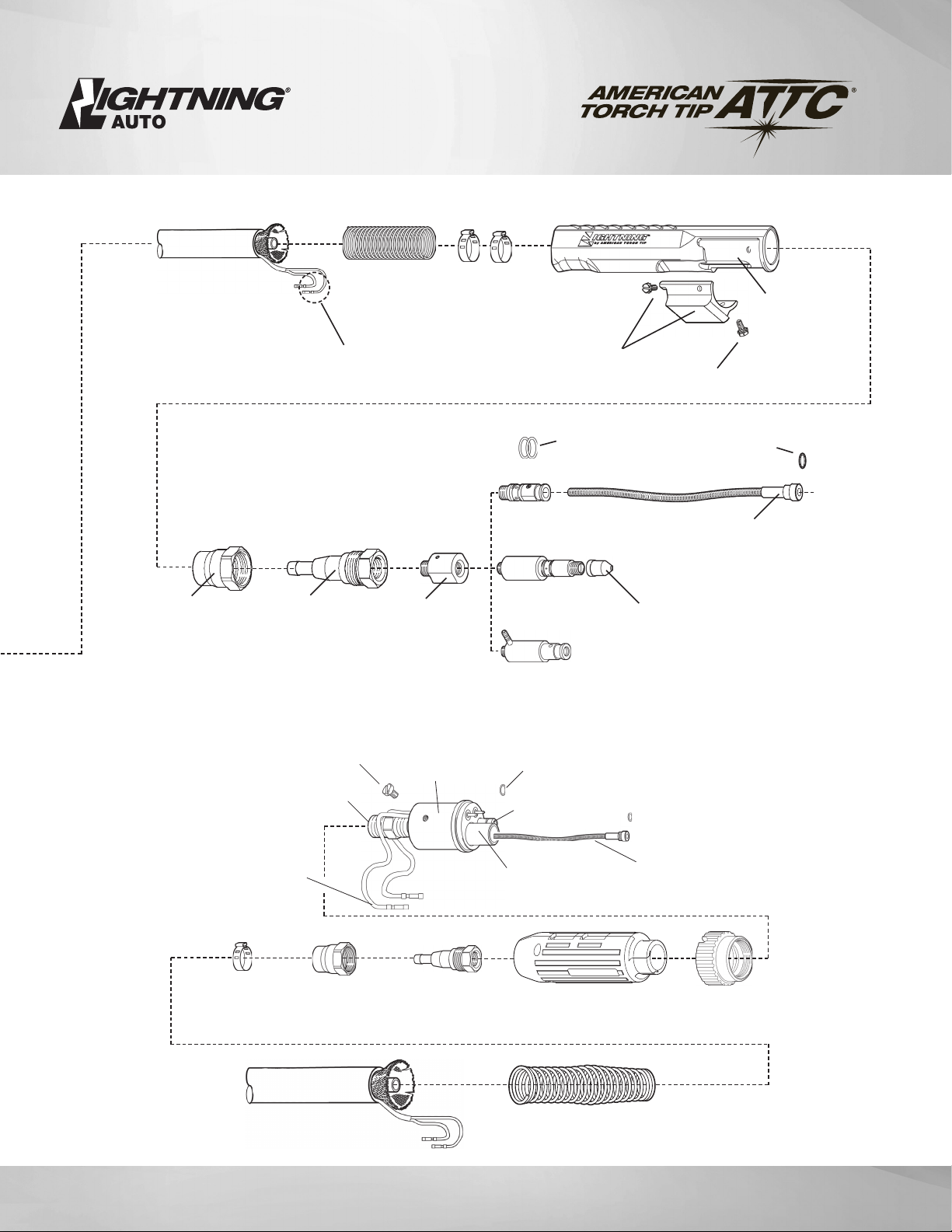

1.1 LINER REPLACEMENT

TOOLS REQUIRED

Vise

5/64 Allen wrench

Lineman pliers

1. Remove nozzle, contact tip and tip holder from gooseneck. (Not shown)

2. With gun straightened, loosen liner set screw on quick connect power

pin at back end of gun using a 5/64” Allen wrench. (See Figure 1)

3. Using pliers, grip liner and remove from gun.

4. Install new liner by feeding through gun. Use short strokes to avoid kinking.

Use clockwise rotation as needed.

5. Be sure o-rings on liner head seats into inside bore of power pin.

6. Tighten set screw on power pin to secure liner. Do not overtighten.

Nozzle (Copper) Contact Tip HD

Contact Tip HD Tprid

Diffuser Assy. 500A

NOTE: Any of the above nozzle and contact tip systems can be used on the LIGHTNING

GUN 50 AMP models. (See chart page 3)

7

LIGHTNING®

941-753-7557 • FAX:941-753-6917 • 800 342-8477 • sales@attcusa.com • www.AmericanTorchTip.com

7

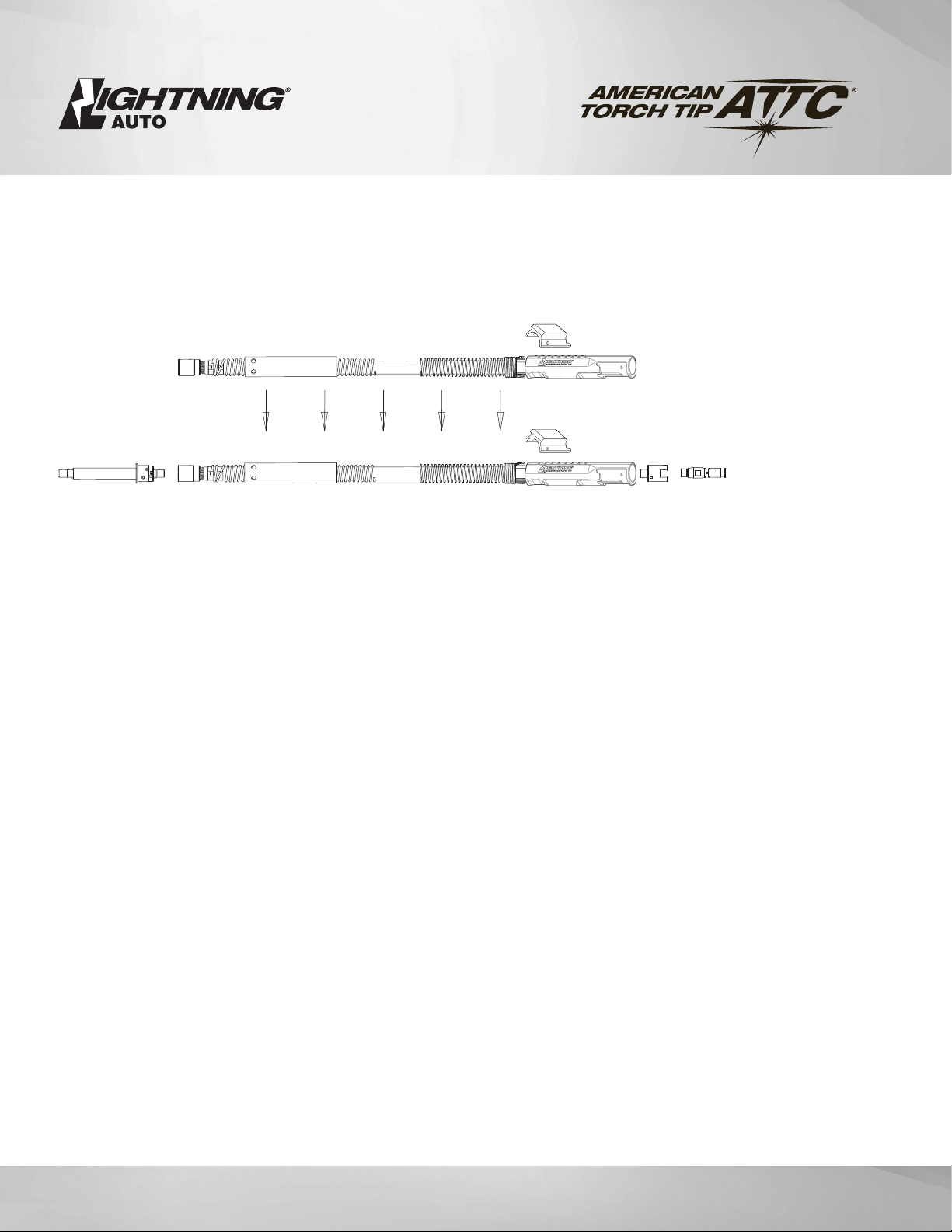

UNICABLE REPAIR / REPLACEMENT

STEP #1

•Remove liner from gun (See Section 2.5 LINER REPLACEMENT).

• Mount neck in vise.

• Remove housing screws and slide housing back (front and back).

• Loosen connector cone from neck using 1” (25 mm) wrench.

• Remove from vise and thread out neck by hand.

• Cable connection between cone and crimp ring should not be disturbed.

• Unthread power pin and remove using 1 1/4” (32 mm) on connector cone and a 5/8” (16

or 3/4” (19 mm) wrench on power pin. Install new power pin.

• Retrieve front and rear housing. Slide housings onto new unicable assembly.

• Repeat procedure in reverse to assemble remaining components.

REPLACEMENT

UNICABLE

USED UNICABLE

8

LIGHTNING®

941-753-7557 • FAX:941-753-6917 • 800 342-8477 • sales@attcusa.com • www.AmericanTorchTip.com

8

A. Wire not feeding or bumpy feeding

Possible Cause Possible Solution

1. Feeder relay / malfunction Consult feeder manufacturer.

2. Broken control lead Connect spare control leads.

3. Poor adaptor connection Test and replace leads and/or contact pins.

4. Incorrect type of drive roll Use manufacturers recommended drive rolls

5. Improper drive rolls size Replace with proper size.

6. Drive roll tension misadjusted Adjust tension at feeder.

7. Burn back to contact tip See “E. Contact tip burn back.”

8. Wrong size liner Replace with correct size.

9. Buildup inside of liner Replace liner, check condition of electrode.

10. Worn drive roll Replace with new drive roll.

11. Improper guide tube relationship Eliminate all gaps in electrode path.

12. Improper wire guide diameter Replace with proper guide diameter.

13. Gaps at liner into gas diuser Reset liner and lock or replace with new liner

B. Premature contact tip failure

Possible Cause Possible Solution

1. Improper voltage or wire feed speed Set parameters.

2. Erratic wire feeding See “G. Erratic arc.”

3. Improper tip stickout Adjust nozzle/tip relationship.

4. Improper electrode stickout Change length of wire stickout.

C. MIG Gun running hot

Possible Cause Possible Solution

1. Exceeding duty cycle Replace with properly rated duty cycle MIG Gun.

Decrease parameters to within Gun rating.

2.

Loose or poor power connection Clean and retighten all electrical connection.

Check rating and condition of ground clamp.

D. Porosity in weld

Possible Cause Possible Solution

1. Nozzle/Insulator/O-rings worn Replace.

2. Retaininghead spring/band Replace retaining head.

3. Extreme heat or duty cycle Use X-heavy-duty consumables.

4. Gas not getting to the weld Check gas regulator/flowmeter/cylinder

5. Gas ports plugged Clean or replace gas diuser/nozzle.

6. Loose fittings or cut gas hose Tighten or repair hose lines.

Lightning® Troubleshooting

9

LIGHTNING®

941-753-7557 • FAX:941-753-6917 • 800 342-8477 • sales@attcusa.com • www.AmericanTorchTip.com

9

Lightning® Troubleshooting

E. Contact tip burn back

Possible Cause Possible Solution

1. Improper voltage and/or wire feed speed Set parameters.

2. Erratic wire feeding See “G. Erratic arc.”

3. Improper tip stickout Adjust nozzle / tip relationship.

4. Improper electrode stickout Adjust torch to base metal relationship.

5. Faulty ground Repair all cables and connectors.

F. Tip disengages from retaining head

Possible Cause Possible Solution

1. Worn retaining head Replace tip and/or retaining head.

2. Improper tip installation Finger tighten then slightly tighten with correct tool.

G. Erratic arc

Possible Cause Possible Solution

1. Worn contact tip Replace.

2. Buildup inside of liner Replace liner, check condition of electrode.

3. Wrong tip size Replace with correct tip size.

4. Incorrect welding parameters Use wire manufacturers parameters.

H. Excess spatter

Possible Cause Possible Solution

1. Improper machine parameters Adjust parameters.

2. Incorrect tip or installation Adjust nozzle / tip relationship.

3. Incorrect nozzle or shielding Use correct nozzle and shielding gas coverage.

4. Contaminated wire or work piece Replace wire and clean work piece.

I. Discolored Liner

Possible Cause Possible Solution

1. Short circuit to electrode Check for wire short circuiting in feeder

2. Cuts in outer jacket, copper exposed Replace gun.

10

LIGHTNING®

941-753-7557 • FAX:941-753-6917 • 800 342-8477 • sales@attcusa.com • www.AmericanTorchTip.com

Nozzle 64-2387

7/8” Bore

1/4” Recess

Brass

1.062” O.D.

Straight Bore

64-2950

1/2” Bore

1/8” Stickout

Brass

0.938” O.D.

Straight Bore

64-2962

5/8” Bore

Flush

Copper

1.062” O.D.

Bottle Neck

65-2562

5/8” Bore

1/8” Recess

Copper

1.062” O.D.

65-2362

5/8” Bore

1/8” Stickout

Brass

1.062” O.D.

65-2375

3/4” Bore

1/4” Recess

Brass

1.120” O.D.

Straight Bore

65-2575

3/4” Bore

1/8” Recess

Copper

1.062” O.D.

65-2662

5/8” Bore

1/8” Stickout

Copper

1.062” O.D.

65-2550

1/2” Bore

1/8” Recess

Copper

1.062” O.D.

Diuser 63-3103 63-3103 63-3103 63-3103 63-3103 63-3103 63-3103 63-3103 63-3103

Tip 63-11XX 63-11XX 63-11XX 63-11XX 63-11XX 63-11XX 63-11XX 63-11XX 63-11XX

Nozzle 63-2138

3/8” Bore

Flush

Copper

0.938” O.D.

63-2150

1/2” Bore

1/8” Recess

Copper

0.938” O.D.

63-2162

5/8” Bore

1/8” Recess

Copper

0.938” O.D.

63-2175

3/4” Bore

1/8” Recess

Copper

0.938” O.D.

Straight Bore

63-2362

5/8” Bore

1/8” Recess

Brass

1.120” O.D.

Straight Bore

63-2662

5/8” Bore

1/8” Stickout

Copper

0.938” O.D.

63-2950B

1/2” Bore

1/8” Recess

Brass

0.938” O.D.

Straight Bore

64-2562

5/8” Bore

1/4” Recess

Copper

1.062” O.D.

64-2575

3/4” Bore

1/4” Recess

Copper

1.062” O.D.

Diuser 63-3103-2 63-3103-2 63-3103 63-3103 63-3103 63-3103 63-3103-2 63-3103 63-3103

Tip 63-12XX 63-11XX 63-11XX 63-11XX 63-11XX 63-11XX 63-11XX 63-11XX 63-11XX

XX denotes wire size.

See chart on page 3 for details.

Visit LightningMIG.com for more information

and helpful MIG resources, including catalogs, videos and articles.

MIG Consumable Parts Reference

All Lightning® consumables are interchangable for custom configurations.

All nozzles are available in threaded versions for use with threaded diuser.

11

LIGHTNING®

941-753-7557 • FAX:941-753-6917 • 800 342-8477 • sales@attcusa.com • www.AmericanTorchTip.com

11

11

LIGHTNING®

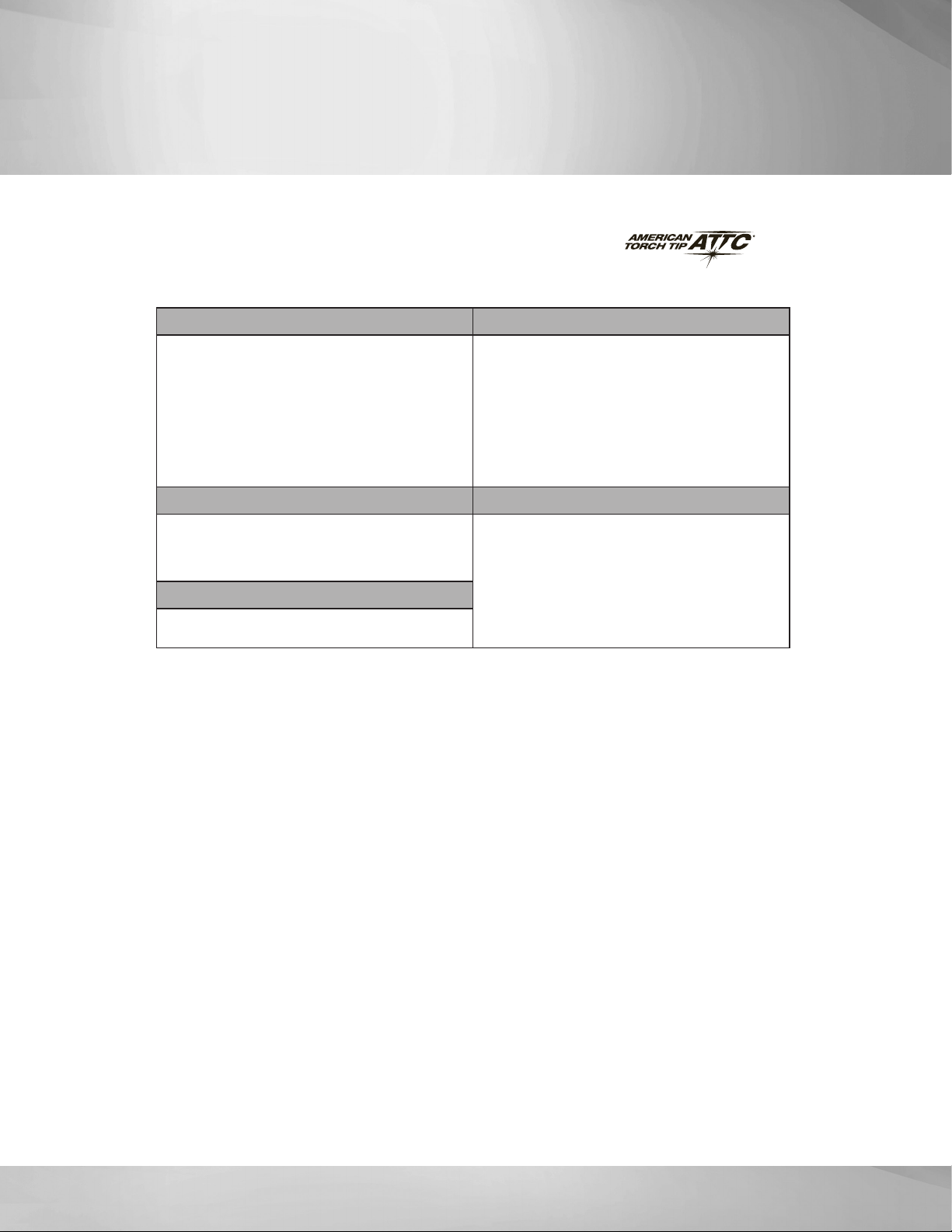

Warranty Terms

This warranty shall not apply to any product that has been modified or used in a manner inconsistent with ATTC’s installaton

instructons and operatng guidelines. Within the warranty periods listed above and at ATTC’s sole discreton, ATTC will repair or replace

any warranted parts or components that fail due to such defects in material or workmanship. ATTC must be notfied within thirty (30)

days of such defect or failure, at which tme ATTC will determine if a Return Goods Authorizaton (RGA) is justfied and issue an RGA

number, authorizaton of a RGA number shall not be unreasonably withheld. ATTC will supply a RGA form, which must be included

with the returned products for inspection by ATTC. Shipping and packing costs shall be the responsibility of the party returning the

goods. Once received, ATTC shall inspect and determine if a warranty claim is justified and at ATTC’s sole discreton authorize a repair

or replacement. Once authorizaton has been granted ATTC shall provide instructons on the warranty claim procedures to be followed.

Where authorized, repair or replacement consttutes the sole remedy for breach of warranty and expressly excludes claims for lost

revenue, down tme and other consequental damages. The warranty is limited to the conditons stated above and excludes, to the

fullest extent permited by law, all conditons, warrantes and representatons express or implied by statue, law or otherwise in relaton to

the supply or delay in supplying the goods/services. There are no agreements, promises or understandings, either verbal or writen that

are not fully expressed in this warranty. This warranty may be amended or altered only if agreed to in writing and signed by ATTC.

ATTC Limited Warranty 0516

LIMITED WARRANTY − Subject to the terms and conditions below

American Torch Tip Co. (ATTC) warrants its products to the original end user for the periods listed below:

PLASMA MIG

LIFETIME

*PHD and PHDX Torch Bodies

LIFETIME

*Lightning® Handle and Trigger Switch

ONE YEAR

*Lightning® Semi-Automatic MIG Guns

*Lightning® Robotic MIG Guns

*Lightning® Fixed Automation MIG Guns

180 DAYS

*All Other Gun Models

GAS APPARATUS TIG

THREE YEARS

*Complete Oxy-Fuel Kit Components

*Regulators/Flowmeters/Flowregulators

*Torches, Handles & Cutting Attachments

ONE YEAR

*TIG Torches

THERMAL SPRAY

ONE YEAR

*Thermal Spray Guns

*Limited Warranty on Manufacturing and Material Defects. Warranty Terms Do Not Apply to Consumable Products.

12

LIGHTNING®

941-753-7557 • FAX:941-753-6917 • 800 342-8477 • sales@attcusa.com • www.AmericanTorchTip.com

For selecting the Lightning® MIG Gun. The Lightning® Gun is for welding professionals who want

durability and comfort while working in harsh welding environments. This technical guide with

instructions and illustrations is designed to make it easy to maintain your Lightning®Gun. Please

read and follow all the safety procedures. For technical support, please call our Customer Service

department at 1-800-371-8477 between 8:00 AM and 5:00 PM EST Monday through Friday. We are

committed to providing the best-quality products and services. We are constantly working to improve

our products. We would appreciate hearing your suggestions.

THANK YOU

Robotic MIG GunAutomatic MIG Gun

The Family of MIG Guns, Consumables and Accessories

Semi-Auto MIG Gun Large Curve MIG Gun Small Curve MIG Gun

Made in the USA by

American Torch Tip

MAR-TECH-MIG-011

This manual suits for next models

1

Table of contents