AUSTRACK CAMPERS TELEGRAPH LT User manual

®

Please read owner’s manual before using the equipment. Third party component manuals

should be read in conjunction with this manual. Maintenance guidelines must be met or

exceeded, failing to meet these guidelines may result in serious injury or death and property

damage. Specication may change without notice.

©Copyright Austrack Campers 2023

USER MANUAL

Page | 1

Table of contents

Store Locator.................................................... 2

Re-sellers and suppliers .................................. 3

Rising Sun Townsville –Re-seller ............... 3

Precision Motors Armidale –Re-seller ....... 3

Redarc........................................................... 3

Projecta......................................................... 3

Truma hot water systems ........................... 3

Country Comfort hot water systems.......... 3

Dometic Air Conditioners............................ 3

Cruisemaster ................................................ 3

Ark ................................................................. 3

General Safety Introduction............................ 4

Weight Explanations........................................ 5

Load Distribution ............................................. 6

Specifications................................................... 7

Electrical System.............................................. 8

Batteries........................................................ 8

Solar.............................................................. 8

Water system.................................................... 9

Water Pump.................................................. 9

Braking Systems............................................. 10

Electric Brakes............................................ 10

Trailer Plug Wiring ..................................... 10

Anderson Plug............................................ 10

Handbrake...................................................11

Regular Checks............................................... 12

Setting up campsite....................................... 13

Stabiliser Leg.............................................. 13

Jockey wheel.............................................. 13

Camper & Canvas Care .................................. 14

Seasoning the canvas................................ 14

Setting up the tent..................................... 14

Closing the camper.................................... 14

Wet weather camping ................................14

Gas System ......................................................15

External Kitchen..............................................16

Care Advice......................................................17

Troubleshooting .............................................18

Warranty T&C’s............................................... 20

Maintenance schedule .................................. 27

Quick Links ..................................................... 28

Austrack Academy ..................................... 28

Spare parts request form.......................... 28

Austrack Campers Blog............................. 28

Page | 2

Store Locator

Head Office

07 5498 3888

Scan for Map

Caboolture Showroom

73 Lear Jet Drive Caboolture, QLD 4510

07 5408 7111

caboolture@austrackcampers.com.au

Rocklea Showroom

7 Collinsvale Street Rocklea, QLD 4106

07 3112 7868

rocklea@austrackcampers.com.au

Newcastle Showroom

4/2364 Pacific Highway Heatherbrae, NSW 2324

02 4006 6833

newcastle@austrackcampers.com.au

Melbourne Showroom

1644 Hume Highway Campbellfield, VIC 3061

03 9357 5081

Melb@austrackcampers.com.au

Perth Showroom

634 Casella Place Kewdale, WA 6105

08 6252 7007

perth@austrackcampers.com.au

Adelaide Showroom

113-119 Morphett Road Camden Park, SA 5038

08 7009 1018

adelaide@austrackcampers.com.au

Page | 3

Re-sellers and suppliers

Rising Sun Townsville –Re-seller

35 Bowen Road Rosslea, QLD 4812

07 4779 0211

Precision Motors Armidale –Re-seller

101/107 Barney Street Armidale, NSW

02 36772 5866

Redarc

www.redarc.com.au

Technical support 1300 733 272

Projecta

www.projecta.com.au

Technical support 1800 422 422

Truma hot water systems

https://www.leisure-tec.com.au/services/

Technical support 1300 072 018

Country Comfort hot water systems

https://countrycomfortwaterheater.com.au/

Technical support 0438 242 813 or 0412 111 656

Dometic Air Conditioners

https://www.dometic.com/en-au/support/service-locator

Technical support 1800 21 21 21

Cruisemaster

https://cruisemaster.com.au/

Customer Service & Support 1300 35 45 65

Ark

https://www.arkcorp.com.au/

Customer Service & Support 02 9678 9036

Page | 4

General Safety Introduction

WARNING–Before using this product you should read this manual and

those manuals supplied by component manufacturers applicable to this

product.

This manual is supplied as a reference to required maintenance of your new Austrack Campers

Hybrid offroad camper.

Failure to use and maintain the product in accordance with what is outlined in thismanual may affect

your warranty.

Incorrect and/or insufficient maintenance may cause product failure resulting in property loss,

damage or injury or death.

Maintenance intervals are critical for normal use; extreme use may require shorter or additional

maintenance intervals. See Maintenance Schedule for more details.

This manual content does not imply, express or other any warranty, the owner should read the

Warranty T&C’s included in this manual.

Before using this product, you need to be certain that your tow vehicle is suitably rated and equipped

to tow the product safely and legally.

The trailer and vehicle pairing must we within the safe “Maximum Towing Capacity”, “Ball Weight

Capacity” and “Gross Combination Mass” as stated by the vehicle manufacturer.

This Hybrid camper is fitted with electric brakes and a “Breakaway System”. Requirements for

breakaway systems can vary from state to state. The breakaway battery draws its charge from the

house battery system of the Tanami. See Braking Systems section for more details.

Austrack Campers reserves the right to modify an advertised component (e.g., air conditioning unit,

stove, inverter) with an item of similar value and quality, due to supply and availability. In order to

fulfill orders, all Austrack Campers are subject to change at Austrack's discretion.

Page | 5

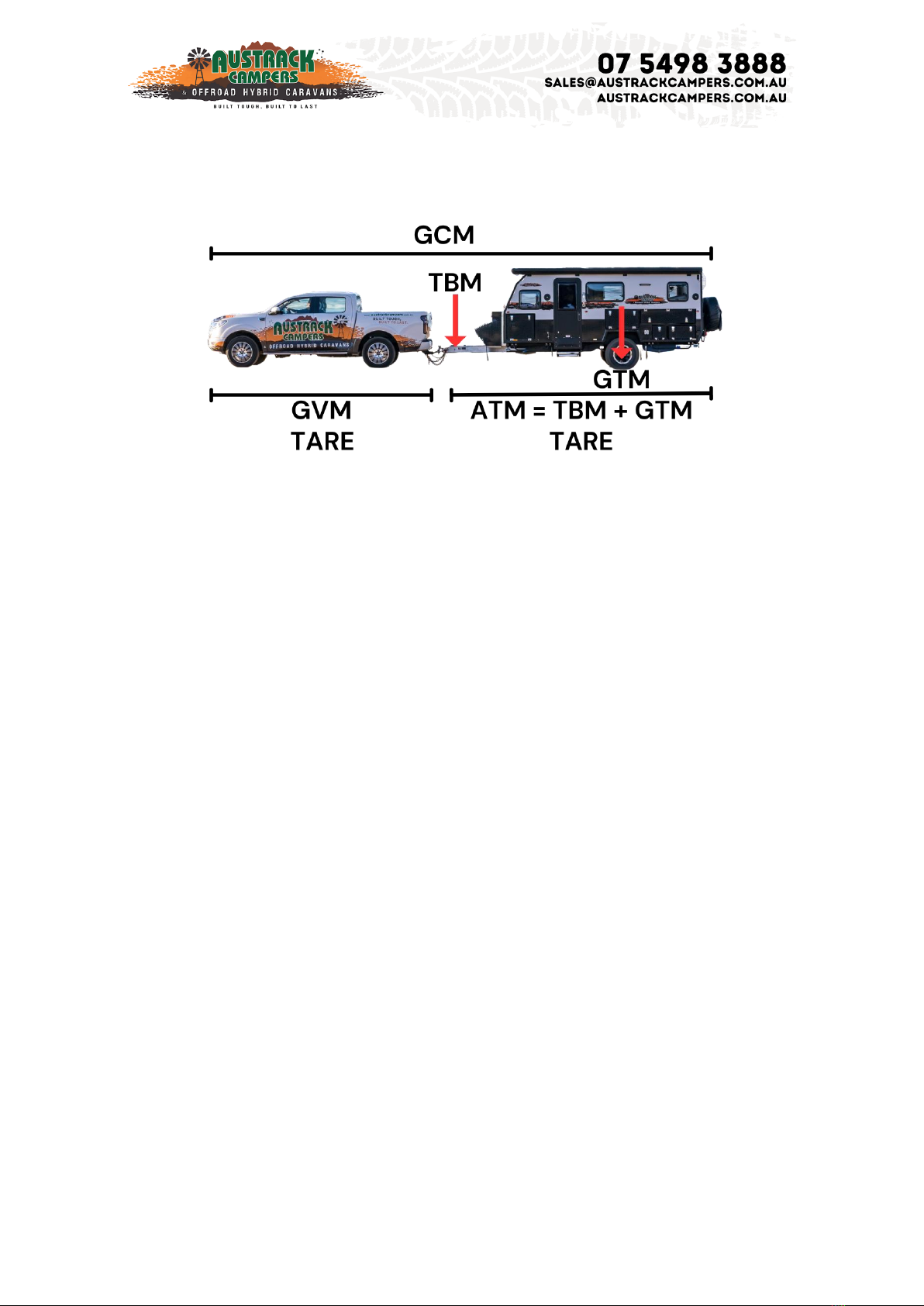

Weight Explanations

GCM Gross Combination Mass. The weight of your fully loaded vehicle and fully loaded trailer when

hitched together.

GVM Gross Vehicle Mass. This is the weight of your fully loaded vehicle.

TARE The weight of the vehicle or trailer without water, fuel or any cargo.

ATM Aggregate Trailer Mass. The maximum your trailer can weigh fully loaded.

GTM Gross Trailer Mass. The maximum weight on the axle when fully loaded.

TBM Tow Ball Mass. The weight exerted on the vehicle when hitched. This weight transfers to your

vehicle when hitched and becomes a part of the vehicles GVM.

GCM = ATM + GVM

ATM = TBM + GTM

Payload = ATM –TARE

Your Vehicle’s towing capacity is the maximum weight your vehicle can legally and safely pull when

towing, however it is also crucial to know theGross Combination Mass allowed by the towing vehicle.

State laws regulate all towing requirements, including speed limits. It's crucial to understand and

adhere to towing capacity limits for several reasons.

Exceeding these limits is both dangerous and against the law. It also places undue stress on your

vehicle's brakes and components, leading to damage and wear. Furthermore, an overweight vehicle

usually isn't covered by insurance.

When it comes to towing your camper, one of the most critical factors to consider is the tow ball

weight. This often-overlooked aspect of towing can significantly impact your safety and the handling

of your camper on the road.

A general rule of thumb is that the tow ball weight should be around 9-11% of the loaded camper's

total weight. For example, if your loaded camper weighs 3,000 kg, your ideal tow ball weight should

be between 270 kg (9%) and 330 kg (11%).

Page | 6

Load Distribution

When heading away on your next big adventure it is important to load your camper correctly to

distribute weight evenly and achieve a suitable ball weight load and prevent loading in a manner

that can cause a caravan to sway and/or roll excessively left and right. The optimum ball weight on

a caravan is between 8% and 12% of the total camper weight.

WARNING: BALL LOADING (DOWNWARD LOAD ON TOW HITCH) MUST NOT EXCEED 350KG

OR THE MAXIMUM ALLOWABLE LOAD BY THE VEHICLE MANUFACTURER OR TOW BAR RATING,

WHICH EVER IS THE LOWEST.

Exceeding these limits may result in an accident, causing property damage and/or serious injury or

death.

• Always load both sides of the camper evenly

• Load heavy items low and directly over the axle.

• Secure all items to prevent damage to the camper during travel.

• Consider water tank levels and how they may affect the balance front and back and the percentage

of ball weight.

• Heavy cooking equipment should be stored in lower cupboards.

• Tinned and bottled food for cooking etc. should be stored in the pantry drawer.

• Never load in a manner that causes the ball weight to exceed the limit of the tow vehicle.

Page | 7

Specifications

Finish • Baked enamel metallic finish with polished aluminium trim.

Construction • Zincanneal steel with underbody deadener protected chassis & drawbar. Fully Welded

hot dipped galvanised full RHS box drawbar and chassis 100 x 50 x 4.0mm Hitch • McHitch 3.5T Full

Off-road Coupling. ADR approved rated safety chains.

Brakes • 6 stud hubs, heavy duty parallel bearings and 12 inch heavy duty electric brakes with

mechanical handbrake.

Suspension • Heavy Duty Independent Coil Spring Suspension with Double Shock Absorber per

independent Coil Arm.

Jockey Wheel • Ark XO 500 Series extra heavy duty swing away dual wheel jockey wheel.

Electrical Connection • 7 pin round or 7 pin flat trailer plug, to suit your vehicle & 50amp Anderson

Plug wired to batteries.

Electrical System • 2 x 100ah lithium batteries with 12v accessory & USB sockets. Projecta 12V 25A

battery charger. Digital display voltmeter, ampmeter. LED brake and indicator lights, LED number

plate & clearance lights, reflectors. Water level gauges.

Stone Guard • Modern aluminium checkerplate stone guard with embossed mud flaps.

Gas & Fuel • 1 x 9 kg gas bottle holder. Space for 2 x 20L Jerry cans.

Storage • Multiple storage compartments with slide out drawers, fridge slide (1100 x 490 x 550mm).

Gas Lines • Fully plumbed gas and gas complied.

Wheels & Tyres • 3 x Brand new alloy wheels with chrome wheel nuts & 3 x Brand new tyres 265/75

16. Front mounted spare wheel. Heavy duty drop down stabiliser legs & winder. Fire extinguisher.

Water Storage • 100L Foodgrade stainless steel water tank with aluminium tank guard & 12v pump

plumbed to kitchen.

Kitchen • Slide out stainless steel kitchen with drawers, electric pump, tap, large sink & AGA approved

multi burner stove.

Dimensions: 1000(w)x400(d)x300(h) (mm).

Measurements • 4100x1800x2200mm

Tare weight (incl tent) • Approx. 850 kg

Registered • 1480 kg trailer

Ball Weight • Approx. 110 kg

VIN plate • all ready for registration

Page | 8

Electrical System

Batteries

The Telegraph LT is fitted with 1 x 100 Ah Lithium Iron Phosphate Batteries. These batteries have an

integrated BMS to prevent accidental damage to the batteries. Included is an activation cable, should

the battery become discharged at or below 10 V, connect the camper to a power source and press

the button on the activation cable to awaken the battery.

Solar

The Telegraph LT comes with a 200 A free standing solar panel. This is designed to plug into the

Anderson plug on the drawbar. It has a built-in solar regulator and is plug and play.

There is a circuit breaker for the Anderson connection in the rear cupboard, above the water tank

change over valve. If the solar panel does not recognise or charge the batteries, check this breaker

to ensure that it has not tripped.

Page | 9

Water system

The Telegraph LT is fitted with 1 x 100 L Foodgrade poly water tank with stainless steel tank guard.

The tank has a bung and tap on the bottom of the tank for easy draining and rinsing.

The water tank filler is closer to the rear of the trailer. The filler is equipped with a breatherhole which

will allow the air to escape the tank while the water is going in. If this hole is blocked, water will not

be able to enter the tank. The tank is full when water comes out of the breather hole.

The camper does not have a grey water tank fitted, please follow all instructions from Caravan Park

management/National Parks officers regarding the management of grey water.

Water Pump

The water pump will need to be switched on using the push button on the control panel. It may make

a noise when initially turned on with all taps closed to pressurise the system, but this should shut off

quickly. If the pump continues to run with all taps closed, this can indicate a leak and requires

investigation and rectification.

The water pump will automatically turn on when a tap is opened and will shut off shortly after the

tap is closed. It may turn on and off quickly a few times to fully pressurise the system, this is totally

normal.

If the water pump is cycling on and off and the system has been thoroughly inspected for leaks with

nothing found, please contact the service department for more instructions.

Page | 10

Braking Systems

Electric Brakes

The Telegraph LT comes fitted with electric brakes which require a brake controller installed into

the towing vehicle that can be controlled from the driver’s seat. There are many systems available

which can either be permanently installed into the tow vehicle or Bluetooth units that are mounted

to the trailer and have a remote to control from the driver’s position. You must have a brake

controller installed in the vehicle or a Bluetooth unit on the day of handover otherwise the camper

will not be released to you.

Electric trailer brakes are designed to assist your vehicle brakes to stop in a safe and effective

manner. It is important that both your vehicle and the trailer are serviced regularly. The trailer

brakes will have a run-in period that will vary trailer to trailer, but it is important to have the trailer

brakes inspected and adjusted by a qualified professional in line with the maintenance schedule.

During your regular services, a qualified professional will complete a visual inspection of the brake

shoes to determine if they require replacement. Replacement will be necessary when the lining is

worn down to approx 1.5mm, or abnormally scored or gouged.

Scouring and gouging of the brake shoe lining is generally due to overheating of the brake system or

dirt caught in between the shoe and the hub. It is important to ensure that the brakes are adjusted

correctly and cleaned thoroughly after each trip, especially if there were water crossings involved.

Trailer Plug Wiring

The Telegraph LT comes fitted standard with a 7-pin flat trailer plug.

If a different plug configuration has been requested, please reach out to your local showroom or

the service department to obtain a copy of the wiring diagram.

Anderson Plug

The Telegraph LT is fitted with an Anderson connection at the drawbar. This is wired directly to the

batteries through a circuit breaker inside the water tank change over compartment. This is designed

to run all regulated sources of charging to the batteries and can also be utilised as a power output if

required.

To adequately charge from your vehicle, you will need to have a DC-DC charger installed into your

vehicle. Without this, you will receive some charge, but it will rarely be enough to charge the batteries

to capacity.

Page | 11

Handbrake

The handbrake is operated mechanically by means of a cable. The cable attaches to the backing

plate and when the handbrake is applied the cable creates a force on the primary and secondary

brake shoe. This causes them to spread until they make contact with the brake drum surface.

The cable adjuster needs to provide enough tension that the handbrake is 1/3 raised when the

camper is unloaded. Once the camper is loaded, test and adjust if necessary. Insufficiently adjusted

handbrake will still allow the camper to move when the handbrake is fully raised.

It is very important to always use wheel chocks and levelling ramps, do not rely solely on the

handbrake even if on a level surface.

To adjust the handbrake, there is an adjuster attached to the cable at the drawbar. To tighten the

handbrake, loosen off the nut and turn the adjuster wheel in a clockwise direction. Ensure that the

nut is re-tightened after the adjustment. Overtightened handbrakes can cause the brake shoes to

drag on the inside of the drum, causing permanent damage.

Page | 12

Regular Checks

Wheel Nuts

Wheel nuts should be checked on a regular basis usings a torque wrench and tightened to 140 Nm.

It is not recommended to use a rattle gun, as there is no way to know how tight the nuts are.

Overtightening will damage the studs and will cause them to fail prematurely. Under tight wheel

nuts will cause vibration of the wheel and will eventually cause the studs or nuts to fail.

Initially, you will need to check the wheel nuts at 50kms, 100kms, 250 kms and 500kms, and then

regularly after that. during travel on especially bumpy or corrugated roads, the wheel nuts will

need to be checked more often.

Hitch

The bolts securing the hitch to the trailer are a high tensile bolt and should be tightened to 180 Nm.

These bolts should be checked with a torque wrench every 2500 –5000kms, depending on the

road conditions.

Suspension bolts

The suspension bolts should be visually inspected daily to make sure they have not moved. They

should otherwise be serviced as per the maintenance schedule. These bolts should be tightened to

180 Nm.

Page | 13

Setting up campsite

Picking a spot that is relatively level, gets sun during the day and is not under any large tree’s,

especially Gum trees, is important.

If you are free camping, do not set up too close to a river or in an area that is prone to flash flooding.

Stabiliser Leg

Levelling ramps will need to be used if excessive side to side levelling is required. Front to back

levelling is done using the jockey wheel. Once the camper is level, drop down the stabiliser legs.

These are only designed to be used for reducing the movement in the camper when set up, these are

not to be used for levelling.

Using a drill or any power tool to adjust the height of the stabiliser leg will damage the internal

components of the leg and will void the warranty.

Jockey wheel

The camper is supplied with the Ark XO500 jockey wheel. This jockey wheel not only winds up and

down, but it also has adjustments available in the outer shaft, so no matter what vehicle or ground

level you are setting up on, you can safely adjust the jockey wheel.

The handle is removable, keep this somewhere inside your camper or vehicle when travelling.

Check out the video from Ark to properly use your jockey wheel -

https://www.youtube.com/watch?v=Ibe7zrAs0nc

It is important however, to never move the camper when the jockey wheel is extended past

the safe moving line on the extension shaft. The safe working load limit reduces past this line, and it

may cause the jockey wheel to bend or break under the load.

Page | 14

Camper & Canvas Care

Seasoning the canvas

The camper trailer canvas is pre-seasoned; however, this is before the camper has been assembled

and sewn together. This means that before you take the camper out for the first time, it will need to

be seasoned to avoid any leaks.

To season the camper, you need to set it up fully, with all windows and door canvas zipped closed.

Hose off the camper, ensuring that the canvas is fully soaked. Let it dry completely and repeat this

process approx. 3-5 times. Ensure to season the annex as well as the main tent. If you continue to

experience water seeping through the seams, you can apply a wax stick to the seams once the canvas

has fully dried.

Setting up the tent

When setting up the canvas tent is important to not overtighten using the poles. When adjusting the

tent, it should be taut but not tight. If you can see exposed stitching in the seams, it is too tight. There

may be rippling of the canvas tent when fully set up, this is a nature of the canvas. Forcing the poles

out to remove the rippling will cause leaking and will overstretch the canvas and this is irreparable.

When packing away the camper, it is important to ensure that the mesh screen windows are fully

zipped up, and the canvas coverings on the inside and outside are closed over the top to avoid any

accidental damage. Mesh screen damage is considered to be misuse and as such is not covered

under warranty.

Closing the camper

When closing the camper it is important to make sure that the door is closed and locked using the

key to ensure a good compression seal to reduce water and dust ingress.

It is also important to ensure that there is no material sitting between the camper edge and the

compression seal on the lid. If there isanything between,this will causewater and dust ingress inside

the camper.

Always ensure that the cushions are laid flat inside the camper and that if there is more resistance

than normal when closing the camper, not to force it closed. Always check to see the reason for the

resistance, generally this will either be too much height on the cushions or a pole has not be retracted

fully. If the camper is forced closed and poles are bent, this is considered to be misuse and is not

covered under warranty.

Wet weather camping

During periods of wet or windy weather, you will need to reduce the height of the end poles inside

the main camper to give the tent more pitch and also to drop the corners of the annex to give the

water somewhere to run off. Pooling water is extremely heavy and will stretch the canvas and if left

for long enough, bend/break the poles.

This damage is considered to be storm damage and is not covered under warranty.

Page | 15

Gas System

The Telegraph LT is fitted with plumbed gas, with the gas cylinder holders mounted inside the front

stone guard. The gas hose has the LCC27 connection and requires the matching gas cylinder to be

able to use the system. The regulator has a one-way valve on top to allow for easy switching of the

gas cylinders. The valve must be pointing in the direction of the gas cylinder being used for the gas

to flow through the system. You cannot draw from both gas cylinders at the same time.

Once the gas cylinders are connected, you can connect the external 3 burner stove top to the

mounted bayonet fitting using the attached hose. Once the stove top is connected, turn on the gas

cylinder. The control knob for the stove top needs to be turned to the high position and held in whilst

pressing the ignition switch. It can take up to 2 mins for the gas to flow to the burner from the gas

cylinders. Once the burner has lit, continue holding the control knob down for a further 5 secs to

ensure it stays lit.

When travelling the gas supply MUST be turned off, and it is recommended to purge the lines of gas

before travel.

•Light the external kitchen gas burner

•Turn off the gas cylinder in the front storage box

•Allow the burner to go out

•Wait until the burner is touch cool before closing the kitchen

Page | 16

External Kitchen

Your Telegraph LT is equipped with a quality stainless steel kitchen complete with a Dometic 3

burner cooktop, sink and drying rack.

The kitchen is located at the front passenger side of the camper and can be accessed by opening the

access hatch, once the hatch is open you will see 2 blue handles, one on each side, press down and

gently slide the kitchen out.

Do not pour boiling water down the sink, the drain hose underneath is made of plastic, and it will

melt with boiling water.

Now it’s time to connect your gas to the burner, underneath of the kitchen you will see a section that

has been cut away, inside that recess is the gas line which is fitted with a gas bayonet. Extend the gas

line to the rear of your camper connect to the gas point. Remove the black cap from the gas fitting

and plug the gas bayonet in and if you haven’t already, turn on your gas cylinder.

To close the kitchen, follow these steps in reverse.

Always ensure that the gas cylinder is turned off prior to travel and that the burners are touch

cool before closing the glass lid.

Page | 17

Care Advice

External Paint

The external surface requires regular maintenance in the same way as your vehicle. Only use mild,

ammonia free detergents paired with a non-abrasive wash pad or sponge to wash the camper.

Only use wax-based polishes, do not use cutting compounds or abrasive pastes. These will leave

scratches and may expose the base material.

Corrosion Protection

Australia has some of the most beautiful areas to explore, but unfortunately these areas are also

the most harsh on your vehicle and trailer. Water crossings and beach driving are some of the

harshest areas that your trailer will be used and without proper maintenance, your trailer will

suffer. It is important that after any water crossing or beach driving that the trailer is thoroughly

cleaned, top to bottom, including a flush to the chassis.

After all uses of the trailer, it is important to complete a full clean, inside, and out to keep

everything at tip top condition.

Products like Lanotec, WD40 and Inox do a great job of protecting the metal surfaces of the trailer,

it is important to use these regularly on the fittings of the trailer.

Condensation/Mould

Condensation is a normal part of living in Australia, and this is highlighted when camping. The

temperature difference inside and outside a camper can be quite significant, and with the moisture

in the Australian air and the smaller living area of a camper, condensation can build up overnight.

While this can be quite disconcerting, it is totally normal. Ensure that there is sufficient air flow in

the camper to allow the moisture to escape overnight.

If you do encounter a build up of condensation in the camper, make sure to air this out in the

morning to avoid the moisture building up in the soft furnishings, especially mattresses.

It is recommended to place moisture absorbing tubs in the camper especially when it is in storage

and change these out on a regular basis to avoid mould growing.

Page | 18

Troubleshooting

Category

Issue

•Troubleshooting Steps

Electrical –

12 v

Not Charging from 240 V

•Check mains power is connected

•Check RCD not tripped on incoming power

supply

•Check RCD not tripped in camper

•Check charger is plugged into power point

next to batteries and turned on

•Make sure batteries are above 10 v

•Contact Service department or Projecta for

more advice

Electrical –

12 v

No power

•Check main 12V switch is turned on

•Make sure batteries are charged

•Check fuse box for any blown fuses

Electrical –

12 v

Power dropping too

quickly

•Ensure inverter is not left on all the time

•Ensure that breakaway pin is not removed

from switch on the drawbar

•If running off grid, make sure that appliances

and lights are not left on all the time.

•Make sure fridge is set to a temp so that the

compressor is not running all the time and

that the lids are not being opened all the

time/left open

Water

No water to taps

•Make sure water pump is on

•Make sure there is water in the tank selected

•Swap water tank used

•Let tap run for approx. 20 secs to clear the air

from the lines

Water

Water pump not turning

on

•Check “pump” switch is turned on

•Check fuse is not blown

Water

Water pump is running

nonstop

•Ensure water in the tank selected

•Check for air locks in the system by opening

all taps and purging the hot water system

•Check for any leaks in the system –especially

in cabinets and under the seat

•Contact service department for more advice

Page | 19

Gas

External cooker not lighting

•Make sure bayonet hose is connected to

the fitting on the rear of the camper

•Check gas hose is not kinked

•Make sure there is gas in the bottle

•Make sure the correct gas cylinder is

selected on the regulator

•Hold down button on cooktop to pull the

gas through the lines

Gas

No spark from cooktop

ignition

•Make sure power cable is plugged in for

the ignition

•Make sure 12 v power is turned on in the

control panel

Gas

Cooktop not staying lit

•Make sure there is enough gas in the

bottle

•Reduce wind by setting up windbreak

•Hold down the ignition button for 2 secs

after the flame starts

Fridge

Not switching on

•Make sure “fridge” switch is on

•Check fuse in fuse box

•Try a different lead

•Check fuse in cigarette socket end

Fridge

E1 error code

•Make sure fridge is set to VL

•Make sure battery voltage is above 12.0 v

•Use Anderson lead for fridge

For any further issues or troubleshooting, please call the Service & Warranty department.

Other manuals for TELEGRAPH LT

1

Table of contents

Other AUSTRACK CAMPERS Motorhome manuals