V-Series Dobby Loom User’s Manual Introductory Information

Table of Contents Page | i

Introductory Information.............................................................................................................1

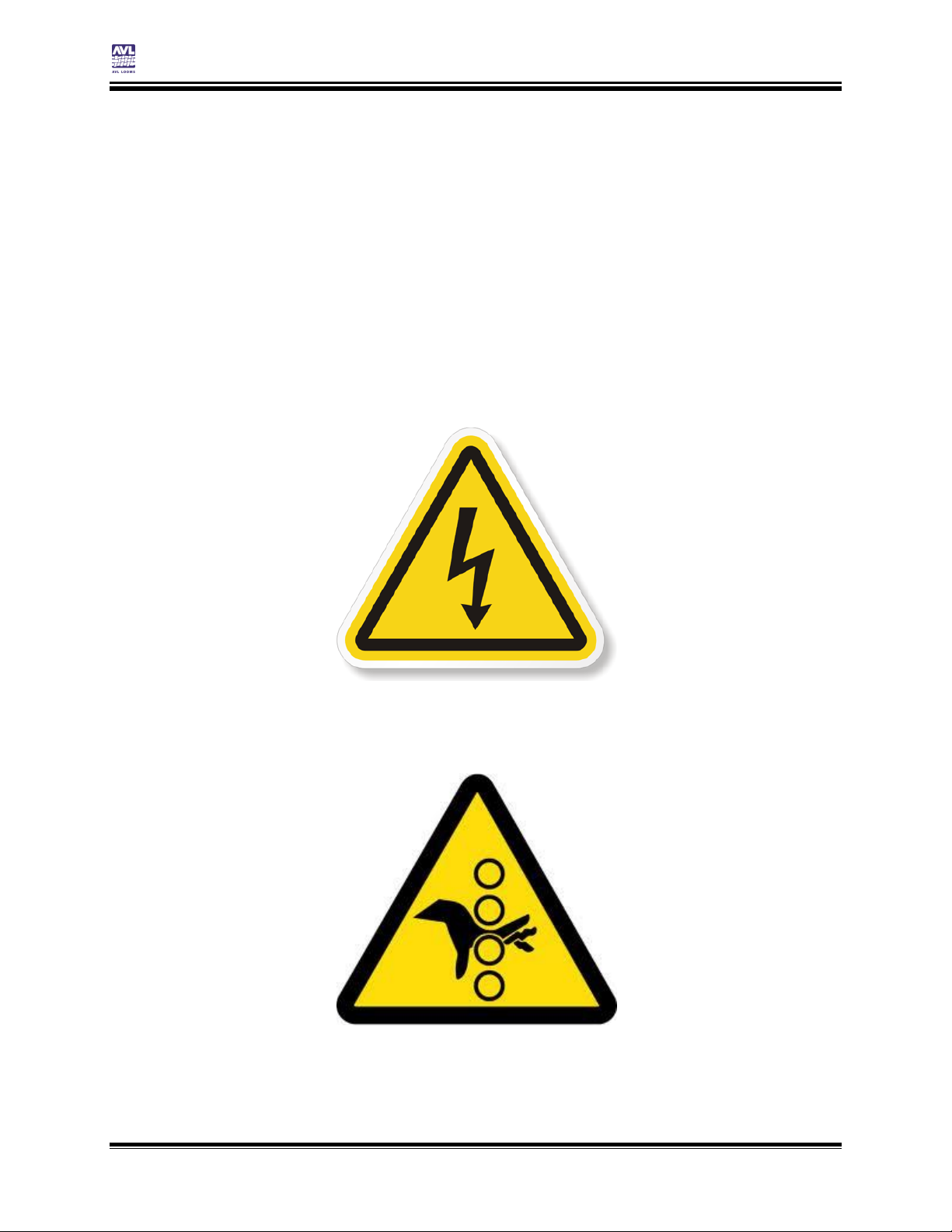

Safety......................................................................................................................................2

Introduction.............................................................................................................................4

Loom Features ........................................................................................................................5

Set Up.....................................................................................................................................7

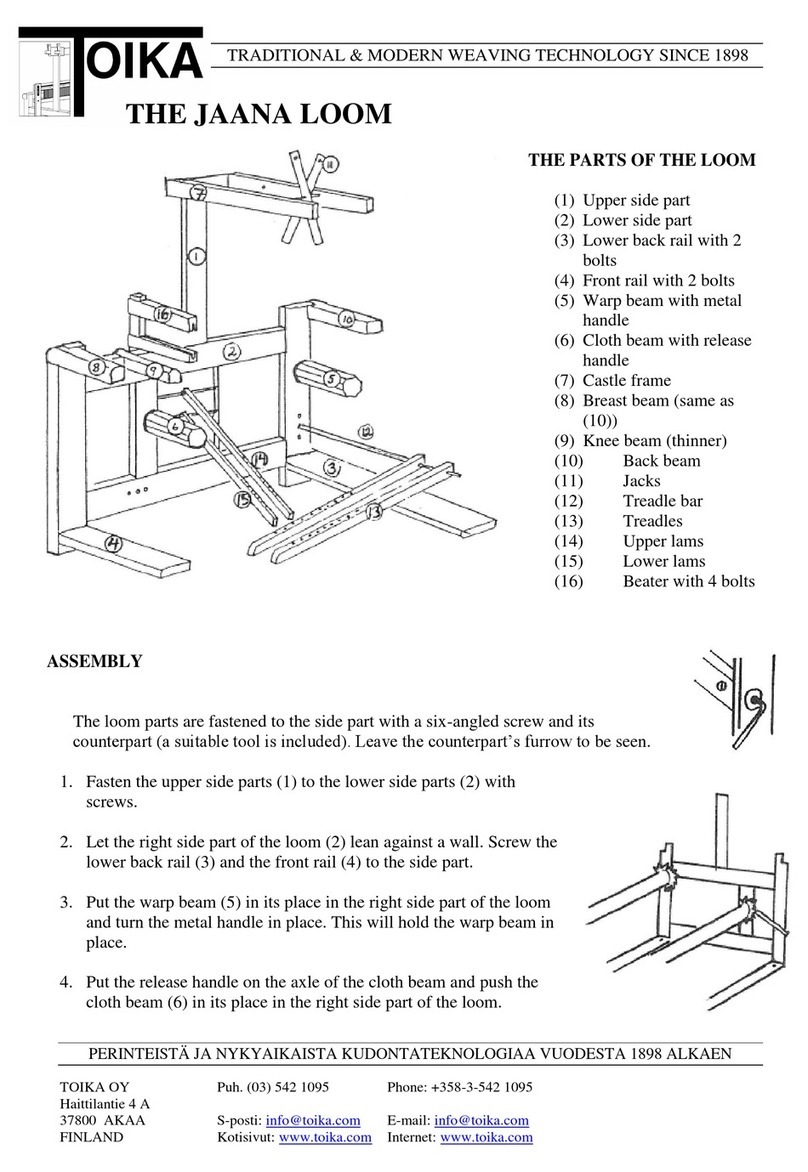

Loom Assembly........................................................................................................................11

Before You Begin .................................................................................................................12

Left And Right Side Frame Assembly ...................................................................................16

Connecting the Frames..........................................................................................................19

Install Harnesses ...................................................................................................................30

Install Beater.........................................................................................................................38

Installation Of The E-Lift II ..................................................................................................44

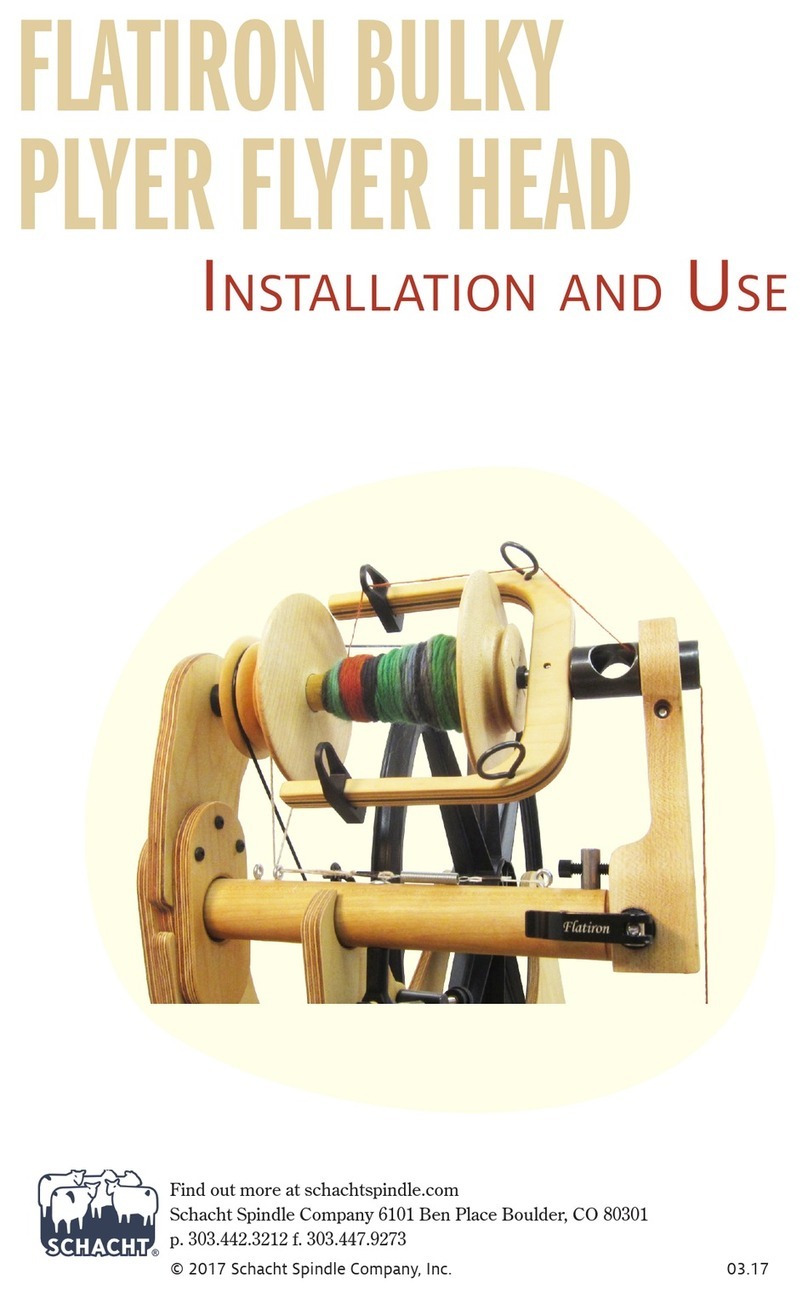

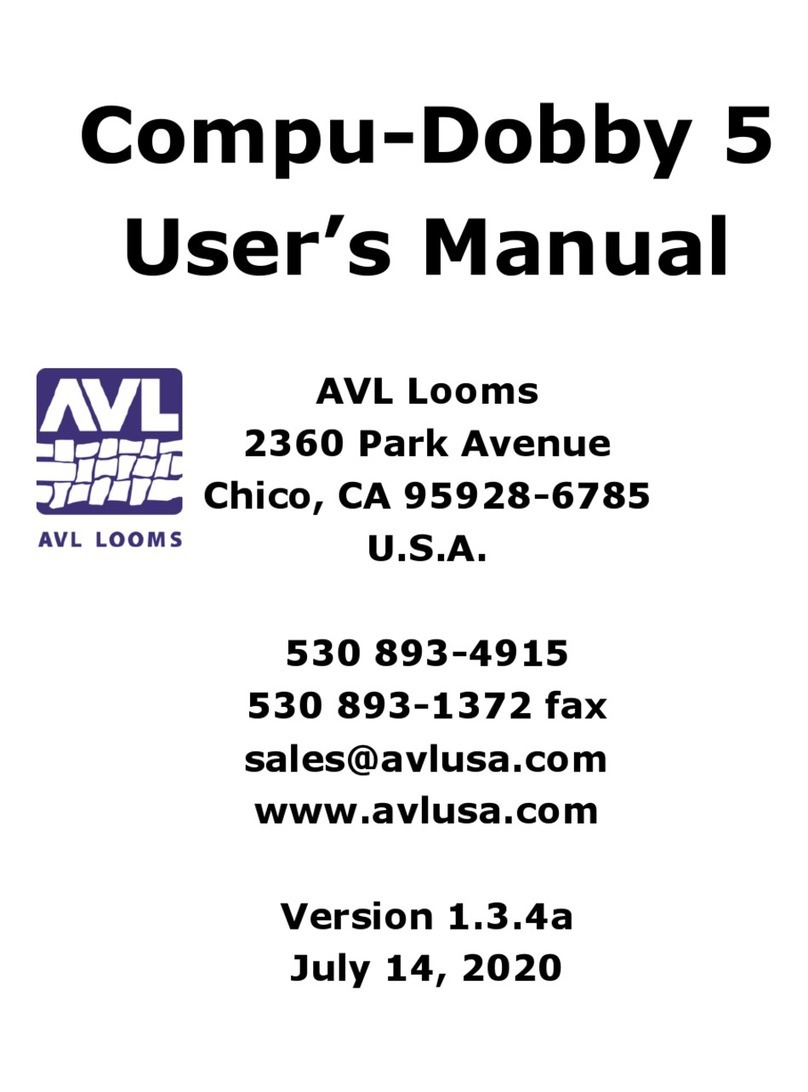

Installation Of The Compu-Dobby ........................................................................................52

Install The Warp Beam..........................................................................................................54

Install The Shelf....................................................................................................................62

Weaving Instructions ................................................................................................................63

Warping The Plain Beam ......................................................................................................64

Warping The Sectional Beam................................................................................................72

Combining Sectional And Plain Warping ..............................................................................87

Threading, Sleying, & Tying On ...........................................................................................88

Additional Loom Information....................................................................................................95

Loom Maintenance................................................................................................................96

Troubleshooting ....................................................................................................................98

The Fine Print .........................................................................................................................103

AVL Customer Service .......................................................................................................104

AVL Warranties..................................................................................................................104

Notice to Users in the European Union................................................................................105

TABLE OF CONTENTS