G01

SPD Owner’s Manual

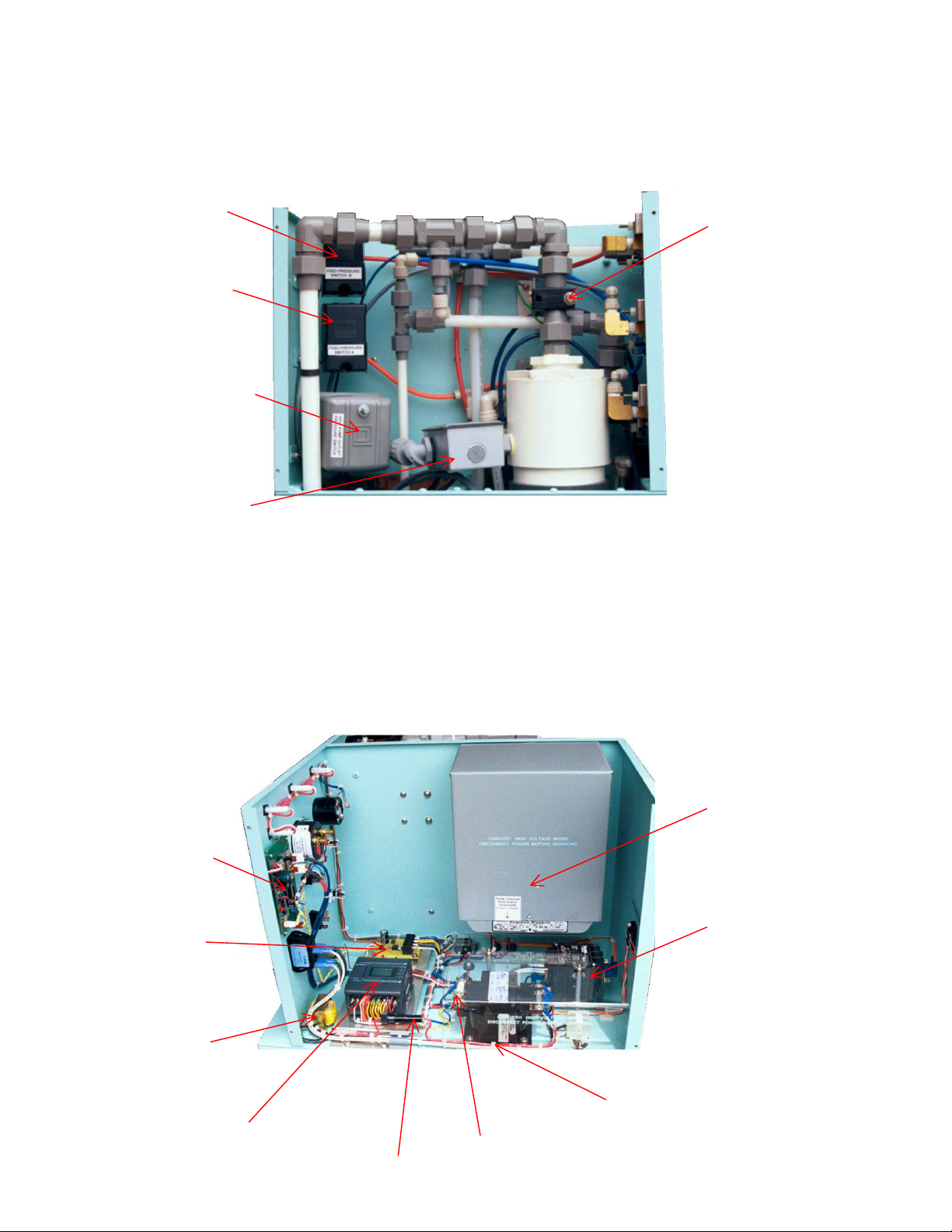

WATER FLOW IN SYSTEM

The operation of the system is best studied with the prefilter housings removed and the top cover off.

Refer to the attached water flow schematic, Figure 5.

Feed water enters the system through a 3/4" MPT bulkhead and passes the main shut off valve before

entering the prefilters. After the prefilters the water passes through the feed water solenoid valve and

then through the feed pressure regulating valve. Then it joins any product or reject recycle flows and

enters the bottom of the submerged pump. The pump inlet pressure is sensed at this point.

The high pressure water comes out the top of the pump, tees to the pump outlet pressure gauge, and

goes to the bottom side of the 1st module. The reject water from this module is the feed for the second

module. The reject water from the second module is the feed for the third module. The reject from the

third module passes through a strainer and then splits. A portion of the water passes through the short

1/4" OD tubing capillary, through a spring loaded check valve, and then goes to the drain standpipe.

Another portion passes through the pressure control valve and joins the pump inlet flow. When the

green flush valve is opened, the capillary is bypassed and drain flow increases. When the reject to tank

valve is opened, the reject water that would otherwise flow to drain is directed into the disinfection tank.

In disinfection mode, a portion of the high pressure reject water passes through the green handled

venturi supply valve to drive the venturi. The venturi lifts the water from the tank into the pump.

The product water from the two or three RO modules is manifolded together and sent through the

flowmeter, a check valve, and then exits the system. The product line also tees to drain through the

product dump solenoid valve and tees to the disinfection tank through both the fill tank solenoid valve

and the product to tank valve.

Unused product water from the distribution loop returns at a 3/4" MPT bulkhead, a check valve, and

product back pressure regulator(s). Discharge from the regulator(s) goes back into the pump inlet

manifold. If two or more SPD units are in parallel, a product return solenoid valve is also in line. This

valve opens whenever the submerged pump runs.

Each RO module has a tap to the annulus volume just below the chevron brine seal. ¼” tubing from

these taps lead to check valves the outlet of which are manifolded and connected to a SS annulus drain

valve. Opening this valve during rinsing positively drains this otherwise dead space.