barfield SC 063 Operator's manual

Copyright © 2022. Barfield Inc. All Rights Reserved

SC063

Sight Compass

USER INSTRUCTION MANUAL

M/N: SC063, P/N: 101-01200

Doc. P/N: 56-101-01200

Revision G

November 9, 2022

__________________________________________

SC063 is designed to be used as

Ground Support Test Equipment.

Not for aircraft installation.

56-101-01200 Revision G Page ii

Corporate Headquarters

4101 Northwest 29thStreet

Miami, Florida 33142

www.barfieldinc.com

Email: [email protected]

Barfield Inc. Confidential and Proprietary Information.

This document and all the information contained herein is the sole property of Barfield Inc.

No intellectual property rights are granted by the delivery of this document or the disclosure of its content.

This entire document is proprietary information and shall not be reproduced or disclosed to a third party

without the express written consent of Barfield Inc.

This document and its content shall not be used for any purpose other than that for which it is supplied.

56-101-01200 Revision G Page iii

CONTACT INFORMATION

Users are requested to notify the manufacturer of any discrepancy, omission, or error found in this

manual. Inquiries should include specific questions and reference the publication title, number, chapter,

page, figure, paragraph, and effective date.

Please send comments to:

TECHNICAL CUSTOMER SUPPORT - GSTE

BARFIELD, INC.

P.O. BOX 025367

MIAMI, FL 33102-5367

USA

Telephone (305) 894-5400

(800) 321-1039

Fax (305) 894-5401

Email gsesales@barfieldinc.com

56-101-01200 Revision G Page iv

MAINTENANCE AND REPAIR INFORMATION

The manufacturer of this equipment does not recommend the user to attempt any maintenance or repair.

In case of malfunction, contact the manufacturer to obtain the list of approved repair facilities worldwide,

ensuring that this equipment will be serviced using proper procedures and certified instruments.

BARFIELD PRODUCT SUPPORT DIVISION

Telephone (305) 894-5400

(800) 321-1039

Fax (305) 894-5401

Email gsesales@barfieldinc.com

Shipping Address:

Barfield, Inc.

4101 NW 29th Street

Miami, Florida 33142

USA

Mailing Address:

Barfield, Inc.

P.O. Box 025367

Miami, FL 33102-5367

USA

56-101-01200 Revision G Page v

REVISION RECORD

REV.

ECO #

REV. DATE

DESCRIPTION OF CHANGE

A

N/A

January 1983

Initial Release.

B

260-00680

October 5, 2006

Page number sequence was changed.

C

260-00702

July 16, 2007

List of Approved Repair Facilities was

updated. Description Section was modified

to reflect current accessories package

(short handle is no longer provided)

D

260-00782

September 9, 2010

Non-applicable sections were removed.

Disclaimer and Recertification paragraphs

were added.

E

260-01057

November 7, 2014

Barfield logo updated.

F

260-01269

June 26, 2020

Updated formatting; Minor grammar

revisions; Addition to Title Page and TOC –

List of Tables; Addition of Publication

Background and Specifications; corrected

color identified in Chapter 1, 1(E) from red

to orange.

G

260-01391

November 9, 2022

Revision of Introduction and Chapter 1.

Addition of Figures 5 & 6, Table 1, and

Chapter 2: Installation.

56-101-01200 Revision G Page vi

TABLE OF CONTENTS

Contact Information

Maintenance and Repair Information

Revision Record

Table of Contents

List of Figures

List of Tables

PAGE

INTRODUCTION................................................................................................................................... 1

1. PUBLICATION BREAKDOWN....................................................................................................1

2. INFORMATION PROVIDED WITH THE UNIT ............................................................................ 1

3. RECERTIFICATION.................................................................................................................... 2

4. DISCLAIMER.............................................................................................................................. 3

CHAPTER 1: GENERAL....................................................................................................................... 5

1. INTENDED USE ......................................................................................................................... 5

2. SPECIFICATIONS...................................................................................................................... 6

3. BACKGROUND INFORMATION................................................................................................. 6

CHAPTER 2: INSTALLATION.............................................................................................................. 8

1. ASSEMBLY................................................................................................................................. 8

CHAPTER 3: OPERATION................................................................................................................... 9

1. ESTABLISHING A PERMANENT REFERENCE POINT............................................................. 9

2. TESTING SIGHT SUITABILITY .................................................................................................. 9

3. VERIFYING EXISTING SWINGING BASE................................................................................ 10

4. DETERMINING MAGNETIC HEADING OF AN AIRCRAFT...................................................... 10

5. PRECOMPENSATION AND PRESWING INSTRUCTIONS...................................................... 10

6. COMPASS COMPENSATION PROCEDURE........................................................................... 11

7. COMPASS SWINGING PROCEDURE ..................................................................................... 12

CHAPTER 4: CARE PROCEDURES .................................................................................................. 14

1. HANDLING ............................................................................................................................... 14

2. STORAGE ................................................................................................................................ 14

CHAPTER 5: RECEIVING & SHIPPING ............................................................................................. 15

1. RECEIVING.............................................................................................................................. 15

2. SHIPPING................................................................................................................................. 15

56-101-01200 Revision G Page vii

LIST OF FIGURES

PAGE

Figure 1 Identification Label.................................................................................................................1

Figure 2 Owner Warranty Registration Card ........................................................................................2

Figure 3 Limited One Year Warranty....................................................................................................4

Figure 4 Sight Compass....................................................................................................................... 5

Figure 5 Container / Shipping Case, P/N 194-00078............................................................................ 8

LIST OF TABLES

PAGE

Table 1 Physical Characteristics...........................................................................................................6

Table 2 Compass Worksheet ............................................................................................................. 13

Table 3 Example of Completed Compass Correction Worksheet ....................................................... 13

56-101-01200 Revision F Page 1

INTRODUCTION

1. PUBLICATION BREAKDOWN

This user instruction manual establishes the standards of operation for the Sight Compass, M/N

SC063, P/N 101-01200.

Its purpose is to provide sufficient information for the personnel unfamiliar with this unit to operate it

in accordance with proper procedures, operating techniques, precautions, and limitations.

Note: The manufacturer has designed this equipment to be safe when operated using the

procedures and instructions detailed in this manual. Do not use this equipment for any

other purpose than that stated, as the protection provided by the equipment may be

impaired.

2. INFORMATION PROVIDED WITH THE UNIT

In addition to this User Instruction Manual, the Sight Compass is delivered with the items described

below.

A. The identification label (similar to Figure 1) attached to the instrument, provides the following

information:

Manufacturer Name

Designation of Equipment

Equipment Part Number

Equipment Model Number Equipment Serial Number

Figure 1 Identification Label

SIGHT COMPASS

101-01200

SC063

####

56-101-01200 Revision G Page 2

B. A laminated instruction sheet card, with a summary of the most frequently used operating

instructions indicated in this manual. This card is not intended to be a substitute of this manual;

it is provided as a quick reference card that can be conveniently carried to the location where

the procedures involving the aircraft will be performed.

C. The Owner’s Warranty Registration card (refer to Figure 2) is to be completed by the owner and

returned to Barfield, Inc. within ten (10) days of purchase to ensure automatic update of printed

matter and validation of warranty.

To register your unit, please visit https://www.barfieldinc.com/warranty_registration or scan the

QR code on the supplied Warranty Registration.

Figure 2 Owner Warranty Registration Card

D. Each new or re-certified unit is delivered with a Certificate (not pictured) that shows the date

when the unit was tested by the manufacturer, its serial number and when the next certification

is due. This certificate confirms that the unit performed according to its design specifications.

E. The Limited Warranty Statement (refer to Figure 3) lists the manufacturer’s obligation to the

original purchaser.

3. RECERTIFICATION

The Barfield Sight Compass, M/N SC063, P/N 101-01200, has a one-year recertification

requirement. Maintenance required by this unit must be performed by qualified technicians in a

shop equipped with the necessary tooling and facilities. Contact Barfield for Maintenance and

Calibration requirements.

56-101-01200 Revision G Page 3

4. DISCLAIMER

BARFIELD, INC., neither a vendor nor supplier of airworthy compasses or an airframe

manufacturer, has control over aircraft calibration and certification procedures. The information

provided in this Instruction Manual is presented as reference only, and therefore the compass

manufacturer calibration procedures and aircraft maintenance manual shall take precedence over

this Manual. However, the information presented is correct to the best of our knowledge at the time

of publication.

56-101-01200 Revision G Page 4

Figure 3 Limited One Year Warranty

56-101-01200 Revision G Page 5

CHAPTER 1: GENERAL

1. INTENDED USE

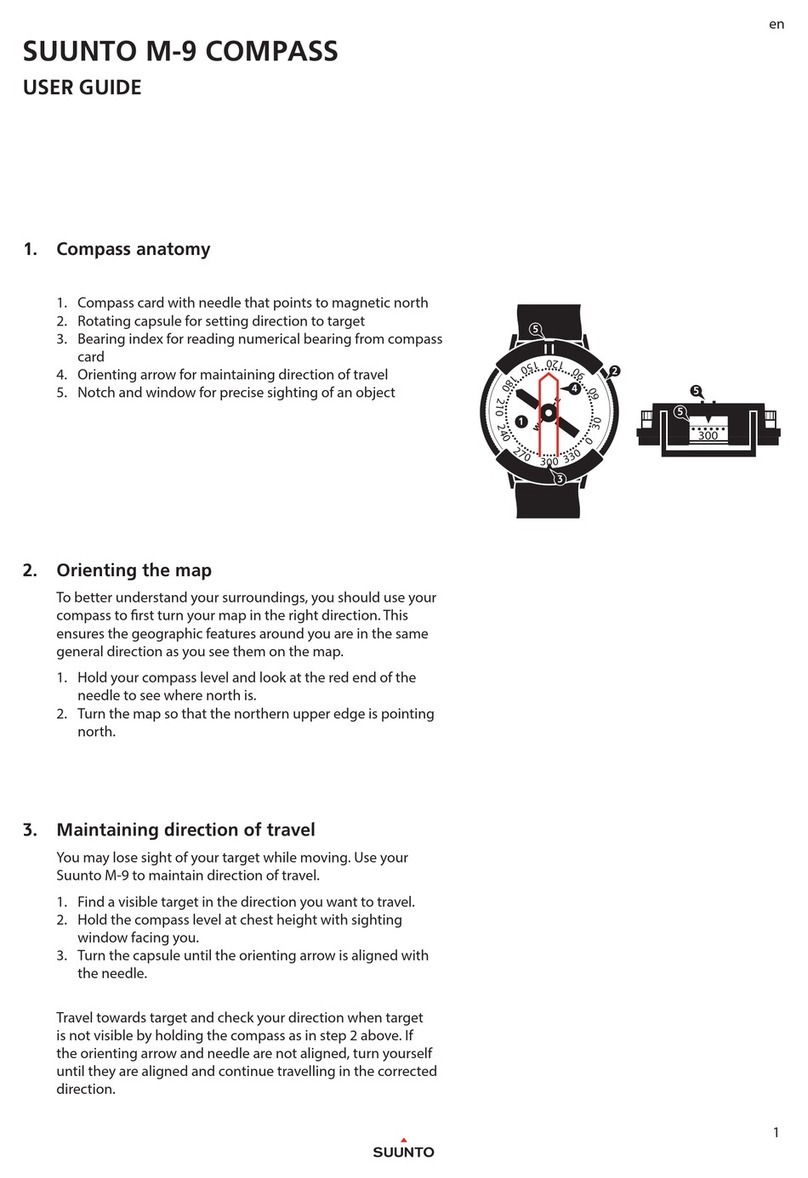

A. The BARFIELD INC. SC063 Sight Compass (P/N 101-01200) is a modified version of a

standby Aircraft Compass that had its compensating assembly removed and collimator sight

attached (refer to Figure 4). It can be used for determining the magnetic suitability of a Compass

swinging area, checking and laying out Compass swinging bases, and determining the magnetic

heading of an aircraft.

Note: Since the Sight Compass is used extensively when a prepared base is not available,

operating personnel should be familiar with its three uses and method of checking its

accuracy.

B. Modified features include:

1. Reversed magnetic polarity, which permit the operator of the Sight Compass to view the

aircraft being checked from the front. This makes communications (hand signals) between

the aircraft occupant and the Sight Compass operator convenient.

2. Attached to the front of the Sight Compass is a combination magnifying lens (to increase the

readability of the dial) and a collimating lens (to ensure precise sighting alignment).

3. Attached to the rear of the Compass is an adjustable Sight Lens. The lens is precisely

aligned to ensure that the overall accuracy of the dial falls within ± 1°.

4. The Compass is mounted on a bracket, which can be attached to a monopod assembly

(supplied with the Sight Compass).

5. The Sight Compass is painted orange and has a caution label attached to it to prevent

inadvertent installation in an aircraft.

6. The SC063 Sight Compass is packaged in a protective carrying case.

Figure 4 Sight Compass

56-101-01200 Revision G Page 6

2. SPECIFICATIONS

A. Physical Data

Size (H, W, L)

3.34 in. (8.5 cm), 2.36 (6 cm), 2.75 in. (7 cm)

Weight

0.72 lbs. (0.325 kg)

Table 1 Physical Characteristics

B. Scale

The Sight Compass is marked with letters representing the cardinal directions, North (N), East

(E), South (S), and West (W), and a number for each 30 degrees between these letters. For

example, 3 = 30°, 6 = 60°, and 33 = 330°.

There are long and short graduation marks between the letters and numbers, with each long

mark representing 10 degrees and each short mark representing 5 degrees.

C. Accuracy

Accurate to within ±1 degrees.

3. BACKGROUND INFORMATION

A. A compass swing must be performed whenever any ferrous component of the system (i.e., flux

valve compensator, or Standby Compass) is installed, removed, repaired or a new compass is

installed. Additionally, a compass swing must be performed on the following occasions:

1. When the accuracy of the Compass is suspected.

2. After any cockpit modification or major replacement involving ferrous metals.

3. When the Compass has been subjected to shock from a hard landing or turbulence.

4. After aircraft has passed through a severe electrical storm.

5. After a lightning strike.

6. Whenever a change is made to the electrical system.

7. Whenever a change of cargo is likely to affect the Compass.

8. Whenever an aircraft operation is changed to a new geographic location with a major

change in magnetic deviation.

9. After aircraft has been parked on one heading for over a year.

10. When flux valves are replaced.

B. Understanding Compass Errors

The error of any compass is the angular difference between true north and compass north. This

angle is the algebraic sum of the deviation and variation. These are two terms commonly used

in connection with compasses that should not be confused.

1. Compass deviation is the difference between the heading of the aircraft, as indicated by the

compass and the actual magnetic heading of the aircraft. The deviation is called plus or

minus (east or west respectively) to indicate how it must be applied to the compass heading

56-101-01200 Revision G Page 7

to obtain the actual magnetic heading. The deviation and its sign are determined by

subtracting the aircraft compass reading from the magnetic heading of the aircraft.

2. Variation is the difference between the direction indicated by an undisturbed magnetic

compass and the true direction measured in relation to the earth’s geographical North Pole.

C. Causes of Compass Errors

There are several causes for inaccuracy in aircraft compasses: namely faulty installation,

vibration, the Aircraft’s magnetism (metallic and electrical), northerly turning error and

acceleration error. Installation and vibration error can and should be corrected. Northerly turning

error and acceleration error are common in magnetic needle type compasses incorporating a

sensitive element, which may be tilted and cannot be corrected. Errors caused by the aircraft’s

magnetism should be corrected insofar as is practically possible. The aircraft compass is

compensated to accomplish this. Magnetism in aircraft, which is likely to affect the compass,

can be caused by the following:

1. Hard Iron

This term is given to those parts of the Aircraft, which may be regarded as permanent

magnets; that is, parts in which the magnetism tends to remain the same. The effect of hard

iron can be determined with fair accuracy during a compass swing. By using other

permanent magnets (compensating magnets) near the compass, it usually can be

completely compensated. Once such compensation has been accurately made, it will

remain effective so long as the magnets do not alter their strength or position. If the

compensation is not complete and some error remains in the compass, the error will alter as

the aircraft changes magnetic latitude. For this reason, the accurate correction of the

aircraft’s permanent magnetism is extremely important.

2. Soft Iron

This term is given to those parts of the aircraft which continuously change their magnetism,

depending on the influence of other magnets (such as earth) on them. The soft iron

magnetism will change the Compass deviation with the change of magnetic latitude if it

results from the presence of unsymmetrical, vertical soft iron near the Compass. The

compensation of an aircraft for soft iron magnetism is so complicated as to be impractical

and should be performed only by an expert. It is important, therefore, that the Compass

location be such that there is no soft iron near it.

3. Electrical Magnetism

This term is given to the magnets (magnetic fields) which are produced by a direct electrical

current flowing through a wire. Since the direct current, causing electrical magnetism, is

liable to change frequently during a flight, it is of the utmost importance that any single-pole

wires carrying a direct current should not pass anywhere near the compass. If it is

impossible to avoid this wiring, then it is essential that the wiring be of the two-pole type.

Experience has shown that the use of single-pole electrical wiring near the compass has

such a serious effect that it cannot be tolerated.

56-101-01200 Revision G Page 8

CHAPTER 2: INSTALLATION

1. ASSEMBLY

A. Package

A monopod assembly, which is provided in assorted lengths. Combinations of lengths may be

chosen to support the Sight Compass at the operator’s eye level. Although the Sight Compass

can be handheld, experience has shown that the use of the monopod provides more stable

sightings.

Note: All external parts of the Sight Compass, such as the mounting bracket and monopod,

have been selected to contain no materials which could affect the magnetic accuracy of

the Sight Compass. Any other support, such as a camera tripod, must be carefully

checked for the presence of any ferrous materials before being used.

B. Enclosure

1. A case, Barfield P/N 194-00078, which facilitates protecting and carrying the Sight

Compass. Case features include (refer to Figure 5):

a) An injected, molded case.

b) Airtight, watertight, and dustproof case.

c) Custom PE foam insert to secure Sight Compass in place.

Note: Refer to Figure 5 for proper Sight Compass orientation.

Figure 5 Container / Shipping Case, P/N 194-00078

2. A laminated instruction sheet card, Barfield P/N 60-101-01200.

Note: Please use latest revision.

56-101-01200 Revision G Page 9

CHAPTER 3: OPERATION

WARNING: Before performing the procedures indicated in this chapter, remove all personal items

which might contain ferrous material, such as keys, pocketknives, watches, cell phones,

radios, pocket calculators, metal pens and pencils, etc. Beware of metal frame eyeglasses,

sunshades, metal shirt or jacket buttons, and steel belt buckles. All these items may be

magnetic, thus affecting the functioning of the Sight Compass.

1. ESTABLISHING A PERMANENT REFERENCE POINT

When the Sight Compass is first received, it is suggested that a permanent reference check point

be established. If, at any time, there is reason to suspect the readings obtained during the Aircraft

Compass testing, the Sight Compass can be rechecked using these reference points. To determine

one or more appropriate reference procedures:

A. Select an unobstructed view of at least 100 feet away from any buildings, machinery, fences,

power lines, etc. which could affect the magnetic environment. Beware of concrete runways with

embedded steel mesh or of any underground cables or pipelines. Also, the area selected should

be where future construction is unlikely. Battery Installation and Verification.

B. From the selected area, locate a prominent object at least 1 mile distant from the sighting

location. Again, try to anticipate an area where future construction is unlikely.

C. Remove all magnetic personal items that could affect the Compass. Clear the designated

location of any magnetic sources, induced electromagnetic field, or source of ferromagnetic

materials that could affect the Earth’s magnetic field. These items may include, but are not

limited to tools, cellphones, watches, jewelry and metal pens. These items must be removed

from the test set area, at least 5 feet away, to avoid adversely affecting the Compass reading.

Articles that must be worn, such as eyeglasses, should be checked and demagnetized

accordingly.

D. Carefully align the Compass sight on the chosen distant object or objects. Note and record the

Sight Compass readings.

E. Mark the observation point with some non-ferrous item for future reference.

F. Make a permanent record of the observation point, the referenced distant object or objects and

the Sight Compass readings.

2. TESTING SIGHT SUITABILITY

Before attempting to check and calibrate an Aircraft Compass, the area to be used should be

tested. It is recommended that the area be as far as possible from any magnetic disturbance.

Suggested distances are 50 feet from the aircraft being swung and 100 feet from any buildings,

large items of machinery, power lines, fences, etc. However, the area could appear to meet all of

these requirements but be unusable because of the steel mesh in the ramp or underground cables

or pipelines. To ascertain if the chosen area is satisfactory, proceed as follows:

A. Ensure that the area is at least 100 feet in diameter or adequate to accommodate the

dimensions of the aircraft being tested.

56-101-01200 Revision G Page 10

B. Check that a prominent object within the chosen area (at least a mile distant) can be observed.

C. Remove all magnetic personal items that could affect the Sight Compass.

D. Observe the distant object or objects from at least 8 points equidistant on the perimeter of the

chosen 100-foot diameter and note the Sight Compass readings.

E. If all readings are consistent within 1 degree, the area is satisfactory for Compass swinging.

However, the area should be rechecked frequently for possible magnetic charges.

In general, an area can be checked for Compass swinging suitability by taking bearings with the

Sight Compass from random positions within the area in question on an object at least a mile

distant. If all bearings are the same, the area is suitable for use.

3. VERIFYING EXISTING SWINGING BASE

To verify an existing base, the operator aligns himself/herself successively with the marked lines on

the base (standing at least 50 feet from the base) and sights along the line being checked with the

handheld, Sight Compass. If the bearings taken agree with the markings on the base, or the

markings plus or minus 90 degrees (in cases where the aircraft wheels are placed on the line), the

base is satisfactory. If a constant difference between the measured bearings and the markings of

the lines exists, the lines on the base should be redrawn. If the difference varies, the base is

unsuitable for use.

4. DETERMINING MAGNETIC HEADING OF AN AIRCRAFT

A. Standing at least 30 feet from the aircraft, the observer aligns himself/herself with its longitudinal

axis by reference to a radio mast and fin, row of central fuselage rivets or any suitable line or

pair of objects on the Aircraft, and with a handheld Sight Compass, sights on one of the objects

used for alignment. The Sight Compass is read when steadied. The reading obtained is the

magnetic heading of the aircraft if the observer is in front of the aircraft.

B. When using the Sight Compass, the aircraft’s nose is placed on the desired heading according

to the Aircraft Compass. Alignment on the heading need not be exact but should be within 5

degrees.

C. The Sight Compass should be supported and held at a comfortable reading distance from the

eye. A monopod is supplied with the Sight Compass to aid in steadying the Compass. Again,

the observer must take care to remove all magnetic material from his person prior to using the

Sight Compass.

5. PRECOMPENSATION AND PRESWING INSTRUCTIONS

A. When using the Sight Compass, the operator stands directly in front of the aircraft at a minimum

distance of 30 feet, preferably 50 feet or more.

B. The Compass is held as nearly level as possible and sighted through the sighting lens to the

exact center of the aircraft.

56-101-01200 Revision G Page 11

C. Sufficient time should be allowed for the Sight Compass to stabilize before taking readings. It is

best to take a series of three readings before assuming that the readings are correct.

D. Normal procedure is to either taxi or tow the aircraft to approximately the desired heading as

read on the Compass to be compensated (within 5 degrees).

E. The operator using the Sight Compass, then standing directly in front of the aircraft and with the

Sight properly lined on the center line of the aircraft, observes the exact heading on which the

aircraft is positioned, and notes any error that exists between the Sight Compass and the

Aircraft Compass being compensated.

F. Whatever error exists between the Sight Compass and the Aircraft heading is then corrected by

moving the Aircraft the number of degrees difference existing until such time as the Aircraft

heading and the reading of the Sight Compass are corrected for the desired heading (within 5

degrees).

G. It is of the utmost importance that during the swinging procedure a minimum distance of 30 feet

be maintained between the Aircraft being swung and the operator using the Sight Compass.

Also, the operator and the Sight Compass must be a minimum of 50 feet from any other aircraft,

or at least 100 feet from any large building, power lines, or heavy objects which might cause

interference.

H. Insofar as possible, all fixed or movable items containing ferrous materials should be placed in

positions they will occupy in flight before beginning the swing.

I. The Compass should be inspected for general serviceability.

J. An Aircraft Compass is easily affected by stray magnetism from electrical circuits and moveable

steel objects. Before swinging the Compass, the aircraft should be positioned approximately

north, east, south, and west. On each heading, the Compass should be observed with the

engine(s) operating and indicating generator charging, and with the engine(s) stopped. If a

significant difference is observed, the swinging should be done with the engines running and

charging. Also, on each heading, various electrical components should be turned ON and OFF

to determine their effect on the Compass. A determination must be made as to what equipment

will be used during the Compass swing. In some cases, multiple readings may be required to

cover normal, abnormal, and emergency conditions.

K. When swinging the Aircraft, it should be kept (as nearly as possible) in the center of the chosen

area. Since it is easier to move the Sight Compass than the aircraft, it is not essential that the

aircraft be precisely positioned on the selected headings. However, the aircraft should be within

5 degrees of the desired heading for best results. Also, during the actual compensating

procedure on north, east, south, and west, the alignment should be as close to the exact

heading as practical.

6. COMPASS COMPENSATION PROCEDURE

Note: All these corrections shall be made using a non-magnetic screwdriver. The Compass

shall be lightly tapped after each adjustment and be allowed time to settle before taking

readings.

56-101-01200 Revision G Page 12

A. Set the compensator for zero effect by matching the dots on the compensator screws with the

fixed dots on the case.

B. Align the Aircraft as nearly as possible (not to exceed 5 degrees error) to magnetic north (0°).

C. Turn the N-S screw to cause the Aircraft Compass to read the same as the Sight Compass.

D. Align the Aircraft as nearly as possible (not to exceed 5 degrees error) to magnetic east (90°).

E. Turn the E-W screw to cause the Aircraft Compass to read the same as the Sight Compass.

CAUTION: IF THE N-S SCREW IS INADVERTENTLY TURNED, THE NORTH HEADING

MUST BE RECHECKED AND COMPENSATED.

F. Align the aircraft as nearly as possible (not to exceed 5 degrees error) to magnetic south (180°).

G. Turn the N-S screw to remove one-half of the error between the Aircraft Compass and the Sight

Compass.

H. Align the Aircraft as nearly as possible (not to exceed 5 degrees error) to magnetic west (270°).

I. Turn the E-W screw to remove one-half of the error between the Aircraft Compass and the Sight

Compass.

7. COMPASS SWINGING PROCEDURE

A. Prepare a worksheet similar to the one shown in Table 2 by first making a copy of the blank

worksheet as shown in Table 1 and populating it with the data recorded and calculated by

accomplishing the steps that follow.

B. Starting on any convenient 30-degree heading, align the Aircraft so that the Sight Compass

reads within 5 degrees of the desired heading.

C. Record the Aircraft Compass reading in column 2 and the Sight Compass reading in column 3

adjacent to the appropriate heading in column 1.

D. Repeat steps 7.B and 7.C for each subsequent 30-degree heading.

E. Record the difference between the readings of the Aircraft and Sight Compass readings in

column 4.

F. Add or subtract the Compass errors in column 4, to or from, respectively, the desired headings

in column 1. Enter the results in column 5. Refer to Table 2 as a guide to these calculations.

G. There should not be more than plus or minus 10° difference between any of the Aircraft

Compass readings and the Sight Compass readings. If the Aircraft Compass cannot be

adjusted to meet the requirements, install another one.

H. Enter the values from column 5 in the “STEER” portion of the Aircraft Compass correction card.

56-101-01200 Revision G Page 13

(Column 1)

DESIRED

HEADING

(Column 2)

AIRCRAFT

COMPASS

READING

(Column 3)

SIGHT

COMPASS

READING

(Column 4)

AIRCRAFT

COMPASS

ERROR

(Column 5)

CORRECTED

AIRCRAFT

COMPASS

N

030

060

E

120

150

S

210

240

W

300

330

Table 2 Compass Worksheet

(Column 1)

DESIRED

HEADING

(Column 2)

AIRCRAFT

COMPASS

READING

(Column 3)

SIGHT

COMPASS

READING

(Column 4)

AIRCRAFT

COMPASS

ERROR

(Column 5)

CORRECTED

AIRCRAFT

COMPASS

N

356

359

-3

357

030

032

034

-2

028

060

062

063

-1

059

E

088

086

+2

092

120

125

121

+4

124

150

150

148

+2

152

S

177

175

+2

182

210

213

213

0

210

240

245

246

-1

239

W

268

270

-2

268

300

300

297

+3

303

330

333

335

-2

328

Table 3 Example of Completed Compass Correction Worksheet

Other manuals for SC 063

1

This manual suits for next models

1

Table of contents

Other barfield Compass manuals