Barnstead International 1305 Series User manual

EASYpure®II RF

OPERATION MANUAL

AND PARTS LIST

Series 1305

Model D7031

100-240 Volts

LT1305X1 • 8/22/05

Safety Information ..............................................................................................................................................4

Alert Signals..................................................................................................................................................4

Warnings ......................................................................................................................................................4

Introduction..........................................................................................................................................................6

General Specifications ........................................................................................................................................7

Dimensions and Clearance Requirements. ..................................................................................................7

Electrical Requirements ................................................................................................................................7

Feedwater Requirements..............................................................................................................................7

Product Water ..............................................................................................................................................7

Environmental Conditions ............................................................................................................................8

Declaration of Conformity ............................................................................................................................8

Unpacking ..........................................................................................................................................................9

Installation ........................................................................................................................................................10

Locating Unit ..............................................................................................................................................10

Cartridge Installation ..................................................................................................................................11

Controls ............................................................................................................................................................12

Power Switch ..............................................................................................................................................12

Control Panel ..............................................................................................................................................12

Switches......................................................................................................................................................12

Display..................................................................................................................................................12

Operational Modes......................................................................................................................................13

Run Mode ............................................................................................................................................13

Standby ................................................................................................................................................13

Idle Mode..............................................................................................................................................13

Initial Operation ................................................................................................................................................14

Storage Reservoir Filling and Cartridge Rinse Up......................................................................................14

Normal Operation ..............................................................................................................................................15

Operation ....................................................................................................................................................15

Water Draw-Off ..........................................................................................................................................15

Feedwater Replenishment ..........................................................................................................................15

Maintenance and Servicing ..............................................................................................................................16

System Sanitization ....................................................................................................................................16

Cleaning the Resistivity Cell ......................................................................................................................18

General Cleaning Instructions ....................................................................................................................20

Cartridge Replacement ..............................................................................................................................20

Cartridge Removal ......................................................................................................................................21

0.2 Micron Final Filter Replacement ..........................................................................................................21

Ventgard Cap Replacement........................................................................................................................21

Fuse Replacement......................................................................................................................................22

Unit Shutdown ............................................................................................................................................22

Troubleshooting ................................................................................................................................................23

Error Conditions ..........................................................................................................................................25

Replacement Parts............................................................................................................................................26

Consumables ..............................................................................................................................................26

General Maintenance..................................................................................................................................26

Safety Stock................................................................................................................................................27

Wiring Diagram..................................................................................................................................................28

Ordering Procedures ........................................................................................................................................29

One Year Limited Warranty ..............................................................................................................................32

2

Table of Contents

3

Figures

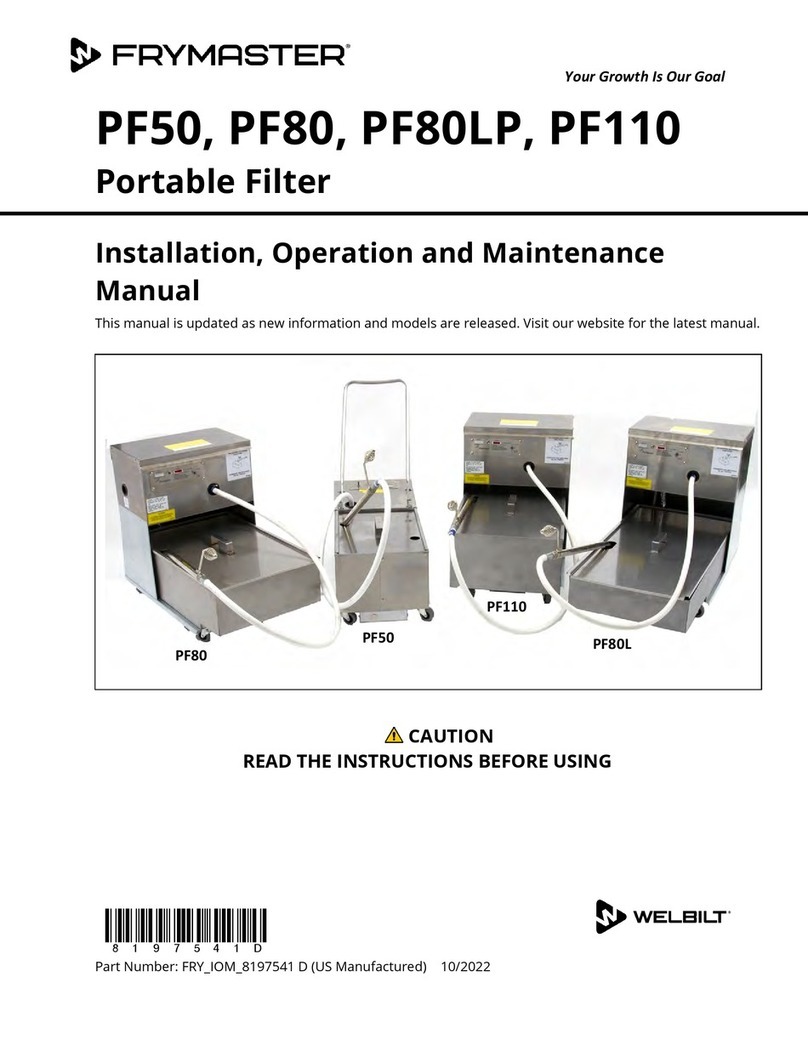

Figure 1: EASYpure II RF Front ........................................................................................................................10

Figure 2: EASYpure II RF Back ........................................................................................................................10

Figure 3: Cartridge Installation ..........................................................................................................................11

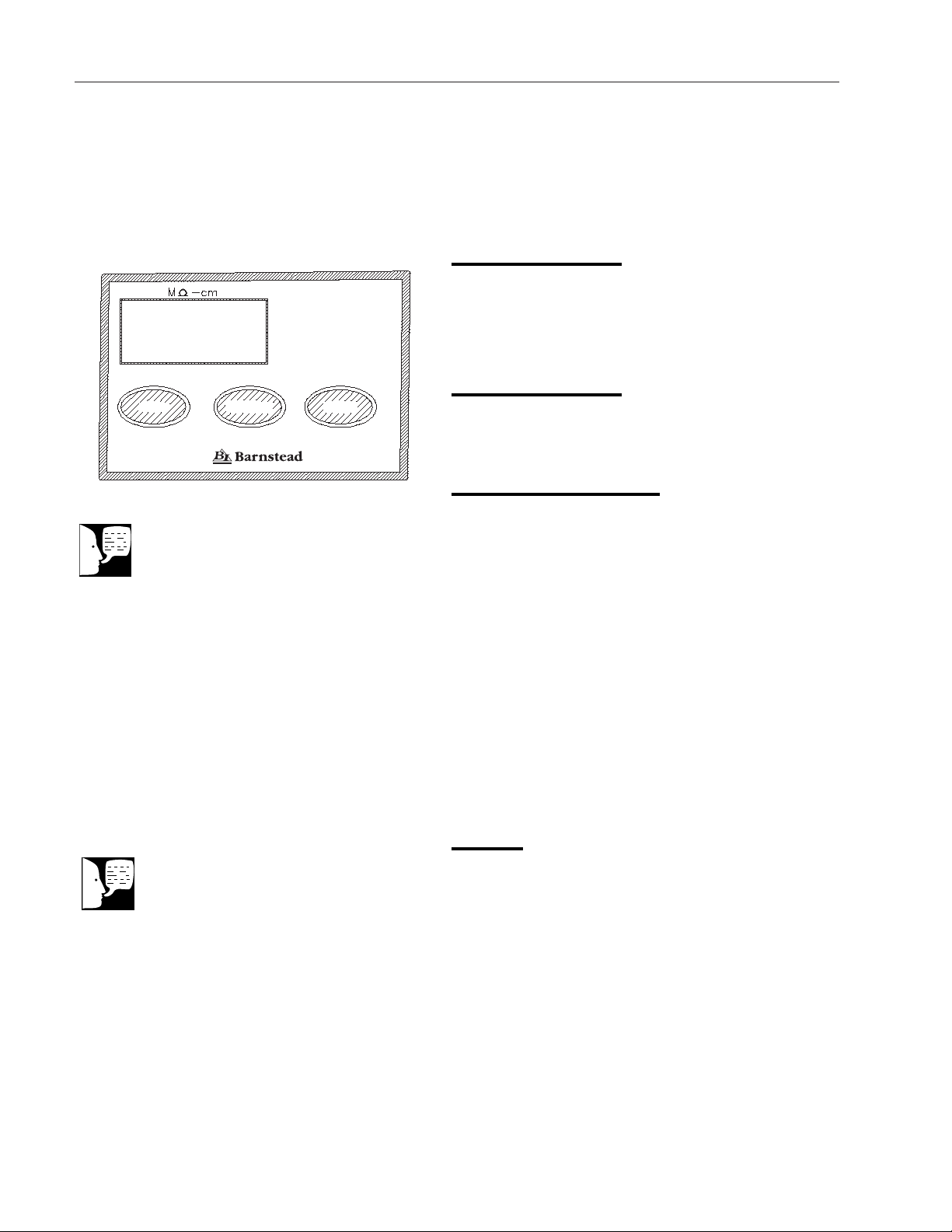

Figure 4: Control Panel ....................................................................................................................................12

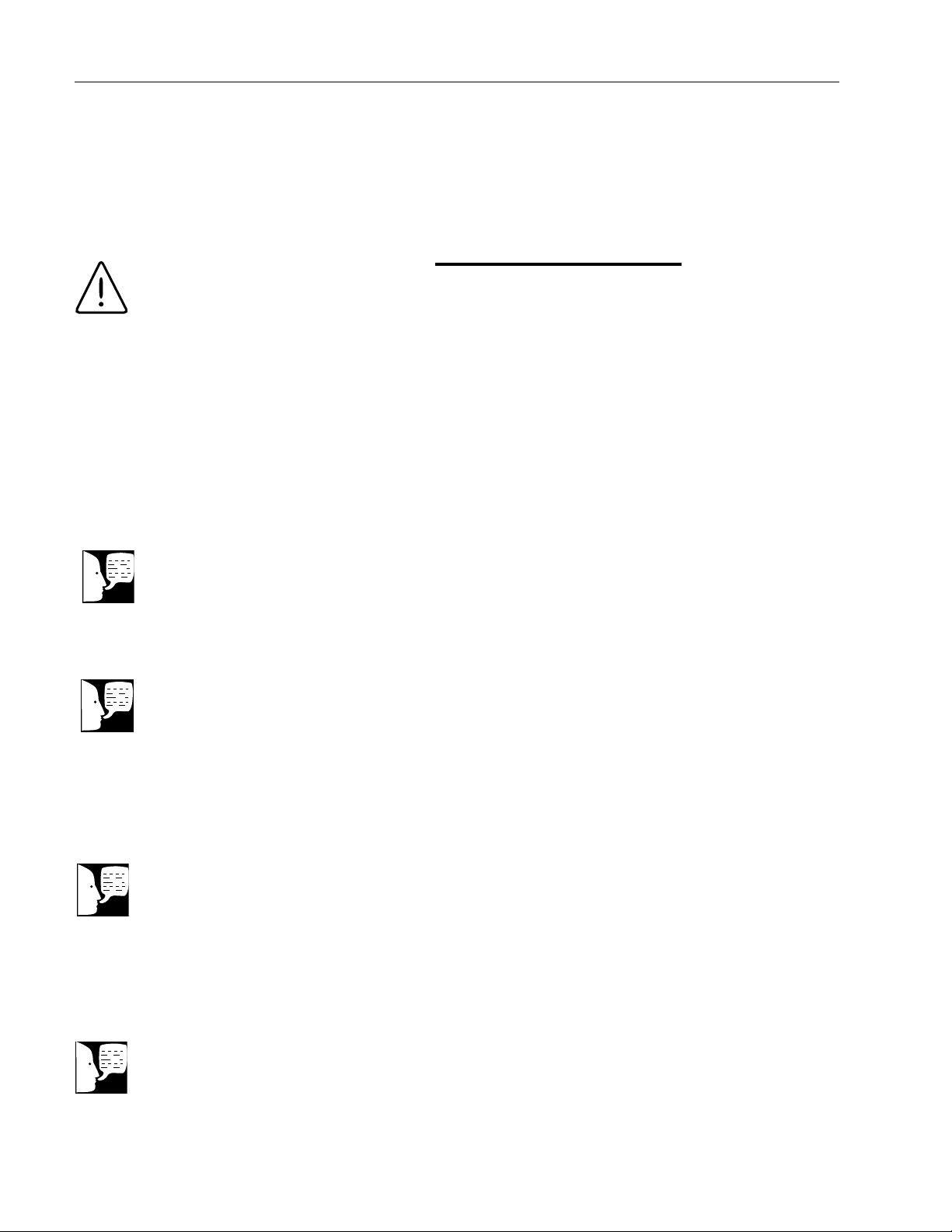

Figure 5: Disconnecting Resistivity Cell ............................................................................................................18

TABLE OF CONTENTS

4

Safety Information

Warning

Warnings alert you to a possibility of

personal injury.

Caution

Cautions alert you to a possibility of

damage to the equipment.

Note

Notes alert you to pertinent facts and

conditions.

Alert Signals Your Barnstead EASYpure®II RF has been designed

with function, reliability, and safety in mind. It is your re-

sponsibility to install it in conformance with local electri-

cal codes. For safe operation, please pay attention to

the alert signals throughout the manual.

This manual contains important operating and safety

information. You must carefully read and understand the

contents of this manual prior to the use of this equip-

ment.

Water purification technology employs one or more of

the following: chemicals, electrical devices, mercury

vapor lamps, steam and heated vessels. Care should be

taken when installing, operating or servicing Barnstead

products. The specific safety notes pertinent to this

Barnstead product are listed below.

Warnings

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of

correct voltage and current handling capacity.

2. Do not place the EASYpure II RF directly

over equipment that requires electrical serv-

ice. Routine maintenance of this unit may

involve water spillage and subsequent electri-

cal shock hazard if improperly located.

3. Replace fuses with those of the same type

and rating.

4. Do not disassemble water lines or remove

cartridges where spilled water could contact

equipment that requires electrical service.

Electrical shock hazard could result.

5. Disconnect from the power supply prior to

maintenance and servicing.

To avoid personal injury:

1. Do not use in the presence of flammable or

combustible materials; fire or explosion may

result. This device contains components

which may ignite such materials.

2. Do not use in the presence of highly corrosive

substances such as bleach or acid baths; fire

may result.

3. This device is to be used with water feeds only.

Sanitizing/cleaning agents must be used in

compliance with instructions in this manual.

Failure to comply with the above could result in

explosion and personal injury.

4. Avoid splashing disinfecting solutions on cloth-

ing or skin.

5. Ensure all piping connections are tight to avoid

chemical leakage.

6. Carefully follow manufacturer’s safety instruc-

tions on labels of chemical containers and ma-

terial safety data sheets.

7. Refer servicing to qualified personnel.

8. Ensure adequate ventilation.

9. Depressurize system prior to opening cartridge

access door or removing top cover.

5

SAFETY INFORMATION

The Barnstead EASYpure II RF is a batch-fed water puri-

fication system designed to provide Type I reagent-grade

water with extremely low organic carbon content. It uses

a three-stage deionization process combined with a 0.2

micron final filter to polish pretreated water (distilled,

deionized, or reverse osmosis) to produce water with a

resistivity of up to 18.2 megohms-cm and with a total

organic carbon content of less than 10 ppb. Water resis-

tivity is continuously sensed by a resistivity cell and dis-

played on a digital display.

The EASYpure II RF is designed to be a bench mounted

unit. If wall mounting is required, contact Barnstead

International customer service for information on a wall

bracket and mounting accessory.

6

Introduction

EASYpure II RF

Dimensions and Clearance Requirements

EASYpure II RF dimensions - 12" W X 19" D X 18 1/8" H (30.5 cm X 48.3 cm X 46.0 cm).

Clearances:

Sides - 4" (10.1 cm) minimum to allow air flow

Above - 12" (30.5 cm) minimum for reservoir replenishment

Cartridge replacement requires that you be able to access the back of the unit and open the cartridge

access door (total depth, unit + open door, = 34") (86.4 cm).

Storage Reservoir Capacity - Approximately 6.5 liters usable, 7.0 liters total

Electrical Requirements

The EASYpure II RF is equipped with two power cords and corresponding fuses taped to each power cord to

be plugged into a grounded electrical outlet of the appropriate voltage.

Model D7031: 100-240 VAC +5% -10%, 47-63 Hz.

Feedwater Requirements

The EASYpure II RF requires water pretreated by either distillation, deionization or reverse osmosis.

TOC - Less than 1.0 ppm

Turbidity - Less than 1.0 N.T.U.

Temperature - 40°F - 104°F (4.4°C - 40°C)

Silica - Less than 1 ppm

TDS (CaCO3) -

RO - Less than 50 ppm

DI - Less than 100 ppm

Distilled - Less than 2 ppm

Product Water

Quality

Resistivity: ASTM Type I

TOC: 5-15 ppb

Flow Rate: greater than or equal to 0.8 LPM with a new final filter

7

General Specifications

Environmental Conditions

Operating: 4°C - 49°C; 20% - 80% relative humidity,

non-condensing. Installation Category II (overvoltage) in

accordance with IEC 664. Pollution Degree 2 in

accordance with IEC 664.

Altitude limit: 3,500 meters.

Storage: -25°C - 65°C; 10% to 85% relative humidity.

Declaration of Conformity

Barnstead International hereby declares under its sole responsibility that

this product conforms with the technical requirements of the following

standards:

EMC: EN61000-3-2 Limits for Harmonic Current Emissions

EN61000-3-3 Limits for Voltage Fluctuations and

Flicker

EN 61326-1 Electrical Equipment for Measurement,

Control, and Laboratory Use; Part I:

General Requirements

Safety: EN 61010-1 Safety Requirements for Electrical

Equipment for Measurement, Control

and Laboratory Use; Part I:

General Requirements

per the provisions of the Low Voltage Directive 73/23/EEC, as amended

by 93/68/EEC.

The authorized representative located within the European Community is:

Electrothermal Engineering, Ltd.

419 Sutton Road

Southend On Sea

Essex SS2 5PH

United Kingdom

Copies of the Declaration of Conformity are available upon request.

8

GENERAL SPECIFICATIONS

Unpacking

Remove the unit from its shipping container and

ensure that the following items are removed from the

packaging materials before discarding:

a) EASYpure II RF unit

b) Ventgard®reservoir cap (CV703X4A)

c) North American power cord with attached fuse

bag (CRX72)

d) European power cord with attached fuse

(CRX70)

e) Operation Manual (LT1305X1)

9

Unpacking

Note

Cartridges and the 0.2 micron final filter

are not provided with the EASYpure II

RF and must be ordered separately:

EASYpure Kit Ultra low Organics

Deionized Feed (No Final Filter)

Part No. D502124

EASYpure Kit Ultra low Organics

Distilled or RO Feed (No Final Filter)

Part No. D502125

EASYpure Kit Type I Deionized Feed

(No Final Filter)

Part No. D502126

EASYpure Kit Type I Distilled or

RO Feed (No Final Filter)

Part No. D502127

0.2 Micron Final Filter

Part No. D3750

Locating Unit

1. Place the EASYpure II RF on a bench top con-

venient to your work area, noting the

Clearance Requirements. If wall mounting is

required contact Customer Service.

2. Using 1/2" I.D. tubing and tubing connectors

(user supplied), connect the overflow drain tub-

ing (lower left corner of the rear of the unit) to

an atmospherically vented sink or floor drain. If

an atmospherically vented sink or floor drain is

not accessible, a bucket or other container

may be placed on the floor beneath the

EASYpure II RF’s location and emptied when

full.

10

Installation

Figure 1: EASYpure II RF Front Figure 2: EASYpure II RF Back

Warning

Do not place the EASYpure II RF

directly over equipment that

requires electrical service. Rou-

tine maintenance of this unit may

involve water spillage and subse-

quent electrical shock hazard if

improperly located.

Warning

Do not use in the presence of flam-

mable or combustible materials; fire

or explosion may result. This de-

vice contains components which

may ignite such materials.

Warning

This device is to be used with water

feeds only. Sanitizing/cleaning

agents must be used in compliance

with instructions in this manual.

Failure to comply with the above

could result in explosion and per-

sonal injury.

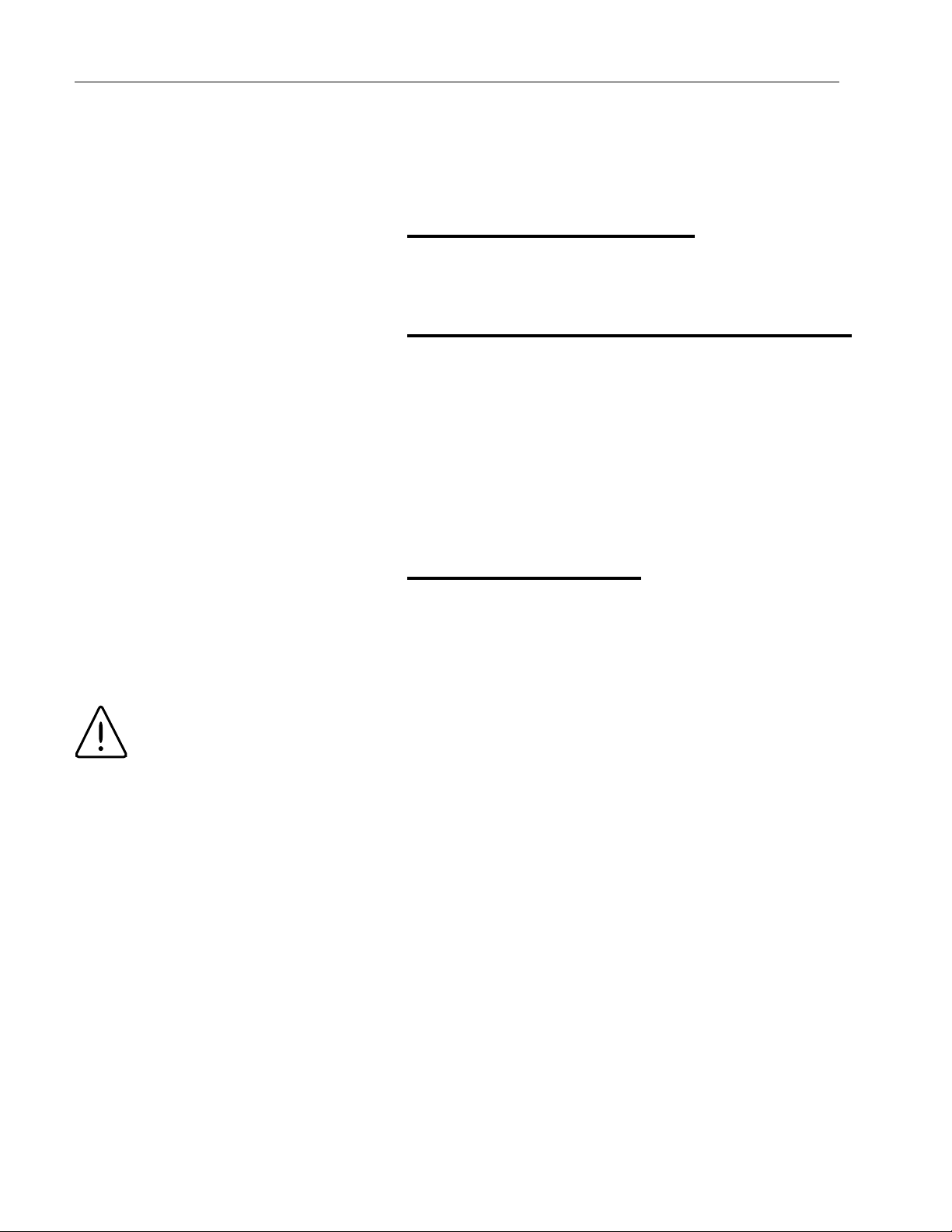

Cartridge Installation (See Fig. 3)

1. Open cartridge access door in the rear of the unit

by pushing the door latch down.

2. Remove a new Pretreatment cartridge (part num-

ber D50230 or D50231) from its plastic bag.

3. Wet the o-rings with water on both end caps.

4. Press the upper end cap into the pretreatment

position until it bottoms out.

5. Lower the cartridge and insert the lower end cap

into the lower socket until it is firmly seated.

6. Repeat steps 2 - 5 with the Ultrapure cartridge

(Catalog No. D50233) and then the EASYpure

High Purity/Low TOC (Catalog No. D50229) or

Ultrapure cartridge, placing them in positions 2

and 3.

7. Close cartridge access door. This serves to veri-

fy the cartridges have been properly seated.

11

INSTALLATION

Note

The upper end cap is the one with the

right-angle turn and the two flanges.

The lower end cap extends straight

out from the cartridge. (See Fig. 3.)

Note

The two flanges on the end cap

should be able to slide down on each

side of the keyway wall.

Figure 3: Cartridge Installation

12

Power Switch

The power switch on the EASYpure II RF is located on

the back right side of the unit directly above the power

cord receptacle.

Control Panel

The EASYpure II RF control panel incorporates three

switches and a digital display.

Switches (See Fig. 4)

When the main power switch is on, the three switches

on the control panel function as follows:

1. START: Pressing the START switch when the

unit is in either the stop (“IdL”) or standby

(“SbY”) mode will put the unit into run mode.

2. STANDBY: Pressing the STANDBY switch

when the unit is in either the start (run) or

stop (“IdL”) mode will put the unit into a stand-

by mode.

3. STOP: Pressing the STOP switch when the

unit is in either the start (run) or standby

(“SbY”) mode will put the unit into a stop

(“IdL”) mode.

Display

In addition to displaying the temperature compensated

(25°C) resistivity in megohms, the display also indi-

cates operational modes and error indicators. The fol-

lowing is what can appear on the display:

SbY Er1

rEC Er4

IdL Er5

Add

Controls

Figure 4: Control Panel

STOP STANDBY START

Note

On initial start-up, the purity meter may

display “Er.1”. This is caused by air in

the cell and should soon be replaced

by a resistivity reading. If “Er.1” does

not go out after the pump has run for a

minute or if it appears any time while

the EASYpure II RF is in operation,

refer to the “Troubleshooting” section of

this manual.

Note

On initial power-up, the display will run

the following sequence:

- Model type is scrolled -RF

- The display’s LEDs will light up,

- Followed by the unit software

revision,

- Finally, IdL will be displayed.

Operational Modes

Run Mode

Since not all qualities of permissible feedwater will reach

maximum resistivity after one pass through the unit’s car-

tridges (especially as the cartridges near exhaustion), the

EASYpure II RF has two operational modes; run and

standby.

In the run mode, the pump continuously recirculates water

through the cartridges. It is recommended that the

EASYpure II RF be left in the run mode during the day. In

the run mode, the purity meter display indicates the resis-

tivity of the water available for draw off. Allow the water’s

resistivity to rise to the desired purity before drawing off

water.

STANDBY (“SbY”)

In STANDBY (“SbY”) mode, the pump will restart for ten

minutes out of every hour (i.e 50 minutes off, 10 minutes

on). The display reads “rEC” which indicates recircula-

tion. This will allow the unit to produce high quality water

quickly upon being placed in the run mode. It is recom-

mended that the EASYpure II RF be placed in the

STANDBY mode during non-work hours. At the end of

the work day, press the STANDBY switch on the front of

the EASYpure II RF to place the unit in STANDBY mode

for the night. “SbY” will appear on the display.

Idle Mode (“IdL”)

“IdL” indicates the unit is powered and waiting to be

placed in Run or STANDBY mode.

13

CONTROLS

Note

When the unit is first put in the Run

Mode, the display will show 10.0 for

a few seconds. This is an arbitrary

number that indicates the unit is run-

ning. Any number that appears after

10.0 indicates purity.

Note

Do not put unit into Idle Mode or

turn off the EASYpure II RF during

non-work hours. Doing so will allow

bacterial growth and other contami-

nation of the water in the system.

As a result, the system will require

a lengthy rinse-up period at the

beginning of the work day to

achieve high-quality product water.

Note

If the unit is in standby and power

to the unit is turned off or lost, the

unit will return to standby once

power is restored.

Storage Reservoir Filling and

Cartridge Rinse Up

To fill the reservoir:

1. Remove the molded plastic Ventgard cap.

2. Carefully pour pretreated feedwater into the reser-

voir until the water is level with the top of the sight

gauge on the front of the unit (See Fig. 1). Replace

the Ventgard cap.

3. The power connection is located on the right side of

the unit, in the upper back corner.

4. Determine which power cord you need (this will be

based on your country and outlets available in your

lab). Both North American and European power

cords are provided with the unit.

5. Remove the fuse holder, install the fuses included

with the power cord to be used, and reinstall holder.

6. Verify power switch is turned off and attach recepta-

cle end of power cord into the power socket.

7. Plug other end of power cord into facility power.

Turn main power on at power entry module.

8. Place suitable container under draw-off valve. Open

draw-off valve.

9. Press START and rinse one complete reservoir vol-

ume of water through the cartridges to drain.

10. Close draw-off valve.

11. Remove hose barb connection from draw-off valve.

Keep hose barb for future use.

12. Remove the new 0.2 micron final filter assembly

from its bag and insert it into the draw-off valve.

Gently tighten, turning the filter to the right.

13. Refill the reservoir with pretreated water.

14. Open the draw-off valve and flush second reservoir

volume of water through the 0.2 micron final filter.

Initial Operation

Note

Cartridge rinse up procedure must be

followed after each cartridge and/or fil-

ter replacement.

Note

In the event that you overfill the feed-

water reservoir, allow the excess water

to drain from the reservoir through the

overflow drain tubing before replacing

the Ventgard cap. This will prevent

wetting the filter element.

Note

For more demanding applications

where low TOC water is required, a

third reservoir volume rinse of the car-

tridges and filter may be necessary.

Teflon®is a registered trademark of DuPont

Warning

Use a properly grounded electri-

cal outlet of correct voltage and

current handling capacity.

Warning

This device is to be used with water

feeds only. Sanitizing/cleaning

agents must be used in compliance

with instructions in this manual.

Failure to comply with the above

could result in explosion and person-

al injury.

Note

It is suggested that Teflon®tape be

applied to the threads of the 0.2 micron

final filter to ensure a tight seal.

14

Operation

1. Remove the Ventgard cap. Do not allow water

to enter the Ventgard cap.

2. Carefully pour pretreated feedwater into the

feedwater reservoir until the water is level with

the top of the sight gauge. Replace the

Ventgard cap.

3. Turn main power on at power entry module.

4. Press the “START” button on the front of the

EASYpure II RF. The EASYpure II RF’s pump

will begin to run and the purity meter will dis-

play “10.0” followed by the number indicating

the resistivity of the water in megohm-cm.

5. Allow the water’s resistivity to rise to the

desired purity before drawing off water.

Water Draw-Off

1. Remove the protective cap from the 0.2

micron final filter bell.

2. Depress the draw-off lever.

3. When draw off is complete, lift the draw-off

lever and replace the protective cap on the 0.2

micron final filter bell.

Feedwater Replenishment

As water is drawn off from the EASYpure II RF, the feed-

water reservoir will require refilling. This will be indicated

by a low water level in the sight gauge or by the message

“Add” on the display. To refill the reservoir:

1. Repeat steps 1 and 2 from “Operation” above.

2. Allow the water’s resistivity to rise to the

desired purity before drawing off water.

15

Normal Operation

Note

When the unit is first put in the Run

Mode, the display will show 10.0 for a

few seconds. This is an arbitrary num-

ber that indicates the unit is running.

Any number that appears after 10.0

indicates purity.

System Sanitization

Frequency of cleaning is difficult to determine because of

variability in feedwater and usage. Cleaning is necessary

when residual deposits are evident inside the feedwater

reservoir or if a new 0.2 micron final filter clogs rapidly

after installation even though the cartridges were properly

rinsed before the 0.2 micron final filter was installed. To

sanitize the EASYpure II RF, remove the 0.2 micron final

filter and attach the hose barb that came installed on the

unit. The purification cartridges must be removed and

replaced with empty cartridges. These must be ordered

separately. Contact Barnstead International and order part

number D7034.

1. Drain the system.

a. Place the 0.2 micron final filter over a sink or

place a bucket or other suitable large container

under the filter and draw off water as described

under Water Draw-Off in the Operation sec-

tion of this manual. Draw off water until the

water level in the feedwater reservoir is lowered

to the point that the reservoir float switch dis-

ables the pump. Lift draw-off valve to closed

position.

b. Disconnect the power cord from the power

entry module.

c. Turn the unit around to provide access to the

drain plug on the lower edge of the back panel.

d. Place the drain plug over a sink, or place a

bucket or other suitable large container under

the drain plug. Remove the drain plug by turn-

ing it while pulling until it comes out.

e. Drain remaining water from the reservoir and

system.

f. Replace the drain plug, taking care to fully

insert it into the drain tubing.

g. Remove cartridges and install empty cartridge

tubes (part number D7034) according to the

instructions in Cartridge Replacement.

16

Maintenance and Servicing

Warning

Disconnect from the power supply prior

to maintenance and servicing.

Do not disassemble water lines or re-

move cartridges where spilled water

could contact equipment that requires

electrical service. Electrical shock haz-

ard could result.

Refer servicing to qualified personnel.

Note

The cartridges will still contain water

when removed. Therefore, you will

want to have a sink, bucket or other

waterproof container available to place

them in after removal.

Note

Asmall amount of water will drain from

the cartridge when it is disconnected

from the lower socket. Plug the car-

tridge’s lower opening with your finger

to minimize water spillage while you

finish removing the cartridge.

Note

Used cartridges may be recycled. See

P.U.R.E. information packed with new

cartridges.

Note

Drain plug is not attached to unit; use

care when removing it over an open

drain to avoid dropping it into the

drain.

h. Remove 0.2 micron final filter and install the

hose barb that was shipped with the system.

2. Remove Ventgard cap and pour 6 liters of pre-

treated feedwater into reservoir.

3. Add 10ml to 20ml of household chlorine bleach

(5.25% sodium hypochlorite) to reservoir.

4. Reconnect power cord to the power entry mod-

ule and turn unit on. Press the “START” button

and put unit into Run Mode.

5. Allow the unit to recirculate the disinfecting

solution for thirty minutes. Cycle the draw-off

valve to sanitize the valve.

6. Drain the system as described in step 1 of this

section.

7. Refill the reservoir with suitable feedwater and

recirculate the water through the system for ten

minutes.

8. Drain the system as described in step 1 of this

section.

9. Remove the empty cartridge tubes according

to the instructions in the Cartridge Removal

section. Drain and retain the empty cartridge

tubes for future use. Remove the hose barb fro

the draw-off valve.

10. Install and rinse new cartridges according to

the instructions in the Cartridge Installation

section. Do not reinstall used cartridges or 0.2

micron final filter (they may contain large

amounts of bacteria.)

11. Install and rinse new 0.2 micron final filter

according to the instructions in the 0.2 Micron

Final Filter Replacement section of this man-

ual.

12. Reconnect power cord to the power entry mod-

ule and turn unit on. Press the “START” but-

ton.

17

MAINTENANCE AND SERVICING

Warning

Avoid splashing disinfecting solutions

on clothing or skin.

Ensure all piping connections are tight

to avoid chemical leakage.

Ensure adequate ventilation.

Carefully follow manufacturer’s safety

instructions on labels of chemical con-

tainers and material safety data

sheets.

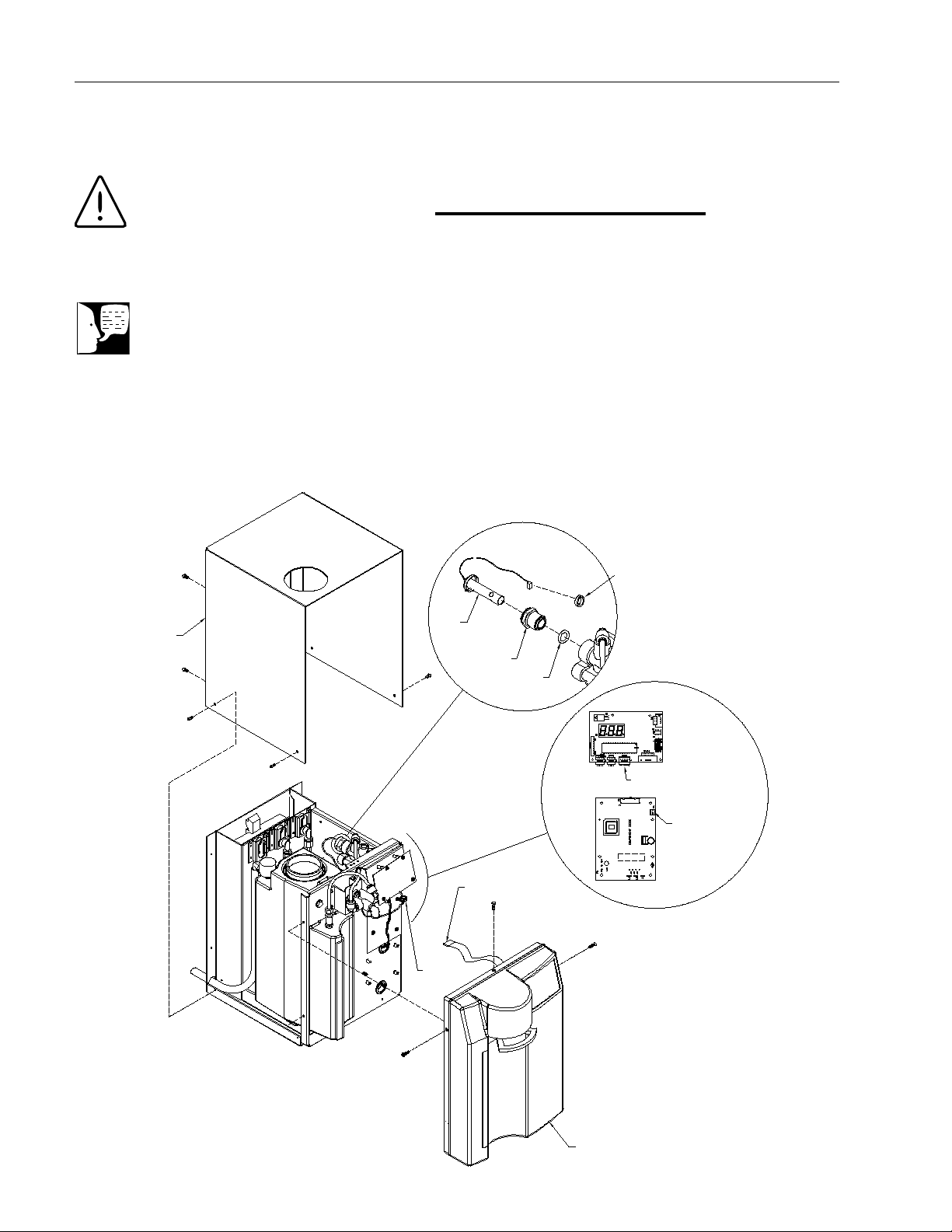

Membrane Switch Lead

Remove Front Cover

and Screws

Remove Top

Cover and Screws

Meter Board Display Board

Disconnect Cell

Lead From Here

Disconnect Membrane

Switch Lead From Here

EMI Filter

EMI/RFI

Suppression Filter

(one loop around filter)

Cell

Bushing

O-ring

Cleaning the Resistivity Cell

1. Turn off the EASYpure II RF. Remove the

power cord.

2. Depressurize the system by opening the unit

dispenser draw-off valve, allowing water to

drain until no more flows from the valve.

3. Remove the Ventgard cap.

4. Remove the screws securing the EASYpure II

RF top cover.

18

MAINTENANCE AND SERVICING

Warning

Depressurize system prior to opening

cartridge access door.

Note

Ensure you have an o-ring (part #

GSX29) available prior to cleaning

resistivity cell.

Figure 5: Disconnecting Resistivity Cell

5. Remove the cover by lifting it straight up.

6. Remove the 0.2 micron final filter. Carefully remove

the front cover screws and pull the cover off.

Disconnect membrane switch lead from the display

board (see Fig. 5).

7. Disconnect the cell lead from the meter board,

remove the EMI/RFI suppression filter and gently

pull the cable out of the EASYpure II RF frame.

Note orientation.

8. Unscrew and remove the cell.

9. Carefully remove and discard the o-ring before

cleaning the cell.

10. Wash the cell in a mild detergent solution followed

by a 10% Hydrochloric or 10% Sulfuric acid solu-

tion (follow acid manufacturers warnings and rec-

ommended handling procedures found on package

labels and Material Safety Data Sheets). This may

be done in an ultrasonic cleaner or with a soft

brush.

11. Thoroughly rinse the cell in deionized or distilled

water following the detergent and/or acid cleaning.

12. After cleaning, reinstall with the replacement

o-ring on cell (part # GSX29).

13. Reinstall the cell and hand tighten. Reroute the

cable up through the housing, reinstall the EMI/RFI

suppression filter (loop wire 1 time around filter)

and reconnect cell lead to meter board.

14. Reinstall membrane switch lead. While lifting dis-

pense handle, replace the front cover. Reinstall the

0.2 micron final filter.

15. Reinstall the EASYpure II RF top cover.

16. Reinstall the Ventgard cap and 0.2 micron final fil-

ter.

17. Reattach the power cord and reconnect the unit to

the power supply.

18. Refill the reservoir with feedwater and operate nor-

mally.

19

MAINTENANCE AND SERVICING

Caution

The cell electrodes are etched to

improve wetting characteristics. Do not

mechanically abrade or damage this

surface (i.e. do not clean with a wire

brush, sandpaper, etc.).

Do not immerse the entire cell assem-

bly in cleaning solution, only the elec-

trode portion.

Warning

Carefully follow manufacturer’s safety

instructions on labels of chemical con-

tainers and material safety data

sheets.

General Cleaning Instructions

Wipe exterior surfaces with lightly dampened cloth containing

mild soap solution.

Cartridge Replacement (See Fig. 3)

The frequency with which you will need to replace cartridges is

dependent on your feedwater characteristics, your purity require-

ments, and your daily usage. Replace the cartridges when the

product water purity drops below acceptable levels of resistivity

or when organic levels become too high.

Remember, used cartridges can be recycled; See P.U.R.E. infor-

mation packed with your new cartridges.

Cartridge Removal

1. Turn off the EASYpure II RF and depressurize system

by disconnecting unit feedwater, opening draw-off

valve and allowing water to drain from the unit until

draining ceases.

2. Open the cartridge access door in the rear of the unit by

pushing back the door latch.

3. Remove the cartridge in the pretreatment position by

pulling the cartridge straight up until the upper socket is

in the keyhole of the keyway. Next pull the cartridge

straight out.

4. Remove a new Pretreatment cartridge (Part No.

D50230 or D50231) from its plastic bag.

5. Wet the o-rings with water on both end caps.

6. Press the upper end cap into the pretreatment position

until it bottoms out.

7. Lower the cartridge and insert the lower end cap into

the lower socket until it is firmly seated.

8. Repeat steps 3-7 with the EASYpure ULTRApure (Part

No. D50233) cartridge, placing it in position 2 and the

EASYpure High Purity/Low TOC (Part No. D50229)

cartridge, placing it in position 3. Be sure to remove

and replace one cartridge at a time.

20

MAINTENANCE AND SERVICING

Warning

Depressurize system prior to opening

cartridge access door.

This manual suits for next models

2

Table of contents

Popular Water Filtration System manuals by other brands

Range Master

Range Master TSA1 quick start guide

AquaticLife

AquaticLife 420343 Installation, operation, maintenance guide

Bluewater

Bluewater Pro Series user manual

AlkaViva

AlkaViva UltraWater Elita CT-700 user manual

Pure-Pro

Pure-Pro RO103TDS user manual

PureAir

PureAir Ecozone Cumulus PA-CUM-10 user manual

Aqua Medic

Aqua Medic Systemfilter 2000 Operation manual

Pure-Pro

Pure-Pro HRO-400 user manual

Pure-Pro

Pure-Pro RS-106M user manual

Welbilt

Welbilt FRYMASTER PF80L Installation, operation and maintenance manual

Power Fist

Power Fist 8723298 user manual

Bluebird

Bluebird Blue Moon RO Instruction handbook for installation, operation and maintenance