Barnstead A1011 User manual

1

Classic

Electrically Heated Stills

OPERATION MANUAL

AND PARTS LIST

SERIES 495

Model Numbers

A1011 A1015

A1013 A1016

60004 • 5/5/04

2

Safety Information ..............................................................................................................................................3

Alert Signals ......................................................................................................................................................3

Warnings ..........................................................................................................................................................3

Introduction..........................................................................................................................................................5

Evaporator ........................................................................................................................................................5

Condenser ........................................................................................................................................................6

Features Provided ............................................................................................................................................6

Electric Heat......................................................................................................................................................6

Low Water Cut-Off ............................................................................................................................................6

Still Heat Control ..............................................................................................................................................7

Unpacking ..........................................................................................................................................................8

Installation ..........................................................................................................................................................9

Siting ................................................................................................................................................................9

Accessories ......................................................................................................................................................9

Plumbing Connections ......................................................................................................................................9

Electrical Connections ....................................................................................................................................11

Operation ..........................................................................................................................................................13

Initial Startup ..................................................................................................................................................13

Initial Operation ..............................................................................................................................................13

Deconcentrator Adjustment ............................................................................................................................14

Normal Operation............................................................................................................................................15

Maintenance and Servicing ..............................................................................................................................17

Cleaning Methods ..........................................................................................................................................17

Disassembly for Cleaning ..............................................................................................................................18

Theory of Operation ..........................................................................................................................................21

Troubleshooting ................................................................................................................................................22

Tests for Condenser Leaks ............................................................................................................................22

Condenser Test for Scale. ..............................................................................................................................23

Heating Element Test and Replacement ........................................................................................................24

Heating Elements............................................................................................................................................26

Troubleshooting Chart ......................................................................................................................................27

Parts List ..........................................................................................................................................................28

Accessories for Electric Stills ............................................................................................................................37

Ordering Procedures ........................................................................................................................................39

Warranty ............................................................................................................................................................40

Table of Contents

3

This manual contains important operating and

safety information. The user must carefully

read and understand the contents of this manu-

al prior to the use of this equipment.

Water purification technology employs one or

more of the following: chemicals, electrical

devices, mercury vapor lamps, steam and heat-

ed vessels. Care should be taken when

installing, operating or servicing Barnstead

products. The specific safety notes pertinent to

the Barnstead Electrically Heated Stills are list-

ed in safety information section.

Your Barnstead Electrically Heated Still has

been designed with function, reliability, and

safety in mind. It is the user’s responsibility to

install it in conformance with local electrical

codes. For safe operation, please pay attention

to the alert signals throughout the manual.

Warnings

To avoid electrical shock, always:

1. Ensure that the equipment is connect-

ed to electrical service according to

local and national standards. Failure

to properly connect may create a fire

or shock hazard.

2. Do not connect unit to electrical ser-

vice until instructed to do so.

3. Disconnect from the power supply

prior to maintenance and servicing.

To avoid personal injury:

1. Do not use in the presence of flamma-

ble or combustible materials; fire or

explosion may result. This device con-

tains components which may ignite

such materials.

Safety Information

Alert Signals

Warning

Warnings alert you to a possibili-

ty of personal injury.

Caution

Cautions alert you to a possibili-

ty of damage to the equipment.

Note

Notes alert you to pertinent

facts and conditions.

4

2. Use this device with water feed only.

Sanitizing/cleaning agents must be used

in compliance with the instructions in

this manual. Failure to comply with the

above could result in explosion and per-

sonal injury.

3. Avoid splashing disinfecting solutions on

clothing or skin.

4. Ensure all piping connections are tight

to avoid leakage of chemicals.

5. Always depressurize chemical lines

before disassembly.

6. Ensure adequate ventilation.

7. Follow carefully the manufacturers’ safe-

ty instructions on labels of chemical

containers and Material Safety Data

Sheets (M.S.D.S.).

8. “Caution: Hot Surface. Avoid Contact.”

9. Refer servicing to qualified personnel.

SAFETY INFORMATION

5

Introduction

Barnstead electrically heated water stills are

available in four sizes; 1, 2, 5 and 10 gallons

per hour of distilled water. The distilled water

produced by the stills contains not more than

1.0 ppm total solids, with a pH value of 5.4 to

7.2 and an electrical resistance of not less than

300,000 ohms at 25°C when the stills are

operated on most potable water. The stills are

designed to use not more than 9 gallons of

cooling water and feedwater combined, for

each gallon of distilled water produced. The still

consists of: an evaporator with its heat supply,

a condenser, and devices to control the water

level and salt concentration in the evaporator, a

Q baffle for pyrogen removal and a low water

cutoff control. The operating characteristics for

each size still are shown in the Installation

Diagram.

Evaporator

Still evaporators are the vertical, cylindrical

double-wall type with air-insulating space. The

evaporators are built sufficiently high and wide

to provide ample vapor disengaging space and

operation at low velocity.

The evaporator shell is of polished stainless

steel. The inner shell (boiler) is fabricated of

copper, brass and bronze. The evaporator

cover is brass, finished in polished nickel and is

provided with a Q baffle. All surfaces that

contact the vapor and distillate are coated with

pure tin to prevent metallic contamination. A

water level sight glass is provided on all 5 and

10 gph stills.

6

Condenser

Still condensers are the horizontal type, slightly

inclined and atmospherically vented for final

elimination of volatiles. The condensers are fab-

ricated of copper and brass and are finished in

polished nickel. All surfaces that contact the

vapor and distillate are coated with pure tin to

prevent metallic contamination. A distillate

delivery tube of block tin is provided to connect

the distillate outlet of the condenser to a storage

tank or other suitable container.

Features Provided

All stills are equipped with a deconcentrator to

continuously deconcentrate impurities from the

evaporator and retard scale formation. A con-

stant level device with hot well arrangement is

provided for evaporator water level control and

for primary elimination of volatile impurities. All

stills are equipped with a drain valve. Cooling

water discharge piping is provided between

the cooling water outlet of the condenser and

the constant level device. Self-resetting solid

state low water cutoff controls prevent the heat-

ing elements from burning out in a low water sit-

uation.

Electric Heat

Electrically powered, immersion type heaters are

used to give complete heat transfer and maxi-

mum heating efficiency.

Low Water Cut-Off

Electric current to the still heating elements is

controlled by an ON/OFF switch and a self-

resetting low water cutoff. The solid state low

water cutoff is designed to prevent damage

caused by low water conditions in the still

evaporator.

Figure 1

Electrically Heated Still

INTRODUCTION

Note

Heater life may be reduced

when operated above maximum

stated voltage. Operation of still

at a voltage less than the stated

voltages will cause a drop in still

output. Electrically heated stills

wired for 240 volts AC, 2 or 3

wire, will operate on 208 volts, 2

or 3 wire respectively with resul-

tant 25 percent drop in distillate

capacity. Special heaters for

208 volts are needed to obtain

rated still output. The electric

heaters will burn out if operated

in air. To eliminate the possibility

of heating element burnout, a

solid state low water cutoff con-

trol is provided.

Condenser

Distillate

Outlet

Cooling Water/

Feedwater

Inlet Tube

Constant Level

Device

Preheated

Feedwater Tube

Q-Baffle

Deconcentrator

Valve

Evaporator

7

When the water level is at a safe level in the still

evaporator (the water level is above the immer-

sion type heaters and makes contact with the

probe), the circuit across probe terminals 1 and

2 at the terminal board (TB1) is completed. The

completion of this circuit, after a two-second

delay to prevent contactor chatter, will start the

contactor to energize the contactor coil to con-

nect the heater service to the still. Opening of

the probe circuit (water no longer makes contact

with the probe) will stop the contactor without

delay.

The Barnstead solid state low water cutoff is

designed to prevent damage caused by low

water conditions in the evaporator of Barnstead

electrically heated water stills. The low water cut-

off consists of the Barnstead Solid State Low

Water Control, a probe assembly for installation

on Barnstead stills, and still heat control (contac-

tor).

Still Heat Control

The heat control consists of a cabinetized con-

tactor designed for wall mounting. The contactor

cabinet has a removable cover and knockouts

for conduit connections. The contactor is provid-

ed to control the heat supply to the still heating

elements, as determined by the low water cutoff

controller. The contactor coil operates from a 115

VAC, 50/60 hertz, single phase electrical service

and derives its control voltage at terminals 6 and

11 at the terminal board in the low water cutoff

control cabinet. See Figure 8 for information on

the contactor size required for a given size still

and the available heating service. Unpack the

still carefully so as not to damage any of the

parts. Ensure that all parts are removed from the

container before discarding the packing materi-

als.

INTRODUCTION

8

Unpacking

Unpack the still carefully so as not to damage any

of the parts. Ensure that all parts are removed

from the container befoer discarding the packing

materials.

9

Siting

Move the still evaporator to the operating location

and install the evaporator so that it is level and

plumb.

Accessories

All operating and convenience accessories

purchased with the still should be installed after

the still has been assembled on its mounting and

before connecting the service lines to the still.

Plumbing Connections

Ensure that all fittings are tight in the still and still

accessory piping and connect the water and

waste service to the still as shown in the installa-

tion diagram.

Installation

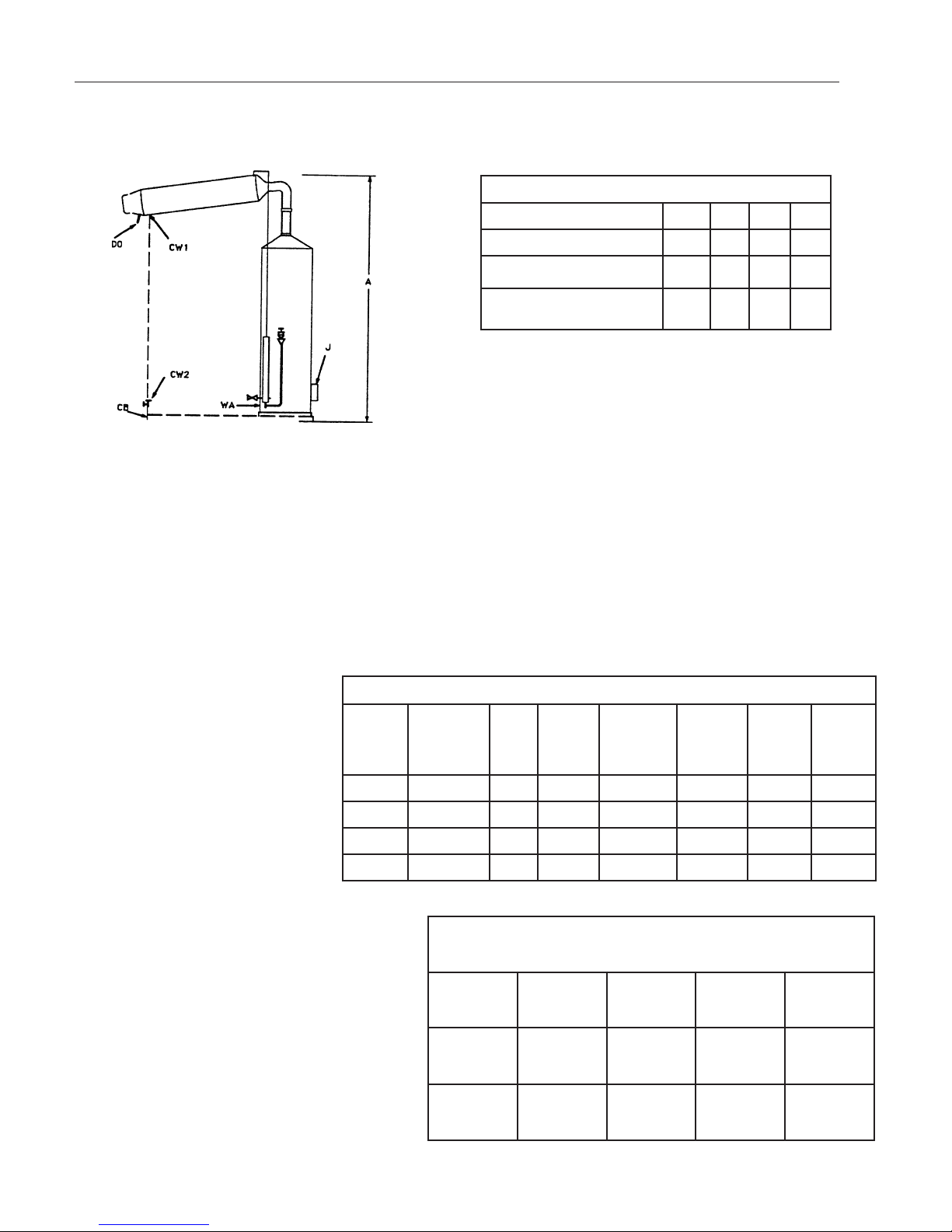

Bench Dimensions in Inches

Electric Heat

Still Cap (GPH) 1 2 5 10

Dimension A* 20 35 45 58

Dimension B 22 23 35 43

Dimension C 10 11 14 14

Figure 2

Top View

* Overall height includes enough

clearance to facilitate condenser

removal.

Note

The still is not designed to sup-

port the service piping. Ensure

that the service piping is ade-

quately supported. If no control

valves were purchased with the

still, a shutoff valve and throt-

tling valve should be installed in

the cooling water supply line,

just before the still.

10

stnemeriuqeRtaeHcirtcelE

ledoM

rebmuN

llitS

yticapaC WK

taspmA

V021

eriW2

esahP1

taspmA

V042/V021

eriW3

esahP1

taspmA

V8o2/021

eriW4

esahP3

taspmA

V042

eriW3

esahP3

taspmA

V084

eriW3

esahP3

1101AHPG16.23221ANANAN

3101AHPG26AN6271ANAN

5101AHPG531AN756333AN

6101AHPG0162ANAN376633

tnemeriuqeRerusserPtelnIdnaretaWgnilooC

llitS

yticapaC HPG1HPG2HPG5HPG01

gnilooC

retaW

tnemeriuqeR

rh/L03

HPG8

rh/L16

HPG61

rh/L151

HPG04

rh/L303

HPG08

retaWtelnI

erusserP

isp09-04

3.6-8.2

mc/gk

2

isp09-04

3.6-8.2

mc/gk

2

isp09-04

3.6-8.2

mc/gk

2

isp09-04

3.6-8.2

mc/gk

2

sehcnIniseziSeniLecivreS

)HPG(yticapaCllitS12501

ylppuSretaWgnilooC-WC4/14/14/18/3

etsaW-AW2/12/14/34/3

gnittifretawdeeftnemtaerterP

)ylnosllitstnemtaerterprof( 8/38/38/38/3

Notes

CW-1: Cooling water inlet connection 1, 2 and GPH

stills (water supply pressure - 40 to 90 psi.)

CW-2: Cooling water inlet connection on 10 GPH still

(water supply pressure - 40 to 90 psi.

CB: Channel base, supplied on 10 GPH stills.

J: Junction box for heating element connections on elec-

trically heated stills.

DO: Distillate outlet.

WA: Waste line must be atmospherically vented and

gravity flow.

Figure 3

Front View

INSTALLATION

11

Electrical Connections

Connect the electrical heating service to the still as

shown in Figure 14. The heating service terminal

board is located inside the junction box at the base

of the still. Customer must supply adequate on-off

control for electrical heating service.

Make the electrical connection to the terminal

board in the low water cutoff control cabinet as

shown in Figure 9 and in accordance with the fol-

lowing instructions:

1. Remove the low water cutoff cabinet front

panel. To remove the panel, remove the

two lower screws in the front of the cabi-

net and press firmly down at the bottom

center of the panel to free the panel from

the cabinet. The panel fits tightly in the

cabinet. Do not attempt to pry the panel

from the cabinet.

2. Connect the low water cutoff probe wires

to terminals 1 and 2 with #18 AWG strand-

ed wire. Connect the outer shield wire of

the probe to terminal #1 and the center

wire of the probe to terminal #2. Solder

and tape the connections. At the evapora-

tor both wires should protrude through the

grommet in the probe shield which is

secured in place with 2 screws over the

cutoff access hole in the evaporator cas-

ing.

3. Connect the still heat control contactor coil

to terminals 6 and 11.

4. Connect a 3-wire, 115-VAC, 60-hertz elec-

trical service to terminals 9 (AC high), 7

(AC low), and the ground screw just below

the terminal board. This electrical service

will provide control voltage for the low

INSTALLATION

12

water cutoff controls and the contactor

coil (see See Figure 9).

5. Connect the heater electrical service

to the contactor (see Figure 9). See

the still wiring diagram when connect-

ing the still heating elements to the

contactor - the heater electrical ser-

vice requirements will be indicated on

the nameplate decal at the base of the

still evaporator.

6. Install the front panel on the low water

cutoff cabinet and install the cover on

the contactor cabinet.

INSTALLATION

13

Initial Startup

The first time that the still is started, or after

cleaning, operate the still as follows:

1. Close the drain valve.

2. Open the deconcentrator valve slightly.

3. Open the cooling water inlet valve.

4. Open the cooling water throttling valve

about 1/2 turn.

5. When water begins to issue steadily

from the deconcentrator valve, turn on

the still heat supply.

6. When the still begins to produce distilled

water, close the deconcentrator valve

and adjust the cooling water throttling

valve until a puff of steam issues from

the condenser vent. Discard the first two

hours production of distillate to allow the

still to clean itself out.

7. Adjust the deconcentrator as described

below.

Initial Operation

The first time the still is operated, or after

cleaning, set the low water cutoff control

“ON/OFF” toggle switch to ON position, open the

manual drain valve and operate the still accord-

ing to the basic still operating instructions. The

lighted switch will remain lit as long as the switch

is in the ON position. The “Still On” lamp will light

when the water in the evaporator makes contact

with the probe. The still is started and stopped

with the “ON/OFF” toggle switch.

Operation

Warning

Afire hazard may result if the

still is used with a flammable liq-

uid. “Caution: Hot Surface. Avoid

Contact.”

Note

During the procedures listed

below, check all connections for

leaks and tighten as required.

Note

The cooling water inlet and

throttling valves are shown in

dotted lines. If these were not

purchased with the still, they

must be installed in the cooling

water inlet line by the customer

to ensure proper operation.

Caution

Ensure that the water level in

the evaporator is above the

heating elements before turning

on the still. The heaters are the

immersion type and will burn out

if operated in air. The water level

should be safe when water

issues steadily from the decon-

centrator valve.

Note

Ideally, the temperature of the

steam and gases escaping the

vent should be 70°C or higher.

To measure the vent

temperature, use a

thermocouple probe, such as

the Thermolyne PM20700

Digital Pyrometer, inserted into

the vent.

14

Deconcentrator Adjustment

The function of the deconcentrator is to maintain

a minimum concentration of dissolved impurities

in the evaporator, thus reducing scale formation

and tendency to foam to a minimum. The decon-

centrator is adjusted as follows:

1. Permanent Hard Water or Softened

Water (Softened feed is not

recommended). The deconcentrator

valve should be left open at all times to

bleed water from the evaporator at ap-

proximately 1-1/2 times the capacity of

the still. This valve should be left open

permanently at the required setting.

Care should be exercised to see that it

is never clogged. The valve should be

inspected periodically and if required,

disassembled and cleaned with a brush

or scraper.

2. Temporary Hard Water. If the feedwater

to the evaporator is high in temporary

hardness, i.e., high in bicarbonates, the

deconcentrator valve should be closed.

The reason for this is that bicarbonates

in solution tend to precipitate out at tem-

peratures exceeding 150°F. With the

deconcentrator valve opened, a larger

quantity of feedwater passes through the

evaporator, precipitating out

bicarbonates, increasing the amount of

scale formed. Keeping the to 150°

deconcentrator closed will result in an in-

creased concentration of solids in the

evaporator as time goes on, thus

creating a tendency to foam. This

condition is corrected by draining the still

through the drain valve at frequent

intervals.

3. Demineralized Water

When demineralized water is used as

feedwater the deconcentrator valve may

be kept closed.

OPERATION

15

Normal Operation

Starting - Start the still as follows:

1. Close the drain valve.

2. Open the deconcentrator valve slightly,

if not adjusted.

3. Open the cooling water inlet valve.

4. When water begins to issue steadily

from the deconcentrator valve, turn on

the still heat supply.

As long as the low water cutoff control “ON/OFF”

toggle switch is in the ON position, the still will

start and stop automatically, depending on the

stored distilled water distribution requirements

and the operating cycle of the interval drain timer.

To stop the still, set the low water cutoff control

“ON/OFF” toggle switch to the OFF position.

When this is done, the still will drain

automatically.

5. If necessary, adjust the cooling water

throttling valve until a puff of steam

issues from the condenser vent.

Stopping - Stop the still as follows:

1. Shut off the still heat supply.

2. Close the cooling water inlet valve.

3. Open the drain valve and let the still

drain completely.

OPERATION

Caution

Ensure that the water level in

the evaporator is above the

heating elements before turning

on the still. The heaters are the

immersion type and will burn out

if operated in air. The water level

should be safe when water

issues steadily from the decon-

centrator valve.

Note

Ideally, the temperature of the

steam and gases escaping the

vent should be 70°C or higher.

To measure the vent

temperature, use a

thermocouple probe, such as

the Thermolyne PM20700

Digital Pyrometer, inserted into

the vent.

Note

Do not change the setting of the

cooling water throttling valve

and deconcentrator valve.

16

Figure 4

Operating Controls

OPERATION

Note

Valves shown in dotted lines

must be installed by customer.

Available as optional equip-

ment.

Condenser

Vent

Distillate

Tube Cooling Water

Throttling Valve

Cooling Water

Inlet Valve

Deconcentrator

Valve

Drain Valve

Electrical Terminal

Connection Box

17

Cleaning Methods

Cleaning requirements fall into two classes, scale

removal and biological cleaning. Scale removal

may be accomplished chemically or mechanical-

ly. Biological cleaning is accomplished with an

isopropyl alcohol solution. For best results all

solutions and water should be heated. The vari-

ous methods of cleaning are described below:

Soft Scale Removal. Soft scale may be re-

moved with a stiff bristle brush. After cleaning, all

scale particles should be flushed out with water.

Hard Scale Removal. Hard scale may be re-

moved by using a 10% solution of inhibited HCI.

This acid cleaner is available commercially or

may be prepared using 20 parts water and 6

parts 30% HCI. When using the acid, do not

allow the acid to remain in contact with the part

for more than 20 minutes. Flush the part thor-

oughly after using the acid cleaner. A 5% Sodium

Bicarbonate solution may be used to remove any

acid left on the part.

Organic Scale and Sludge Removal. If the

scale has a dark brown or black color, it may be

formed from organic impurities present in the

feedwater. This type of scale may be removed

with a strong detergent solution. The detergent

solution should be allowed to be in contact with

the scale or sludge for 24 hours. Rinse off the

parts with water after cleaning.

Silica Scale Removal. Silica scale is usually

clear and shiny and hard to detect visually. It is

very hard and cannot be removed with an acid

solution. Silica scale formation can be reduced

by controlling the quality of the feedwater by rout-

ing it through a mixed bed deionizer. It is best re-

moved with a blunt instrument.

Maintenance and Servicing

Note

If desired, 10% solutions of sul-

famic or acetic acids may be

used instead of the HCI.

Sulfamic and acetic acids have

an advantage over hydrochloric

acid in that they will not corrode

the metal parts being cleaned.

Under no circumstances

should any concentrated acid

be allowed to come in contact

with tinned surfaces.

Warning

Always wear protective clothing

and eye shields when handling

acid. Disconnect from the power

supply prior to maintenance and

servicing. Refer servicing to

qualified personnel.

18

Biological Cleaning. Biological cleaning is used

on the parts that come in contact with the

distillate (such as, the distilled water side of the

condenser, or the distilled water transmission

tubing) to remove any biological contamination

from the affected part. This may be accomplished

as follows:

1. Immerse the part in an isopropyl alcohol

or a mild detergent (not containing

bleach) solution overnight. Do not rinse

the part with water after cleaning. Drain

parts before reassembly.

2. After the still is reassembled and has

operated for 30 minutes to flush, reduce

the cooling water flow rate with the cool-

ing water throttling valve until steam

issues from the condenser vent at least

12 inches. Operate the still in this

manner for 30-60 minutes. Ventilate the

room during this operation.

Disassembly for Cleaning

The frequency of cleaning will depend upon the

purity of the water being used. For example, the

evaporator should require infrequent cleaning if it

is fed partially purified water; however, the

cooling water side of the condenser will have to

be cleaned at more frequent intervals due to the

fact that raw water is flowing through it and it will

scale up sooner. The still should be inspected at

frequent intervals until cleaning intervals are

determined. Disassemble, inspect, and clean the

still as follows:

MAINTENANCE AND SERVICING

Warning

Avoid splashing the isopropyl

alcohol solution on open cuts.

Caution

Do not use chlorine bleach for

biological cleaning. The chlorine

will interact with and damage the

tinned surfaces.

19

1. Shut off and drain the still.

2. Shut off the water supply to the still.

3. Remove the condenser from the still.

Inspect the cooling water side of the

condenser for scale and clean as re-

quired. If required, clean the distilled

water side of the condenser as

described under “Biological Cleaning.”

4. Disassemble until the interior of the

evaporator is visible. The evaporator

cover, high purity chamber and pre-

heater (if supplied) may be removed

as a unit and the interior of the evapo-

rator will be visible. Inspect the interior

of the evaporator for scale. Remove

as much scale as possible manually.

5. Disassemble the drain line and clean

as required. Ensure that the drain line

is clear (including the drain opening in

the evaporator) before using detergent

or acid cleaners. Reassemble the

drain line.

6. Soft scale may be removed as

described under “Soft Scale

Removal.” Silica scale may be re-

moved as described under “Silica

Scale Removal.” To remove hard

scale or organic scale, fill the evapora-

tor with concentrated acid (see “Hard

Scale Removal”) or detergent solution

(see “Organic Scale and Sludge Re-

moval”) or detergent solution (see

“Organic Scale and Sludge Removal”)

as required.

MAINTENANCE AND SERVICING

Note

Stills equipped with a high purity

chamber or preheater should

not be cleaned with acid unless

the high purity chamber can be

removed. The fumes given off

by the acid may damage the tin

coating used in these

accessories.

20

7. Inspect the constant level device and

drain line. Clean as required.

8. If the still is equipped with a gauge

glass, remove and clean the gauge

glass cocks and gauge glass:

a. Unscrew the nuts that hold the gauge

glass in place.

b. Lift the gauge glass up into the top

gauge glass cock about 1/2 inch.

c. After the bottom of the gauge glass is

clear of the bottom gauge glass cock,

move it away from the still and

remove it from the upper gauge glass

cock.

d. Remove and clean the gauge glass

cocks and clean the gauge glass.

9. Reassemble the still. Assembly is

essentially the reverse of disassembly.

10. Connect the water, waste and distillate

lines.

11. Start the still as described under “Initial

Startup.”

12. Lower the cooling water flow rate (with

the cooling water throttling valve) until

steam spouts out of the condenser vent

at least 12 inches. Operate in this

manner for 30-60 minutes to sterilize

and clean out the still.

13. Adjust the still as described in “Initial

Operation.”

MAINTENANCE AND SERVICING

Caution

Ventilate the room during this

operation.

This manual suits for next models

3

Table of contents