Bauer Kompressoren SECCANT IV Installer manual

INSTRUCTION MANUAL

AND SPARE PARTS CATALOGUE

BAUER KOMPRESSOREN GmbH

Postfach 710260 D−81452 München Tel. 089/78049−0 Fax 089/78049167

SECCANT IV

SECCANT IV A

HIGH PRESSURE

REGENERATIVE TYPE DRYER

with B−Control Unit

Instruction Manual SECCANT IV

i

INTRODUCTION

This manual contains operating and maintenance instructions for the

high pressure regenerative dryers

All instructions should be observed and carried out in the order laid

down to prevent damage and premature wear to the equipment and

the units served by it. The company voids all warranties for malfunc-

tion and damage resulting from failing to follow these instructions.

All information and illustrations are without obligation −we reserve the

right to make changes to state of the art requirements, in improving

performance, or as required by safety or commercial restrictions.

We are happy to give you advice on any questions regarding your

BAUER unit, and help as soon as possible with any arising problems.

You can contact us Mondays to Thursdays from 0800 till 1630, Fridays

from 0800 till 1400 on phone no. (089) 78049−0.

Calling the following extensions directly will save you time and conti-

nuous dialling.

Do you want to order spare parts?

Customer service

Phone no: (089) 78049−129 or −149

Fax no: (089) 78049−101

Do you have problems with maintenance or repair work?

Technical customer service

Phone no: (089) 78049−246 or −176

Fax no: (089) 78049−101

Do you need further information regarding your unit, accessories, pri-

ces etc.?

Sales department

Phone no: (089) 78049−138, −185, −154, −205 or −202

Fax no: (089) 78049−103

Are you interested in any training courses?

Training manager

Phone no: (089) 78049−175

Fax no: (089) 78049−103

Or visit us in the internet at:

www.bauer−kompressoren.de

Edition June 2005

2005 BAUER Kompressoren GmbH, München

All rights reserved

SECCANT IV

SECCANT IV A

Instruction Manual SECCANT IV

ii

TABLE OF CONTENTS

1. GENERAL 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. FUNCTION 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INSTALLATION, OPERATION 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. INSPECTION AND MAINTENANCE 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. TROUBLE−SHOOTING 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. ANNEX 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE OF FIGURES

Fig. 1 High pressure regenerative dryer SECCANT IV 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 2 SECCANT IV, regenerative dryer design 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 3 SECCANT IV A, regenerative dryer design 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

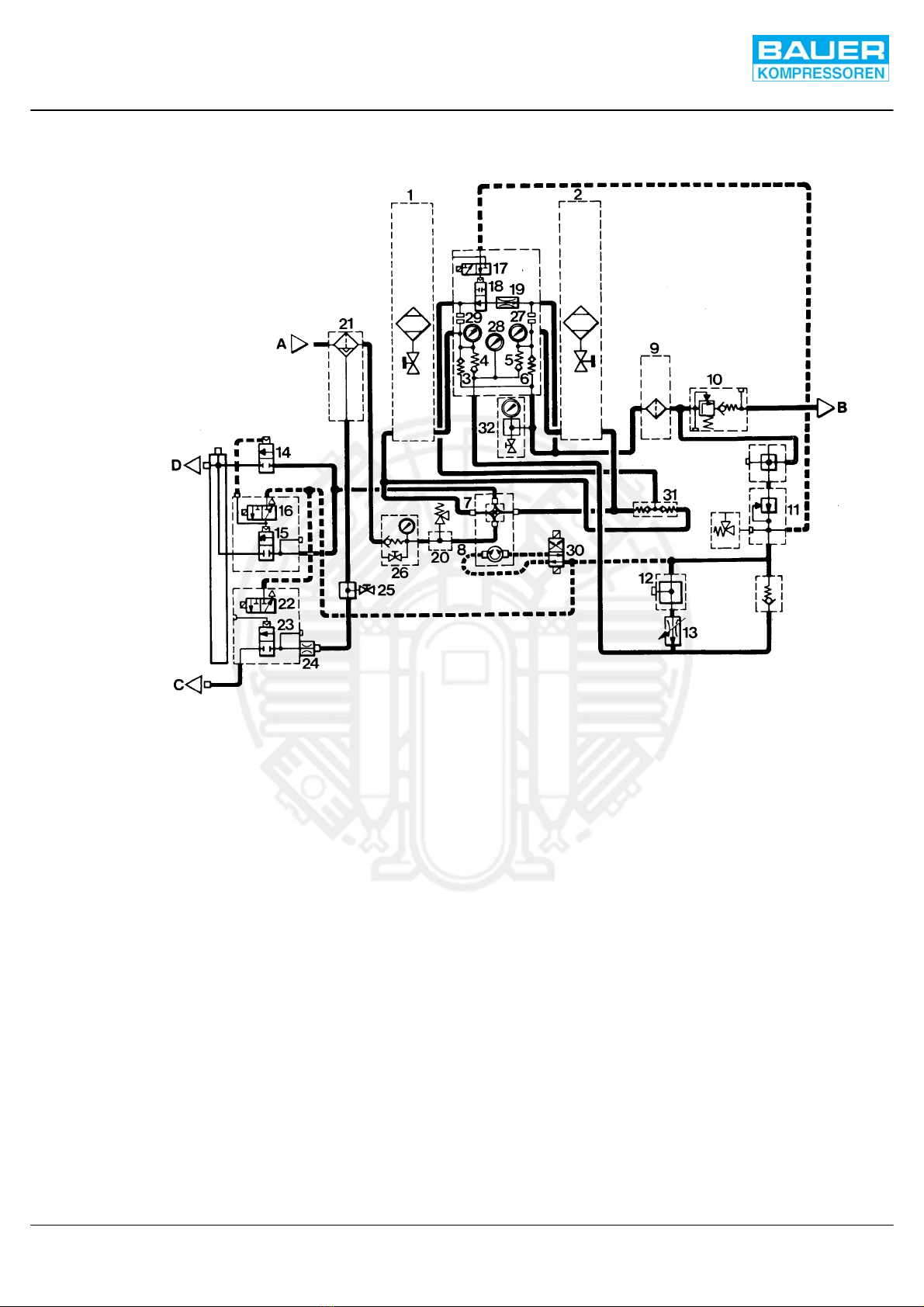

Fig. 4 Standard flow diagram, example SECCANT IV 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 5 Controls and monitors 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 6 Start page 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 7 Actual values page I 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 8 Main menu page 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 9 Maintenance menu 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 10 Operation menue 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 11 Operation modes 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 12 Filter parameters 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 13 Condensate drain valve parameters 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 14 Pressure units 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 15 Language selection 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 16 Maintenance data page 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 17 Main service data page 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 18 Dryer cartridge service data page 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 19 Activated carbon cartridge data page 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 20 Filter housing service data page 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 21 Final separator service data page 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 22 Logbook page 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 23 Logbook page 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 24 Configuration page 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 25 Sensor setting page 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 26 Sensor limits page 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 27 Filter for logbook 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 28 Control voltage transformer 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 29 Installation diagram 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 30 Cartridge change 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 31 Oil and water separator 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 32 Particle filter 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instruction Manual SECCANT IV

iii

ANNEX

Flow diagram

Seccant IV/IV−A−350 bar 76936*

Seccant IV/IV−A−420 bar 90965*

Seccant IV/IV−AH−350 bar (helium version) 82727−01 + 82727−02*

Drawing of regenerative dryer

Plan de construction SECCANT IV/IV A 81983

Plan de construction SECCANT IV/IV A−420 bar 82828

Schematic diagrams:

100 −127 V 82948*

220 −240 V 82949*

Applicable parts list: Code

SECCANT IV, SECCANT IV A (air) G25

SECCANT IV, SECCANT IV A (gas) G29

Change notice

Change No. Change date

1. Basic edition July 1996

2. January 2003

3. August 2004

4. June 2005

*) or according to order

Instruction Manual SECCANT IV

iv

Instruction Manual SECCANT IV

1

1. GENERAL

APPLICATION AND SHORT DESCRIPTION

The regenerative dryers of the SECCANT series are used for

automatic drying of compressed air and non−explosive gases.

A significant feature of this series is the simultaneous occur-

rence of drying phase and regeneration phase during one oper-

ating cycle: as one filter dries the compressed medium, the

other is being regenerated. This ensures continuous and effec-

tive operation.

To avoid excessive wear of the filter fillings, the SECCANT dry-

ers are equipped with a pressure compensation system which

ensures a slow and gentle pressurization when switching from

regeneration phase (low pressure) to drying phase (high pres-

sure).

Regenerative dryers which are used for drying gases, are

equipped with a gas feed−back system which leads the regen-

eration and the control gas back to the compressor intake (see

flow diagram in the annex).

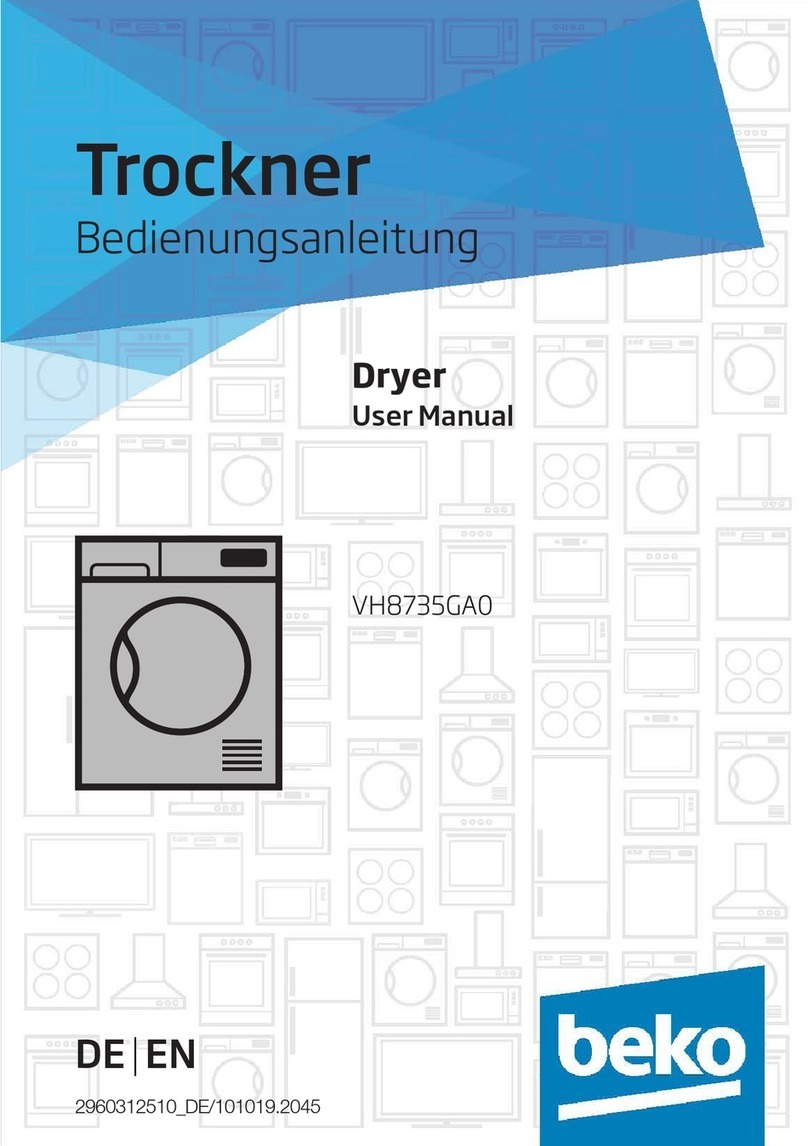

Fig. 1 High pressure regenerative dryer SECCANT IV

Instruction Manual SECCANT IV

2

DESIGN

For all mentioned parts and numbers refer to dryer design SEC-

CANT IV, Fig. 2 and SECCANT IV A, Fig. 3.

The regenerative dryer consists of two filters (1 and 2), which

are equipped with replaceable cartridges. The cartridges are

filled with a highly porous dehydrating agent (molecular sieve).

Upstream of the drying and regenerating system, an oil and wa-

ter separator (23) should be mounted. It absorbs any fluid oil

and water particles out of the pressurized air or gas from the

compressor. Safety valve (25) protects the pressure system

from excessive pressure.

The non−return valve with gauge and venting valve (22) which

is situated downstream from the oil and water separator pre-

vents the dried medium from flowing back to the separator when

draining condensate.

For breathing air processing, a final purifier (27, Fig. 3) should

be placed downstream of the drying and regenerating filters. It

is equipped with a filter cartridge with activated charcoal which

removes residual oil vapours and makes the air tasteless and

odourless as required for breathing air quality. The final purifier

can also be installed in industrial air or gas dryers if air or gas

of the purest quality is required.

A discharge valve with pressure gauge (28) is placed down-

stream of the valve block.

4

5

6

7

1 Drying filter

2 Drying filter

3 Control unit

4 3/2−way solenoid valve, pressure comp.

5 Pressure compensation valve

6 Pressure gauge, regeneration pressure

7 Pressure gauge, operating pressure

8 Pressure maintaining/non−return valve

9 Air/gas outlet

10 Regulating valve

11 Safety valve, 14 bar

12 Pressure reducer

13 4/2−way solenoid valve,

drying/regeneration phase

14 Switch−over valve,

drying/regeneration phase

15 Pneumatic actuator

16 3/2−way solenoid valve, shut−off

17 Shut−off valve

18 Control/regeneration air/gas outlet

19 Air/gas inlet

20 Condensate drain valve

21 3/2−way solenoid valve, condensate drain

22 Non−return valve with pressure gauge

and venting valve

23 Oil and water separator

24 Particle filter

25 Safety valve, final pressure

26 Feed back manifold (only gas models)

27 Manual condensate drain tap

28 Discharge valve with pressure gauge

Fig. 2 SECCANT IV, regenerative dryer designa)

a) to ensure clarity, piping is not shown

Instruction Manual SECCANT IV

3

4

5

6

7

1 Drying filter

2 Drying filter

3 Control unit

4 3/2−way solenoid valve, pressure comp.

5 Pressure compensation valve

6 Pressure gauge, regeneration pressure

7 Pressure gauge, operating pressure

8 Pressure maintaining/non−return valve

9 Air/gas outlet

10 Regulating valve

11 Safety valve, 14 bar

12 Pressure reducer

13 4/2−way solenoid valve,

drying/regeneration phase

14 Switch−over valve,

drying/regeneration phase

15 Pneumatic actuator

16 3/2−way solenoid valve, shut−off

17 Shut−off valve

18 Control/regeneration air/gas outlet

19 Air/gas inlet

20 Condensate drain valve

21 3/2−way solenoid valve, condensate drain

22 Non−return valve with pressure gauge

and venting valve

23 Oil and water separator

24 Particle filter

25 Safety valve, final pressure

26 Feed back manifold

27 Final purifier

28 Discharge valve with pressure gauge

29 Manual condensate drain tap

Fig. 3 SECCANT IV A, regenerative dryer designa)

Particle filter (24) is placed downstream of the drying and regen-

erating filters/the final purifier. After the filters, a pressure re-

ducer (12) is connected into the line. It provides the air or gas

that is needed to control the regenerating and switch−over pro-

cedures, the pressure compensation and the automatic con-

densate drain.

After the pressure reducer, within the regeneration circuit, a

safety valve (11) and a regulating valve (10) are situated. The

regulating valve regulates the amount of regenerative air or gas

supplied according to its setting.

The regeneration dryer is also equipped with a switch−over

valve (14), controlled by solenoid valve (13) and pneumatic ac-

tuator (15), which switches to and from the regenerating and

drying process.

Pressure compensation valve (5), controlled by solenoid valve

(4) makes sure that before switching over from regenerating to

drying phase, a compensation of pressure takes place in the re-

generating filter.

The operating pressure is indicated by pressure gauge (7).

The regenerating pressure is indicated by pressure gauge (6).

A combined pressure maintaining/non−return valve (8) is

placed at the gas and/or air outlet (9) of the regenerative dryer,

which keeps the pressure at the set minimum.

a) to ensure clarity, piping is not shown

Instruction Manual SECCANT IV

4

TECHNICAL DATA

Operating pressure, max. (Setting pressure of safety valve) 90 −350 bar (2,175 −5,000 psi)

Flow rate at 200 bar 1500−3500 l/min. (53 −124 c.f.m.)

Regeneration volume related to 1 bar absolute (equiv. to 5% of delivery) 75 −175 l/min. (2.65 −6.6.2 c.f.m.)

Intake temperature, max. +50 C (122 F)

Intake temperature, min. + 5 C (41 F)

Ambient temperature + 5 C...+ 40 C (41 F ...113 F)

Pneumatic intake and outlet connections, tube diameter 12 mm

Power consumption 0.02 kWh

Pressure dew point of dried medium −20 C (−4 F)

Length (mm) 1545

height (mm) 1285

Width(mm) 260

Operating voltages 24 VAC, 50/60 Hz

100 VAC, 50/60 Hz

110 VAC, 50/60 Hz

115 VAC, 50/60 Hz

120 VAC, 50/60 Hz

127 VAC, 50/60 Hz

220 VAC, 50/60 Hz

230 VAC, 50/60 Hz

240 VAC, 50/60 Hz

250 VAC, 50/60 Hz

3800 VAC, 50/60 Hz

400 VAC, 50/60 Hz

415 VAC, 50/60 Hz

440 VAC, 50/60 Hz

Subject to change without prior notice

Instruction Manual SECCANT IV

5

2. FUNCTION

The following position numbers refer to stan-

dard air flow diagram SECCANT IV, Fig. 4. For

detailed information, also see air flow dia-

gram corresponding to your dryer type in the

annex.

DRYING CIRCUIT

Both filters of the dryer (1 and 2) are passed through alternately

by humid, compressed medium applied from the compressor,

and by already dried, expanded medium for regeneration.

Non−return valves (3 and 4) are built into the drying circuit and

non−return valves (5 and 6) are built into the regeneration cir-

cuit. They prevent the medium from flowing back into the filters

as well as overstream of high pressure medium into the depres-

surized filter which is in the regeneration process.

The humid medium coming from the compressor flows through

4−way switch−over valve (7) to drying filter (1). The switch−over

valve is operated by pneumatic actuator (8). The desiccant con-

tained in the dryer cartridge absorbs the humidity from the com-

pressed medium.

Non−return valve (4) prevents the air from flowing over to the

depressurized regeneration filter.

Through non−return valve (3), discharge valve with pressure

gauge (28), particle filter (9) and pressure maintaining/non−re-

turn valve (10) the compressed, and now dry and clean medium

flows to the consuming devices.

The dryer operating pressure is indicated at pressure gauge

(29).

The drying phase is coupled to the operation of the compressor.

When shutting off the compressor, 3/2−way solenoid valve (16)

closes, so do the shut−off valves (14) and (15). The SECCANT

unit is then hermetically sealed to prevent loading of the car-

tridge with ambient humidity. On restarting the compressor the

drying phase will be reassumed where it was interrupted and

will continue until the process is switched over by the timer.

REGENERATION CIRCUIT

Drying phase and regenerating phase occur simultaneously

during one cycle, i. e. while the drying phase is taking place in

filter (1), as shown in flow diagram Fig. 4, the regeneration

phase is taking place in filter (2). For that purpose a small

amount of the compressed and dried medium is deviated after

particle filter (9) and expanded by pressure reducer (11) to

approx. 10 bar (145 psi). This pressure is monitored by safety

valve (12).

Through regulating valve (13) and non−return valve (5) the re-

generative medium flows to filter (2). The desiccant moisturized

during the previous drying phase transfers the humidity to the

dry, depressurized medium, and will thus be regenerated.

The flow rate of the regenerative medium depends on the ad-

justment of regulating valve (13). It is set at the required value

in the factory. Should the setting have been changed for some

reason, the regeneration air or gas flow must be re−adjusted by

our technical service. For the flow rate refer to Technical Data

in chapter 2.

Non−return valve (6) prevents high pressure air or gas coming

from drying filter from entering the regeneration circuit. Pres-

sure gauge (27) indicates the pressure in the regenerated filter.

After the regeneration medium has dried the cartridge, it passes

through 4−way change−over valve (7), and shut−off valves (14)

and (15) into the open air or to the compressor intake.

PESSURE COMPENSATION

Regeneration is performed at atmospheric pressure. When

switching from regeneration to drying phase, abruptly loading

the filter with the highly compressed medium coming from the

compressor at up to 350 bar (5,000 psi) must be avoided. This

would cause excessive wear or even destruction of the molecu-

lar sieve filter filling and the cartridge. For this reason, the dryer

is equipped with a pressure compensation system.

At the end of the regeneration phase, i.e. every 15 minutes,

pressure compensation valve (18) opens by applied control air

from 3/2−way solenoid valve (17). At the same time, shut−off

valves (14) and (15) receive control medium from 3/2−way sole-

noid valve (16) and close to avoid regenerative medium from

escaping into the open air/to the compressor intake.

A certain quantity of the medium, which is determined by nozzle

(19), now flows over non−return valve (31) into the regenerated

filter until the pressure inside the two filters is compensated. Af-

ter 80 seconds, pressure compensation valve (18) closes

again, a 3/2−way solenoid valve (16) opens shut−off valves

(14) and (15). Switch−over by valve (7) can now take place.

SWITCH−OVER

After a predetermined time interval, e.g. 15 minutes, 4−way

switch−over valve (7) changes state. The compressed medium

produced by the compressor unit will now be dried in dryer cylin-

der (2, previously regenerated) while the regeneration of the de-

hydrating agent takes place in cylinder (1, previously loaded

with moisture by drying). Cycle switching, i. e. status change of

4−way switch−over valve (7), is performed automatically by

4/2−way solenoid valve (30) activating pneumatic actuator (8).

Pressure gauge (27) now monitors the operating pressure.

CONDENSATE DRAIN

The condensate resulting from the cooling of the compressed

medium is drained automatically. Every 15 minutes, 3/2 way so-

lenoid valve (22) applies control pressure to condensate drain

valve (23) and the condensate is purged via condensate drain

valve (23) and nozzle (24). The condensate can also be drained

manually using tap (25) which is used to check the function of

the automatic drain device. Refer to maintenance procedures

in chapter 6.

Non−return valve with pressure gauge and venting valve (26)

prevents already dried air/gas from flowing back to the separa-

tor when the condensate is drained.

CAUTION

Disposal of condensate according to applicable lo-

cal regulations; (in Germany: special waste dispo-

sal no. 54405).

Instruction Manual SECCANT IV

6

PNEUMATIC CONTROL

The air or gas needed to regenerate the filter and to control the

pressure compensation, the switch−over and the condensate

drain, is regulated by pressure reducer (11). The pressure is

approx. 10 bar.

Regeneration

The air or gas needed for regeneration flows through regulating

valve (13) and non−return valve (5) into the regenerating filter

where it absorbs the humidity in the drying agent. Then it flows

through switch−over valve (7) and open shut−off valves (14)

and (15) into the open air or to the compressor intake (optional

for gas compressors). The shut−off valves are controlled pneu-

matically by the 3/2 way solenoid valve (16).

Pressure compensation

Every 15 minutes, 3/2−way solenoid valves (17, n.o.) and (16,

n.c.) are activated for approx. 80 seconds: solenoid valve (17)

receives an electrical impulse, closes and interrupts the flow of

control medium to pressure compensation valve (18), which

opens then. Solenoid valve (16) receives no electrical im-

pulses, closes and interrupts the flow of control medium to

shut−off valves (14) and (15) which also close.

Switch−over

Immediately after pressure compensation, 4/2−way solenoid

valve (30) receives an electrical impulse and opens.

Depending on the position of the 4/2−way solenoid valve, the

control air or gas flows either to the right or to the left chamber

of pneumatic actuator (8). The chamber is put under pressure

and so switch−over valve (7) is actuated.

Condensate drain

Every 15 minutes 3/2−way solenoid valve of automatic conden-

sate drain (22) receives an electrical impulse and opens. The

control medium now flows to condensate drain valve (23),

which also opens.

When drying gas, the control medium flows from solenoid

valves (16), (17), (22) and (30) to the intake tube of the com-

pressor.

Instruction Manual SECCANT IV

7

FLOW DIAGRAM

A= Inlet

B= Outlet

C= Condensate outlet

D= Regeneration outlet

Fig. 4 Standard flow diagram, example SECCANT IV

1 High pressure filter

2 High pressure filter

3 Non−return valve

4 Non−return valve

5 Non−return valve

6 Non−return valve

7 Switch−over valve

8 Pneumatic actuator

9 Particle filter

10 Pressure maintaining/non−return valve

11 Pressure reducer

12 Safety valve 14 bar, control pressure

13 Regulating valve

14 Shut−off valve

15 Shut−off valve

16 3/2−way solenoid valve for shut−off valves

17 3/2−way solenoid valve for pressure compensation

18 Pressure compensation valve

19 Nozzle

20 Safety valve, final pressure

21 Oil and water separatorb)

22 3/2−way solenoid valve

23 Condensate drain valve

24 Nozzle

25 Manual drain tap

26 Non−return valve with pressure gauge

and venting valve

27 Pressure gauge, operating pressure

28 Pressure gauge, regenerating pressure

29 Pressure gauge, operating pressure

30 4/2−way solenoid valve

31 Non−return valve

32 Discharge valve with pressure gauge

b) Optional extra

Instruction Manual SECCANT IV

8

B−CONTROL UNIT

GENERAL

BAUER B−CONTROL is a free−programmable electronic

compressor control system with a modern display. The control

system is specially designed for BAUER units, and can be set

and configured for all BAUER models.

HARDWARE AND CONNECTIONS

For reference to the hardware and connections refer to the

respective schematic diagram in the annex.

−Power supply for the unit is connected to terminal strip

X0/F1, 1 and PE. According to the supply voltage, the power

is connected to the respective connection at transformer

T1.

−Collective warning signal from the SECCANT dryer to a

max. number of 3 compressors is at terminals X0/2 to X0/7.

−Operating status signal from a max. number of 3 compres-

sors to the SECCANT dryer is from terminals X0/9 to X0/14.

CONFIGURATION DATA

The configuration of the software with respect to the hardware

is performed in the configuration file. This file is automatically

generated at factory start−up, and normally does not need any

further modification. If a change should become necessary due

to modifications on the unit, please contact the BAUER

after−sales service dept.

CONTROL AND MONITORING ELEMENTS

The control and monitoring panel features a display, 2 indicating

lamps (LED’s), as well as 10 soft touch keys to control the

compressor and the display.

The function of the control keys is as follows:

OShuts the compressor off. On a higher menu level,

returns you to the main menu.

IStarts the compressor, provided there are no failure

messages present or maintenance work due. On a

higher menu level, returns you to the main menu.

Moves the cursor up. If already in the top line, jumps

to the bottom line.

Moves the cursor down. If already in the bottom line,

jumps to the top line.

Decreases a selected value. Press and hold will

decrease the value increasingly faster.

Increases a selected value. Press and hold will

increase the value increasingly faster.

menu change to the next page of the same menu level

enter accept the new value and refresh page

reset change to next higher menu level without storing the

changed values.

code combination key to start initialization routines

(setting “restore defaults” in combination with reset

key).

General notes on the use of the keys

Please do not be impatient. Allow some seconds for the

windows to build up, the time will depend on the amount of

information. In the meantime, please do not press any keys,

even if you know how to proceed.

The red and yellow LED’s next to the display indicate fault and

warning messages. The details for the message are shown on

the display. The red LED indicates a compressor failure, and the

unit will be shut down automatically. The yellow LED indicates

a warning, e.g. imminent maintenance work, the compressor

will not be shut down.

For new faults or warnings the respective LED will flash quickly

until the message is acknowledged with the “reset” key. If the

message is still present after pressing the reset key, the LED will

change to slow flashing, and would extinguish if the cause of the

message would not be present any more. After that, the

compressor can be switched on again.

Fig. 5 Controls and monitors

1

23

4

5

6

7

8

9

1 Alarm indicator (Shut−off)

2 Warning indicator

3 8 line, 21 char. display

4ON−key with indicator

5 OFF key with indicator

6 Code key

7 Reset key

8 Enter key

9 Cursor keys with menu key in the centre

Fig. 6 Start page

S E C C A N T

F1: flush

F2: activ

---TIMER OPERATION---

Dewpointsensor -31 °C

Operation-h 6893 h

Fig. 7 Actual values page I

** ACTUAL VALUES I **

rem. time: 15 min

dew point: -32 °C

securus: ok

Contr.pres: -1 bar

--- bar

DIN start:

CAN start: OFF

Fig. 8 Main menu page

**** MAIN MENU ****

OPERATION . . . . . . . . . . .

MAINTENANCE . . . . . . . . . .

CONFIGURATION . . . . . . . . .

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

AB4321-9876 [S1.00.G]

Fig. 9 Maintenance menu

**** MAINTENANCE ****

Main service ok

Dryer cartridge ok

Act. carbon cart. ok

Filter housing ok

Final separator ok

Logbook 20 R

[2368 h]

Instruction Manual SECCANT IV

9

MENU AND NAVIGATION

The 8−line, 21−digit display contains all the important

information on the present condition of your BAUER unit.

Normally, the start page is displayed which shows the most

important general data in a very clear presentation. This way

you can find out the actual unit status.

According to the operating requirements the menu is split into

four levels:

Level 0: Main page and survey

Level 1: Operation level

Level 2: Maintenance level

Level 3: Configuration level

Each menu level again consists of several windows or pages

which can be paged through comfortably, finally leading back

to the start page (roundabout system). In all higher levels

consisting of a larger number of pages, direct access to the

desired pages from the select menu is possible.

Due to different access codes, changing between operation,

maintenance, and config levels is allowed only from the main

menu. Within one level, you have free movement without being

asked for an access code again. If a higher level has been

accessed by entering the required code, the yellow LED will

start flashing slowly to indicate that you are staying in a

protected area.

The following describes the pages in each level.

LEVEL 0: START PAGE AND SURVEYS

This level consists of four windows or pages giving a quick

survey on the status of your BAUER unit. At unit start, and also

when a signal is received the following page will be displayed

showing the most important data at a glance.

By pressing the menu key repeatedly, the following three pages

of this level are displayed in the order shown below.

By each pressing of the reset key the respective previous page

will be shown, until finally the main page is reached again.

At the bottom of the main menu page you find the data important

and required by the BAUER service dept. At the left you find the

serial no. of the unit unit, at the right in brackets the installed

software version.

From the maintenance page pressing the menu key will get you

back to the start page, pressing the reset key takes you back

to the Main Menu page.

HIGHER MENU LEVEL BRANCHING AND CODE REQUEST

In order to divert into the next higher menu level you have to

select the Main Menu page (Fig. 8). Select the desired level

using the and keys and press enter key.

Before you can select pages at this level, you are requested to

enter the access code. There are different codes for each level

which cannot be overridden.

As long as the unit is operating, access to the adjustments of the

maintenance and configuration levels is disabled. A respective

note will show up in the code window and the display will

automatically change back to the main menu page.

Different from the legend to Fig. 5 the cursor (i.e. the highlighted

figure) will move to the left or right using the or key,

respectively. With the and keys the highlighted value

can be increased or decreased by one. By finishing the code

input with the enter key, you will get access to the selected level.

If a wrong code should have been entered, a respective note

will be displayed, then the menu returns automatically to the

Fig. 10 Operation menue

***** OPERATION *****

Operation modes

Filter parameters

Cond.valve parameters

Pressure units

Language selection

Fig. 11 Operation modes

* OPERATION MODES *

Automatic >time

test sequence no

manual change no

Instruction Manual SECCANT IV

10

main menu. A new entry may be tried now. The number of

attempts is not limited.

With higher priority (level) codes you will automatically get

access to all lower priority levels, also, e.g. with the code for the

configuration level you will have access to all levels, whereas

with the operation code you would have access to the operation

level, only.

After entry of the correct access code the diplay changes to the

selected menu level.

OPERATION LEVEL

Entering the operation level, a survey menu will be opened at

first (Fig. 10).

The desired parameter can be selected with the and

keys. By pressing the enter key the selected adjustment page

will be shown. As an alternative, after having selected a menu

point, you may browse through the rest of the pages with the

menu key.

Operation mode

On the Operation modes page (Fig. 11) you can select between

diffferent operation modes:

Time operation mode

Test sequence

Manual change

Time operation mode

When the operation mode is set to time, the filter change−over

is controlled by the filter parameters setting for

filter/regeneration time, see Fig. 12.

Test sequence

When set to yes, a complete test cycle of the regeneration

dryer will be started, inclunding automatic condensate drain, for

test purposes.

Manual change

When set to yes, filters will be changed over from filtering to

regeneration and vice versa.

Fig. 12 Filter parameters

**** PARAMETERS ****

filter / regeneration

intervall 15 min

balance 40 sec

Fig. 13 Condensate drain valve parameters

* PARAMETERS *

* LANGUAGESELECTION *

German (D)

English (GB)

French (F)

Spanish (E)

Italian (I)

Swedish (S)

Dutch (NL)

**** PRESSURE UNITS ****

Megapascal (MPa)

Bar relativ (bar)

Pounds per sq. in. (psi)

Psi relativ (psig)

Cond.valve num. 1:

normal open

Intervall 15 min

Blowtime 6 sec

Fig. 14 Pressure units

Fig. 15 Language selection

Instruction Manual SECCANT IV

11

Filter parameters

Fiter regeneration

This parameter sets the time periods for filter change−over, and

pressure balance. The factory setting is 15 minutes and 40

seconds.

Condensate drain valve parameters

Pushing the menu key again will lead you to the adjustment of

the 1st condensate drain valve.

Consecutive pressing then leads to the adjustment of the other

condensate drain valves, if provided.

Pressure units

Pushing the menu key again or by directly selecting in the

operation menu will lead you to the pressure units page.

With the and keys and the enter key you can select

between the different pressure units.

If you are still using bar or psi units please

note that MPa is the only internationally valid

pressure unit !

Language selection

Pushing the menu key again or by directly selecting in the

operation menu will lead you to the language selection page.

With the and keys and the enter key you can select

between the different languages.

Fig. 16 Maintenance data page

**** MAINTENANCE ****

Main service ok

Dryer cartridge ok

Act. carbon cart. ok

Filter housing ok

Final separator ok

Logbook 20 R

[2368 h]

Fig. 17 Main service data page

* MAINTENANCE-INTVL.*

Main service

Actual runtime:

2345 h

Target runtime

4000 h

Reset > no

Fig. 18 Dryer cartridge service data page

* MAINTENANCE-INTVL.*

Dryer cartridge

Actual runtime:

812 h

Target runtime

1000 h

Reset > no

Fig. 19 Activated carbon cartridge data page

* MAINTENANCE-INTVL.*

Act. carbon cartr.

Actual runtime:

812 h

Target runtime

1000 h

Reset > no

Instruction Manual SECCANT IV

12

MAINTENANCE LEVEL

The maintenance level is accessible after prompting the correct

access code. At first you will come upon the maintenance data

window:

The difference now is that there will be a cursor which enables

you to jump to additional pages.

For the maintenance data of the first five criteria a similiar

window will appear where you can see the expired operating

time since the last service, and also the allowed interval time in

between two services. As soon as the actual time period

reaches 90 % of the max. allowed time, the status indication

changes from”ok” to “warn” to point out that a service will be due

in forseeable time.

If still no service should be accomplished, indication would then

change to “crit”, when the unit reaches 100% of the allowed

operationg hours.

Always keep an eye on the maintenance interval display and

service your unit in time! This will not only extend the lifetime of

your BAUER unit significantly, but also save you expensive

repairs at the most unfavourable point of time.

When the necessary service has been done, then quit the reset

by selecting “yes” on the lower right hand side of the display by

pressing the or key and confirm with the enter key. This

step is not reversible!

Fig. 20 Filter housing service data page

* MAINTENANCE-INTVL.*

Filter housing

Actual runtime:

784 x10 Cycl

Target runtime

2000 x10 Cycl

Reset > no

Fig. 21 Final separator service data page

* MAINTENANCE-INTVL.*

Final separator

Actual runtime:

2437 x10 cycles

Target runtime

8500 x10 cycles

Reset > no

Fig. 22 Logbook page

****** LOGBOOK ******

Display

Print

Fig. 23 Logbook page

****** LOGBOOK ******

Number: 1

Oper.h.: 12

Oper.min.: 24

Operhour 10

- - - - Oper. message:- - - - -

Securus saturated

check filter

Instruction Manual SECCANT IV

13

By consecutively pressing the menu key, you can browse

through the different maintenance pages.

Direct selection from the maintenance menu is also possible.

Finally you will get to the logbook page:

Logbook page:

After selection of the menu point “Display” a second window will

be opened showing the entries in the logbook. An example is

shown in Fig. 23., provided there are entries at all.

The latest (newest) message is shown as entry no. 1. If this is

an error message, it will be shown in bold letters and with two

digits, if it is an operation message, it will be in one line with the

respective headline.

Using the −und −buttons, the different entries can be

selected.

The print function is not activated for customer’s use. It allows

the logbook to be printed at BAUER service dept. with a special

service printer.

Fig. 24 Configuration page

*** CONFIGURATION ***

Sensor setting . . . . . . #

Sensor limits . . . . . . .#

Filter for logbook . . . . #

Fig. 25 Sensor setting page

*** SENSOR SETTING ***

Sens.press.res.

Raw value -1 bar

* factor 1000 %

+ offset 0 bar

= act. value -1 bar

Fig. 26 Sensor limits page

*** SENSOR LIMITS ***

Sens.cont.press

Shut-off >> 370 bar

Warning > --- bar

- - - - - - - - - - - - - - - - - -

Warning < --- bar

Shut-off << -15 bar

Fig. 27 Filter for logbook

FILTER FOR LOGBOOK

Msg. Number:

Unit running

Enable? no

Instruction Manual SECCANT IV

14

CONFIGURATION LEVEL

The configuration level allows basic adjustments to be

changed. Because of the possibility to change also values

concerning the warning and safety adjustments, this level is

accessible only with a special code.

The following menu pages can then be selected.

Sensor setting

The sensor calibration is performed in the same way for all six

possible sensors. Under “actual value” the present,

uncorrected raw value is displayed. With “offset” the sensor

characteristic can be shifted up or down, with “factor” the slope

of the characteristic can be changed. With all BAUER sensors,

this should be necessary in very special applications, only.

For both adjustments a reference instrument to measure the

actual value is necessary. By changing the “offset” and “factor”

values with the or keys you can adapt the calculated

characteristics to your specific requirements. The resulting,

corrected actual value will be displayed in the 4th line. Only this

value will be shown in all the other windows.

Sensor limits

The sensor limits adjustment is performed in the same way for

all six possible sensors.

Four values can be adjusted for each sensor.

The following table shows which values are actually processed

for each sensor. Adjustment is performed as usual by selecting

the value which you want to change with the and keys

and increasing or decreasing the values with the and

keys. After all values have been changed as desired, press the

enter key to accept and store the new values. Now this new

values are active throughout the program.

Please note that the limit values can only be adjusted in “bar”

regardless of the pressure units you have selected for being

displayed.

Filter for logbook

The filter for the logbook is defined as follows: with the −and

−keys the respective message is selected. Pressing the

−or −keys sets the message or error to be recorded or not.

On “Enable?” “yes” the message will be recorded. On “no” it will

not be recorded.

This manual suits for next models

1

Table of contents

Popular Dryer manuals by other brands

Miele

Miele Novotronic T 1520 operating manual

Frigidaire

Frigidaire FER641FS - 27" Electric Dryer owner's guide

Menuett

Menuett 001-641 operating instructions

AEG

AEG Lavatherm 720 operating instructions

Fisher & Paykel

Fisher & Paykel DE09 Use and installation guide

Bobrick

Bobrick B-700 installation instructions