© 2018 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 2/53

qSCALE maestro (PLC v01.00.00) Operators Manual / Issue H (HMI v1.0.0) 01/2018 / rbm.

TABLE OF CONTENTS

1Safety Instructions...........................................................................................6

1.1EC Conformity Declaration........................................................................6

2Product Description.........................................................................................7

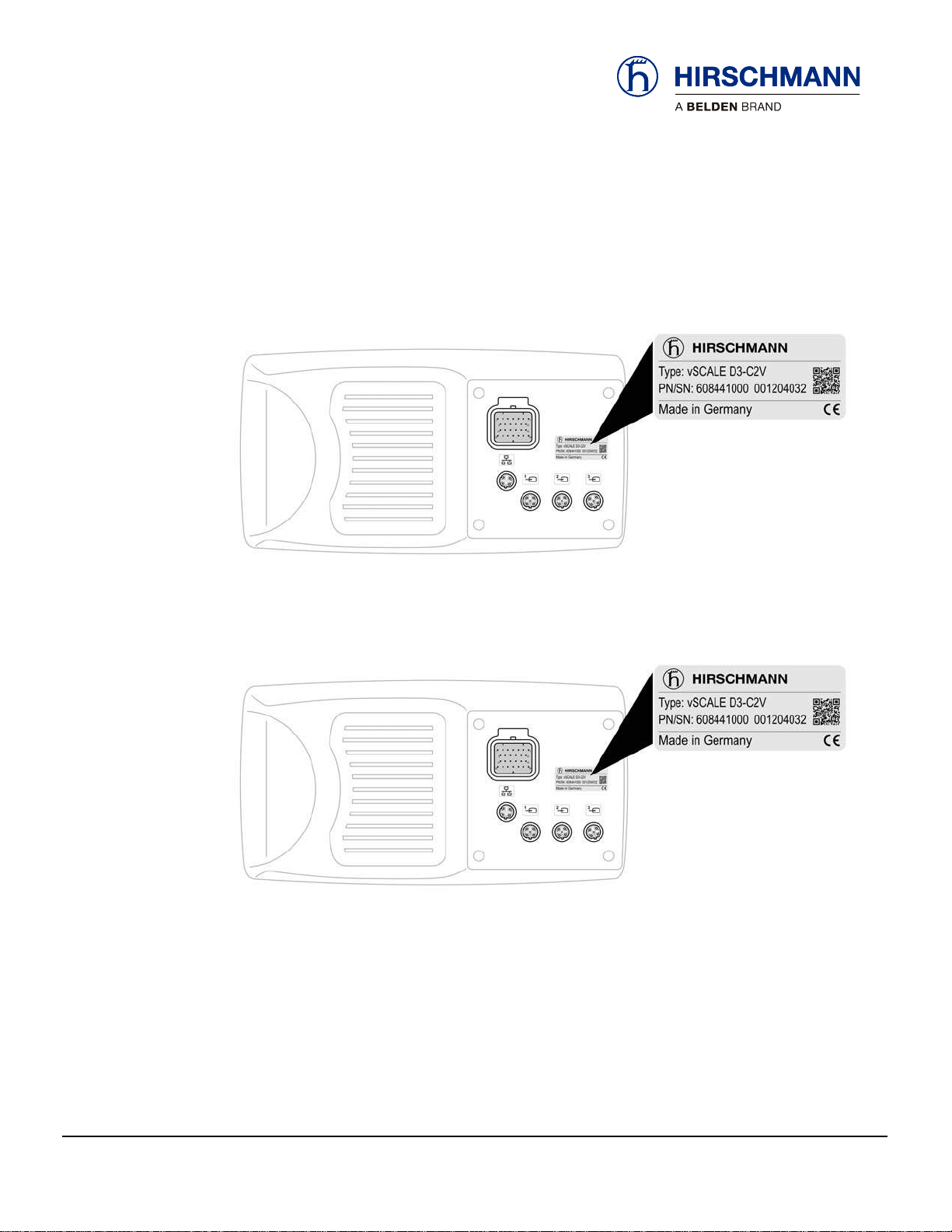

2.1Product Identification.................................................................................8

2.2Overview of Console Elements..................................................................9

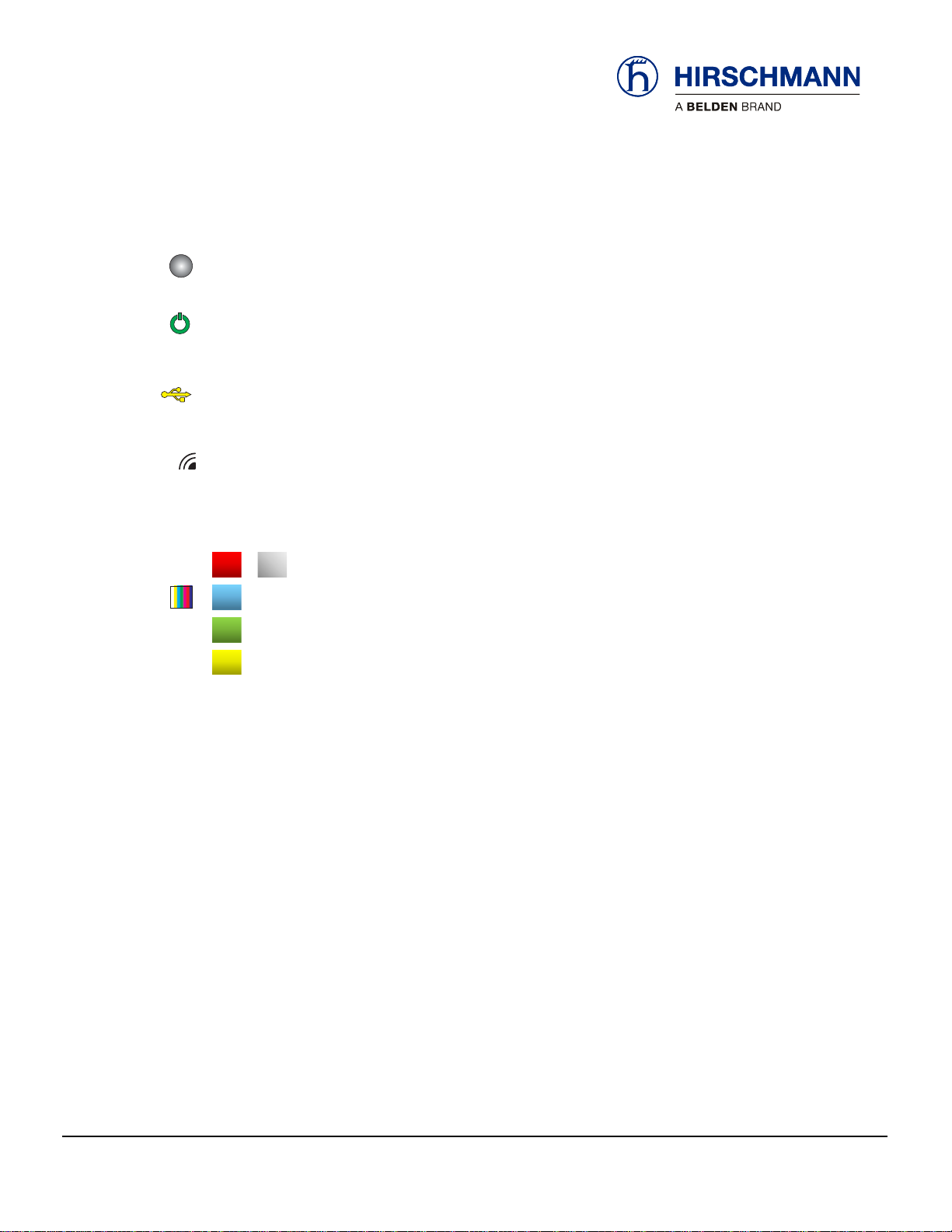

2.3Overview Feedback Elements.................................................................10

3Operating Mode Selection.............................................................................11

3.1Switching Device On and Off...................................................................11

3.2Setting the Operation Mode.....................................................................13

4Operation.........................................................................................................16

4.1Main Working Screen ..............................................................................17

4.1.1Warning Lights / Audible Alarm ...........................................................18

4.2Work Area Limitations..............................................................................19

4.2.1Height Monitoring.................................................................................21

4.2.2Radius Monitoring................................................................................22

4.2.3Boom Angle Monitoring .......................................................................23

4.2.4Wind Speed Monitoring .......................................................................24

4.3Tare Weight .............................................................................................26

4.4Switching Off Audible Alarm....................................................................26

4.5Error Events.............................................................................................27

4.6Camera....................................................................................................28

5Service and Maintenance ..............................................................................29

5.1Settings Menu..........................................................................................29

5.2Machine Information ................................................................................30

5.2.1System Version Information.................................................................30

5.2.2Status of Digital Outputs......................................................................31

5.2.3Status of Digital Inputs.........................................................................32

5.2.4Readings of Analog Sensors...............................................................33

5.3User Screen.............................................................................................34

5.3.1LCD Brightness....................................................................................35

5.3.2Key Brightness.....................................................................................36

5.3.3Unit Selection.......................................................................................37

5.4Sensor Calibration ...................................................................................38