Benezan Electronics Beamicon2Basic User manual

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 1

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

Installation manual for Beamicon2Basic

and the MDLCNC driver from Letmathe

Foreword

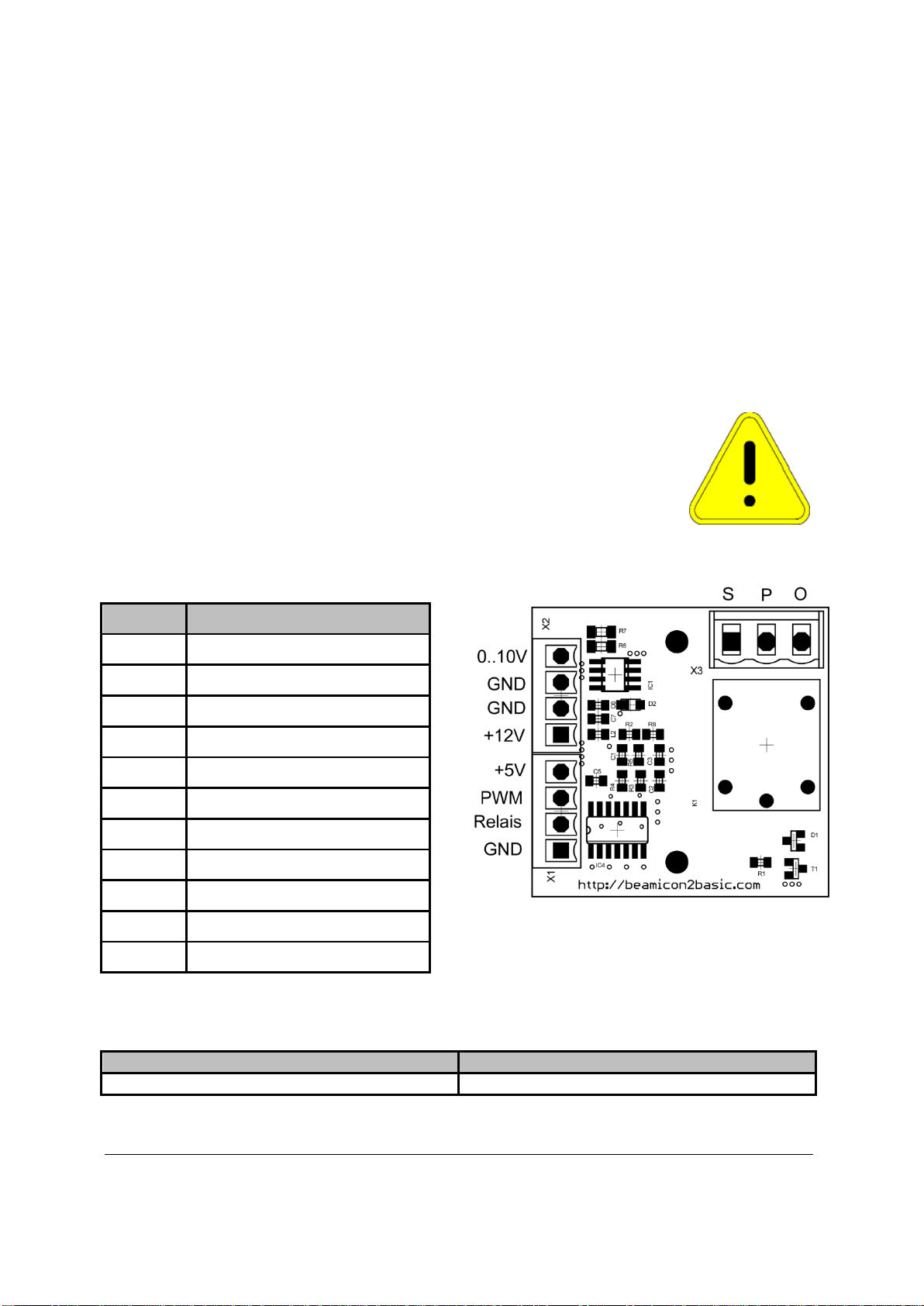

The stepper motor output stage MDLCNC-T4V6 is a low-cost output stage for 4 axes with up

to 4.5A/36V.The driver has not been developed for the Beamicon2-Basic, but can be used

with small restrictions. There is also a frequency converter module, which allows the

connection of a frequency converter (1 relay 230V and 1 0..10V output).

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 2

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

Table of contents

Foreword............................................................................................................................... 1

Safety Instructions................................................................................................................. 4

System requirements............................................................................................................. 4

Assembly............................................................................................................................... 5

Description of the connections............................................................................................... 5

Setting the motors................................................................................................................. 6

Setting the motor current ................................................................................................... 6

Setting the microsteps ....................................................................................................... 6

Connection of the motors................................................................................................... 6

Meaning of the LEDs ......................................................................................................... 6

Connection of the reference switches and emergency stop buttons................................... 7

Relay 1 .............................................................................................................................. 7

Power supply 18-36V......................................................................................................... 8

Connecting the Micropod....................................................................................................... 9

Safety Instructions ............................................................................................................. 9

Connections....................................................................................................................... 9

Status LEDs....................................................................................................................... 9

Supply voltage................................................................................................................ 9

Other connections:........................................................................................................10

Functional description...........................................................................................................10

PC / network connection...................................................................................................10

Power supply....................................................................................................................11

Configuration........................................................................................................................12

FU module............................................................................................................................13

Description........................................................................................................................13

Connection .......................................................................................................................13

Technical data Micropod ......................................................................................................15

Absolute limit values.........................................................................................................15

Electrical connection values:.............................................................................................15

Dimensions:......................................................................................................................15

Technical data MDLCNC-T4V4 Power amplifier...................................................................16

Absolute limit values.........................................................................................................16

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 3

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

Electrical limit values.........................................................................................................16

Dimensions.......................................................................................................................16

Technical data FU module....................................................................................................17

Absolute limit values.........................................................................................................17

Electrical limit values.........................................................................................................18

Dimensions.......................................................................................................................18

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 4

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

Safety Instructions

The MDLCNC stepper motor driver may only be installed and commissioned by

qualified personnel. Please read the operating instructions carefully and follow

all instructions exactly. Improper installation or operation of the device can cause

damage to the electronics or the machine and can result in dangers to the health

of the operating personnel. The system manufacturer, who assembles the power

amplifier and other components to form the overall system, and the system

operator are responsible for compliance with the legal regulations.

Caution: Danger to life! The device can be operated with voltages up to 230V

(relay outputs). If you operate the system with more than 60V, the installation

and commissioning may only be carried out by a trained electrician or must be approved by

such an electrician. No liability is accepted for damage or injury resulting from failure to

observe the safety regulations or improper use.

Always use a power supply unit with potential separation (no autotransformer or variac)!

Machine, motor and housing must be grounded according to the regulations.

System requirements

To obtain a functional drive system, the following components are required in addition to the

MDLCNC driver:

One to four two-phase stepper motors with a rated current between 0.5 and 4.5A. Three- or

five-phase motors or high-impedance motors from printers and disk drives are not suitable.

A power supply unit for the power supply. with an output voltage between 18 and 36V

Stabilization is not absolutely necessary. More detailed selection criteria are given in chapter

3.2.

A PC with the Beamicon2Basic software installed (to select the PC and operating system

please refer to the Beamicon2 software user manual), and a Micropod2 with firmware for the

MDLCNC driver. This firmware is included with the Beamicon2Basic and can be loaded later

(see Installation Software).

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 5

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

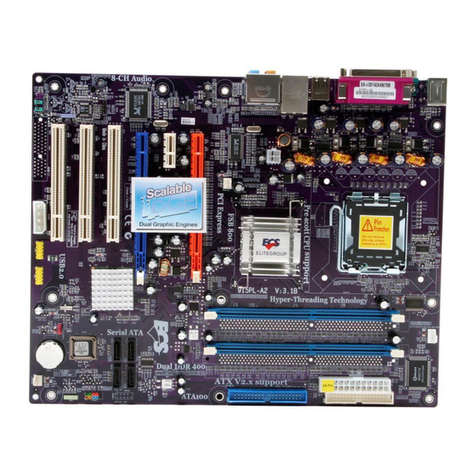

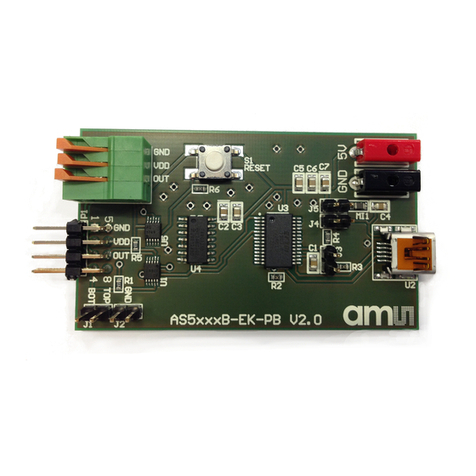

Assembly

For mounting it is recommended to replace the 4 screws in the corners with longer ones and

to mount the board with non-conductive spacers. Another possibility is the mounting with 4

small brackets (see picture). For this purpose M3 screws are screwed between the cooling

fins. If necessary, the distance between the cooling fins can be bent to fit.

Description of the connections

FI interface

Reference

switch and

emergency

stop

Relay 1

18V-36V

4. Axis

Z-axis

Y-axis

X- axis

Ethernet

connection

5

V

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 6

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

Setting the motors

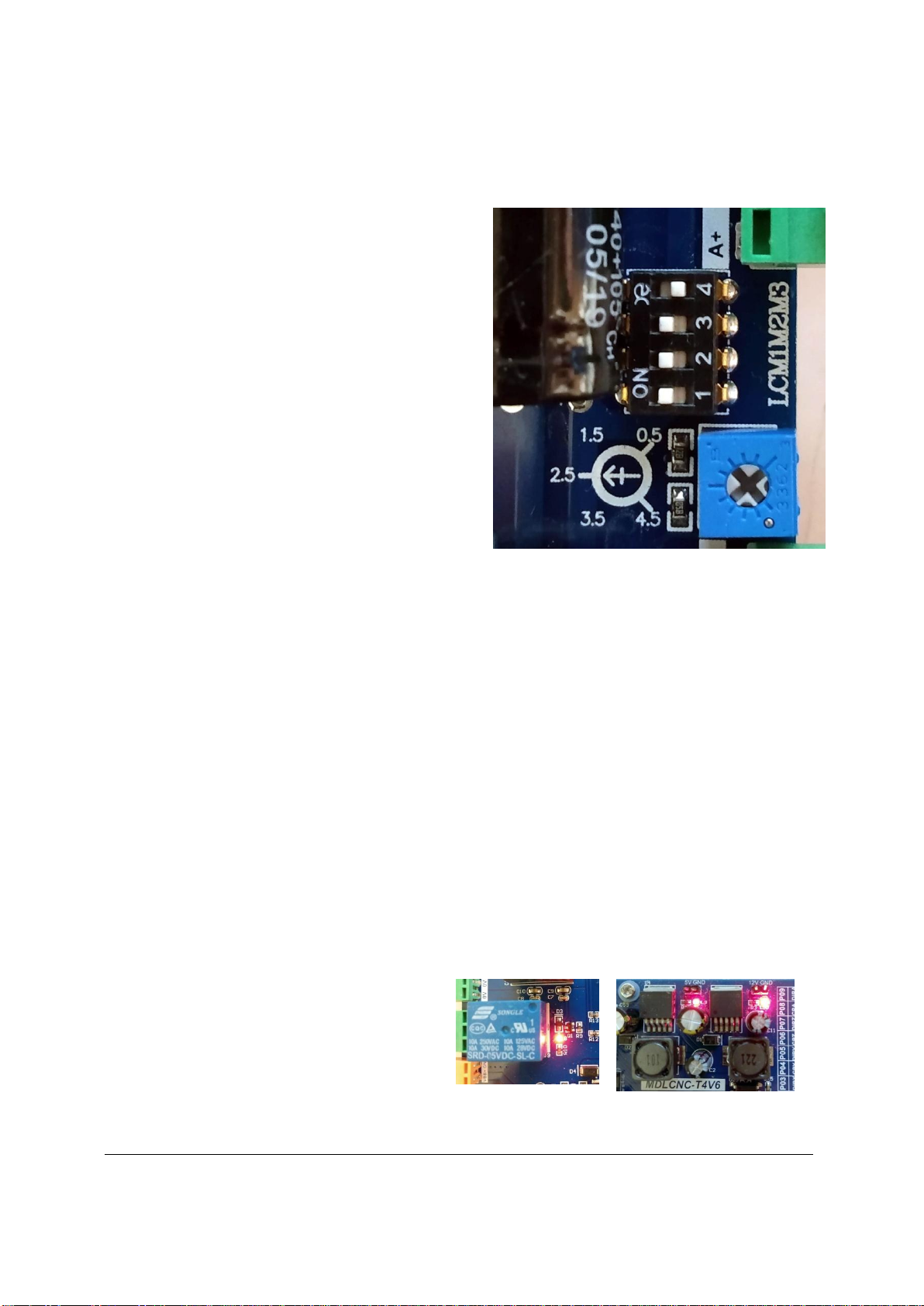

Setting the motor current

Attention: Make sure to set the correct phase

current before you switch on the power supply.

Too high a current - even for a short time - can

damage the motor. If you do not need the full

torque of the motor, you can also set a slightly

lower current. This significantly reduces heat

generation. However, do not set less than 70%

of the rated current, otherwise the motor may

not run smoothly.

The phase current of the motor is adjusted with

the small blue control dial. Use a small

screwdriver for this. The regulator is very easy

to turn, do not use force. In the picture on the

right the regulator is now at 4.5A. You can set

any value, the adjustment is linear.

Setting the microsteps

The microsteps are set by means of the dip switch (the black box with the white levers in the

picture above right). Please set the switch as shown in the photo. This corresponds to 16

microsteps.

Connection of the motors

The motors are connected to the sockets X-axis to 4th axis. Where A+ and A- is one coil of

the motor and B+ B- is the other coil of the motor. If you do not have a data sheet at hand,

you can quickly test it with a multimeter. There must be continuity between the terminals of

one coil, the other two terminals must not have continuity. It does not matter which coil you

connect to A and B. It also does not matter how the coil is connected (i.e. A+ and A-

reversed). It is only important that between A+ and A- is one coil and between B+ and B- is

the other coil.

Use a shielded cable to connect the stepper motors and connect the shield to the ground of

the control cabinet.

Meaning of the LEDs

The two LEDs near the FI-Interface

indicate that the device is ready for

operation.The four LEDs in the middle of

the board indicate the control signals from

the PC for the 4 motors.

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 7

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

The LED near the relay connector indicates the control signal for the relay.

Connection of the reference switches and emergency stop buttons

The reference switches can be connected to the socket below the micropod and an

emergency stop button must be connected.

The reference switches and the emergency stop button are connected to ground (GND) and

are closed in the idle state. So in an emergency, you can also detect a broken cable.In

addition to mechanical limit switches, inductive limit switches of type NPN can also be

connected. The power supply is provided via the terminals 0V and 12V.

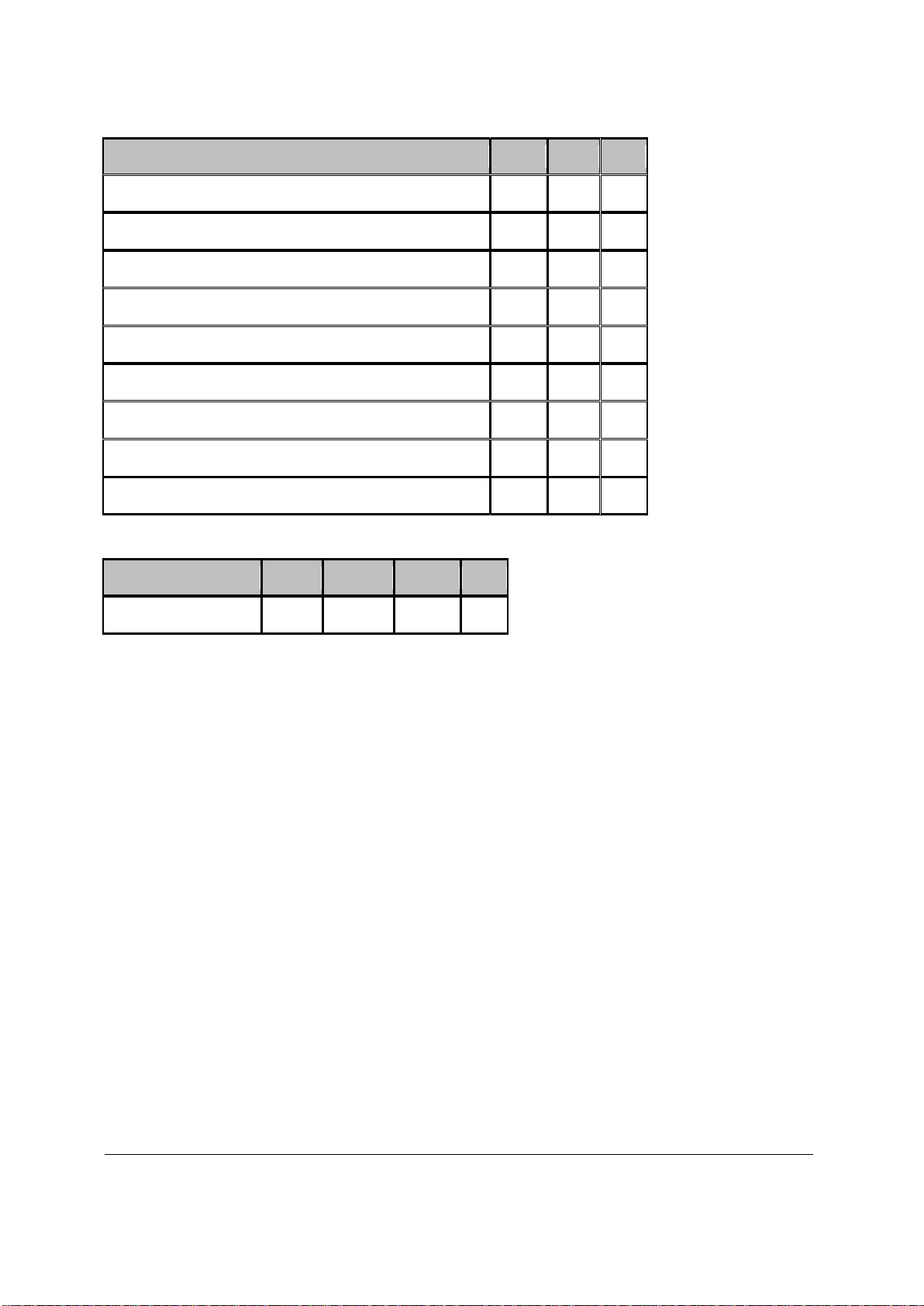

Pin

Designation

12V

Voltage connection for the FU module

IN1

Reference switch X-axis

IN2

Emergency stop button

IN3

Reference switch Y-axis

IN4

Reference switch Z-axis

IN5

Reference switch 4th axis or 3D probe/WZL probe

0V

Ground (GND)

0V

Ground (GND)

Attention! The emergency stop button is not the only safety feature. Depending on the

hazard potential of the machine, additional safety measures may be required, such as door

interlocks and standstill monitoring. As a rule, such safety functions must

be implemented purely electromechanically with external circuits (not

included in the scope of delivery) and must not depend solely on

software and PC hardware. The system manufacturer, who assembles

the interface board and other components to form the overall system,

and the system operator are responsible for compliance with the legal

regulations.

Relay 1

Unfortunately, relay1 is connected incorrectly and is energized when the machine is

deactivated and the emergency stop circuit is activated. It cannot therefore be used to switch

a spindle, as it can tighten/drop uncontrollably in the event of an emergency stop or when the

control is switched on.

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 8

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

The use of the relay for non-critical tasks is however (limited) conceivable.

If a relay is required to switch on a spindle, the FU module must be used.

Power supply 18-36V

A voltage of 36V is recommended, even for small machines. Since with a higher voltage a

higher speed of the motors can also be achieved. The design of the power supply unit

depends on the number of connected motors and their current consumption. If you are not

able to design the power supply yourself, please consult your dealer. Often there are also

complete sets with motors and power supply.

Attention! Pay attention to correct polarity of the supply voltage !

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 9

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

Connecting the Micropod

The micropod is the heart of the controller. It contains a powerful 32bit microcomputer with 8

cores. This takes over the calculation of the steps and ramps and evaluates the reference

switches and 3D probes. The connection to the PC is made via an Ethernet cable.The

micropod requires 5V operating voltage. These can be removed from the connector of the FI

module.

Safety Instructions

The interface module may only be installed and put into operation by

qualified personnel. Please read the operating instructions carefully and

follow all instructions exactly. Improper installation or operation of the

device can cause damage to the electronics or the machine and can

result in dangers to the health of the operating personnel.

Depending on the hazard potential of the machine, additional safety

measures may be required, such as door interlocks and standstill monitoring. As a rule, such

safety functions must be implemented purely electromechanically with external circuits (not

included in the scope of delivery) and must not depend solely on software and PC hardware.

The system manufacturer, who assembles the interface board and other components to form

the overall system, and the system operator are responsible for compliance with the legal

regulations.

Reversing the polarity of the operating voltage of 5V at X1 can permanently damage

the module and is not a warranty case.

Connections

Status LEDs

No.

Description

3

Network traffic

4

Network Carrier (connected)

Supply voltage

(terminal X1 left)

No.

Description

1

Signal ground

2

+5V

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 10

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

Other connections:

Network / PC

LPT1 (SUBD-25)

Functional description

The MicroPod is in a way an "intelligent external LPT interface card". Unlike PCI plug-in

cards with LPT port or LPT interfaces integrated on the PC motherboard, the MicroPod has a

built-in, powerful 8-core 32-bit processor that is optimized for generating step/direction

signals and also calculates S-shaped acceleration ramps. This is otherwise only known from

expensive industrial controls. The PC is not burdened with this task, but only has to send

coordinates to the MicroPod at regular intervals via a network interface (Ethernet IEEE802,

10MBit/s). All time-critical operations run in the MicroPod, so that the PC is relieved and is

only needed for the user interface.

Much higher step frequencies (1.6MHz) are possible than with LPT port-based solutions, and

the timing is precise and reliable. Compromises in the selection of the resolution in

connection with the maximum possible speed are therefore no longer necessary. Servo

drives can also be operated with high resolution and speed. Step losses due to short

"dropouts" of the PC or too "low performance" PC are excluded. Similarly, errors of the

operating system, such as Windows, do not affect the speed or precision.

Even for the user difficult to understand setting of the pulse duration and distance is

completely omitted. The MicroPod always generates the step signals with a perfect duty

cycle of 50%. Changes of direction always occur exactly in the middle of the pauses between

clock pulses. This ensures that the maximum pulse duration is always output in accordance

with the frequency. Violations of the setup and hold time by simultaneous change of step and

direction signal state are avoided.

PC / network connection

The data transfer from the PC software to the MicroPod takes place via an Ethernet network

connection (IEEE802.3 10BASE-T). The connection can be made with standard patch cables

to the RJ45 socket ST1.

In contrast to similar products from competitors (e.g. Smoothstepper or Eding-CNC) no

exclusive interface has to be reserved on the PC, but the infrastructure of an existing network

with switches can be used. There is also no need to change IP addresses or otherwise

interfere with the Windows Control Panel. The Beamicon2 software automatically detects the

MicroPod, even if it is connected "somewhere" in the network. To ensure reliable operation,

however, the following rules must be observed:

The MicroPod must be connected either directly to the PC or to the first switch after the PC.

A further switch may only be added if only devices of the machine are connected to the

second switch, e.g. within the control cabinet of the machine. All devices not involved in

machine control (Internet router, printer, NAS, etc.) must be connected to the first switch or to

additional switches behind the first.

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 11

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

The transmission speed between the PC and the first switch must be higher than the

maximum data rate of any existing Internet

routers (DSL modem, etc.). For home

networks with few PCs 100MBit is

recommended, for larger networks Gigabit-

Ethernet.

Since no TCP/IP is used but a separate

protocol, this cannot be forwarded by routers,

external firewalls, proxies, etc. Therefore only

so-called "unmanaged switches" may be used

between the control PC and the MicroPod.

Switches must support Fast Forward and

Store-and-Forward (virtually all modern

switches meet this criterion)

Hubs are also allowed for test purposes

(listening with diagnostic tools on taps), but

are not recommended.

The data traffic of the machine controller must

not be routed via slow (DSL modem) or

unreliable (wireless) connections (WLAN). All

wireless interfaces are therefore intentionally

hidden.

If the MicroPod is connected directly to the

PC and the PC interface does not support automatic crossover, a crossover cable must be

used (usually marked with a red connector or "X"). The network interface is galvanically

isolated from the PC. Power-over-Ethernet (PoE) is not supported.

Power supply

The MicroPod can be supplied with an operating voltage of 4.5 to 6V DC. The input is not

protected against accidental reverse polarity. The connection is easy

to make at the socket for the FI extension. Connect the 5V from the

micropod to terminal 5V from the connector of the FI-extension and the

ground (GND, 0V) to terminal GND of the FI-extension.

Check the cabling again before switching on.

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 12

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

Configuration

Note: If you have NOT purchased the Micropod in combination with a power amplifier

MDLCNC, you will have to make a firmware update of the Micropod to ensure correct

function. The firmware update is very easy and described in the Beamicon2 software

user manual. To do this, select the firmware "MicroPod

Benezan_V131_Letmathe.binary" and follow the instructions.

The assignment of the inputs and outputs is done in the Beamicon2Basic software. The

installation and operation of the software as well as the setting of the machine parameters is

described in detail in the Beamicon2Basic software manuals. Therefore only the special

features of the MicroPod will be discussed here. The easiest way of configuration is to select

the default parameter set "Default_MicroPod MDLCNC" when starting the software for the

first time. Then you do not have to make all settings again, but only enter the deviations from

the standard values. You can also load the default values later by selecting "File -> Import

settings" from the menu and clicking "Default parameters".

After the first start, the MicroPod must first be connected. If the hardware dialog does not

open automatically, you can do this in the menu under "Configuration -> Hardware". Select

the module and then click on "connect" and "save".

The step and direction signals for up to 4 axes are automatically assigned to pins 2 to 9 of

the SUBD connector for LPT1. No settings need to be made for this. In particular, there is no

need to set a pulse time, as the step signal always has a 50% duty cycle. The direction of

movement can be reversed in the machine parameters (Menu -> Configuration -> Machine)

on the "Axis Parameters" page with the "Inverted direction" button.

For the assignment of the signals switch to the page "Inputs/Outputs". Actually all

outputs/inputs including the FI module are already set. Only if the reference switch of the 4th

axis is not needed, it can be assigned to a 3D probe or tool length sensor, for example.

The following inputs/outputs are permanently assigned and cannot be changed:-LPT1 Pin 11

is permanently reserved for the emergency stop input.-The PWM output can only be

assigned to either LPT1 pin 1 or LPT1 pin 17.-The step/direction outputs cannot be changed.

Input signals can be used multiple times if required. For example, the same switch input can

be used simultaneously as a reference and limit switch.

In contrast to inputs, output signals cannot be inverted (active low/hi) because otherwise the

safe off state would not be defined.

If the number of available outputs or inputs is not sufficient for the application, they can be

expanded as desired with an I/O-Ext expansion module from Benezan-Electronics.

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 13

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

FU module

Description

The FU module is an expansion board which is connected to the "FU module" expansion

connector of the power amplifier. It can also be used with other breakout boards.

The board is used to convert the PWM signal, which is provided by the controller, into an

analog signal of 0-10V. This is required to control a frequency converter. There is also a

relay on the expansion board which can be used to switch on the frequency converter or a

spindle directly.

The relay has a changeover contact / changeover switch which can be loaded up to 230V

and 6A.

Caution: Danger to life! If the relay is operated with more than 60V, the

installation and commissioning must only be carried out by a trained

electrician or must be approved by such an electrician. No liability is

accepted for damage or injury resulting from disregard of safety

regulations or improper use.

Connection

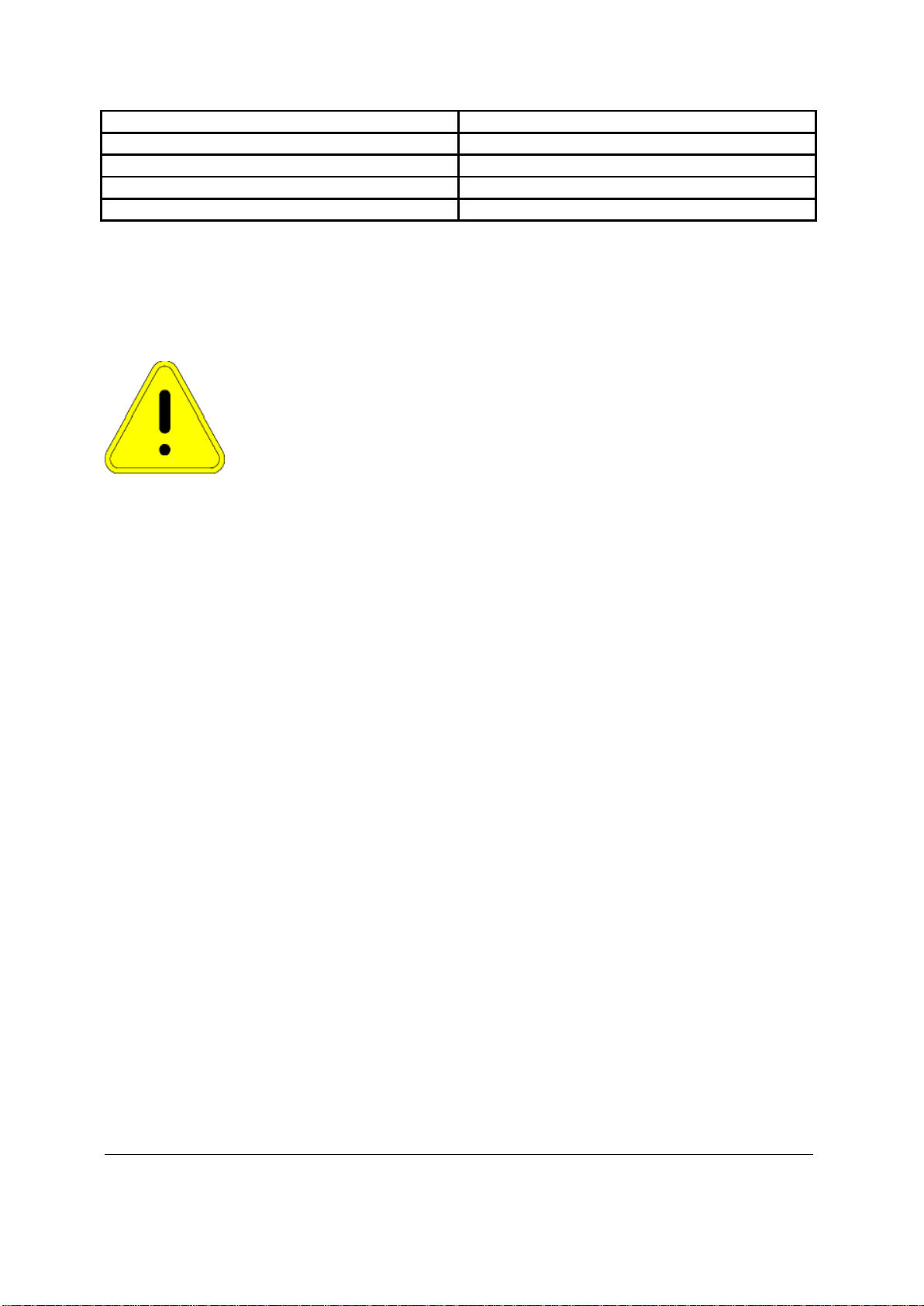

Pin

Designation

0..10V

Analog output 0-10V

GND

Ground (0V) for the 0-10V

PWM

Digital input PWM

Relay

Digital input relay

+12V

Power supply +12V

+5V

Power supply +5V

GND12V

Ground (0V) for the +12V

GND5V

Ground (0V) for the +5V

S

Relay contact N/O contact

P

Relay contact centre

O

Relay contact normally closed

Connect the connections as follows to the FU module connector on the power amplifier:

Pin FU module

Pin to power amplifier MDLCNC

PWM

FU plug "DIR"

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 14

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

Relay

FU plug "CK"

+5V

FU plug "5V"

GND5V

FU plug "GND“

+12V

Plug reference inputs "12V“

GND12V

Plug reference inputs "0V“

Hint: By plugging in the "FU module" expansion module, the electrical isolation of the 5V and the

operating voltage of the output stage is removed. This is absolutely no problem and poses no risk, as

the galvanic isolation to the PC is provided by the micropod. By using the micropod, breakout boards

and power amplifiers do not need to have galvanic isolation.

Attention! The connections for the operating voltage "+5V" and "+12V" are

not protected against reverse polarity! Make sure that the connection is

correct.

Connect the output "0..10V" together with the connection "GND" according to the manual of

your frequency inverter. The output is short-circuit proof and safe against accidental

application of a voltage up to max. 31V. This will destroy the module.

The relay can be used to switch the input for spindle forward of your frequency converter.

Please refer to the manual of your frequency inverter.

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 15

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

Technical data Micropod

Absolute limit values

The following parameters must not be exceeded under any circumstances to prevent

damage to the device:

Parameters

min.

max.

Unit

Operating voltage

-0.7

13

V

Storage temperature

-40

+70

°C

Operating temperature

0

+70

°C

Voltage at digital inputs

-0.5

+5.5

V

Voltage at digital outputs

-0.5

+5.5

V

Current at any pin of LPT1

-20

+20

mA

Electrical connection values:

Parameters

min.

max.

Unit

Operating voltage (nominal 5V)

+4.5

+6

V

Power consumption (without external consumers)

0.85

1.5

W

Ambient temperature

0

+50

°C

Level for logical 0 at inputs

-0.3

+0.8

V

Level for logical 1 at inputs

2.0

5.5

V

Level for logical 0 at outputs

0

0.5

V

Level for logic 1 at outputs

2.5

3.5

V

Stepping frequency (all 4 axes independent)

0

1.61

MHz

Driver Power Step/Dir Outputs

8

-

mA

Dimensions:

Description

Width

Length

Height

Unit

Overall dimensions

54

61

22

mm

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 16

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

Technical data MDLCNC-T4V4 Power amplifier

Absolute limit values

The following parameters must not be exceeded under any circumstances to prevent

damage to the device:

Parameters

min.

max.

Unit

Operating voltage

-0.7

40

V

Storage temperature

-40

+70

°C

Operating temperature

0

+70

°C

Voltage at digital inputs

-0.5

+5.5

V

Voltage at digital outputs

-0.5

+5.5

V

Current at 12V output

0

+300

mA

Current at 5V output

0

+300

mA

Electrical limit values

Parameters

min.

max.

Unit

Operating voltage

+18

+36

V

Power consumption (without external consumers)

1.9

3.0

W

Ambient temperature

0

+50

°C

Level for logical 0 at inputs

-0.3

+0.8

V

Level for logical 1 at inputs

2.0

5.5

V

Level for logical 0 at outputs

0

0.5

V

Level for logic 1 at outputs

2.5

4.9

V

Driver power Motor outputs

0.5

4.5

A

Voltage at 5V output

4.8

5.5

V

Dimensions

Description

Width

Length

Height

Unit

Overall dimensions

150

151

35

mm

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 17

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

Technical data FU module

Absolute limit values

The following parameters must not be exceeded under any circumstances to prevent

damage to the device:

Parameters

min.

max.

Unit

Operating voltage 12V

-0.7

31

V

Operating voltage 5V

-0.7

6V

Storage temperature

-40

+70

°C

Operating temperature

0

+70

°C

Voltage at digital inputs

-0.5

+5.5

V

Voltage at digital outputs

-0.5

+5.5

V

Voltage at relay contacts

-

380

VAC

-

110

VDC

Current at relay contacts

-

20

A

Switching capacity relay contacts

-

2500

VA

420

W

Voltage at analog output

-

31

V

Benezan Electronics Installation Guide for Beamicon2Basic

Hardware and software development and the MDLCNC-T4V6 driver

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-

electronics.de

Page 18

Beamicon2Basic_Manual_Letmathe_Englisch

(Vereinigte Staaten).docx

02.10.2020

Electrical limit values

Parameters

min.

max.

Unit

Operating voltage 12V

+11.8

+13

V

Operating voltage 5V

+4.5

+5.5

V

Power consumption (without external consumers)

0.05

0.4

W

Ambient temperature

0

+50

°C

Level for logical 0 at inputs

-0.3

+0.8

V

Level for logical 1 at inputs

2.0

5.5

V

Level at analog output

0

10.5

V

Switching capacity relay at 28VDC (TÜV rating)

-

6

A

Switching capacity relay at 28VDC (TÜV rating)

-

6

A

Dimensions

Description

Width

Length

Height

Unit

Overall dimensions

42

43

20

mm

Table of contents