Benton Harbor Washer User manual

Bi

Installation Instructions

120~volt

60-Hz

Washer

IhilPORTANT:

Read and save these

instructions.

IMPORTANT:

Installer: Leave Installation Instructions with the homeowner.

Homeowner: Keep Installation Instructions for future reference.

Cave Installation Instructions for local electrical inspector’s use.

Your safety and the safety of others is very important.

We have provided many important safety messages in this manual and on

your appliance. Always read and obey all safety messages.

This is the safety alert symbol. This symbol alerts you to hazards that

can kill or hurt you and others. All safety messages will be preceded

by the safety alert symbol and the word “DANGER” or “WARNING”.

These words mean:

You will be killed or seriously injured if

you don’t follow instructions.

All safety messages will identify the hazard, tell you how to reduce the

chance of injury, and tell you what can happen if the instructions are not

followed.

Q

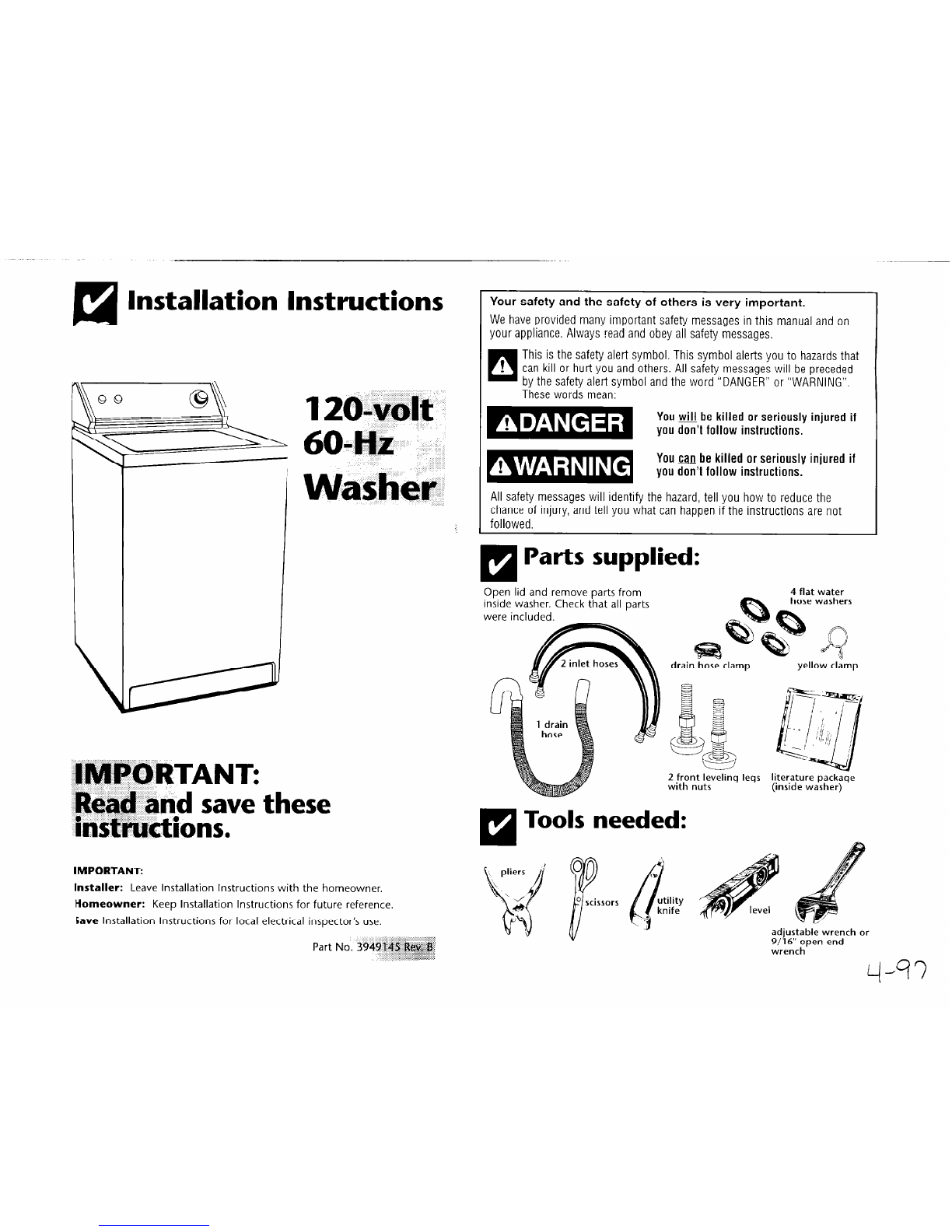

Parts supplied:

Open lid and remove parts from

inside washer. Check that all parts

were included.

4 flat water

drain ho&clamp yellow cl&np

2 front leveling legs

with nuts literature package

(inside washer)

wrench

Location of washer:

Check location where washer will be installed. Make sure you have everything necessary

for correct installation. Proper installation is your responsibility.

Hot and cold

water faucets:

Recessed area instructions

Should be within

4 feet of upper right

This washer may be installed in a recessed area or closet.

The installation dimensions

hand corner of shown are the minimum minimum air openings in top and

washer cabinet (if not

see chart below). spaces allowable. Additional bottom of door are required.

spacing should be Louvered doors with air openings in

Provide water considered for ease of top and bottom are acceptable.

installation and servicing. If Companion appliance spacing

should be considered.

closet door is installed, the

Minimum installation spacing

m

Grounded electrical

outlet is required

within 5 feet of upper

right corner of washer

cabinet. See “Electrical

requirements,” Panel A.

The hot and cold water

inlets on the back of the

washer have 314 -

11-l /2 American hose

coupling standard

threads.

Support: Floor must be

sturdy enough to

support washer weight a

(with water) of 315

Imodrtant: Observe

all ‘governing codes

and ordinances.

1Water

closet door.

I

heater:

Set to deliver

140°F water

to washer.

WS”

I

48 sq. in.

?t

nnllnriz

Do Not store or

operate washer

24 sq. in.

\

u

To use drain hose (some water may

\”“W

-L‘:-7ed with washer,

See Use & Care

information.

,closet door

t 4”

min.

washer - 1 inch.

48 sq.

If your home has: You wlli need to buy:

39” high, 2” dia. standpipe nothing. If your installation is different, see “Drain system” below.

1” dia. standpipe 2” dia. to 1” dia. standpipe

adapter, Part No. 3363920.

floor drain si hon break, Part No. 285320; additional drain hose, Part No.

3

P

57090; and Connector Kit, Part No. 285442.

overhead sewer standard 20 gal., 34” hi h laundry tub or utility sink, sump pump

and connectors (availab e from

local plumbing suppliers).7

standard 20 gal., 34” high laundry

tub or utility sink nothing.

water not close by 2 longer water inlet hoses: 6 ft. hoses, Part No. 76313 or

10 ft. hoses, Part No. 350008.

24

sq.

-+ +-1”min.

l

Additional clearances for wall, door and floor moldings may be

required.

Parts listed are available from your local dealer or authorized parts distributor.

Drain system.

Remove parts package. Untape and open washer lid. Remove literature package from washer.

. Look at drain systems below to decide which system to use.

1. Laundry tub or utility

sink drain system: 2. Floor drain system:

Needs a 20-gallon laundry tub. An

3. Standpipe drain system:

Needs a two-inch minimum diameter standpipe with minimum carry-away

capacity of 17 gallons per minute. A 2” dia. to 1” dia. standpipe adapter, Part No.

3363920, must be used with 1” dia. drain systems.

Wall standpipe drain

Floor StandDiDe k

drain ’ ’

A

-Top of

stand ipe

Emust e

at least 39

inches

high and

no hi her

than 2

3..

Top of tub must’be at

least 34

inches high

and no hi her than

72 inches 7rom

bottom of washer.

285320. Siphon

break must be

water level in

washer, at least

28 inches

from

Top of /

stand ipe

rlmust eat

least 39

inches high

and no

higher than

72 inches**

from

bottom of

washer.

12 bottom of

washer

Additional drain

“‘If the drain height is greater than 72 inches, a sump pump system must be used.

If

a

longer drain hose is needed,

use complete drain hose assembly (56 inches long), Part No. 661575, or drain hose (21 inches long), Part No. 3357090, and

Connector Kit, Part No. 285442. These kits are available from your local dealer or an authorized parts distributor.

Electrical requirements

If codes permit and a separate

ground wire is used, it is

recommended that a qualifled

electrician determine that the

ground path is adequate.

Do Not ground to a gas pipe.

Check with a qualified electrician if

you are not sure the washer is

properly grounded.

Recommended ground method

3-pron 8groun -

For your personal safety, this washer

must be grounded. This washer is

equipped with a power supply cord

having a 3-prong ground plug.

To minimize possible shock hazard,

the cord must be plugged into a

mating 3-prong ground-type wall

receptacle, grounded in accordance

with local codes and ordinances. If a

mating wall receptacle is not available,

it is the personal responsibility and

obligation of the customer to have the

proper grounded wall receptacle

installed by a qualified electrician.

Do Not have a fuse in the neutral or

ground circuit.

Electrical Shock Hazard

Plug into a grounded 3-prong

outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these

instructions can result in

death, fire, or electrical shock.

A 120~volt, 60-Hz, AC-only, 15- or

20-ampere, fused electrical supply is

required. Time-delay fuse or circuit

breaker is recommended. It is

recommended that a separate circuit

serving only this appliance be provided.

Panel A

Level washer.

been leveled.

tub or

standpipe.

Shipping strap

must be removed

for rear leveling

legs to drop down.

Preparation:

..:::/:~‘//~/::,::/:/:,.,,

.:’ ::,‘.,:,:‘,:‘:‘,:,‘,‘..:,’,,:

:.;‘::./,‘.,:,/:.

., :.:.:.:.:..::./.:./,;:::::/

‘::,:,//,,,~:‘.,:~,~,

‘.‘../ ;

(to washer)

Panel B

SLIDE WASHER ONTO CARDBOARD OR

HARDBOARD BEFORE MOVING ACROSS

FLOOR.

Move washer close to Its final

location.

Read, then remove

label

l

that covers power supply cord.

Remove yellow shipping strap.

completely out of the washe

2 cotte; pins

2

Pull yellow shipping strap with two cotter pins

l

entirely out of washer. The power supply cord

will still be attached to shipping strap.

3

Pull firmly to remove the

l

other end of shipping

strap from the back of the

washer to release self-leveling

legs.

Save the shipping strap for use In

Step 17.

L

Inlet hose

connection:

Use new hoses and washers that came with your washer.

Inlets are plastic.

Do Not strlp or

crossthread.

Slip and Fall Hazard

5 Attach one hose to the hot

l

water (bottom) inlet valve first

Use new water inlet hoses.

Failure to do so can result

in head injury or broken

bones.

Check inlet hoses periodically.

4

Insert

a

flat washer into each

then

other hose to the cold water

l

end of the inlet hoses. Check (top) inlet valve. Tighten couplings

Replace inlet hoses if you find that washers are firmly seated in by hand. Then use pliers to make an

bulges, kinks, cuts, wear or leaking. couplings. additional two-thirds turn.

Replace

inlet hoses after five years DO NOT OVERTIGHTEN; this could

of use. cause damage to couplings.

Drain hose

connection:

:I

1

..:.:.:

c

Met hose

connection:

(to water faucets)

Leveling

washer:

Securing

drain hose:

IMPORTANT: THIS PROCEDURE

MUST BE FOLLOWED TO

ASSURE PROPER

INSTALLATION.

(6

To prevent the drain hose

l

from coming off or leaking,

it must be installed per the

following instructions.

. Wet the inside end of the drain

hose with tap water. DO NOT USE

ANY OTHER LUBRICANT.

l

Squeeze ears of drain hose clamp

with pliers to open and place

clamp over the end of the drain

hose.

l

Open clamp and push end of drain

hose onto drain connector until

hose contacts ribbed stop.

l

Place clamp over area marked

“clamp”. Release clamp.

7

Standpipe or

l

laundry tub drain system:

Open yellow clamp and slide over

“hook” end of drain hose

to secure the rubber

and corrugated

sections together.

Floor drain system:

Do Not install “hook”

end of drain hose to

corrugated section. Consult your

plumber for proper installation.

8

both faucets into

a bucket to aet

rid of particl& in the water lines

that might clog hoses. Mark the hot

water faucet.

9

Put “hook” end of drain

l

hose into laundry tub or

standpipe. Check for proper length

of drain hose.

To prevent drain water from

going back into washer:

l

Do Not straighten “hook”

end of drain hose and force

excess drain hose into

standpipe.

l

Do Not lay excess drain hose

in bottom of laundry tub.

Check inlet hoses

periodically. Replace inlet

hoses if you find bulges,

kinks, cuts, wear or leaking.

Replace inlet hoses after

five years of use.

Inlets are plastic.

Do Not strip or

crossthread.

cold water

inlet valve

hot water

inlet valve

10

Attach bottom hose from

l

the inlet marked “H” to

the hot water faucet. Attach top

hose from the inlet marked “C” to

the cold water faucet. Tighten

couplings to faucets. DO NOT

OVERTIGHTEN; this could cause

damage to couplings.

ill

Stack two corner posts

l

on top of each other.

” Tilt washer backwards and slide

corner posts under washer 3

inches from each side of washer

as shown.

-

12

Screw nut down on

l

legs to within l/2 inch

of base.

13

0 Insert legs into correct

holes at each front corner of washer

until nuts touch washer. DO NOT

tighten nuts until Step 16.

14

Tilt washer backward and

0 remove corner posts.

Gently lower washer to floor.

Move washer to Its final

location. Remove cardboard or

hardboard from under washer.

IS

Tilt washer forward

l

slightly so that back legs

are about 1 inch off floor, Drop

washer to floor. Check levelness of

the washer by placing a carpenter’s

level on top of the washer, first side

to side; then front to back.

16 0

If washer is not level, repeat Step

11, and adjust the front legs up or

down. Then repeat Steps 14 81 15.

When washer Is level, use

wrench to turn nuts on front

legs up tightly against washer

base. if nuts are not tight

against washer base, the

washer may vibrate.

NOTE:

Use shipping strap to

secure drain hose. Water pressure

could cause drain hose to come

out of standpipe or laundry tub if

drain hose is not secured.

After shipping strap has been

removed (Step l), look for the

words “cut here” marked on the

shipping strap, about 16 inches

from plug end.

Cut the shipping strap at this

mark. Pull shipping strap out of

the power supply cord.

Check that hose is not twisted

or kinked and is securely in

place.

Put “hook” end of drain hose in

laundry tub or standpipe. Tightly

wrap the shipping strap around the

drain hose and laundry tub or

standpipe as shown in Figures A-B.

Push plug into the nearest hole in

the shipping strap.

If the water inlet

faucets and drain

standpipe are

recessed, put

“hook” end of

drain hose in

standpipe. Tightly

wrap the shipping

strap around the

drain hose and

faucet body (not the handles or

stems) as shown in Figure C. Push

plug into the nearest hole in the

shipping strap.

If a longer drain hose is needed, use

a 21” or 54” drain hose and

Connector Kit, Part No. 285442. If

drain hose must be shortened, use

Connector Kit Part No. 285442.

These parts are available from your

local dealer or authorized parts

distributor.

Note: if washer is moved to

adjust drain hose, the washer

must be leveled again. Repeat

Steps 15-l 6. Place cardboard

under the washer and carefully

move washer to avoid

damaglng floor covering.

Panel C

Completing

Installation:

Need

Assistance?

18

l

CHECK ELECTRICAL

REQUIREMENTS. BE SURE YOU

HAVE CORRECT ELECTRICAL

SUPPLY AND RECOMMENDED

GROUND METHOD.

20

l

Turn on water faucets

22

l

Plug power supply cord

and check for leaks. Tighten into qrounded outlet.

couplings if there is leaking. DO

NOT OVERTIGHTEN; this could

cause damage to couplings.

23

l

Read the Use and Care

19

l

Check that all parts are

now

installed. If there is an extra

part, go back through steps to see

which step was skipped.

Guide. Start the washer and allow it

to complete the regular cycle.

l

Check that you have all

nyo,‘, tonic. Check that the vellow

You have successfully instailed

your new washer. To get the

most efficient use from your

new washer, read your Use and

Care Guide.

shipping strap was removed from the

back of the washer and used to

secure the drain hose.

Keep Installation Instructions

) and Guide. ,

Call your dealer or local authorized

service company.

When you call, you will need the

washer model number and serial

number. Both numbers are on the

model/serial rating plate located

under the washer lid and on the top

of the washer.

Part No. 3949145 Rev. B

0 1997 Benton Harbor, Michigan 49022 Printed in U.S.A.

Table of contents

Other Benton Harbor Washer manuals