Bestlink BLGSW905CF User manual

BESTLINK INTERNATIONAL

User instructions

Maintenance instructions

Installation & service instructions

Cooktop models:

BLGSW905CF

BLGSW905C

BLGSW705CF

BLGSW705C

BLGSW704CF

BLGSW704C

BLGSW60CF

BLGSW60C

BLGS60CF

BLGS60C

BLGS60EF

BLGS60E

BLGSW60EF

BLGSW60E

BLGSW30CF

BLGSW30C

GMK 10023

AS 4551

This cooktop is approved for use with Natural and Propane gases.

Leave instructions with the owner.

2

Table of content

Table of content -----------------------------------2

Introducing your new cooktop -----------------3

Dear customer --------------------------------------- 3

Notes on disposal ------------------------------------ 3

Gas supply -------------------------------------------- 3

Electrical supply ------------------------------------ 3

What to do if you smell gas ----------------------- 3

Safety considerations ------------------------------- 4

Warnings: -------------------------------------------- 4

User instructions ----------------------------------5

Burner operation and ignition ------------------- 5

Manual ignition ------------------------------------- 6

Ventilation-------------------------------------------- 6

Abnormal operation -------------------------------- 6

Cleaning the cooktop -----------------------------7

Preventative maintenance ------------------------- 7

Installation instructions -------------------------7

Installer instructions ------------------------------- 7

Statutory requirements ---------------------------- 7

Overall dimensions --------------------------------- 8

Installation dimensions & clearances ----------- 8

Installation procedure ---------------------------9

Gas connection -------------------------------------- 9

Boiling burner adjustments--------------------- 10

Energy consumption ----------------------------- 10

Electrical connection ----------------------------- 10

Warranty warning-------------------------------- 10

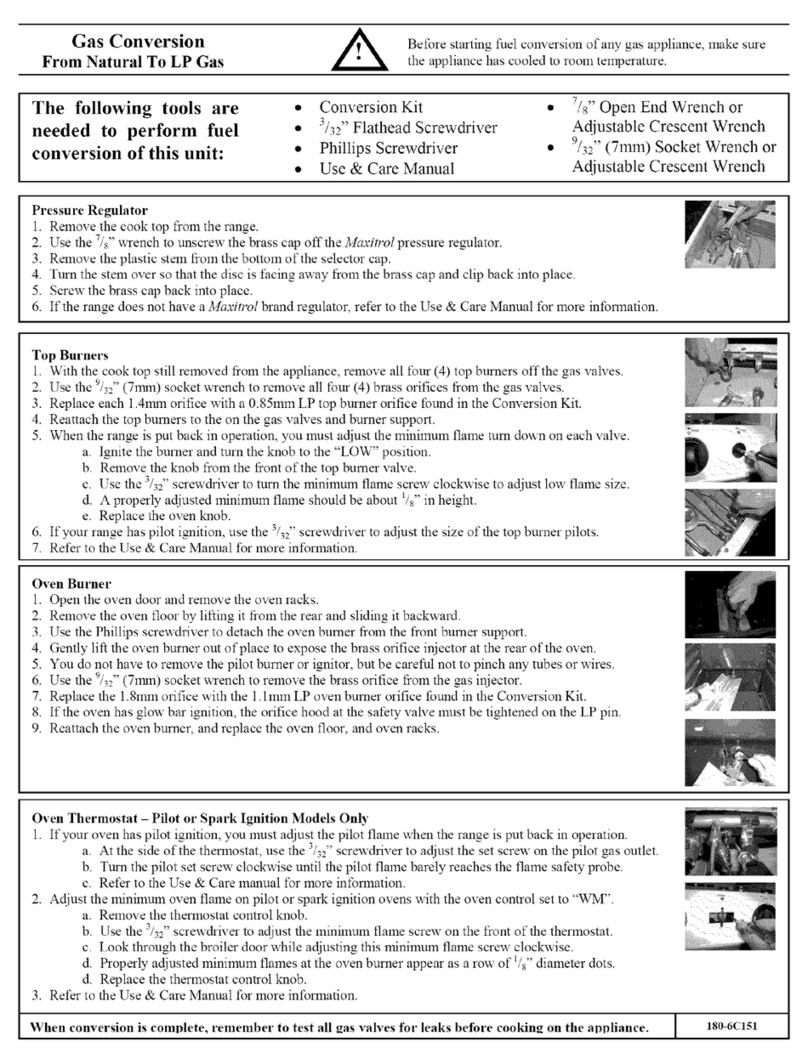

Conversion --------------------------------------- 11

Propane Gas to Natural Gas-------------------- 11

Natural Gas to Propane ------------------------- 11

Trouble shooting -------------------------------- 12

Service--------------------------------------------- 13

To replace injectors------------------------------- 13

To remove hob------------------------------------- 13

To remove and service gas control valves---- 13

To replace the thermocouple ------------------- 13

To replace the spark electrode ----------------- 13

To replace the electronic ignition module--- 13

To replace internal wiring and gas control

ignition micro switch ----------------------------- 13

Wiring diagrams ---------------------------------- 13

Data plates------------------------------------------ 14

For service and spare parts contact: ---------- 14

3

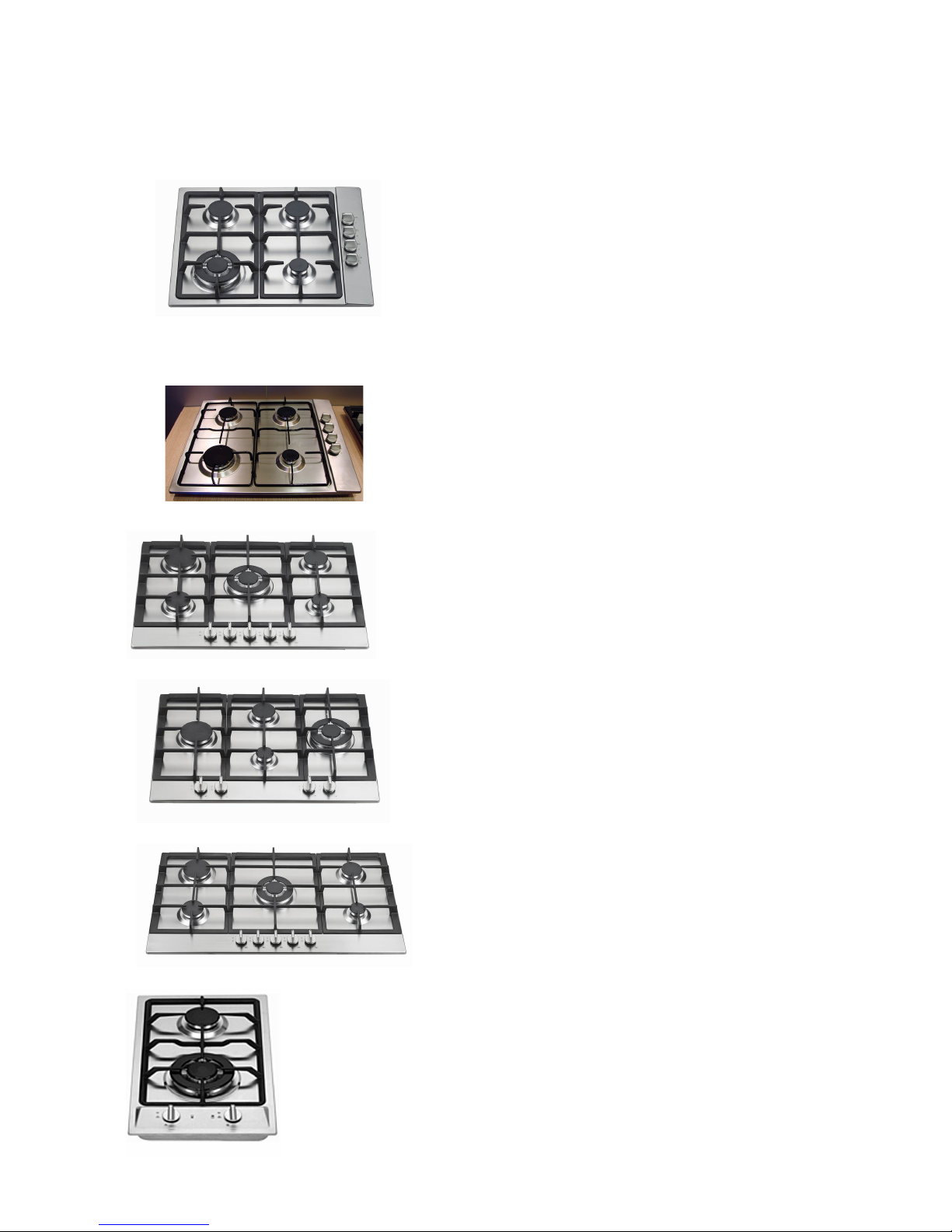

Models

Model numbers with the ‘F’ extension are fitted with

flame failure device.

BLGSW60CF, BLGSW60C (cast iron pan sup-

ports. Shown below)

BLGSW60EF, BLGSW60E (enamel pan supports)

BLGS60EF & BLGS60E (enamel pan supports,

shown below)

BLGS60CF & BLGS60C (cast iron pan supports)

BLGSW705CF & BLGSW705C

BLGSW704CF & BLGSW704C

BLGSW905CF & BLGSW905C

BLGSW30CF & BLGSW30C

Introducing your new cooktop

Dear customer

Thank you for having purchased one of our pro-

ducts.

We are certain that this new modern, functional and

practical appliance, built with the very highest quality

materials, will meet your requirements in the best

possible way. This appliance is easy to use, it is

however important to thoroughly read the instruc-

tions in this manual, in order to obtain the best re-

sults.

These instructions are only valid for Australia. We

shall not be held responsible for any damages to

persons or property caused by incorrect installation

or use of the appliance.

We shall not be held responsible for any inaccura-

cies in this manual due to printing or transcription

errors; the designs in the figures are purely indica-

tive. We also reserve the right to make modifications

to the products as may be considered necessary or

useful, also in the interest of the user, without jeop-

ardising the main functional and safety features of

the products themselves

These instructions cover 6 cooktops of varying cook-

top burner configurations. All cooktops are fitted with

a stainless steel hob, electronic spark ignition.

Model numbers with the ‘F’ extension are fitted with

flame failure device.

Please consult the instructions pertaining to your

individual cooktop as they are described in these

instructions.

The cooktop’s data plate is accessible even with the

cooktop fully installed. It is positioned on the bottom

of the unit. A duplicate copy is supplied at the back

of this instruction manual. Always quote the details

from it to identify the appliance when ordering spare

parts or requesting a service.

♦In case of malfunction, turn off the cooktop’s

gas supply before contacting the service

centre for assistance.

♦Only an authorized person should connect

and service this appliance.

Notes on disposal

Old appliances still have some residual value. En-

sure an environmental means of disposal in order for

valuable raw materials to be recovered and used

again.

Please dispose of packaging materials appropri-

ately.

Gas supply

Check that the data plate shows the appliance is

suitable for the available gas.

Electrical supply

This appliance requires connection to a 10 Amp wall

socket.

What to do if you smell gas

♦Do not try and light the appliance.

♦Do not touch any electrical switches; do not use

4

a phone in your building.

♦Immediately call your gas supplier from a neigh-

bour’s phone. Follow the gas supplier’s instruc-

tions.

♦If you cannot reach your gas supplier, call the

fire department.

Safety considerations

If the information in this manual is not followed ex-

actly, a fire or explosion may result, causing property

damage, personal injury or death.

♦Be sure to disconnect the electrical supply be-

fore disassembly of the appliance.

♦Never leave the appliance unattended when

cooking with fat or oil. It could ignite if over-

heated.

♦In case of defect, switch electric power off at the

mains.

♦Never use an appliance that is not working cor-

rectly.

♦Only ignite the gas burners when all the burner

components are correctly assembled.

♦Leads from electrical appliances must not touch

the cooktop. They will melt and the cable insula-

tion will be damaged.

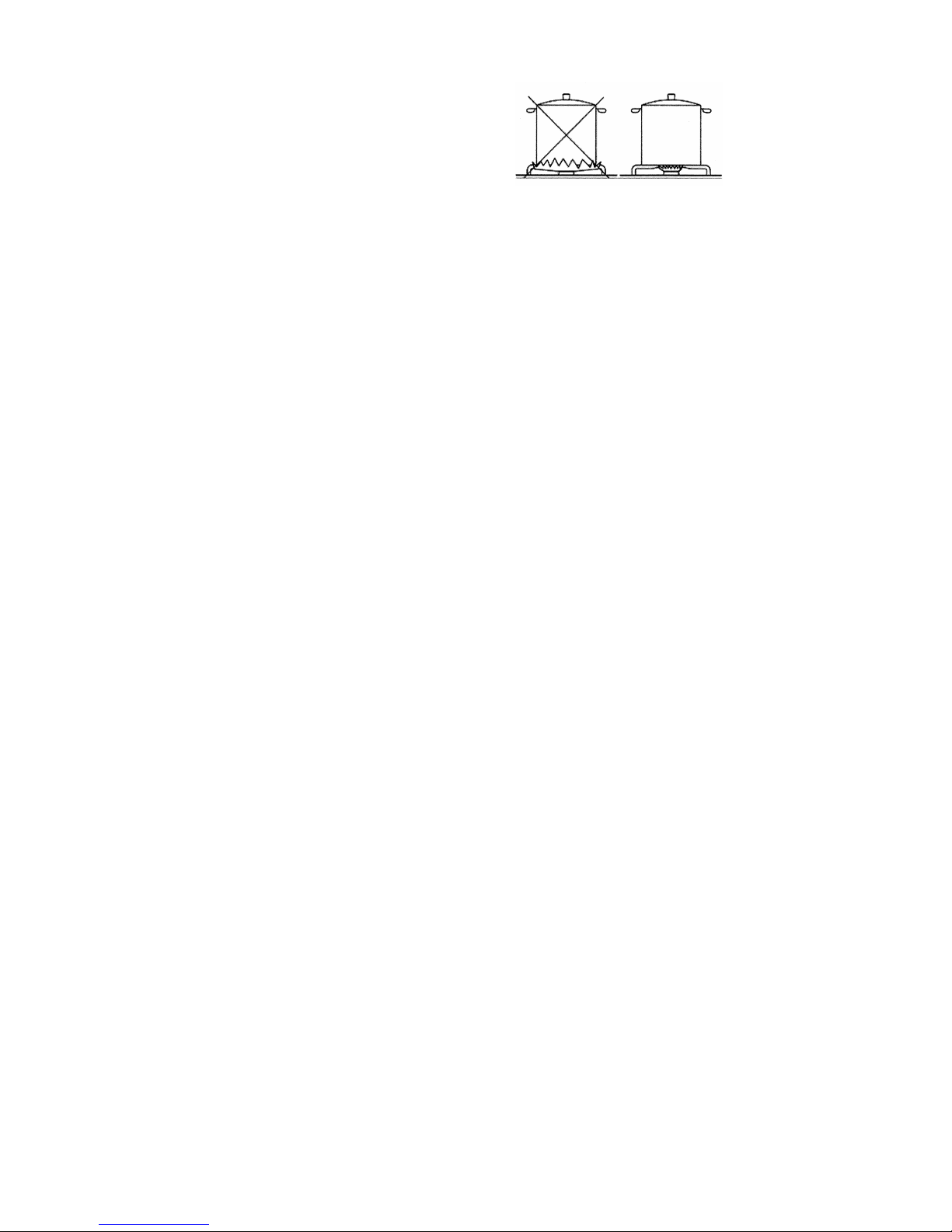

♦Do not allow the flame to extend beyond the

edge of the cooking utensil. This instruction is

based on safety considerations.

♦Do not forget that the unit becomes hot when in

use. Common sense is important. Just because

the flame is out, does not mean that the parts

cannot still be hot.

♦Small children must be kept at a safe distance

from the appliance.

♦Keep the appliance area clear and free from

combustible materials.

♦Note: To avoid jeapordising the electrical safety

of the appliance, it is forbidden to use high-

pressure or steam jet cleaning devices.

♦Cabinets installed above the gas cooktop must

have a minimum clearance of 650 mm (24”).

♦Important.

♦When using a very large pot, leave a gap of at

least 50 mm (2”) to avoid damaging parts in

bench top wood, plastic or other non-heat re-

sistant materials. Never leave oil of hot fat unat-

tended.

♦Never leave the appliance unattended when the

burners are being used. Make sure there are no

children in the near vicinity. Particularly make

sure that the pan handle are correctly positioned

and keep a check on foods requiring oil and

grease to cook since these products can easily

catch fire.

♦Don’t use pans with buckled bottoms

♦Never pour water on burning fat or oil. Cover

with a damp cloth to extinguish fire and discon-

nect the cooking appliance.

♦Never place unstable pans or containers on the

cooking hob or burners as they may accidentally

tip over.

Warnings:

♦In the event of a fault disconnect the electri-

cal power to the cooktop and shut OFF the

gas supply. Contact your local gas supplier

or service agent. The service agent details

are at the rear of this manual.

♦Do not spray aerosols in the vicinity of this

appliance while it is in operation.

♦Where this appliance is installed in a marine

craft or in caravans, for safety reasons it

shall not be used as a space heater.

♦Unsuitable for use in a marine craft, cara-

vans or mobile homes, unless each burner is

fitted with a flame guard.

♦Do not modify this appliance.

♦This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities, or

lack of experience and knowledge, unless

they have been given supervision or instruc-

tion concerning use of the appliance by a

person responsible for their safety. Children

should be supervised to ensure that they do

not play with the appliance.

♦Make sure you keep these instructions for

use and assembly in a safe place, so that

you can hand them on with the appliance if

it ever changes owner.

5

User instructions

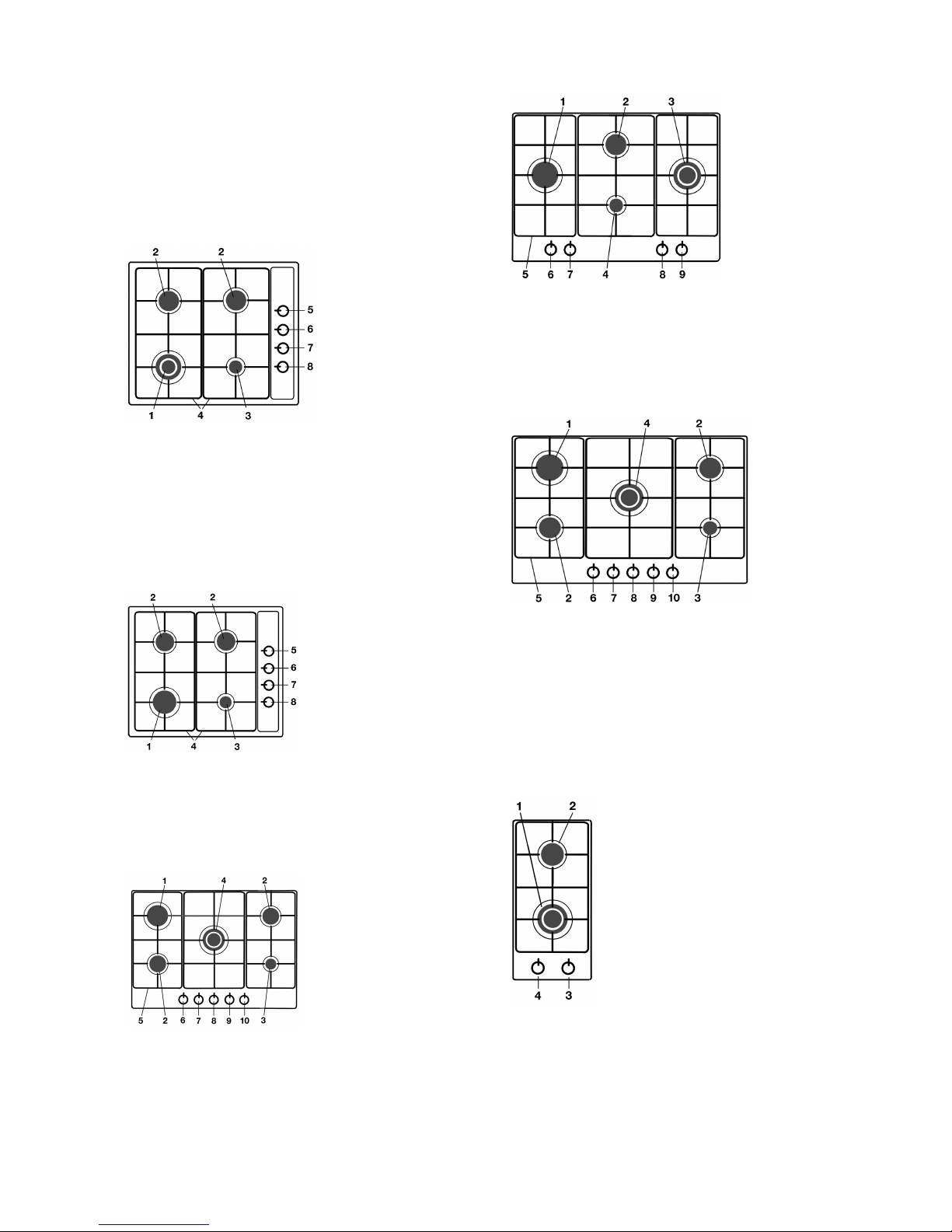

The lay-outs of the 5 cooktops covered in these in-

structions are shown below. Please check the model

number of your particular cooktop to identify your

lay-out.

Model No’s: BLGSW60CF & BLGSW60C (cast

iron pan supports).

Model No’s BLGSW60EF & BLGSW60E (enamel

pan supports)

1. Triple ring (wok) burner

2. Semi-rapid boiling burner

3. Auxiliary boiling burner

4. Cast iron pan support

5. Right front boiling burner control knob

6. Right rear boiling burner control knob

7. Left rear boiling burner control knob

8. Left front boiling burner control knob

Model No’s: BLGS60CF & BLGS60C (cast iron

pan supports)

Model No’s BLGS60EF & BLGS60E (enamel pan

supports)

1. Rapid boiling burner

2. Semi-rapid boiling burners

3. Auxiliary boiling burner

4. Wire pan support or cast iron pan support

5. Right front boiling burner control knob

6. Right rear boiling burner control knob

7. Left rear boiling burner control knob

8. Left front boiling burner control knob

Model No: BLGSW705CF & BLGSW705C

1. Rapid boiling burner

2. Semi-rapid boiling burners

3. Auxiliary boiling burner

4. Triple ring (wok) burner

5. Cast iron pan support

6. Left front boiling burner control knob

7. Left rear boiling burner control knob

8. Central triple ring (wok) burner control knob

9. Right rear boiling burner control knob

10. Right front boiling burner control knob

Model No: BLGSW704CF & BLGSW704C

1. Rapid boiling burner

2. Semi-rapid boiling burner

3. Triple ring (wok) burner

4. Auxiliary boiling burner

5. Cast iron pan support

6. Left boiling burner control knob

7. Central rear boiling burner

8. Central front boiling burner

9. Right boiling burner

Model No: BLGSW905CF & BLGSW905C

1. Rapid boiling burner

2. Semi-rapid boiling burners

3. Auxiliary boiling burner

4. Triple ring (wok) burner

5. Cast iron pan support

6. Left front boiling burner control knob

7. Left rear boiling burner control knob

8. Central triple ring (wok) burner control knob

9. Right rear boiling burner control knob

10. Right front boiling burner control knob

Model No: BLGSW30CF & BLGSW30C

1. Triple ring (wok) burner

2. Semi rapid boiling burner

3. Semi rapid burner control knob

4. Wok burner control knob

6

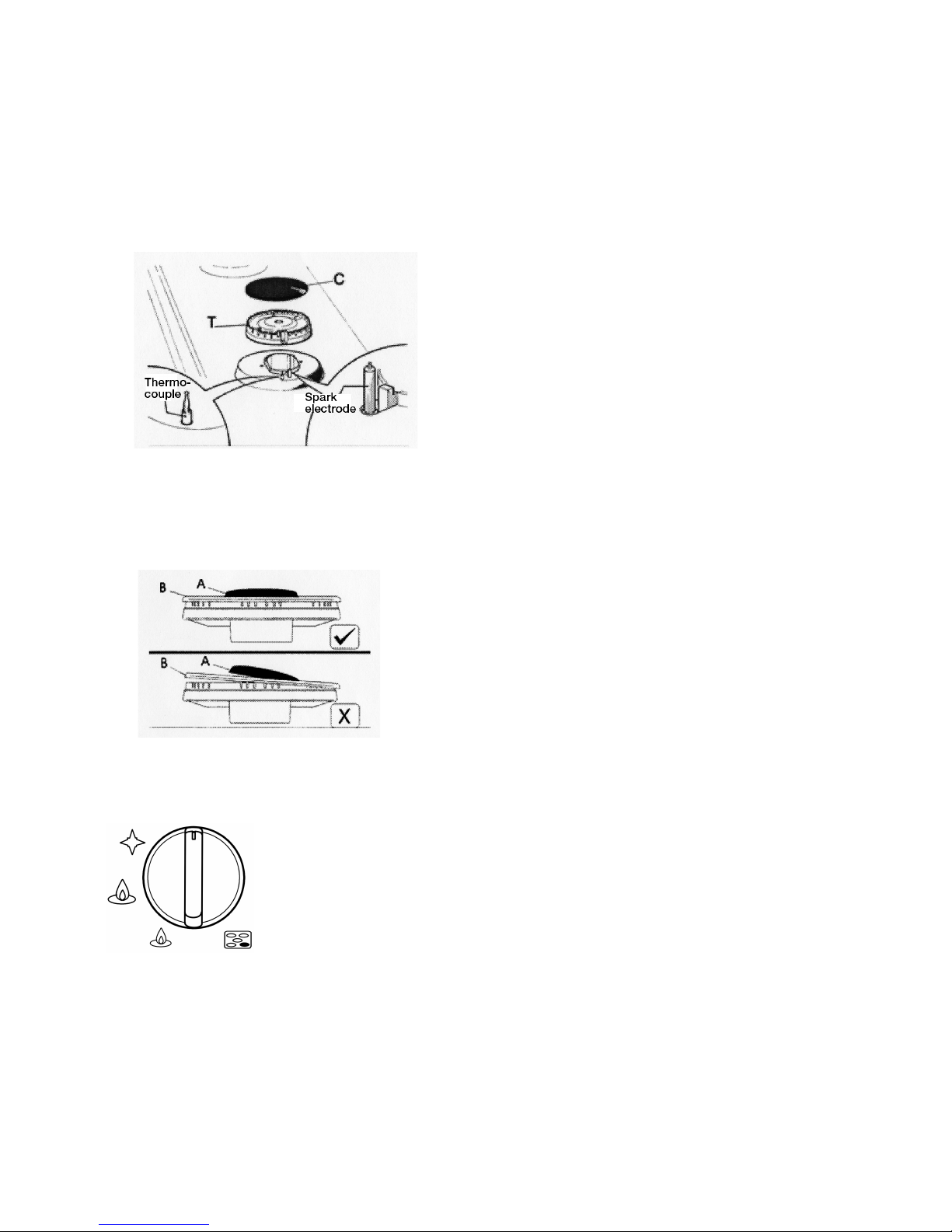

Burner operation and ignition

A graphic screen printed on the hob identifies the

individual control knob with the relevant boiling

burner. See preceding figures.

Place the boiling burner body (T) over the burner

stem ensuring that the boiling burner body is posi-

tively located over the spark ignition electrode and

that the burner cap (C) sits squarely on the burner

body.

The triple ring (wok) burner body is also placed over

the burner stem and is positively located over 4 re-

taining channels. The spark electrode is located out-

side the burner head perimeter. Place the outer

burner ring (B) cap and the inner burner cap (A) on

the burner head ensuring they are positively located

in position.

The burners have 2 heat settings:

Large flame = highest setting

Small flame = lowest (simmer) setting

The highest flame setting

is used for initial boiling.

For ongoing cooking a

variable setting between

high and low flame can be

made.

To activate the burner de-

press the control knob and

turn to the ‘high’ flame’ position. Keep knob de-

pressed for approx. 6-7 seconds to allow the safety

shut-off device to activate. The flame will extinguish

if the knob is released too soon. If ignition fails de-

press the control knob and try again. If the flame is

not established in 15 seconds, release the control

knob and open a door for ventilation and wait one

minute before attempting a new procedure.

If the burner flames are extinguished – for whatever

reason – turn OFF the control knob and wait at least

one minute before retrying to ignite the burner.

Ensure that the flames do not extinguish when you

reduce to low flame quickly.

To turn off the gas supply to the burner, return the

control knob to the ‘OFF’ position.

Manual ignition

In case of a power failure the burners can be manu-

ally ignited with a match.

Ventilation

Use of a cooking appliance produces heat and mois-

ture in the room in which it is installed. The room

must therefore be properly ventilated by keeping

natural air vents clear and by activating a mechani-

cal aeration device such as a range hood or exhaust

fan.

Abnormal operation

Burner flames should be clear blue, with no yellow

tipping. If the burner shows any abnormality check

that the burner heads are correctly located.

Any of the following are also considered to be ab-

normal and may require servicing:

♦Sooting of cooking utensils

♦Burners not igniting properly.

♦Burners failing to remain alight.

♦Burners extinguish by cupboard doors operation.

♦Gas valves are difficult to turn.

♦If service or spare parts are required refer to

contact details on rear page of this manual.

7

Cleaning the cooktop

Please clean cooktop thoroughly before first use.

Operate boiling burners and wok burner on HIGH for

a few minutes to eliminate the ‘new’ smell.

After installation, wipe clean all stainless steel parts

with a damp cloth to remove any traces of dirt. When

using a stainless steel cleaner ensure that all traces

of the cleaner are thoroughly removed.

Periodically wash the hotplate, the cast iron (or en-

amelled) pan supports, the burner heads and the

enamelled burner caps. Following this all parts

should be thoroughly rinsed and dried.

♦Never wash them while they are still warm .

♦Never use abrasive powders to clean the parts.

Do not allow vinegar, coffee, milk, salted water,

lemon or tomato juices to remain in contact with

the enamelled surfaces for long periods of time.

♦Check that burner heads and slots have not be-

come clogged with foreign bodies.

♦Check that burner heads and caps are posi-

tioned correctly. Refer figures on page 6

♦Check that pan supports are replaced correctly.

The rounded corners should be set towards the

side edges of the cooktop.

♦Do not use steam jets for cleaning the cooktop.

♦Always keep stainless steel from contact

with acid or acid based solvents (liquid or

vapour).

Preventative maintenance

This cooktop should not require ongoing mainte-

nance provided you ensure:

♦All spillages are cleaned as soon as they occur.

♦Burners are kept clean.

♦Burner ports are free of debris, food and any-

thing else that may cause obstruction.

♦Spark electrodes and thermocouples are kept

clean

♦Burners are assembled correctly.

♦Do not allow water into the area where the injec-

tors are located.

Installation instructions

Installer instructions

These instructions cover the installation of 8 different

cooktops. For dimensions refer drawings following

these installer instructions.

This appliance must be installed in a position with

the proper level of ventilation. Do not obstruct the

flow of combustion and ventilation air.

♦The gas pressure regulator supplied with the

appliance must be installed in line with the gas

pipe (N.G. only)

♦Before commencing any work, make sure that

the power point switches are turned off and the

three pin plug is removed.

♦If the appliance cannot be adjusted to perform

correctly contact Bestlink International or the

local gas utility. For service contact telephone

number refer page 15.

♦Instruct the user in the operation of the appli-

ance before leaving.

♦For pressure testing in excess of 3.5 kPa (1/2”

psig) the appliance and its individual shut-off

valve must be disconnected from the gas supply

piping system. For pressure testing of the gas

piping system at pressures equal or less than

3.5 kPa (1/2”psig) that appliance must be iso-

lated from the gas supply system by closing its

individual shut-off valve during any pressure

testing.

♦The data plate is attached to the bottom of the

unit. A duplicate copy is supplied at the back of

this instruction manual. The duplicate data plate

can be attached to the inside of an adjacent

cupboard door.

♦This appliance should not be connected to a

combustion product evacuation device.

♦Before installing the new cooktop make sure that

the measurements are all correct.

Statutory requirements

This appliance shall be installed in accordance with

the manufacturer’s installation instructions, local gas

fitting regulations, municipal building codes, electri-

cal wiring regulations and AS5601 the Australian

Standard for gas installations. Refer also AS5601 for

pipe sizing.

8

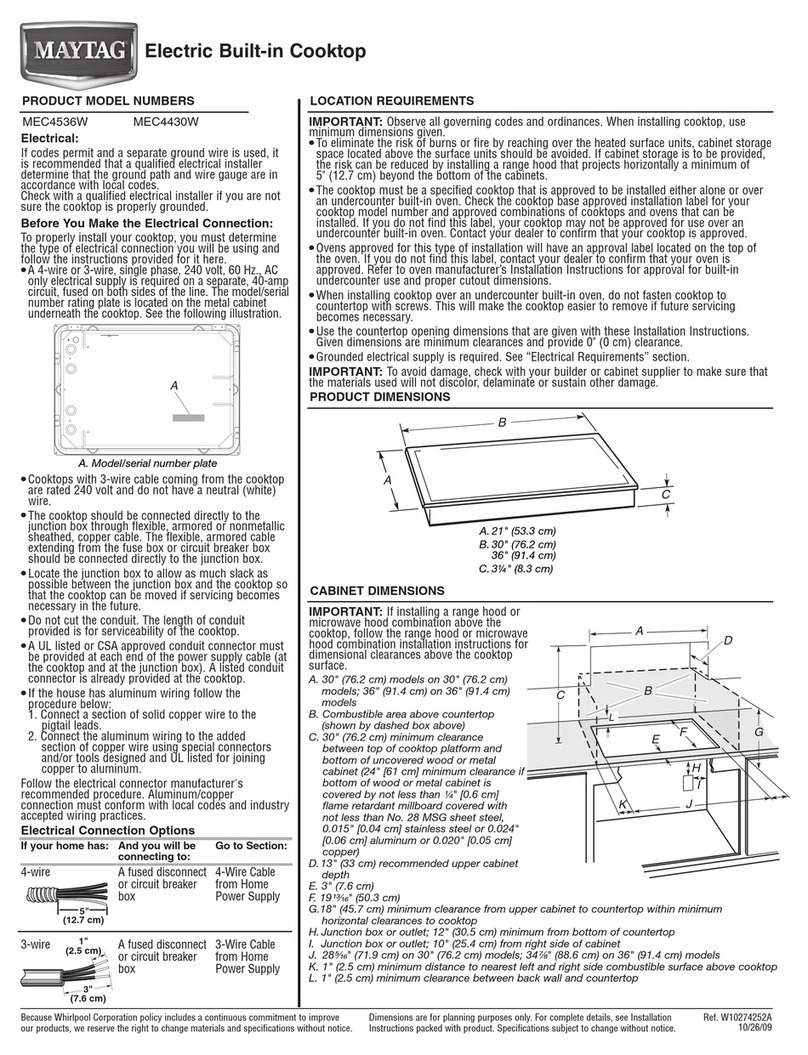

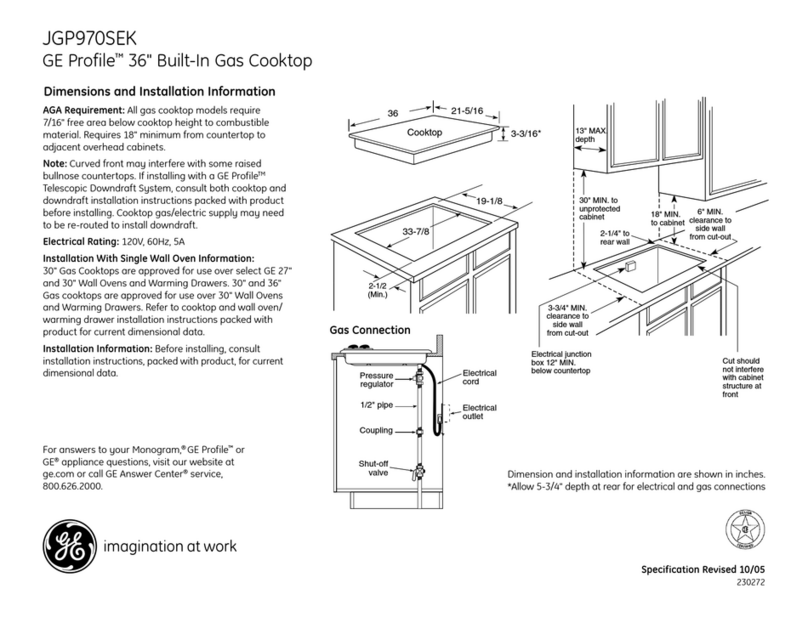

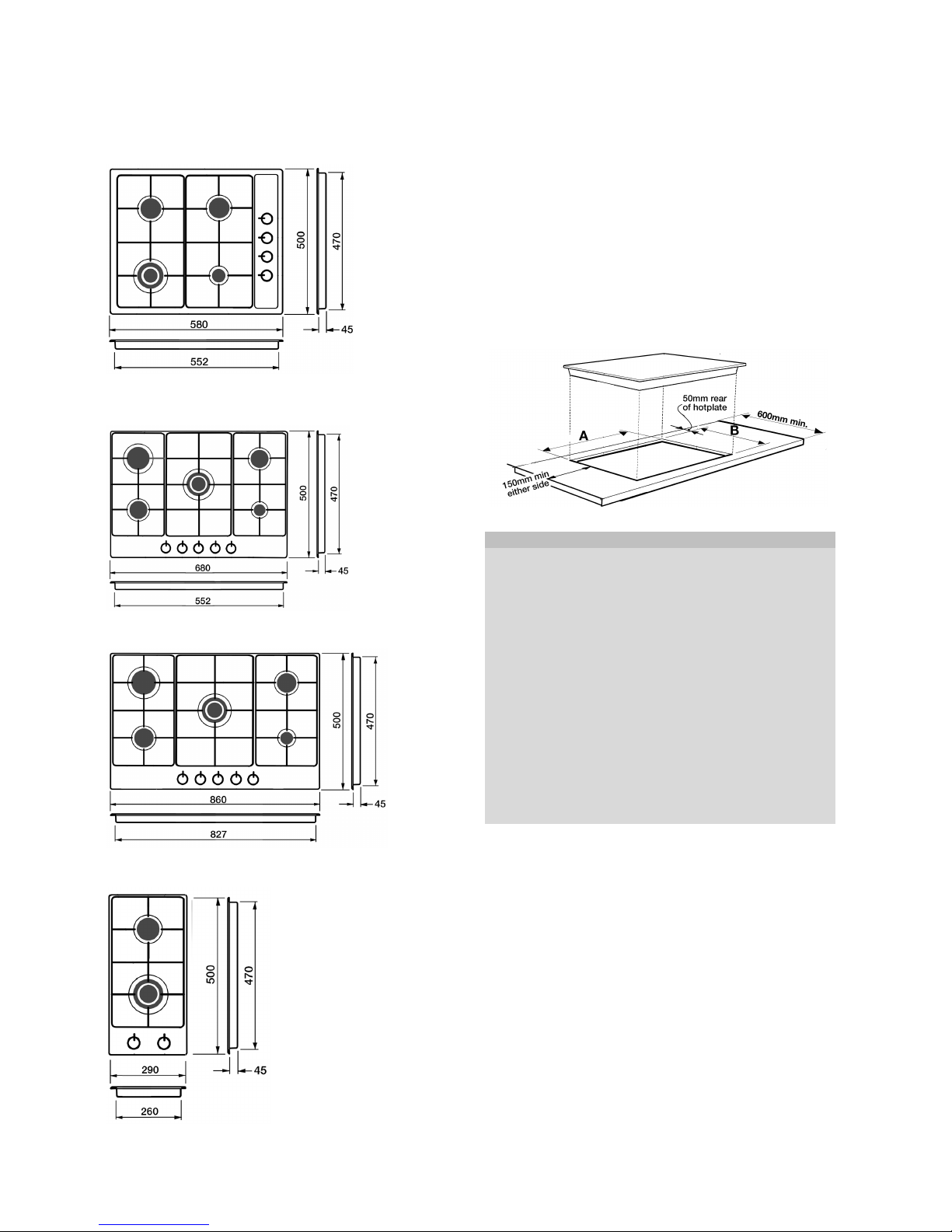

Overall dimensions

Model No’s: BLGSW60CF & BLGSW60C

BLGS60CF & BLGS60C

BLGS60EF & BLGS60E

BLGSW60EF & BLGSW60E

Model No’s: BLGSW705CF & BLGSW705C

BLGSW704CF & BLGSW704C

Model No: BLGSW905CF & BLGSW905C

Model No: BLGSW30CF & BLGSW30C

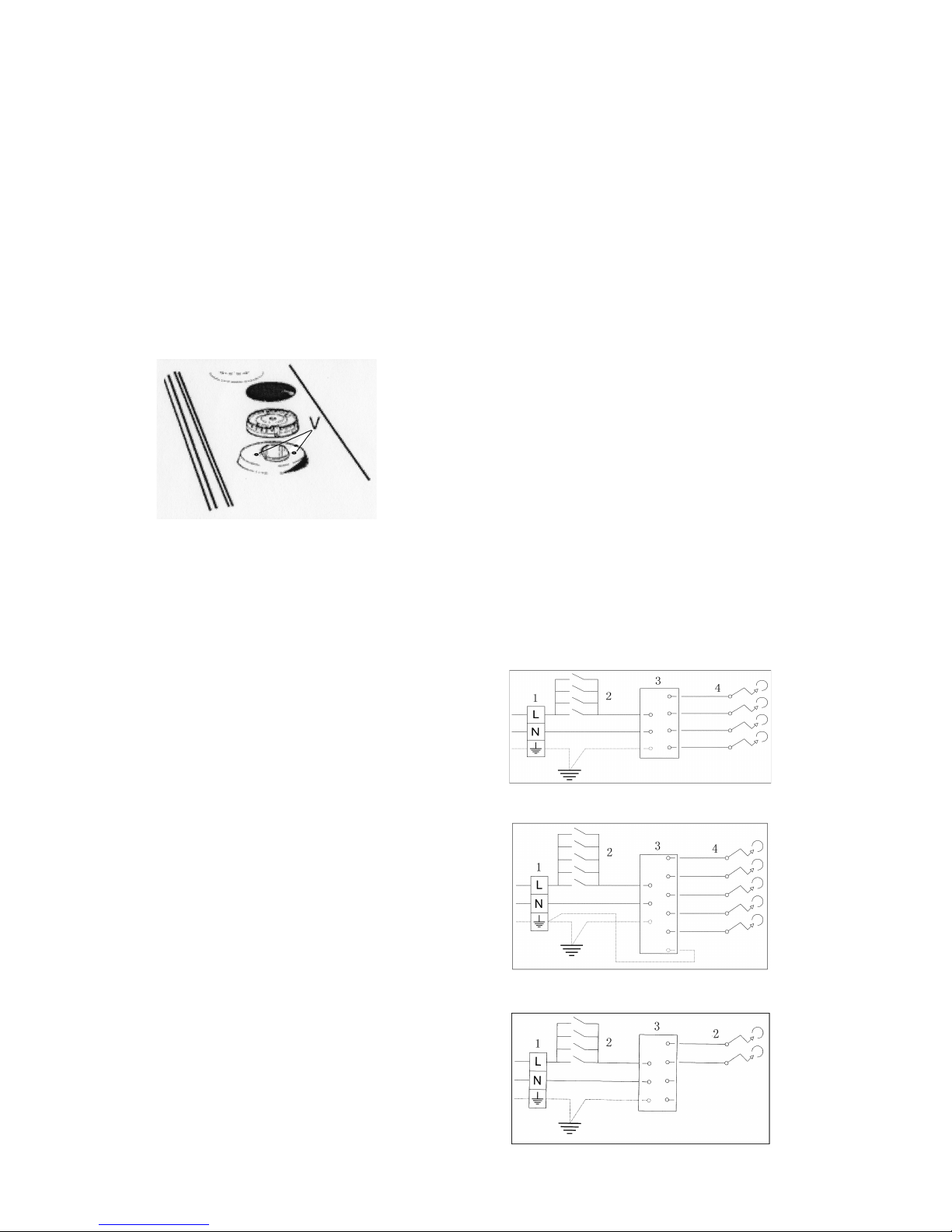

Installation dimensions & clearances

Only an authorised person should connect this ap-

pliance.

Check that the appliance is in good condition after

having removed the outer packaging and internal

wrappings from around the various loose parts.

Never leave the packaging materials (cardboard,

bags, polystyrene foam, staples, etc.) within chil-

dren’s reach since they could become potential

sources of danger.

These built-in cooktops are intended to be inserted

in a bench top cut-out. For cut-out dimensions refer

figure and chart following. Always comply with

measurements given for the cut-out into which the

appliance will be recessed.

Model No

A

B

BLGSW60CF

BLGSW60C

BLGSW60EF

BLGSW60E

BLGS60EF

BLGS60E

BLGS60CF

BLGS60CF

560

480

BLGSW705CF

BLGSW705C

BLGSW704CF

BLGSW704C

635

480

BLGSW90CF

BBLGSW90C

BLGSW30CF

BLGSW30C

830

270

480

480

Overhead clearances

A range hood fitted above the top must be installed

according to the installation instructions for the

range hood. A minimum distance of 650 mm is re-

quired for a range hood and 750 mm for an exhaust

fan. Minimum clearance to an overhead cupboard is

600 mm.

Side clearances

If the distance measured from the periphery of the

nearest burner to any vertical surface is less than

200 mm, the surface shall be protected in accord-

ance with clauses 5.12.1.1 & 5.12.1.2 of AS5601.

Bottom clearances

If an oven is positioned below the cooktop the barrier

does not need to be fitted, but a space of 60 mm

must be maintained between the underside of the

cooktop and the top of the oven.

9

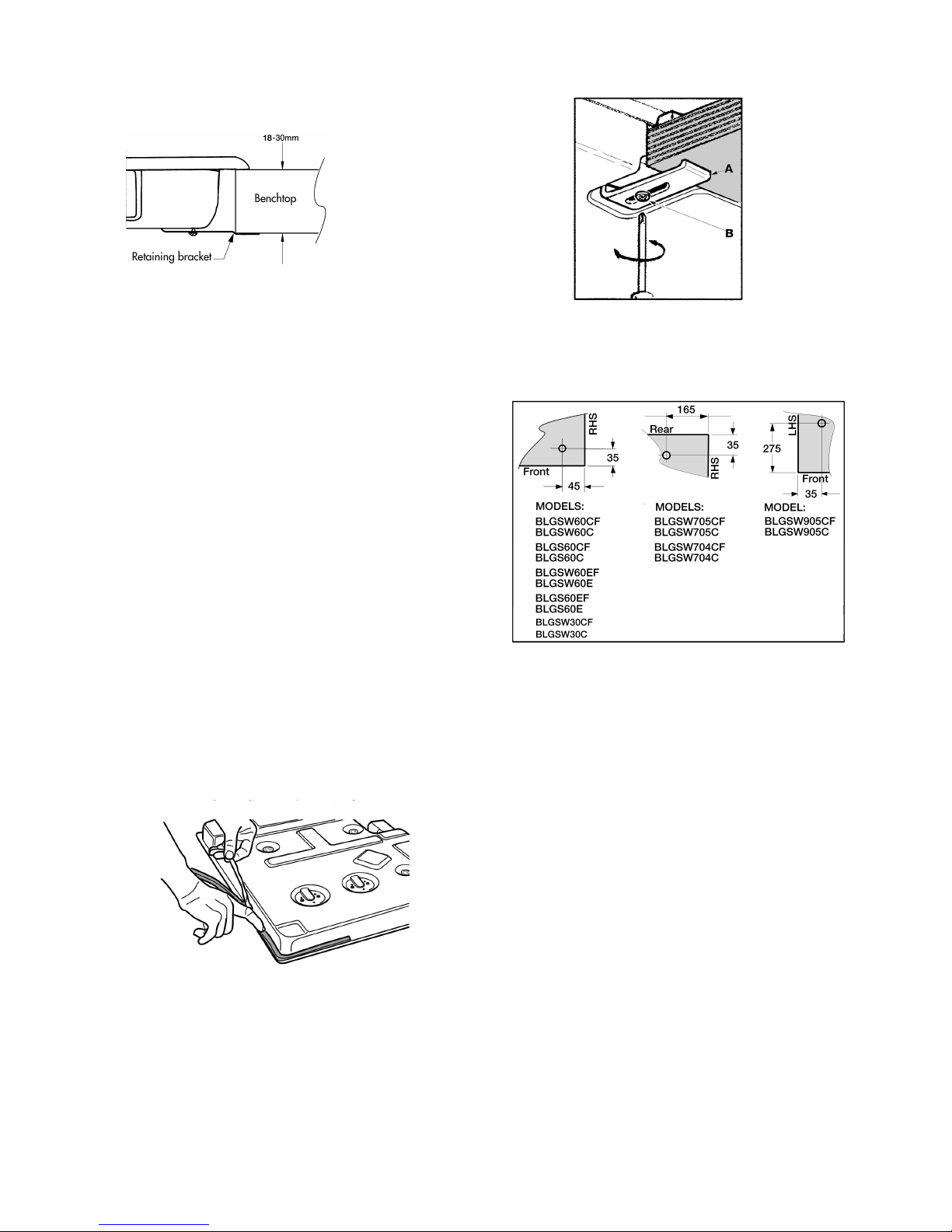

Bench top specifications

The cooktop can

be fitted to a

benchtop of 18-30

mm thickness.

Special considerations for installation over a

under bench oven

If installing the cooktop over an under bench oven

and connecting the cooktop via a hose assembly,

ensure that the hose assembly is retained from ac-

cidental contact with the flue outlet of the under

bench oven.

Installation procedure

Before connecting the unit, check whether the local

conditions (type of gas) are compatible with the

unit’s settings. The model number, type of appliance,

gas pressure, gas type, injector size and total hourly

gas consumption are noted on the data plate at-

tached to the underside of the cooktop base. A du-

plicate of this data plate is at the rear of this manual.

Observe any special conditions imposed by local

suppliers (utilities).

1. The cooktop has a special seal which prevents

liquid from getting into the cabinet. Strickly com-

ply with the following insructions in order to cor-

rectly apply the seal.

2. Detach the seals from their backing, checking

that the transparent protection still adheres to

the seal itself.

3. Turn over the cooktop and position the seal

under the edge of the hotplate itself so that the

outer edge of the seal perfectly matches the

outer edge of the hot plate. The end of the strips

must fit together without overlapping. Press the

seal down you’re your finger whilst removing the

protective paper strip.

4. Drop the cooktop into the cut-out. Check that ad-

joining vertical walls are at the required mini-

mum distance from the hotplate.

5. Fix the hob to the bench with the supplied

brackets (3 or 4 brackets depending on the

model) as indicated in the figure top right.

Gas connection

The position of the gas inlet position (before fitting

the Nat Gas regulator or LP transitional piece) is in-

dicated on the following figures

The cooktop must be connected to the gas supply

with up stream connection of an isolation valve, in

accordance with the respectively valid regulations.

We recommend that the isolation valve be fitted prior

to the cooktop to enable isolation of the cooktop

from the gas supply. The valve must be easily ac-

cessible at all times.

The supply connection point must be accessible with

the appliance installed.

Remove the plastic cap from gas supply prior to in-

stallation.

The unit can be connected with rigid pipe as speci-

fied in AS5601, table 3.1.

If installing with a hose assembly ensure the assem-

bly complies with AS/ANZ1869 (AGA approved), 10

mm ID, class B or D, no more than 1.2 m long and in

accordance with AS5601. Ensure that the hose does

not contact the surfaces of the cooktop, oven, dish-

washer or any other appliance that may be installed

underneath or next to the cooktop. The hose should

not be subjected to abrasion, kinking, or permanent

deformation and should be able to be inspected

along its entire length with the cooktop in the in-

stalled position. Unions compatible with the hose

fittings must be used and all connections tested for

gas leaks.

10

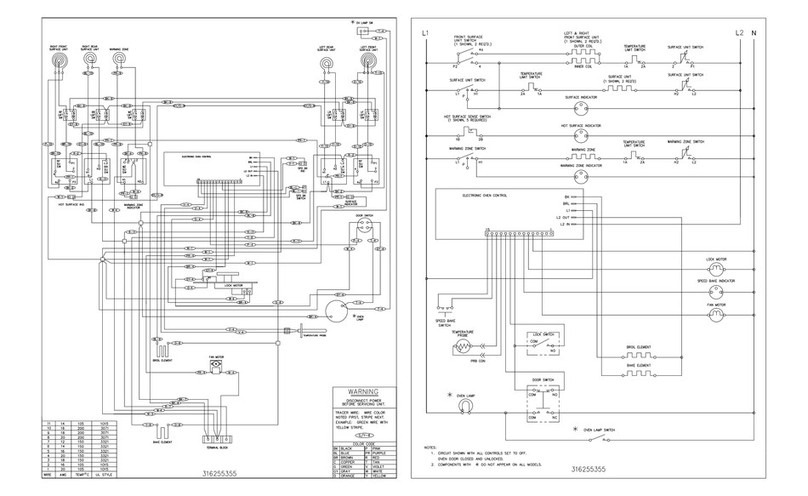

Natural Gas connection

Natural Gas installations

require the connection of

a gas regulator at the ap-

pliance. The regulator

and transition fittings are

supplied with the unit. Fit

as indicated in the adja-

cent figure. The transition

piece on the supply side

of the regulator must be

provided by the installer.

Propane Gas connection

In a LPG installation gas

regulation is made at the

gas cylinder and no fur-

ther regulator is re-

quired. Connect the

supply to the unit as

shown in the adjacent

figure

Check for gas sound-

ness at connections.

NEVER use a naked

flame to check for leaks.

The supply connection point must be accessible with

the appliance installed.

Boiling burner adjustments

These burners have no aeration adjustment.

To adjust the turn-down (simmer) rate (Nat Gas

only):

♦Turn the control knob to the ‘low flame’ position.

♦Pull control knob (M) off the gas tap spindle.

♦Insert a small screwdriver (D) into the hole down

the spindle (C) and turn the throttle screw to in-

crease or reduce flame height.

♦Check that the flame is stable when the control

knob is moved quickly from ‘full on’ to ‘turn-

down’ position.

Note: Burners operating on LPG should not be ad-

justed. The throttle screw must be fully screwed

down.

Check correct operation of each burner individually

and in combination. Burner flames should be clear

blue, with no yellow tipping. If the burner shown any

abnormality, check that the burner heads are cor-

rectly located and refer to the ‘maintenance’ section

on page 14. If satisfactory performance cannot be

obtained, contact Bestlink International or the local

gas utility. For service contact number refer to back

page of the cut-out.

Energy consumption

Natural gas

Burner

NG injector

size (mm)

1 kPa

NG

MJ/hr

Double ring (wok)

burner

1.70

13.50

Rapid burner

1.40

10.50

Semi rapid burner

1.10

6.00

Auxiliary burner

0.90

3.50

LP gas

Burner

LP injector

size (mm)

2.75 kPa

LP

MJ/hr

Double ring (wok)

burner

0.98

12.50

Rapid burner

0.90

10.50

Semi rapid burner

0.70

6.00

Auxiliary burner

0.55

4.00

Electrical connection

The cooktop is fitted with a 1.8 m electric lead. A

10 amp socket must be within 1 m of the cooktop.

The socket must remain accessible after installation

of the unit.

Important note:

The power lead must be fixed to the kitchen unit to

prevent it coming into contact with hot parts of the

hob (or an oven installed underneath) and remain

accessible after installation of the cooktop.

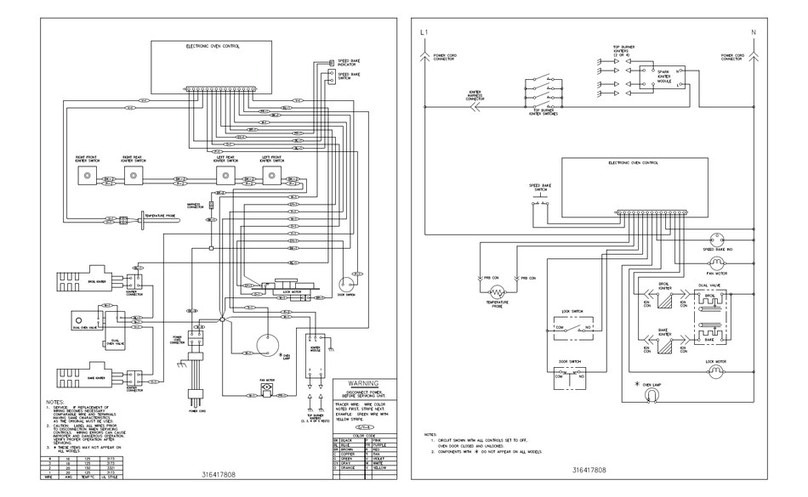

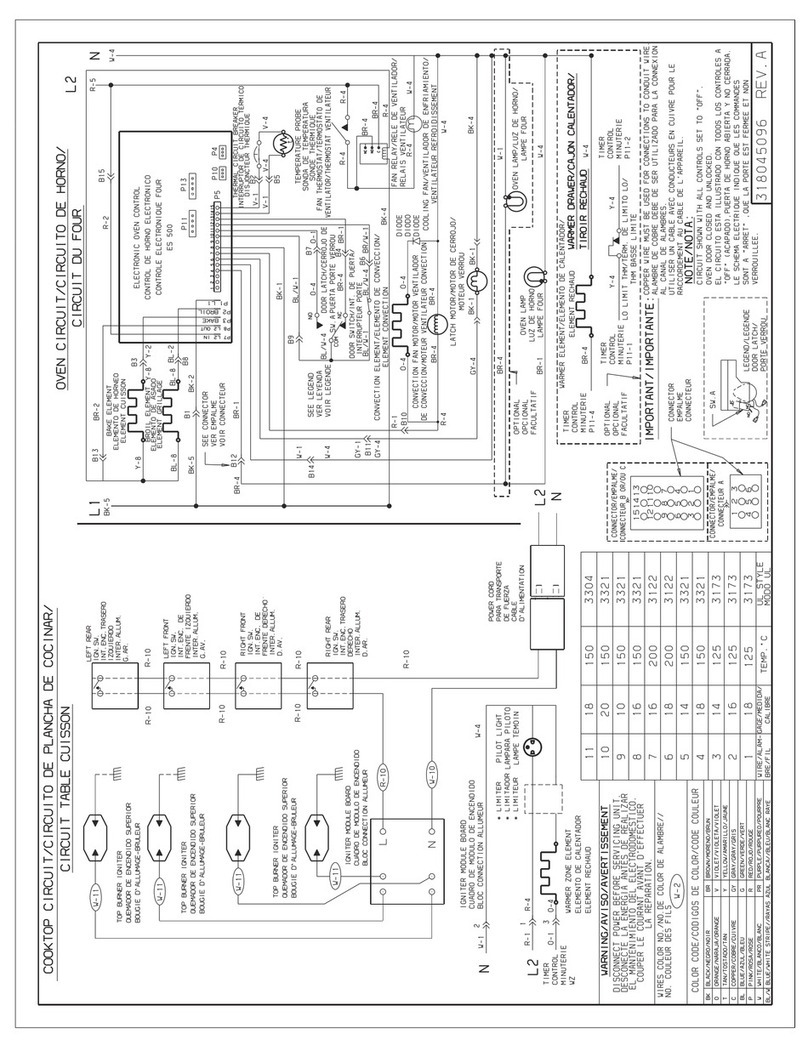

The wiring diagram is attached to the underside of

the unit. A copy is also printed at the back of this

manual.

The appliance must be earthed.

Warranty warning

It should be noted that we can not accept any liability

for direct or indirect damage caused by wrong con-

nection or improper installation. When being re-

paired , the appliance must always be disconnected

from the main gas and electricity supply; if required

notify our customer service.

11

Conversion

Propane Gas to Natural Gas

1. Shut off gas supply to the appliance.

2. Remove each burner cap and burner skirt.

3. Remove the Propane Gas injector (A) with a 7

mm/VF tube spanner (B) and replace with the

appropriate size Natural Gas injector for each

burner. The injector sizes required for Natural

Gas conversion are listed on the table on previ-

ous page.

4. Disconnect gas inlet pipe from the LPG Gas test

point inlet fitting.

5. Remove the Propane Gas test point inlet fitting

from the appliance.

6. Fit the Natural Gas Regulator supplied in the

conversion kit.

7. Connect the gas supply to the regulator. (Check

the direction of the regulator gas flow).

8. Check for gas leaks. NEVER use a naked flame

to check for gas leaks.

9. Adjust the gas pressure to 1.00 kPa.

10. Remove the control knob. Using a thin shaft

blade screwdriver down the centre of each gas

valve shaft, screw the throttle anti-clockwise to

achieve a stable simmer position. Test the ap-

pliance on both high and low flame for each

burner. If the burner fails to remain alight or the

flame is not stable on the simmer setting, adjust

the by-pass screw, until flame is stable.

11.

Remove the ‘Only for use with Propane Gas’

label and replace with ‘Only for use with Natu-

ral Gas’ label. Label supplied in the conversion

kit.

Natural Gas to Propane

1. Remove each burner cap and burner skirt.

2. Shut off gas supply to the appliance.

3. Remove each burner cap and burner skirt.

4. Remove the Natural Gas main injector with a

7

mm/VF tube spanner and replace with the

appropriate size Propane Gas main injector for

each burner. The injector sizes required for Pro-

pane Gas conversion are listed on the table on

previous page.

5. Remove the control knob, with a thin shaft blade

screwdriver down the centre of each gas

valve

spindle, screw the throttle fully down clock-

wise.

6. Disconnect gas inlet pipe from the Natural Gas

Regulator.

7. Remove the Natural Gas Regulator

from the

appliance.

8. Fit the Propane Gas test point

inlet fitting

sup-

plied in the conversion kit.

9. Connect the gas supply to the inlet fitting.

10. Open gas supply to the appliance.

11. Check for gas leaks. NEVER use a naked flame

to check for gas leaks.

12. Adjust the gas pressure to 2.75 kPa.

13. Test the appliance on both high and low flame

for each burner and check the gas pressure. If

the

burner fails to remain alight or the flame

is not

stable on the simmer setting, adjust the

by-pass

screw, until flame is stable.

14. Remove the ‘Only for use with Natural Gas’

label’ and replace with ‘Only for use with Pro-

pane Gas’ label. Label supplied in the conver-

sion kit.

12

Trouble shooting

If problems occur please check the procedures listed

below before calling a service agent. If the fault find-

ing procedures do not rectify the problem contact

your service agent. For contact details refer back

page 14 of this manual.

Important:

Only an authorised person from the Service Agent is

qualified to service gas and electric systems.

What’s wrong

Possible cause

Solution

If none of the electrical systems

work

♦Power turned off.

♦Faulty fuse.

♦The automatic safety switch

has been tripped or a fuse

has blown.

♦Turn power on.

♦Check the fuse in the main

fuse box and replace if

faulty.

♦Check the main fuse to

whether the automatic trip

switch or a differential

switch has tripped.

The electronic ignition system

does not work.

♦There may be food or clean-

ing product particles be-

tween the spark plugs and

the burners.

♦The burners are wet.

♦The burner caps are not

located correctly.

♦Clean the gap between the

spark plug ad the burner.

♦Dry the burner carefully.

♦Make sure that the burner

caps are located correctly.

The flames on the burners are

not evenly distributed.

♦The burner has not been

assembled correctly.

♦The burner gas ports are

dirty.

♦Assemble the burner com-

ponents correctly.

♦Clean the burner gas ports.

The gas flow does not seem

normal or there is no gas flow at

all.

♦The isolation valve is

closed.

♦If gas is supplied from a gas

bottle, the bottle may be

empty.

♦Open the isolation valve.

♦Replace the gas bottle with

a full one.

You can smell gas.

♦One of the gas taps has

been left open.

♦Possible leak on the gas

bottle coupling.

♦Check all the gas taps are

closed.

♦Check that the gas coupling

on the bottles is in order.

If the safety shut off on a burner

does not work.

♦The control knob was not

held down long enough.

♦The burner ports are dirty.

♦Hold the burner down a few

seconds longer on ignition.

♦Clean the burner ports.

Flames are normally blue and sharply defined. If flames are yellowish or noisy, or if the gas does not ig-

nite within the period specified under ‘boiling burner operation’, abnormal operation is indicated. Call your

local Service Agent.

13

Service

THIS APPLIANCE SHALL NOT BE MODIFIED.

Service and maintenance should only be carried

out by an

authorised person.

To replace injectors

Refer page 11.

To remove hob

Close gas isolation valve and disconnect electric

supply.

♦Remove control knobs, pan supports, burner

skirts and caps.

♦

Remove the screws securing the burner bod-

ies to the hob, ‘V’. Two for the boiling burners

and 4 for the wok burner.

.

♦Lift the hob off to expose the

internal parts of

the cooktop.

Replacement of the electrical

components and the taps is now possible.

To remove and service gas control

valves

Access to the burner compartment is as per ‘To re-

move hob’.

The gas control valves are secured to the manifold

by means of a clamp fixed via two screws. If a gas

control valve becomes stiff to operate, it must be

immediately greased in compliance with the following

instructions:

1. Remove the tap.

2. Clean the cone and its housing using a cloth

soaked in solvent.

3. Lightly spread the cone with the relevant grease.

4. Fit the cone back in place, operate it several

times and then remove it again. Eliminate any

excess grease and check that the gas ducts

have not become clogged.

5. Reassemble in reverse order.

6. Check for leaks using a foamy liquid.

If replacing the whole tap it is advisable to replace

the tap gasket to ensure perfect tightness.

To replace the thermocouple

Access to the burner compartment is as per ‘To re-

move hob’.

♦Remove the retaining nut securing the thermo-

couple.

♦Remove connection from the electronic ignition

module.

♦Replace defective apart.

♦Reassemble in reverse order.

To replace the spark electrode

Access to the burner compartment is as per ‘To re-

move hob’.

♦Remove the spring clip securing the spark elec-

trode to the burner body.

♦Disconnect the spark ignition lead from the igni-

tion module.

♦Replace defective part.

♦Reassemble in reverse order.

To replace the electronic ignition

module

Access to the burner compartment is as per ‘To re-

move hob’.

♦Disconnect the leads from the ignition module.

♦Remove the securing nut on either side of the

module.

♦Replace the defective part.

♦Reassemble in reverse order.

To replace internal wiring and gas

control ignition micro switch

Access to the burner compartment is as per ‘To re-

move hob’.

♦Disconnect wiring between ignition module and

gas control.

♦Replace defective part.

♦Reassemble in reverse order.

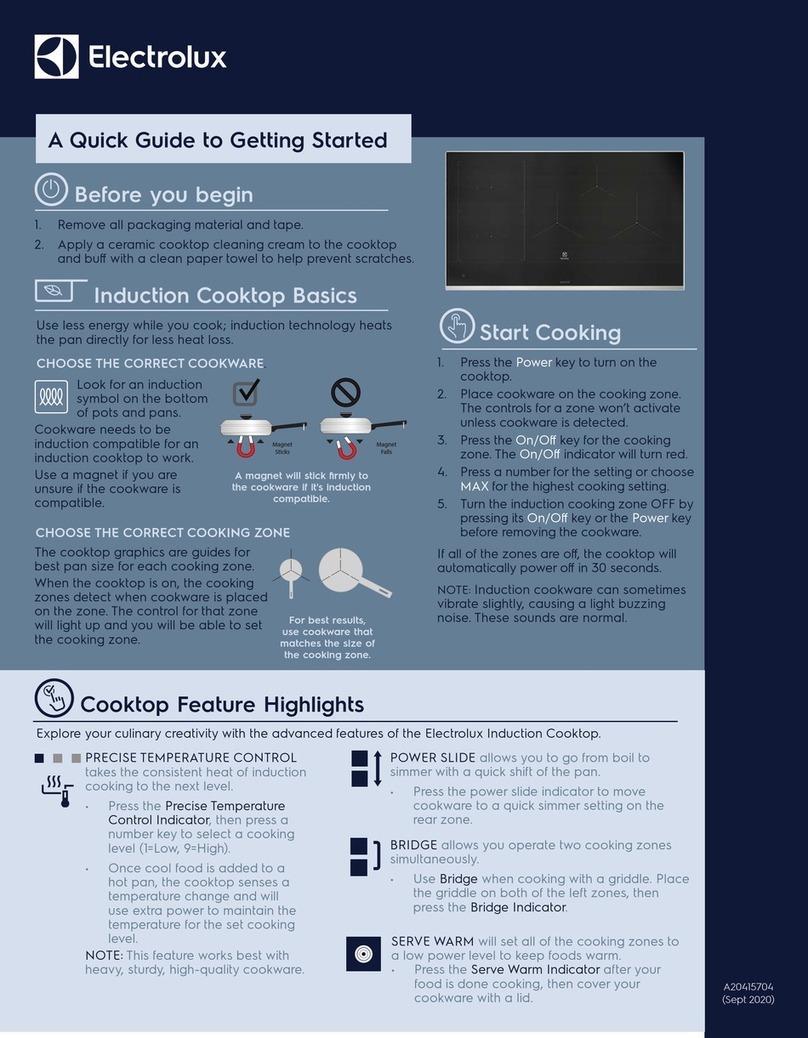

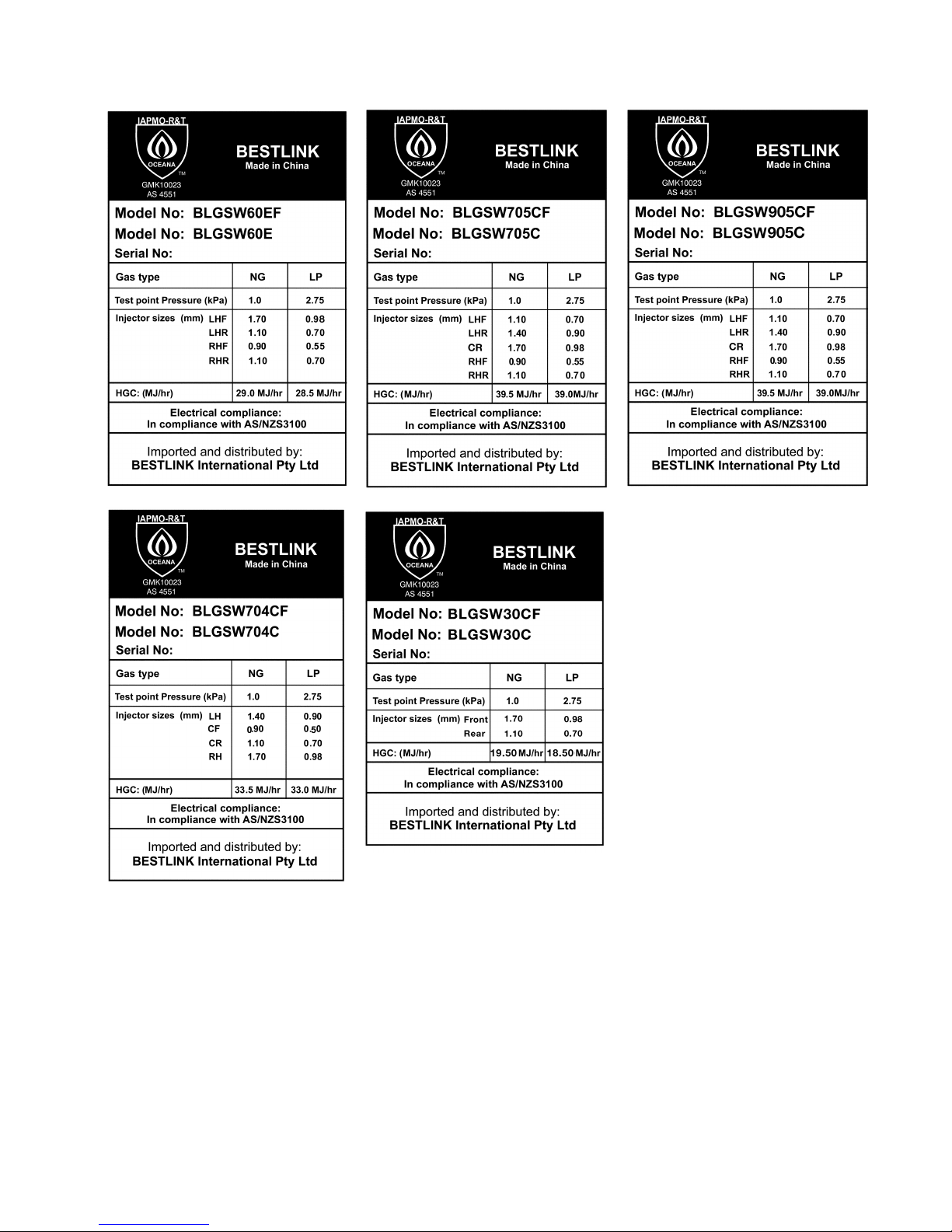

Wiring diagrams

4 Burner models

5 burner models

2 burner model

14

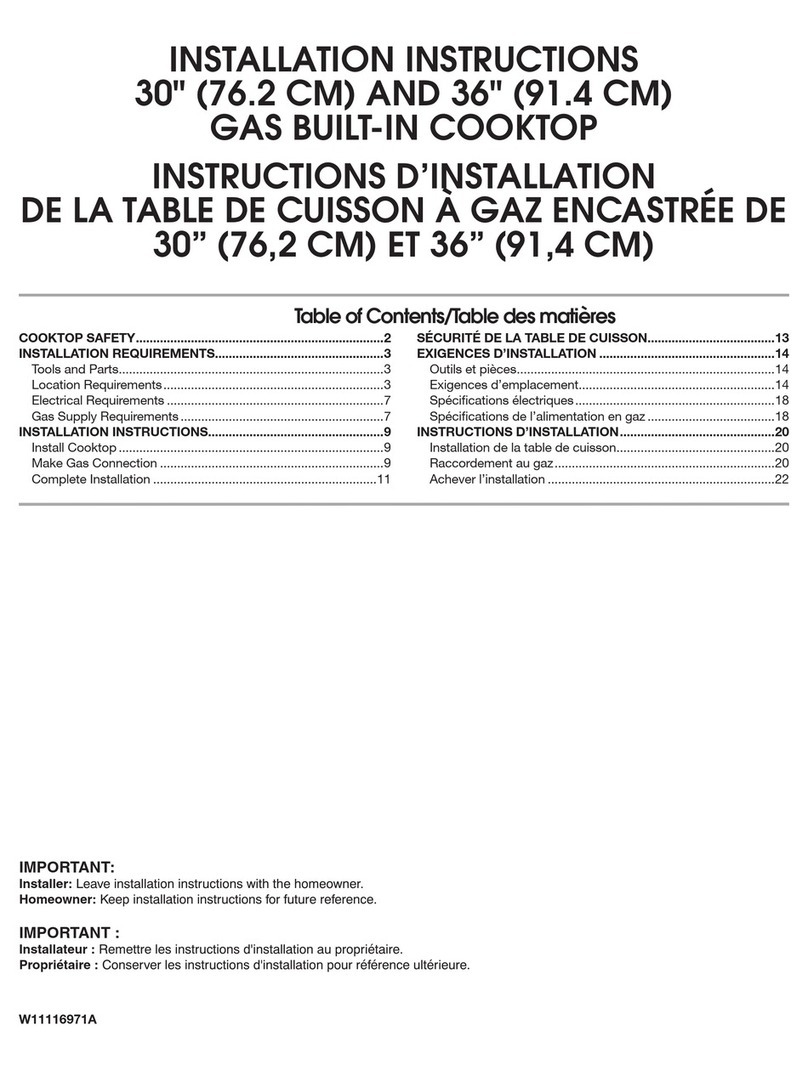

Data plates

For service and spare parts contact:

1800 886 010

This manual suits for next models

15

Table of contents