BHS systems 880600V02 User manual

Cooling / freezing cabinet

MODEL: 880600V02, 880601V02

INSTRUCTION MANUAL

translation of the original manual

Riga, Vagonu iela 23 LV-1009

v2.0 - 02.2019

- 2 -

TABLE OF CONTENTS

1. SAFETY INSTRUCTIONS ..........................................................................................................................3

2. DESCRIPTION AND INTENDED USE OF THE APPLIANCE..................................................................3

3. TECHNICAL SPECIFICATION ..................................................................................................................4

4. PRODUCT CARD .......................................................................................................................................4

5. TRANSPORT AND STORAGE ..................................................................................................................5

6. INSTALLATION ..........................................................................................................................................5

6.1. Positioning of the appliance ................................................................................................................................5

6.2. Electrical connection ...........................................................................................................................................5

7. CONTROL PANEL OPTION 1 ...................................................................................................................5

7.1. Description of parameters ..................................................................................................................................6

7.2. Buttons functions ................................................................................................................................................6

7.3. Compressor operation and defrost function control .........................................................................................6

7.4. Error messages ....................................................................................................................................................7

8. CONTROL PANEL OPTION 2 ...................................................................................................................7

8.1. Description of indicator lights ............................................................................................................................7

8.2. How to check the duration of the alarm and the minimum and maximum temperature ...............................8

8.3. Deleting constantly occurring saved alarm ........................................................................................................8

8.4. How to check the settings ..................................................................................................................................8

8.5. How to change the settings ................................................................................................................................8

8.6. Starting manual defrosting .................................................................................................................................8

8.7. Changing of parameters value ............................................................................................................................8

8.8. Locking of the keyboard .....................................................................................................................................8

8.9. Unlocking of the keyboard ..................................................................................................................................8

8.10. Continuous mode ..............................................................................................................................................8

8.11. Alarms ................................................................................................................................................................8

9. CLEANING AND MAINTENANCE ...........................................................................................................9

10. PROCEDURE IN THE EVENT OF POWER FAILURE .............................................................................9

10.1. Starting the appliance in case the temperature has gone beyond the alarm value .......................................9

10.2. Starting the appliance in case the temperature has gone below the alarm value .........................................9

11. DISPOSAL OF THE OLD APPLIANCE ....................................................................................................9

12. GUARANTEE ............................................................................................................................................9

13. WIRING DIAGRAM ..................................................................................................................................10

14. DECLARATION OF CONFORMITY ........................................................................................................10

+ 371 25522233

- 3 -

Thank you for the purchase of our product. Please read this manual carefully before starting to operate the

appliance.

All rights reserved. No part of this manual may be reproduced by photocopy, printing or in any other way without

prior consent

from the manufacturer.

Photographs and drawings are furnished by way of example and can vary from the purchased appliance.

NOTE: Keep the manual in a safe place accessible for the personnel.

The manufacturer reserves the right to change technical parameters of the appliance at any time without

advance notice.

1. SAFETY INSTRUCTIONS

•Incorrect operation and improper use can result in serious damage to the appliance or personal injury.

•Use this appliance solely for its intended use as described in this manual.

•The manufacturer cannot be held liable for any damage caused by incorrect operation and improper use of the appliance.

•During operating keep the appliance and the plug away from water or other liquids. In case the appliance, as a result of care-

lessness, has been immersed in water or flooded by water immediately unplug the appliance from the wall

socket and prior

to further use contact a qualified technician for examination.

•Failure to observe instructions enclosed in this manual may result in the hazard of injury or death.

•Do not let unauthorized opening of the housing of the appliance.

•Do not insert any foreign objects into the housing of the appliance.

•Do not touch the plug and the power cord with damp hands.

•Regularly check the condition of the plug and the cord. If the power cord or the plug is damaged they should be replaced by

the Authorized Technical Service personnel.

•In case the appliance is dropped or damaged in any other way before turning it on always contact the Authorized Technical

Service for examination and repair.

•Any repairs and work on the appliance should be carried out solely by Authorized Technical Service, never by the end user as

unauthorized tampering could prove highly dangerous for the user.

•Do not let the cord hang over or touch hot surfaces or sharp edges. Keep the cord away from naked fire. When disconnecting

the appliance from the wall socket, pull on the plug, never on the cord.

•Do not let the cord (or extension cord) be inadvertently pulled on or tripped over.

•Check the operation of the appliance during usage.

•This appliance can be used by children in the age of eight and more or by persons with reduced physical, sensory or mental

capabilities or lack of knowledge and experience in operating of the appliance, if they have been given

supervision or instruc-

tion concerning use of the appliance in a safe way by a person responsible for their safety and they

understand the hazards

involved. Children should not play with the appliance. Children should not perform cleaning or maintenance

of the appliance

without supervision.

•Always switch off the appliance and unplug the power cord from the wall socket when the appliance is not in use and prior to

cleaning operations. The disconnected plug should be sited in a visible place.

•Warning: The appliance’s power will remain ON unless unplugged.

•Turn off the appliance before pulling the plug out of the wall socket.

•Never pull the appliance on the cord.

•It is prohibited to store any explosive substances such as aerosol / flammable gas cans in the appliance.

•WARNING: Do not block or cover any ventilation openings in the equipment casing or in the built-in structure.

•WARNING: Do not use mechanical or any other means to accelerate the defrosting process other than recommended by

the manufacturer.

•WARNING: Protect the refrigeration system from damage.

•WARNING: Do not use any type of electrical equipment other than recommended by the manufacturer inside the food

storage chamber.

2. DESCRIPTION AND INTENDED USE OF THE APPLIANCE

•the cooling cabinet is intended for short-term storage of pre-chilled food products.

•the freezing cabinet are intended for storage of pre-frozen food products

•the housing of the appliance is made of stainless steel

•forced air circulation

•digital controller with temperature display

•built-in key lock

•automatic defrosting

- 4 -

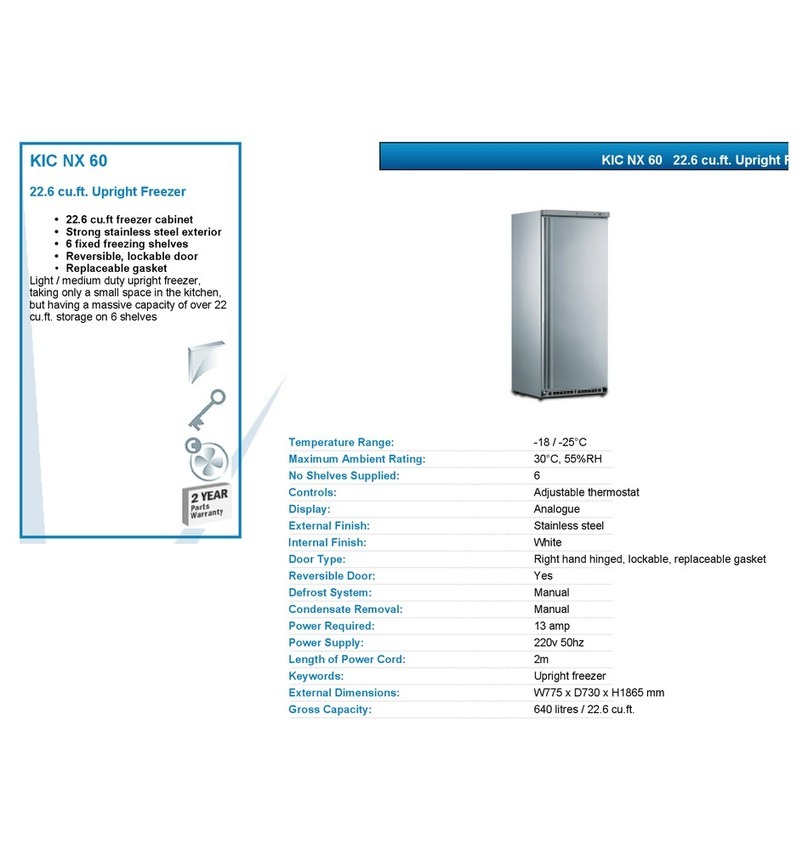

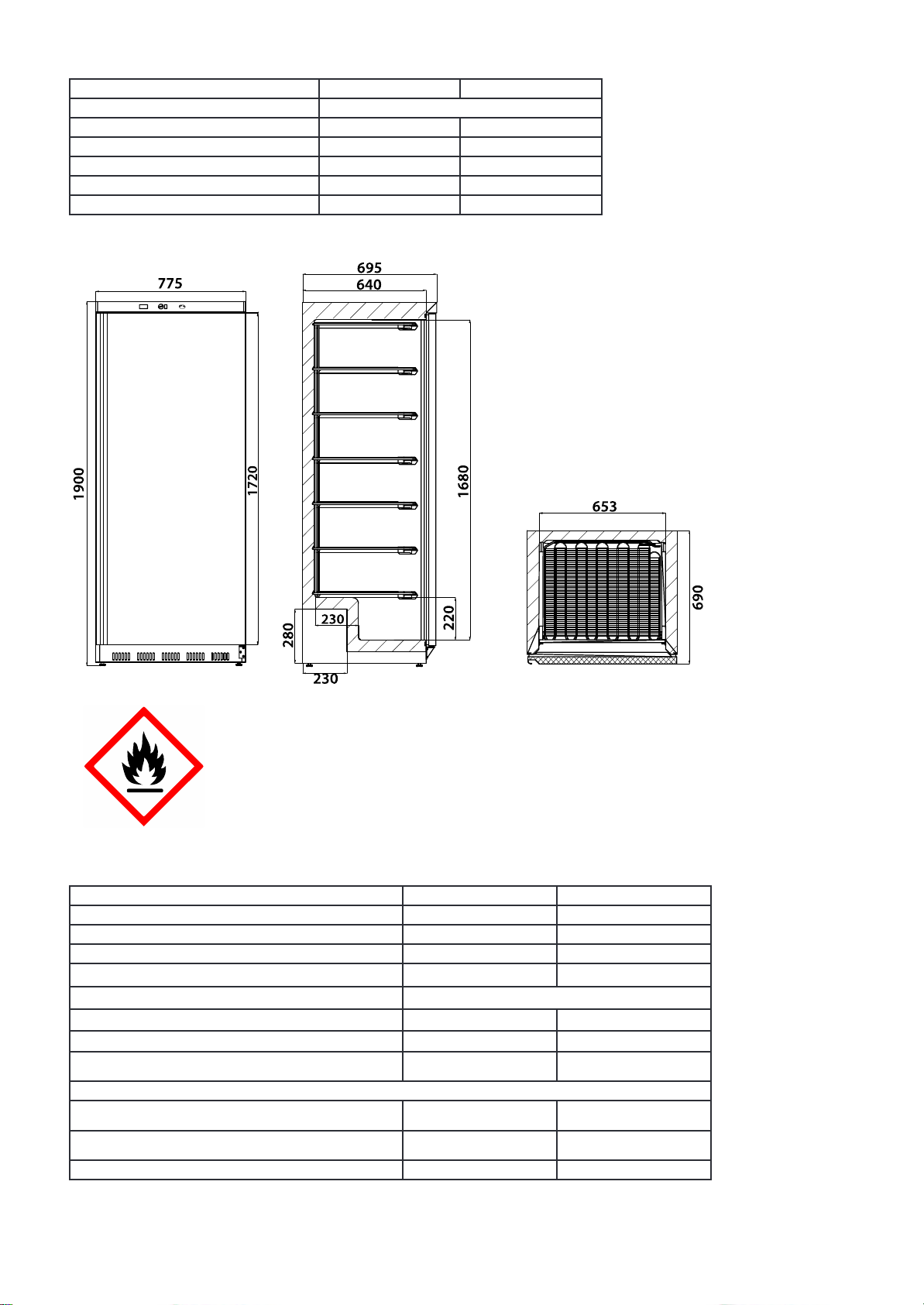

3. TECHNICAL SPECIFICATION

Model 880600v02 880601v02

Voltage (V/Hz) 230 / 50

Power (W) 130 300

Temperature range (

oC) 0 / + 8 -10 / - 18

Dimensions (WxDxH) (mm) 775x695x1900 775x695x1900

Climate class * 4 4

Weight (kg) 90 94

* 4 - to + 30 °C / relative humidity

55 %

* 5 - to + 40 °C / relative humidity

40 %

880600v02

880601v02

The device contains R290 or R600a coolant - natural, ecological, flammable gas.

Take special care when transporting and installing the device to avoid damaging the cooling

circuit.

If a leak is revealed, refrain from using devices/items that could cause sparks or fire and

ventilate the room.

To avoid the formation of a flammable gas mixture in the event of a leak from the

refrigeration system,

install the device in a room with area of 1m

3 per every 8 g of the coolant. The amount of coolant is given in

„TECHNICAL DATA” and on the nameplate.

4. PRODUCT CARD

Model 880600v02 880601v02

Intended use storage storage

Operating temperature cooling freezing

Category vertical vertical

Refrigerants: R600a, GWP=3 R600a, GWP=3

Parameter Value

Annual energy consumption AEC (kWh) 672 989

Coefficient of energetic efficiency EEI 48,3 26.14

Net capacity V

N (L) 476 469

(where applicable)

Refrigeration

capacity V NRef (L) 476 0.0

Freezing capacity V

NFrz (L) 0 469

Amount of refrigerant (kg) 0.10 0.13

- 5 -

5. TRANSPORT AND STORAGE

The appliance is protected with a protective film, placed on a wooden pallet, packed in a cardboard box and secured with stripes.

•packaged appliance should be stored in a covered warehouse at an ambient temperature of 0 °C / + 55 °C and humidity of

30 - 95 %;

•it is forbidden to stack appliances;

•read the data on the appliance rating plate. In case of damage or loss of the rating plate it should be replaced immediately;

•do not unscrew the safety guards;

•after unpacking the appliance, carefully remove the protective film and other elements protecting the appliance during trans-

port;

•while lifting the appliance with a lift, position the lift on the outside of the frame;

•transport the appliance and store it exclusively in a vertical position. Never place the appliance on its side or upside down,

because it can damage the cooling system (not subject to warranty repair);

•after transporting or moving the appliance wait 2 hours before starting it;

•do not place the appliance in the vicinity of flammable products, outdoors or in a place subject to direct sunlight exposure.

6. INSTALLATION

6.1. Positioning of the appliance

The appliance should be placed in a dry, adequately ventilated room. In order to ensure proper work

do not place the appliance near a heat source and do not expose it to direct sunlight. The optimal temperature

range in the room

in which the appliance operates is between: + 16 °C and + 35 °C.

If you install the appliance in a room with high humidity level, you may need to buy an additional tray for

condensed water.

Avoid placing the appliance in rooms with a high chlorine and acids content in the air (e.g.

at a pool), as this may cause corrosion of the surface made of stainless steel.

The cooling cabinet is prepared to be positioned at a wall as a free standing appliance.

Important: The cooling cabinet should be installed in a place with proper ventilation ensuring free air

circulation around the ap -

pliance. The correct distance from the rear panel of the appliance to a wall is ensured by special elements placed

at the back of the

cabinet. Do not place the appliance in the vicinity of flammable products, in the open air or in a place exposed to

direct sunlight.

The rubber bumpers must be screwed into the back of the unit as shown. Failure to do so will void the warranty and may cause

compressor failure

6.2. Electrical connection

The appliance should be connected to an AC power source.

Before connecting the appliance to the mains, make sure that the voltage and frequency values given on the

rating plate of the

appliance correspond with the voltage and frequency values at the place of installation.

The electrical outlet should be properly earthed and equipped with a differential current protection device in accordance with

legal provisions in force.

- 6 -

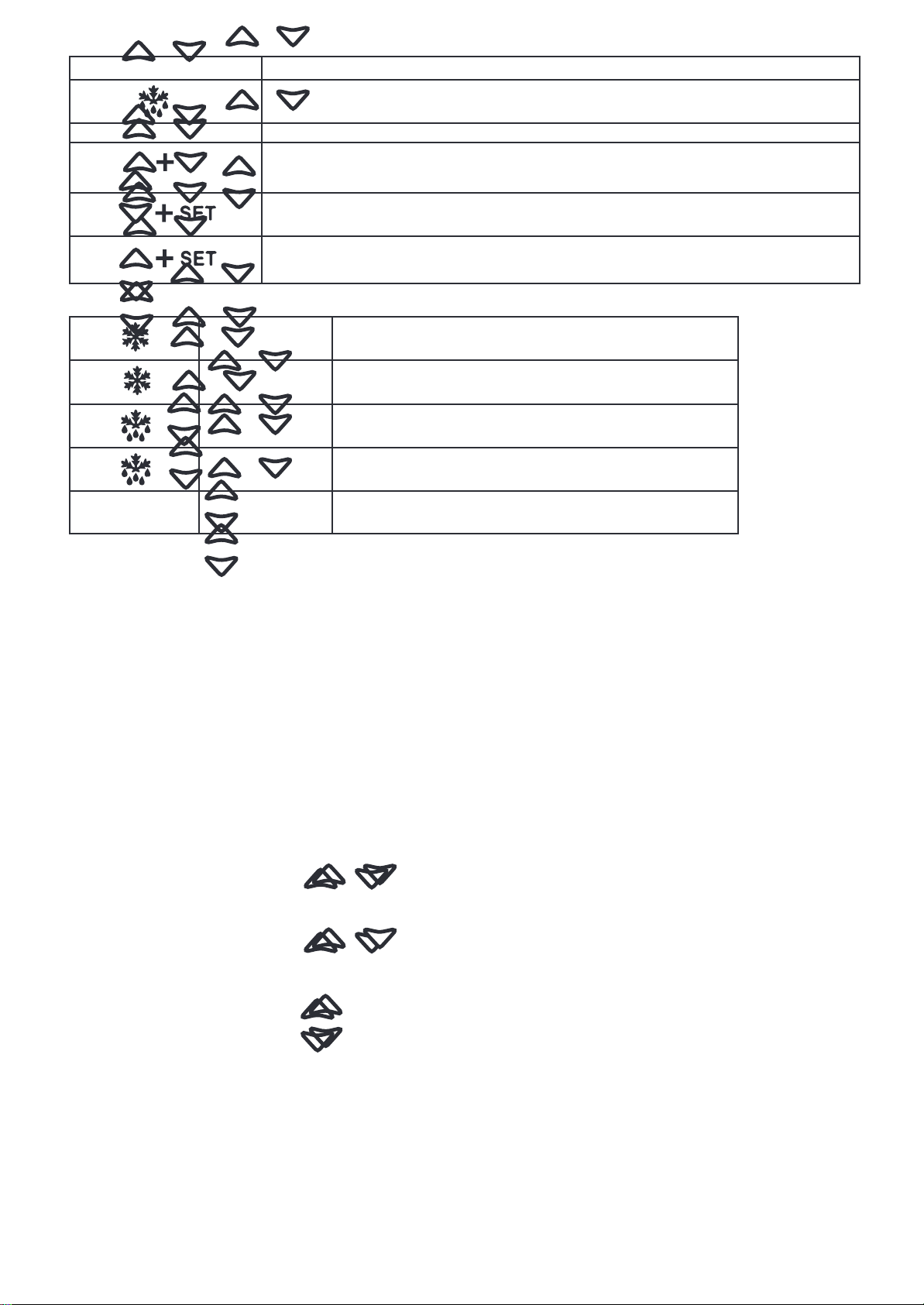

7. CONTROL PANEL OPTION 1

Description:

Indicator light Symbol Status Meaning

Settings indicator light SET

The light is on Parameter setting

The light is off Measurement and control

The light flashes Checking parameters, entering a

password

Refrigeration

indicator

light

The light is on Refrigeration

The light is off Refrigeration stopped

The light flashes Refrigeration delay enabled

Defrosting indicator light The light is on Defrosting

The light is off Defrosting stopped

7.1. Description of parameters

Code Function Setting range Default value Unit

F01 Menu password 00-99

00: buttons lock func-

tion deleting 55 NO

F02 Setting temperature value -40 ~+50 2 °C

F03 Setting temperature difference 1 – 15 4 °C

F04 Compressor activation time

delay 1 – 15 3 min.

F05 Interior temperature calibration -5 ~ +5 0 °C

F06 Maximum defrosting time 1 – 60 20 min.

F07 Defrosting cycle 1 – 30 units 12 1 unit = 30 min.

F08 Defrosting termination tempe-

rature -20 ~+30 7 °C

F09 Evaporator sensor activation or

no activation 00: not active

01: active 1 NO

7.2. Buttons functions

Buttons Function

SET Press to enter the password; Setting parameters mode; Changing between the menu and the parameter

mode.

Press to check the value of the set temperature; Selection of the menu functions; Changing the setting of

parameters and a password.

Press to check the value of the evaporator sensor; Selection of the menu functions; Changing the setting

of parameters and a password.

Exit from the parameter setting mode; Manual activation or stopping of defrosting.

Temperature measurement and control mode

•Press the „SET” button and hold it for 3 seconds.

In case the keypad password has been set to „0”, the settings indicator light is on, the display shows

„F1” code from the menu, there is no password confirmation and you should directly enter the menu mode to

set the parameter.

If the keypad password has not been set to „0”, the indicator light flashes and the display shows

„00”, press the „ ” and „ ”, buttons to enter the password, then press the „SET” button to

confirm the password. If the password is correct, the system will go to the settings menu. If the password is not correct the

settings indicator light will go off and the system will return to the normal temperature measurement and control mode.

Checking parameter settings:

- 7 -

Push the button „ ”. The settings indicator light „SET” starts to flash and the display shows the set temperature value.

Push the button „ ”. The settings indicator light „SET” starts to flash and the display shows the temperature value of the

evaporator sensor.

After entering the settings menu, press the „ ”button and the „ ”, button to select the desired menu function (from F01

to F09).

After selecting the desired menu function, press the „SET” button to set the parameter value, press the „” and „ ” „

and select the desired value of the parameter, then press the” SET „button again to return to the function

selection from the

menu.

In the settings selection mode, press the „ ” button or do not press any buttons for 30 seconds, the system will save the

set parameters values and exit the parameters setting mode.

Press the „ ” button and hold it for 3 seconds to manually activate or terminate defrosting.

7.3. Compressor operation and defrost function control

•Compressor

The compressor will be activated when the time of its activation delay expires if the temperature sensor indicates that the tem-

perature is higher than „set temperature value + temperature difference value „.

The compressor will stop working when the temperature sensor detects that the temperature is lower than the set temperature

value.

•Defrosting:

The system will start defrosting in accordance with the defrosting cycle set or when manual defrosting is

activated.

If the evaporator sensor has been activated and the temperature detected by the evaporator sensor is higher

than the tempera-

ture of the defrosting termination, it is not possible to activate the defrosting function manually.

Defrosting will be terminated when the temperature detected by the evaporator sensor reaches the value equal to the set value

of the defrosting termination temperature or when the set defrosting time has elapsed or when the defrosting

has been turned

off manually.

If the evaporator sensor has not been activated or if an error occurs, defrosting will be interrupted when the set defrosting time

elapses or the defrosting is turned off manually.

7.4. Error messages

Message Cause Solution

E1 Chamber sensor error Contact the Technical Service to replace the cham-

ber sensor. After the fault has been repaired the

system will again calculate the compressor activation

delay time.

E2 Evaporator sensor error

The temperature of defrosting termina-

tion is incorrect

Contact the Technical Service to replace the evapo-

rator sensor.

8. CONTROL PANEL OPTION 2

Button Function

Used to display the setting, in the programming cycle is used to select the parameter or

confirm the operation.

Arrow up With this arrow you can display the last alarm, in the programming cycle, you can scroll thro-

ugh the parameters or increase the displayed value.

Arrow down The arrow turned down is used to display the last alarm, during the programming cycle, to

scroll through the parameters, or to decrease the displayed setting.

- 8 -

Button Function

DEF This button is used to manually start the defrosting process.

Combinations of buttons Used to lock and unlock the keyboard.

Used to enter the programming mode.

Return to display the temperature in the chamber.

8.1. Description of indicator lights

On The compressor is on.

Flashes The programming mode has been activated.

On The defrosting has been activated.

Flashes Programming mode, dripping in progress.

oF

oC On Fahrenheit degrees

Celsius degrees

8.2. How to check the duration of the alarm and the minimum and maximum temperature

If an alarm symbol appears on the display, to see the type of alarm, min (max) temperature, the duration of the alarm, proceed

as follows

1. Press the arrow up or arrow down button

2. The display will show the following message „HAL” for high temperature alarm, „LAL” for low temperature

alarm. Then

„tIM” (time) displays the duration of the alarm in minutes

3. The next step is to return to the temperature display

8.3. Deleting constantly occurring saved alarm

1. Press down the SET button and hold it for more than 3 seconds, in the meantime the saved alarm is displayed (the display

will show rSt message);

2. To confirm the operation, „rSt” message will start flashing and the normal temperature will be displayed

8.4. How to check the settings

Press the „SET” button and immediately release it, the display will show the settings. After pressing and releasing the „SET”

button or hold it down for 5 seconds to display the values of the sensor again.

8.5. How to change the settings

1. Press the „SET” button and hold it down for more than 2 seconds to change

the values;

2. The value of the settings will be displayed and the LED indicator light will

start flashing

3. To change the settings, press or and hold it down for 10 seconds

4. To save the new settings, press the „SET” button and hold it down for 10 seconds.

8.6. Starting manual defrosting

To start manual defrosting process, press the „SET” button and hold it down for 2 seconds, that will activate the defrost process.

8.7. Changing of parameters value

To change the parameters values, proceed as follows:

1. Enter the programming mode by pressing the SET button and the arrow down button and holding them down for 3 se-

conds and the „SET” button will start flashing;

2. Select the parameter

3. Press he „SET” button to display the values

4. Use the up or down arrows to change the settings;

5. Press the „SET” button to save the new parameters;

6. To exit, press the SET + arrow up buttons or wait for 15 seconds without pressing

any buttons.

- 9 -

8.8. Locking of the keyboard

1. Press the buttons arrow up and arrow down and hold them down for 3 seconds.

2. The POF message will appear on the display and the keyboard will be locked. Only information about

maximum and

minimum temperature can be displayed in this mode.

3. If any button is pressed and held down for 3 seconds POF message will be displayed.

8.9. Unlocking of the keyboard

Press the up and down arrow buttons and hold them down for 3 seconds until you see the „Pon”. message.

8.10. Continuous mode

If the defrosting process is not enabled, the continuous mode can be activated by pressing and holding down the arrow up button

for 3 seconds. The compressor will start operating in continuous mode until the Cct parameter setting is

reached. This process

can be terminated before it ends by using the arrow up button and holding it down for 3 seconds.

8.11. Alarms

Message Cause

P1 Chamber sensor error

P2 Evaporator sensor error

HA Maximum temperature reached

LA Minimum temperature alarm

9. CLEANING AND MAINTENANCE

Note: Before starting any maintenance procedure, always disconnect the appliance from the power supply.

The appliance should be washed with water and dishwashing liquid. It is not recommended to clean the

appliance with deter -

gents, because they can damage the walls of the cabinet. Plastic parts of the appliance can be washed with water

at the maximum

temperature of 85 °C.

During daily cleaning of the appliance, remember to thoroughly clean the gasket from crumbs and sticky substances, because

they can damage it.

The ventilation grate of the compressor (located on the back of the appliance) should be cleaned regularly, as dirt and dust may

block free air circulation.

10. PROCEDURE IN THE EVENT OF POWER FAILURE

In case the appliance is disconnected from the power supply (both due to a failure or due to accidental removing of the plug

from the electric socket), the element controlling the work of the compressor will cause that the restarted

appliance will operate

according to the current temperature control knob setting.

10.1. Starting the appliance in case the temperature has gone beyond the alarm value

The compressor starts working immediately after reconnecting the appliance to the

power supply.

The display will be showing the „HH” alarm message until the set temperature is

reached. Then

the value of the current temperature inside the appliance will be displayed.

10.2. Starting the appliance in case the temperature has gone below the alarm value

The compressor starts working 10 minutes after connecting the appliance to the power supply.

The display shows the current temperature value inside the appliance until the value set by the temperature

control knob will

be reached.

11. DISPOSAL OF THE OLD APPLIANCE

Information for users on the rules concerning proper disposal of electrical and electronic equipment at the end of

its life.

•Leave your old equipment in the shop where you purchase a new appliance. Each store is obliged to accept old equ-

ipment free of charge if you buy there the new equipment of the same type and in the same quantity. The only

condition is to

deliver the old equipment to the store at your expense.

•Dispose of your old equipment at a collection point. Information about the location of the nearest collection point can

be found on the local website or the notice board of the municipal office.

•Leave the equipment at a service point. If the repair of the equipment is unprofitable or impossible for technical reasons,

the service is obliged to accept this appliance free of charge.

•Return the used equipment at the end of its life without leaving your home. If you do not have the time or ability to

deliver your equipment to the collection point, you can use the services of specialized companies.

•Remember! Do not dispose of used equipment together with regular waste.

An illegal or incorrect disposal of the product will lead to high penalties being imposed.

- 10 -

The symbol of a crossed-out rubbish bin on the product, its packaging or its instruction manual

means that at the

end of its life the product must not be disposed of with regular waste. The user is obliged to deliver

their used

equipment to a designated collection point for proper processing.

12. GUARANTEE

The dealer of the appliance is liable under the guarantee.

The guarantee does not cover any damage resulting from the build-up of limescale inside the appliance. The

guarantee also does

not cover: damage caused by external forces such as atmospheric discharge, voltage change, incorrect setting of

electrical voltage,

power supply from unsuitable power outlet, any mechanical, thermal, chemical damage and defects resulting from

them.

Furthermore, the guarantee does not cover the replacement of exhaustible parts, namely: light bulbs, rubber elements, heating

elements damaged by limescale, glass and other elements that are exposed to any form of wear or usage, for

example; burners,

rubber units as well as any breakdowns or mechanical damage of the appliance elements caused by incorrect

storage, transport,

maintenance, installation or operation.

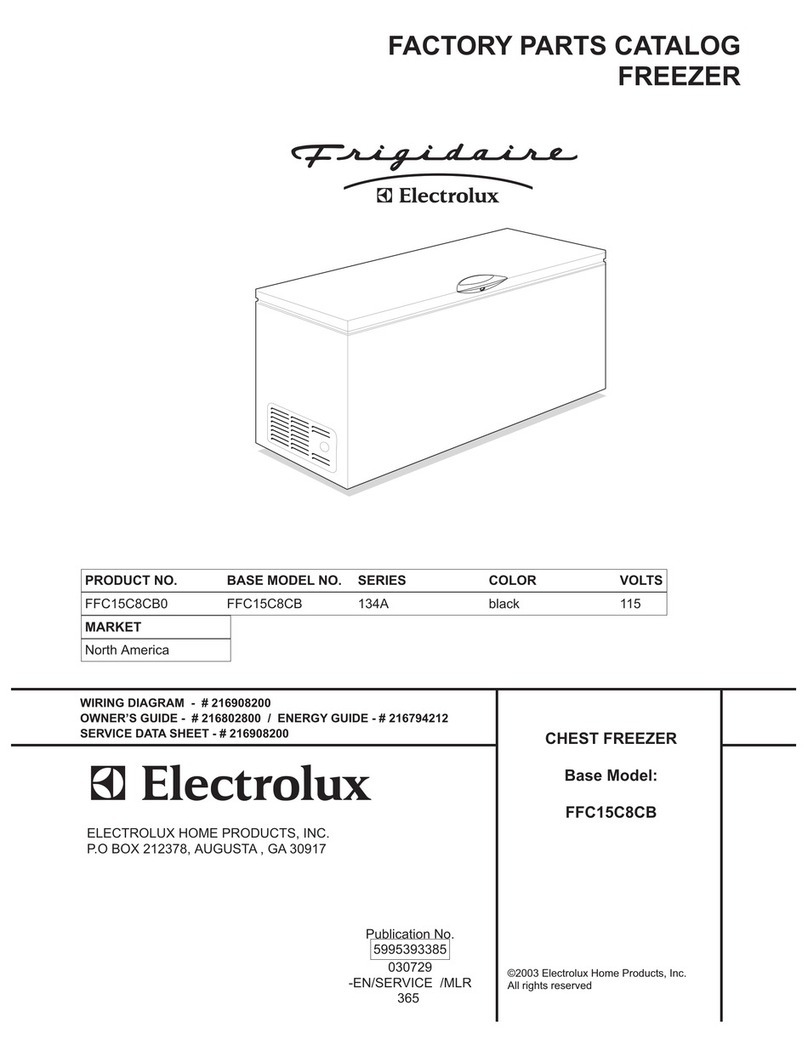

13. WIRING DIAGRAM

1. Controller

2. Overload

protection

3. Compressor

4. Condenser fan

motor

5. Evaporator fan

motor

14. DECLARATION OF CONFORMITY

EU DECLARATION OF CONFORMITY

no 22-02.01/2019

Saogonekd Rejonowy dla m.st. Warszawy w Warszawie, XIII Wydzialslash Gospodarczy Krajowego Rejestru Saogonekdowego KRS 0000010073, NIP 952-18-66-652,

REGON 017223787, Numer GIOSacute E0003390WZ, Numer BDO 000012735, Kapitalslash zaklslashadowy 150.000,00 PLN,

Stalgast sp. z o.o. Plac Konesera 9, Budynek O, 03-736 Warszawa

The manufacturer:

name: STALGAST Sp. z o.o.

address: Plac Konesera 9, Budynek O, 03-736 Warszawa, Poland

declare under his sole responsibility that the product:

name: Cooling cabinet

model: 880600v02

serial number: 1 - 100000000

meets the following essential requirements:

• the Machinery Directive MD 2006/42/EC ,

• the Electromagnetic Compatibility Directive EMC 2014/30/UE ,

• the Restriction of Hazardous Substances Directive RoHS 2011/65/UE ,

• the Regulation on materials and articles intended to come into contact with food FCM 1935/2004 ,

• EcoDesign requirements according to:

• regulation 2015/1095 regard to requirements for professional refrigerated storage cabinets, blast

cabinets, condensing

units and process chillers ,

• regulation 2015/1094 regard to the energy labelling of professional refrigerated storage cabinets,

complies with the requirements of the following harmonized standards:

• EN 60335-2-89:2010+A1:2012

• EN 60335-1:2012

• EN 62233:2008

• EN 55014-1:2006+A1:2009+A2:2011

• EN 55014-2:1997+A1:2001+A2:2008

• EN 61000-3-2:2014

• EN 61000-3-3:2013

This declaration relates exclusively to the product in the state in which it was placed on the market. Any

components added,

handling effected or modi cations carried out subsequently are expressly excluded. The present declaration

ceases to be valid in

the event that the use of the product is not in conformance with the conditions speci

ed in the applicable regulations and in the

product’s technical documentation.

The technical documentation can be obtained at the premises of ST ALGAST sp. z o.o. and is available from the

authorised person

Ireneusz Tarnowski.

Warszawa, 22.02.2019 r . Ireneusz

Tarnowski ,

Product Specialist

place, date signature name, function

EU DECLARATION OF CONFORMITY

no 22-02.02/2019

Saogonekd Rejonowy dla m.st. Warszawy w Warszawie, XIII Wydzialslash Gospodarczy Krajowego Rejestru Saogonekdowego KRS 0000010073, NIP 952-18-66-652,

REGON 017223787, Numer GIOSacute E0003390WZ, Numer BDO 000012735, Kapitalslash zaklslashadowy 150.000,00 PLN,

Stalgast sp. z o.o. Plac Konesera 9, Budynek O, 03-736 Warszawa

The manufacturer:

name: STALGAST Sp. z o.o.

address: Plac Konesera 9, Budynek O, 03-736 Warszawa, Poland

declare under his sole responsibility that the product:

name: Freezing cabinet

model: 880601v02

serial number: 1 - 100000000

meets the following essential requirements:

• the Machinery Directive MD 2006/42/EC ,

• the Electromagnetic Compatibility Directive EMC 2014/30/UE ,

• the Restriction of Hazardous Substances Directive RoHS 2011/65/UE ,

• the Regulation on materials and articles intended to come into contact with food FCM 1935/2004 ,

• EcoDesign requirements according to:

• regulation 2015/1095 regard to requirements for professional refrigerated storage cabinets, blast

cabinets, condensing

units and process chillers ,

• regulation 2015/1094 regard to the energy labelling of professional refrigerated storage cabinets,

complies with the requirements of the following harmonized standards:

• EN 60335-2-89:2010+A1:2012

• EN 60335-1:2012

• EN 62233:2008

• EN 55014-1:2006+A1:2009+A2:2011

• EN 55014-2:1997+A1:2001+A2:2008

• EN 61000-3-2:2014

• EN 61000-3-3:2013

This declaration relates exclusively to the product in the state in which it was placed on the market. Any

components added,

handling effected or modi cations carried out subsequently are expressly excluded. The present declaration

ceases to be valid in

the event that the use of the product is not in conformance with the conditions speci

ed in the applicable regulations and in the

product’s technical documentation.

The technical documentation can be obtained at the premises of ST ALGAST sp. z o.o. and is available from the

authorised person

Ireneusz Tarnowski.

Warszawa, 22.02.2019 r . Ireneusz

Tarnowski ,

Product Specialist

place, date signature name, function

This manual suits for next models

1

Table of contents

Popular Freezer manuals by other brands

Electrolux

Electrolux EUC 05002 W user manual

Dometic

Dometic CoolFreeze CF-18 installation manual

White-Westinghouse

White-Westinghouse WFC1310EW0 owner's guide

Frigidaire

Frigidaire CHEST FREEZER FCFH 103 BW OPERATING AND INSTALLATION Manual

Hotpoint

Hotpoint RFA52P operating instructions

Vinotemp

Vinotemp WINE-MATE WM-4500SSLWC Installation, operation & care manual