Bienfang Vacuum Press 3648H User manual

Bienfang®Vacuum Press® 3648H, 4468H and 5298H

Programmable Combination Vacuum Presses

OWNERS MANUAL

Specifications for Vacuum Press

Important Safeguards

Features

Installation and Preparation

Installation and Preparation

Identification of Controls

Procedures for Use

Procedures for Use

Recommended Time and Temperature Setting

Periodic Maintenance

Warranty

Troubleshooting

Replacement Parts

CONTENTS

2

3

3

4

5

6

7

8

9

10

10

11

12

SPECIFICATIONS FOR THE BIENFANG®VACUUM PRESS

2

5298H 4468H 3648H

Catalog Number 2170 2160 2180

Floor Stand included 2165 2167

Working Area 48" x 96" x 1" 44" x 68" x 1" 36" x 48" x 1"

Outside Dimensions 109" x 65" x 7" 77" x 57" x 7" 57" x 48" x 1"

Net Weight 375 lbs. 215 lbs. 135 lbs.

Shipping Weight 800 lbs. 500 lbs. 350 lbs.

Power Requirements 208-230V/Single Phase 208-230V/Single Phase 208-230V/Single Phase

Power Consumption Approx. 5925 Watts Approx. 3390 Watts Approx. 1700 Watts

Watts-amps @ 230VAC (26 amps) @ 230VAC (15 amps) @ 230VAC (11 amps)

Plug Type NEMA L14-30P NEMA L14-20P NEMA L14-20P

Twist Lock Twist Lock Twist Lock

• International plugs supplied by user.

FEATURES

3

Please read the entire manual and fully understand the

proper operating procedures before proceeding to use

the press.

1. Place the vacuum press in either a BIENFANG® Floor

Stand or a sturdy, flat, level surface and ensure the

feet and hinges are properly adjusted. The press should

not be located in the direct path of air conditioning or

room-cooling vents.

2. Keep the vent cloth positioned so that it covers the

vacuum manifolds (located in the rear corners of the

press) and does not extend across the edge of the

rubber diaphragm. Failure to do so will result in tempo-

rary loss of vacuum.

3. Place all materials inside the press so that they fit into

the recessed chamber in the base. If any materials

extend across the edge of the rubber diaphragm, they

will prevent a seal and cause either low vacuum or no

vacuum at all.

4. When opening and closing the press grasp both han-

dles and keep your body, head and hands away from

the press opening.

5. Foreign objects such as knives, tools, rulers, paper

clips and markers should be kept out of the press and

away from the press opening at all times.

6. Do not stack boards in the press. Placing a smaller

board on top of a larger one may cause lines or dents

in the aluminum platen.

7. Do not use an exposed blade to cut materials in the

press. A slice or puncture in the rubber diaphragm will

result in loss of vacuum.

8. Allow the vacuum level to drop before opening the

press.

9. Turn the power breaker OFF and keep the press in the

closed position when not in use. Disconnect the power

supply before cleaning or replacing parts.

10. High-pressure gas springs make opening and closing

the press easier. If they are to be removed, the top

MUST be held in the fully opened position for safety

and to prevent damage.

Contact your authorized Hunt dealer or Hunt Technical

Service in the event the press needs service for parts not

covered in this Owner’s Manual.

IMPORTANT SAFEGUARDS

The Bienfang® Vacuum Press 3648H, 4468H and 5298H

presses are professional mounting and laminating systems

designed to provide the highest quality results with maximum

versatility and ease of operation. The combination of two

machines in one – a dry mount press and cold vacuum frame –

allows the quick professional application of dry mounting adhe-

sives and laminates, as well as wet and spray adhesives. The

presses decrease labor costs and increase production while

minimizing operator training and supervision.

Specific features and benefits include:

• Easy to Use: Close the top, press a key and wait for the

signal that the work is done - automatic operation frees

the operator for other duties.

• Digital Display: lets the operator know at all times the

vacuum level, platen temperature and cycle time remain-

ing; the display is switchable between showing the original

settings and actual readings.

• Locking: All current models have side latches. Previous

models have the front latch.

•Programmable Settings: The operator can store up to six

programs in memory for repeatable processes. Time and

temperature settings for each program are stored for

quick, easy access.

• High, Uniform Vacuum Pressure: 10-13 psi (20-27" Hg)

ensures good bond penetration for consistent, professional

results.

• Automatic Pressure Adjustment: Self adjusts for boards up

to 1" thick, or mounts several pieces of varying thickness

at one time — without additional set-up time.

• Double-Duty Top: Specially constructed heavy-duty flat top

doubles as work or storage space when the press is not

in use.

• Floor Stand: Optional for 3648H and 4468H. Used to

make the presses freestanding units rather than tabletop

machines. Each incorporates one shelf support. The

5298H model comes with a floor stand.

Each Bienfang®Vacuum Press 3648H, 4468H and 5298H

(floor stand included) is fully assembled, calibrated and

tested at the factory to pull a high level of vacuum in a

minimum amount of time. Once passed by the Quality

Control Department, the completely tested press and pump

are packaged and shipped together to ensure that each

customer receives a complete and tested unit.

During shipping and uncrating, the alignment of the top

and base of the press may be altered and require adjustment

by the user. In addition, placing the press on an uneven or

warped table surface may require adjustment of the leveling

feet and hinges by the user. Follow these instructions to

ensure proper operation.

Installation

For consistent long-term operation of the 3648H and

4468H, Bienfang recommends using the appropriate

Vacuum Press Floor Stand. First assemble the Floor Stand

following the directions supplied with it, then lift the press

out of the shipping crate and position it on the Floor Stand

so that each of the four feet fit into the top of a Floor Stand

leg. Using the bolts supplied with the Floor Stand, bolt the

two support brackets on each leg into the corresponding hole

underneath the frame. When complete, tighten each bolt

fully and the press can be moved into position.

As an alternative to the 3648H/4468H Floor Stand, a

heavy-duty, flat level table can be used. The press should sit

completely on the table, so a 46" x 53" or 57" x 77" surface

area is required. The recommended surface material is 3/4"

Grade B plywood or better. A table height of 30" is typical.

Make sure all four adjustable feet are fully screwed in, place

the press on the prepared table and adjust the feet individu-

ally so that the press is level front to back and side to side.

For a Qualified Electrician

The Bienfang Vacuum Press 3648H and 4468H are rated

for 230VAC/60 Hz Single Phase (with Neutral) on a 20 Amp

circuit. Actual line voltages between 208-230 VAC are

acceptable. The press power-cord has a NEMA L14-20P

twist lock plug which is UL listed for use in this application.

The 5298H is rated for 230VAC/60HZ Single Phase (with

Neutral) on a 30 Amp circuit. Actual line voltages between

208-230VAC are acceptable. The press power cord has a

NEMA L14-30P twist lock plug, which is UL listed for use in

the application.

If you choose to hard-wire direct to a junction box, the

12-gauge power cord (3 wire plus ground) is color-coded

using the conventional standards:

Red - L1 (Hot) White - Neutral

Black - L2 (Hot) Green - Ground

Note that separate ground and neutral lines must be

installed or the pump will not operate and the press will not

meet UL standards or safety codes.

After hookup is complete, check with the Power Switch ON,

the tacking iron outlet on the front of the press measures

110-120VAC between L1 and Neutral, that there are 0 Volts

between neutral and Ground and that there is continuity

between Ground and press frame..

Note: If there are any questions, call your distributor or Hunt

Technical service at 888-240-6021.

Leave at least 5" between the rear of the press and the wall

so the top has room to open easily. The vacuum pump

should be placed on the floor behind the press. The plastic

vacuum line tubing is already connected underneath the

press and the free end will have to be attached to the inlet

side of the pump. To attach, depending on the pump fitting,

slide the vacuum line firmly into the chrome fitting on the

pump until it snaps in place or tighten the brass nut onto

the pump fitting.

(TIP: Hunt recommends the use of a static guard mat in

high-static areas).

With the Power Switch OFF, plug the vacuum pump power

cord into the electrical outlet marked Vacuum Pump Only

on the rear of the press.

To check operation, close the press and turn the Power

Switch ON (on the side of the press). The programmable

systems controller should come on and display room

temperature, 0 time and 0 vacuum.

INSTALLATION AND PREPARATION

4

Press the vacuum "Manual On/Off" key and the pump

should run. If not, check that the pump is plugged into the

back of the press and then have a qualified electrician re-

check the electrical hookup. (If separate ground and neu-

tral lines are not installed, the pump may not operate even

though the display illuminates.)

After turning on the pump, the display should read a mini-

mum of 20" of Hg for: 3648H within 40 seconds, 4468H

within 1 minute and for the 5298H within 2 minutes. If

there is any difficulty in drawing a proper vacuum, refer to

the Owner’s Adjustment Procedures section of Page 24 of

this manual.

Press the "Heat On" key and the press should begin to heat

up to 180ºF (+/- 2ºF) within 15-20 minutes. If not, call

Hunt Technical Service at 888-240-6021.

The press is now ready for use.

Adjustment Procedures

Proper leveling of the press and adjustment of the hinges

and latch are necessary to consistently achieve proper

vacuum. Check the following owner adjustment procedures,

in the order listed, if any difficulty arises.

Leveling

If the press is not placed on a sturdy, flat, level surface,

proper operation cannot be guaranteed. Ensure press level-

ness by opening the press and placing a 2’ carpenter’s level

on the frame. Shim the floor stand legs so that the frame of

the press is level (both front-to-back and side-to-side). If not

on a floor stand, adjust the corner feet until the press is level.

Hinge Adjustment

After leveling the press, check the adjustment of the rear

hinges. These might shift during shipment, handling or

rigorous use and are essential to proper alignment of the

top to the base. To realign, follow these instructions:

1. Close and set temperature to 180ºF.

2. As your assistant holds open the lid, remove the clips

from the bottom of the gas springs (located around the

bottom socket head only) using the needle nose pliers.

This could possibly be done by hand. Bump first the

bottom of the gas spring off the ball sockets from both

left and right sides of the machine. Then remove the top

by grasping the gas spring and tilt away from ball stud.

Spring will come off. The gas springs MUST be taken

completely off the machine.

3. Loosen (do not remove) screws in the slotted holes of the

hinges, located on the back of the machine.

4. Once machine is fully heated, start the vacuum. Give unit

45 seconds to 1 minute to pull full vacuum. If no

vacuum is achieved, walk around machine and put slight

pressure on lid in various sections until a full vacuum is

achieved.

5. Tighten set screws on hinges and replace gas springs.

If any further questions arise, contact your authorized

Bienfang®dealer or the Hunt Technical Service Department

at 1-888-240-6021.

INSTALLATION AND PREPARATION (CONTINUED)

5

IDENTIFICATION OF CONTROLS

6

Before using the press, prepare a Bienfang®overlay, this

performs the function of keeping the press and work clean

while allowing adhesives to be used oversized without

sticking to the press.

Three types of Release Materials are available:

• Single-Sided Release Paper — a heavy white paper coated

with silicone on one side. This also permits mounting of

the uncoated side to a smooth board to create a reusable

release board (recommended size is Bienfang No. A490 -

42” x 30 yds.).

• Double-Sided Release Paper — a thin paper coated with

silicone on both sides to create two non-stick surfaces

(recommended size is Bienfang No. 934 - 42” x 30 yds.

for 3648H/4468H; Bienfang No. 986 - 50” x 36 yds.

for 5298H).

• Release Board — a thin, smooth board coated with silicone

on both sides. Lays flat to smooth out posters, doesn’t

wrinkle or crease so it lasts longer than release papers

(recommended size is Bienfang No. 938 - 32” x 40",

pack of 5). To be used on top of application only.

One sheet of Bienfang Release Paper should be cut to fit

inside the base of the press (on top of the vent cloth), and

either a second sheet of Release Paper or a Release Board

should be placed over the materials being processed. Never

use a sheet of Release Board under another board or dam-

age to the press platen may occur.

NOTE: Please read the entire manual and fully understand

proper operating procedures before using your press.

Handles

Heat Platen

Vent Cloth

Control Panel

Gas Spring

Vacuum Manifold

Tacking Iron Outlet

7

Turning the Press On

A master power switch/circuit breaker on the side of the

press turns on the display and tacking iron outlet.

Running A Factory-Loaded Program

The Bienfang®Vacuum Press controller has 6 preset

programs that automatically turn on the heat and set the

proper time and temperature. They are handy for frequently

used processes as they save time and eliminate guesswork.

Programs are preset as shown below and can be initiated

by pressing the “Program” key, number 1 through 6 from

the numeric keypad, and “Enter”. Before pressing “Enter”

the display will blink to show the setting, upon pressing

“Enter” the display will stop blinking and the press will

begin to warm up to the temperature setting.

When the press warms up and stabilizes (15-20 minutes)

the program can be run by pressing the “Start/Repeat

Cycle” key which starts the pump and timers. The press

will display the set time and then countdown to (time out).

The controller will also display the vacuum level in the

press and the actual platen temperature.

When the time is up, the press will sound an audible signal

that the cycle is over, but the press will not turn off auto-

matically. Upon hearing the signal, the operator should

press the “Stop” key. The vacuum pump will stop, the

vacuum will release and the press can be opened. The

temperature display will continue to show the actual platen

temperature and timer display will show the best time.

The entire sequence to run Program 1 for dry mounting with

ColorMount or MT5 is:

• Program

• 1

• Enter

• Start/Repeat Cycle

• Stop

NOTE: The press does not turn off automatically because

materials could be accidentally left inside the press with-

out pressure, while they are still hot. This could cause

delaminating or excessive warping of the mounting board.

The press should be turned off and the materials removed

immediately by the operator.

Repeating a Program

To repeat the same program again, just press the

"Start/Repeat Cycle" key

To Run Another Program

Press the “Program” key, the number of the program, and

the “Enter” key. When the temperature has stabilized at the

new setting press the “Start/Repeat Cycle” key to start the

cycle.

• Program

• 2

• Enter

• Start/Repeat Cycle

Warming up the Press

Press the “Heat On” key to warm up the press (when the

heat is turned on the light on the switch will illuminate).

The press will start warming up to 180ºF, the default

setting.

Setting the Temperature

To set a temperature, press the "Set Temp" key, enter the

desired temperature on the numeric keypad, and then

press the "Enter" key. (For example, to set the press

temperature at 190ºF, press "Set Temp", press 190 on the

keypad and press "Enter"). After "Enter" is pressed, the

display will show the actual reading.

Setting the Time

Press the “Set Minutes” key, enter the desired number of

minutes on the numeric keypad, and press “Enter”. (For

example, to set the timer for a 5-minute cycle, press “Set

Minutes”, press 5 on the keypad and press “Enter”.) You

can also set seconds using the “Set Seconds” key in the

same sequence. The set time will display until the cycle

is run.

PROCEDURES FOR USE

Temp. Time Application

Program 1 190ºF 5 mins. ColorMount®/MT5®

Program 2 175ºF 5 mins. Fusion®/BufferMount®

Program 3 150ºF 3 mins. SingleStep®Plus

Program 4 180ºF 3 mins. SingleStep®

Program 5 215ºF 7 mins. Finish Guard®UV (posters)

Program 6 215ºF 9 mins. Finish Guard®UV (photos)

Review Settings

To check the temperature setting, press the “Heat On”

key and the setting will blink on the display for 5 seconds

before reverting back to the actual temperature. While

running a cycle the Time/Temperature settings can be seen

by pressing the “Program” key. After 5 seconds, the display

will revert back to the actual readings.

Changing Settings

To change settings use the “Set” keypad and “Enter” keys.

No changes can be made while a cycle is running.

To Change or Store a Program

To store the settings for a new program (6 programs are

possible), press the “Program” key and any keypad number

from 1 to 6. While the display is blinking, set the desired

time/temperature using the “Set” numeric keypad and

“Enter” keys as usual, then press “Enter” a second time at

the end to save the program. The programs will be remem-

bered even after turning the press off.

To change the settings of an existing program, press

“Program”, the keypad number, and then the appropriate

“Set” key, numeric entry and “Enter”. Press “Enter” a

second time to save the program change.

If a mistake is made while entering or changing a program,

press the “Clear” key to cancel the entry (much like a

calculator). The original program will remain unchanged.

Aborting a Cycle while Running

• To stop in mid-cycle, press “Stop”.

Running a pump without the timer

• To run the pump without the timer (for checking fittings,

etc.), press vacuum “Manual On/Off”.

• Press “Manual On/Off” again to stop the pump.

Changing the display to Metric

If you wish, press the temperature “English Metric” key to

change the display to Celcius or back to Fahrenheit. The

vacuum display can also be set for in/Hg or mm/Hg using

the Vacuum “English/Metric” key. The display will show

whether it is in English or Metric mode by illuminating the

appropriate symbol next to each display.

.

PROCEDURES FOR USE (CONTINUED)

8

RECOMMENDED TIME AND TEMPERATURE SETTING

9

The following suggested settings should give professional-level

results under a variety of conditions. Depending on thickness

and size of board, amount of moisture present, actual line

voltage, and other local conditions you may be able to process

materials faster or you may require longer dwell times. It may

also be possible to lower temperatures slightly (up to 10ºF)

without effecting results if the time is set adequately. Follow

the guidelines in the instruction manual and personal experi-

ence for best results.

MOUNTING

FACTORY PROGRAM SETTINGS

MOUNTING AND LAMINATING

FINISH GUARD-UV

MOUNTING AND LAMINATING AND TEXTURING

EXHIBITEX

NOTE: Allow time for the press temperature to rise from the

initial to the bonding temperature and maintain it for 1-4

minutes (dwell time). With the press at the initial tempera-

ture setting, place the materials inside, set the temperature

at the bonding temperature and quickly close the press

and press the “Start/Repeat Cycle” key. Watch the press

temperature rise and, when it reaches the bonding tempera-

ture, allow an additional 1-4 minutes (depending upon

the size and type of material) processing time. Note the

complete cycle time for future reference.

Material Adhesive Temp. Time Program

Foam Boards ColorMount

®

/MT5 190ºF 4-5 min. 1

Fusion

®

180ºF 4-5 min. 2

BufferMount™

Card Stock ColorMount/MT5 190ºF 5-6 min. 1

Fusion/ 180ºF 5-6 min. 2

BufferMount

Masonite

®

ColorMount/MT5 190ºF 8-10 min. N/A

Fusion/ 180ºF 8-10 min. N/A

BufferMount

Any Spray Off 5 min. N/A

Canvas Fusion 4000 175ºF 4-5 min. 2

Cloth Back CanvasMount™ 170ºF 4-5 min. 2

Temp. Time Application

Program 1 190ºF 5 mins. ColorMount/MT5

Program 2 175ºF 5 mins. Fusion/BufferMount

Program 3 150ºF 3 mins. SingleStep®Plus

Program 4 180ºF 3 mins. SingleStep®

Program 5 215ºF 7 mins. Finish Guard UV (posters)

Program 6 215ºF 9 mins. Finish Guard UV (photos)

Material Adhesive Temp. Time Program

Posters ColorMount/MT5 215ºF 7-10 min. 4

Photos ColorMount 225ºF 9-12 min. 5

Start at low 160-180ºF temperature, load bonding temp. before

closing press.

Material Adhesive Temp. Time Program

Any Fusion/ColorMount 215ºF 8-20 min. 6

Start at low 160-180ºF temperature, load bonding temp. before

closing press.

PERIODIC MAINTENANCE

10

Your Bienfang®Vacuum press has been engineered to

require a minimum level of maintenance. Review the

following to keep the press in prime operating condition

throughout its lifetime.

1. Clean the platen regularly; Bienfang UnStik™ adhesive

releasing solvent or Bienfang Platen Cleaner can be used

to dissolve difficult deposits.

2. Check the vent cloth regularly for proper positioning and

cleanliness. Ensure both vacuum manifolds are fully cov-

ered and clean or replace the vent cloth as necessary when

soiled.

3. Check the vacuum manifolds occasionally for blockages.

Make sure that obstructions, paper and debris are

removed.

4. Check the rubber diaphragm occasionally for abrasions,

cuts, slices and cleanliness; repair or clean as necessary.

5. Check the foam support occasionally for tears, depres-

sions, hard or soft spots, and cleanliness. Repair or clean

as necessary.

6. Check the overall press occasionally for levelness, loose

screws or damaged components. Adjust, tighten or fix as

necessary.

7. Check the vacuum pump occasionally for cleanliness,

dryness and any strange or unusual noises. The vacuum

pump requires no maintenance, however, keeping the

pump clean and dry will result in a longer life.

Hunt Corporation warrants to the original consumer purchaser that each new Bienfang®equipment product which proves

defective in materials or workmanship within the applicable warranty period will be repaired or, at our option, replaced

without charge upon its return, postpaid, as outlined below. The applicable warranty shall be one year from date of

purchase. “Original consumer purchaser” means the person who first purchased the product covered by this warranty

other than for purposes of resale.

Hunt’s liability for breach of any warranty express or implied shall be limited to the repair or replacement, at Hunt’s option,

of the defective item. Hunt shall not be liable for damages, including but not limited to incidental or consequential dam-

ages, arising out of or in connection with the use or performance of any Bienfang product.

To get performance under this warranty, contact Bienfang Technical Support (1-888-240-6021) for assistance or to obtain

a Return Authorization. If it is to be returned, pack the product securely to prevent damage in transit and send the

product, postpaid or freight prepaid, with a description of the defect or malfunction and proof of the date of purchase to

Hunt, Attn: RA Number. Hunt is not responsible for damages from mishandling and abuse in transit, in which case a claim

should be filed with the carrier.

This warranty extends to and is enforceable only by the original consumer purchaser, and only for the period (during

applicable term) during which the product remains in the possession of the original consumer purchaser.

Warranty Department • Hunt Corporation • 2301 Speedball Road • Statesville, NC 28677 • Phone: 1-888-240-6021

LIMITED WARRANTY

TROUBLESHOOTING

11

Symptom Probable Cause Action

No Vacuum Pump, fittings, “solenoid” Perform check below

Levelness see Page 5

Hinge Adjustment see Page 5

Low Vacuum Materials extending Reposition materials

across rubber edges placed in press

Vent Cloth Check position, clean

or replace

Leak in diaphragm Locate and patch or

replace diaphragm

No Heat Not plugged in Check power cord

Power supply off Check circuit breaker

Power Switch off Check position

Heat off Check control

setting

Controller malfunction Contact Bienfang®

Technical Service

Uncontrolled Heat Controller Malfunction Contact Bienfang®

Technical Service

Solid State relay (does press heat

up over temp. even when not

calling for heat)

Bumps, pits Cleanliness Clean platen

Bubbles, no adhesion Improper adhesive Check specifications

Inadequate time Reprocess longer

High moisture level Reprocess longer

Low/uneven pressure See low vacuum

Low/high temperature Check specifications

Checking the Pump and Fittings

To check attachment of the vacuum pump and tubing, open the press and fold the vent cloth forward exposing the two

vacuum manifolds Please a small piece of thin plastic, rubber of similar material (i.e., inner tube, heavy shrink wrap or

plastic film approximately 6" x 6") over each vacuum manifold.

Press the “Manual On/Off” key to run the vacuum pump on and observe the reading on the Vacuum display. If the display

does not read a good vacuum (over 20" Hg), check the vacuum line for leaks. If there are no leaks in the line then have

the pump repaired or replaced. If the vacuum display reads over 20" Hg, then the pump, lines and fittings are all fine.

After completing these checks, press the “Manual On/Off” key to turn the vacuum pump off, remove the pieces of plastic

or rubber from both manifolds and reposition the vent cloth.

www.hunt-corp.com

www.forframersonly.com

© 2003 Hunt Corporation

4777-03

(11/03)

®

Hunt Corporation

Customer Service

P.O. Box 5819

Statesville, NC 28687-5819

For Orders:

Phone: 800-USE-HUNT

Phone: 800-873-4868

Phone: 704-872-9511

For Questions or Technical Assistance:

Phone: 888-240-6021

Fax: 704-871-8671

Hrs: 8:00 a.m.-5:00 p.m. (EST)

Hunt Corporation Canada

690 Gana Court

Mississauga, Ontario

Canada, L5S 1P2

Phone: 905-564-7717

Fax: 905-564-7079

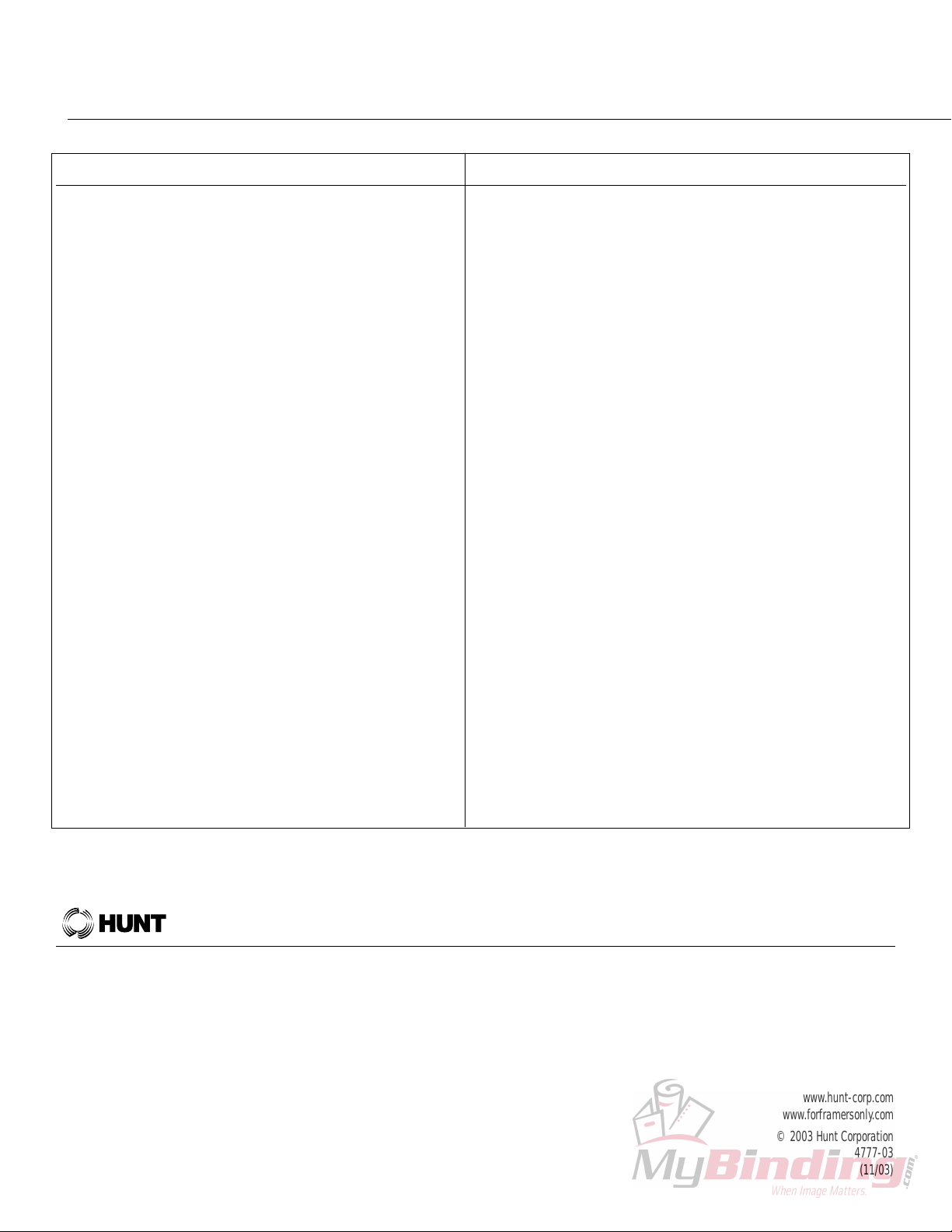

Replacement Part Numbers - Domestic (International)

Description 3648H 4468H 5298H

Pump, Piston

Domestic TS6288126 Kit TS6299126 Kit TS6299126 Kit

International TS56299123 TS6299123 TS6299123

Ball Stud TS1068010 TS1068010 TS1068010

Feet - Leveling TS1103010 TS1103010 TS1103010

Stain Relief, Power Cord

Domestic TS1106045 TS1106045 TS1106045

International TS1106048 TS1106048 TS1106148

Stain Relief, Conduit TS1106046 TS1106046 TS1106046

Union, Tee 3/8” TS1122083 TS1122083 TS1122083

Gas Spring TS1124013 TS1124013 TS1124014

Clip, Gas Spring TS1126015 TS1126015 TS1126015

Plug, Male, Domestic TS12010122 TS1201022 TS1201024

Accessory Plug, Pump TS1202052 TS1202052 TS1202052

Outlet, Tacking Iron

Domestic TS1105024 TS1105024 TS1105024

International TS1105025 TS1105025 TS1105025

Breaker, 2 Pole

Domestic & Intn. TS1308041 TS1308041 TS1308061

Control Board, Assembly

Domestic TS2304093 TS2304093 TS2304093

International TS2304093-1 TS2304093-1 TS2304093-1

R bbon Cable, Interface TS5304026 TS5304026 TS5304026

Insulation TS0511009 TS0511009 TS0511010

New Latch

(Latch Assembly) TS1123013 TS1123013 TS1123013

Replacement Part Numbers - Domestic (International)

Heater(s)

Right TS1202105 TS2302089 TS2302907

Left N/A TS2302089 TS2302097

Center N/A N/A TS2302096

Platen TS5612027 TS5612019 TS5612026

Power Board Assembly

Domestic TS2304092 TS2304092 TS2304092

International TS2304092-1 TS2304092-1 TS2304092-1

Wire Harness

Domestic TS5304027 TS5304027 TS5304053

International TS5304028 TS5304028 TS5304054

Diaphragm Assembly TS6299118 Kit TS6299114 Kit TS6299130KIT

Tubing, 1/4" TS016042 TS016042 TS016042

Tubing, 3/8" TS0509003 TS0509003 TS0509003

Male Elbow, 3/8" Tubing TS1122092 TS1122092 TS1122092

Coupling, F-F TS1122082 TS1122082 TS1122082

Vent Cloth TS5214012 TS5214008 TS5214001

Controller Instructions TB2160C TB2160C TB2160C

Formica Top TS5704016 TS5704014 TS5704013

Sensor, Temperature TS6208075 TS6208075 TS6208075

Relay, SS TS1306026 TS1306026 TS1306028

Solenoid, 12 VDC TS1122087 TS1122087 TS1122087

Flag Terminal, Solenoid TS1238011 TS1238001 TS1238001

Male Elbow, 1/4" Tubing TS1122070 TS1122070 TS1122070

Terminal Block N/A N/A TS1203043

REPLACEMENT PARTS

Other manuals for Vacuum Press 3648H

1

This manual suits for next models

2