Revision B

Revised 5/20/2003 12:33 PM

1

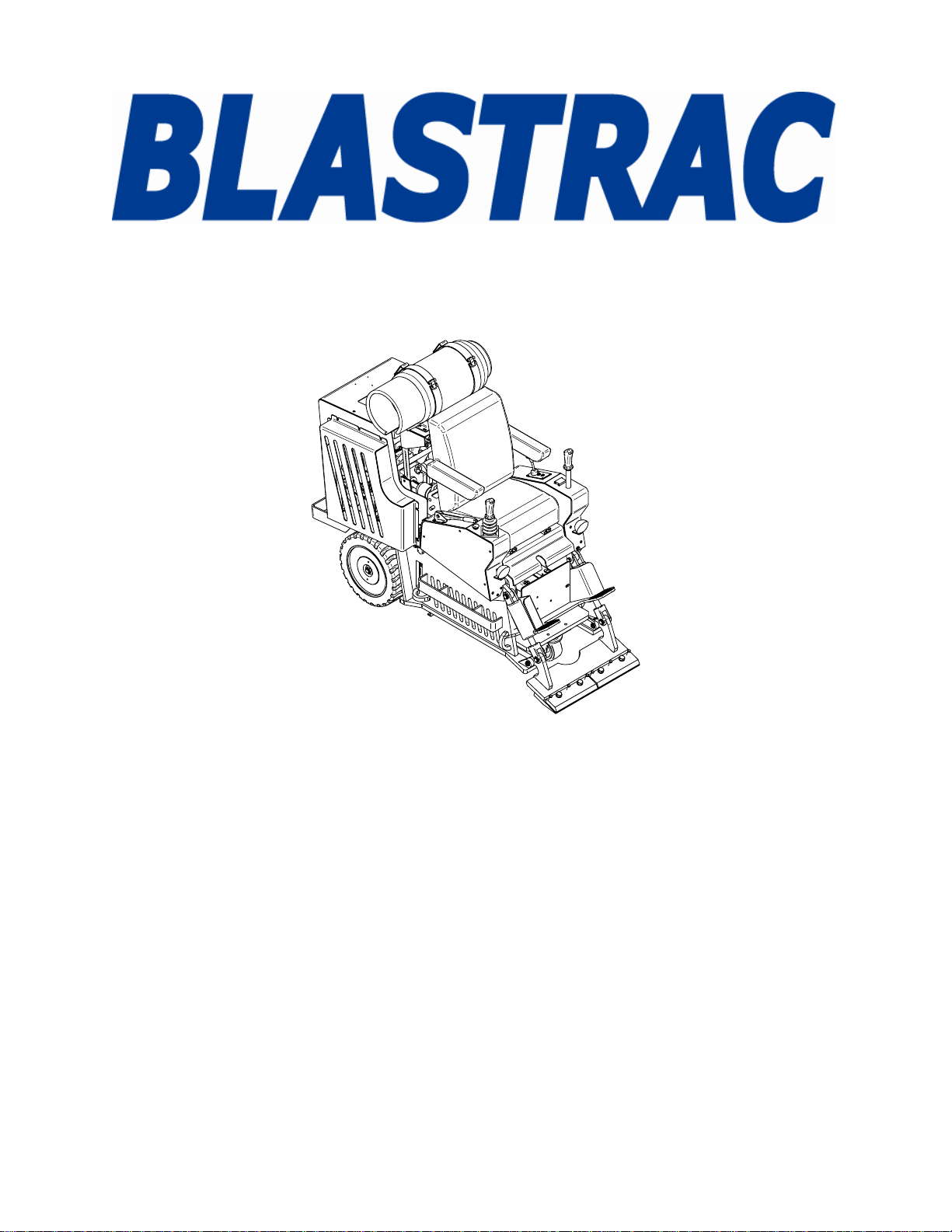

Table of Contents BMS-270LPII

Technical Data ...........................................................................................................3

1.1 Rating ..........................................................................................................4

1.2 Unit Specification.........................................................................................4

1.3 Operative Range and Correct Usage...........................................................5

1.4 Machine Code..............................................................................................5

Safety Precautions.....................................................................................................6

2.1 Organizational Precautions..........................................................................7

2.2 Safety Precautions/Operation......................................................................9

2.3 Safety Precautions/Maintenance ...............................................................10

2.4 Precautions................................................................................................11

2.5 Maintenance Mode ....................................................................................12

2.6 Caution Points............................................................................................13

General ....................................................................................................................15

3.1 Introduction................................................................................................16

3.2 Operating Instructions................................................................................16

3.3 Maintenance ..............................................................................................17

3.4 Delivery (Components) ..............................................................................17

3.5 Description.................................................................................................18

3.6 Operating Controls.....................................................................................19

3.7 Tools..........................................................................................................21

3.7.1 Blade Holder ...................................................................................21

Transport..................................................................................................................22

4.1 General Information...................................................................................23

4.2 Conditions for Initial Set-up........................................................................23

4.3 Initial Set-Up ..............................................................................................23

4.4 Equipment Specifications...........................................................................23

Initial Operation........................................................................................................24

5.1 Preparations Before Initial Operation.........................................................25

5.2 Initial Operation..........................................................................................25

Operation .................................................................................................................27

6.1 Start-up Procedure.....................................................................................28

6.2 Shutting Down............................................................................................29

6.3 Operational and Maintenance Procedures.................................................30

6.4 Start-up After Maintenance or Repair ........................................................30

6.5 Procedures Before and After Long Storage Time......................................30

Maintenance.............................................................................................................31

7.1 Instructions.................................................................................................32

7.2 Maintenance and Inspection List................................................................33

7.3 Repairs.......................................................................................................34

7.4 The Scraper...............................................................................................35

7.4.1 Changing the Scraper Blade and Adjusting the Clamp ...................35

7.4.2 Tool List for Scraper Blade Removal...............................................35