BIOBASIC 210 User manual

BIOBASIC

INSTRUCTIONS FOR USE

Models: 210, 310, 410 & 600

2 | BIOBASIC INSTRUCTIONS FOR USE

Before you proceed

This instructions for use is intended for the following product series:

BIOBASIC

We recommend that you read this instructions for use through thoroughly

before using the cabinet for the rst time. Gram Commercial does not

guarantee safe operation if the cabinet is used for anything other than its

intended use. Contents of the instructions for use can be subject to change

without notice. No part of this instructions for use may be reproduced in

any form without expressed written consent of Gram Commercial. Gram

Commercial guarantees the cabinet under certain warranty conditions. Gram

Commercial is not responsible for any loss or damage of content.

This instructions for use should be considered an integral part of the cabinet

and should be stored close to the cabinet and be easy to access. If the

instructions for use is lost, please refer to your local distributor or Gram

Commercial for a replacement. For current versions of the instructions for use,

please go to www.gram-bioline.com.

Gram BioLine equipment is designed to be used in a system with monitored

additional independent alarms to ensure timely reaction to alarms and thereby

maximum item safety

BIOBASIC INSTRUCTIONS FOR USE | 3

In the event of need for product support, donot hesitate to contact us at:

In the event of technical diculties always contact Gram BioLine technical

support or a Gram BioLine authorized service partner.

Copyright © 2006-2022 Gram BioLine, a division of Gram Commercial, Denmark. All rights

reserved. The content of this publication is owned by Gram BioLine, unless otherwise

noted, and is protected by Danish and international copyright laws and provisions.

Information and images may not be used, copied or transferred without the express

written permission by Gram BioLine.

4 | BIOBASIC INSTRUCTIONS FOR USE

Table of Content

Before you proceed ............................................. 2

Table of Content ................................................ 4

Intended use .................................................... 6

Temperature setpoint range and ambient requirements ......... 6

Symbols used ................................................... 7

Installation ..................................................... 8

Initial setup steps ............................................... 8

Adjusting the base .............................................. 9

Anti tilt bracket ................................................10

Wall mounting .................................................11

Surroundings ..................................................12

Product inspection ............................................13

Voltage free contact ...........................................14

Connecting to power ..........................................16

Equipotential bonding .........................................20

Start up ........................................................22

The digital display controls .....................................22

General introduction to the controller interface ................23

Alarm settings ................................................. 24

Buttons and useful short cuts ..................................25

Operation parameters .........................................26

Error codes ....................................................27

Latching alarms: A2, A3 ........................................27

Sensor oset ..................................................28

Ordinary use ...................................................30

Door gaskets ..................................................32

General info ...................................................33

Responsibility .................................................33

General info ...................................................34

Service ........................................................34

BIOBASIC INSTRUCTIONS FOR USE | 5

Type number plate ............................................35

Access port ....................................................36

Regular maintenance .........................................38

Cleaning .......................................................38

IMPORTANT ....................................................40

Disposal .......................................................41

Datasheet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

General data: BIOBASIC 210, 310, 410 ..........................42

BIOBASIC RR210 – with solid door ..............................44

BIOBASIC RR210 – with glass door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

BIOBASIC RR310 – with solid door ..............................46

BIOBASIC RR310 – with glass door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

BIOBASIC RR410 – with solid door ..............................48

BIOBASIC RR410 – with glass door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

BIOBASIC RF210 ...............................................50

BIOBASIC RF310 ...............................................51

BIOBASIC RF410 ...............................................52

General data: BIOBASIC 600 ...................................54

BIOBASIC RR600 ............................................... 56

BIOBASIC RF600 ...............................................57

Declaration of Conformity .....................................58

Wiring diagrams ............................................... 59

BIOBASIC RR/RF210, RR/RF310, RR/RF410 ......................59

BIOBASIC RR600 ............................................... 60

BIOBASIC RF600 ...............................................61

Piping diagram ................................................62

Notes ..........................................................64

6 | BIOBASIC INSTRUCTIONS FOR USE

Intended use

BIOBASIC refrigerators (RR) and freezers (RF), are designed and manufactured

to provide general purpose storage of non-critical laboratory items.

The BIOBASIC range complies with EN/IEC 60079-15, covering electrical

apparatus in Category 3, Zone 2 locations where explosive atmospheres may be

present.

Enabling placement of BIOBASIC refrigerators and freezers, in Zone 2 areas

categorised according to EN/IEC 60079-14.

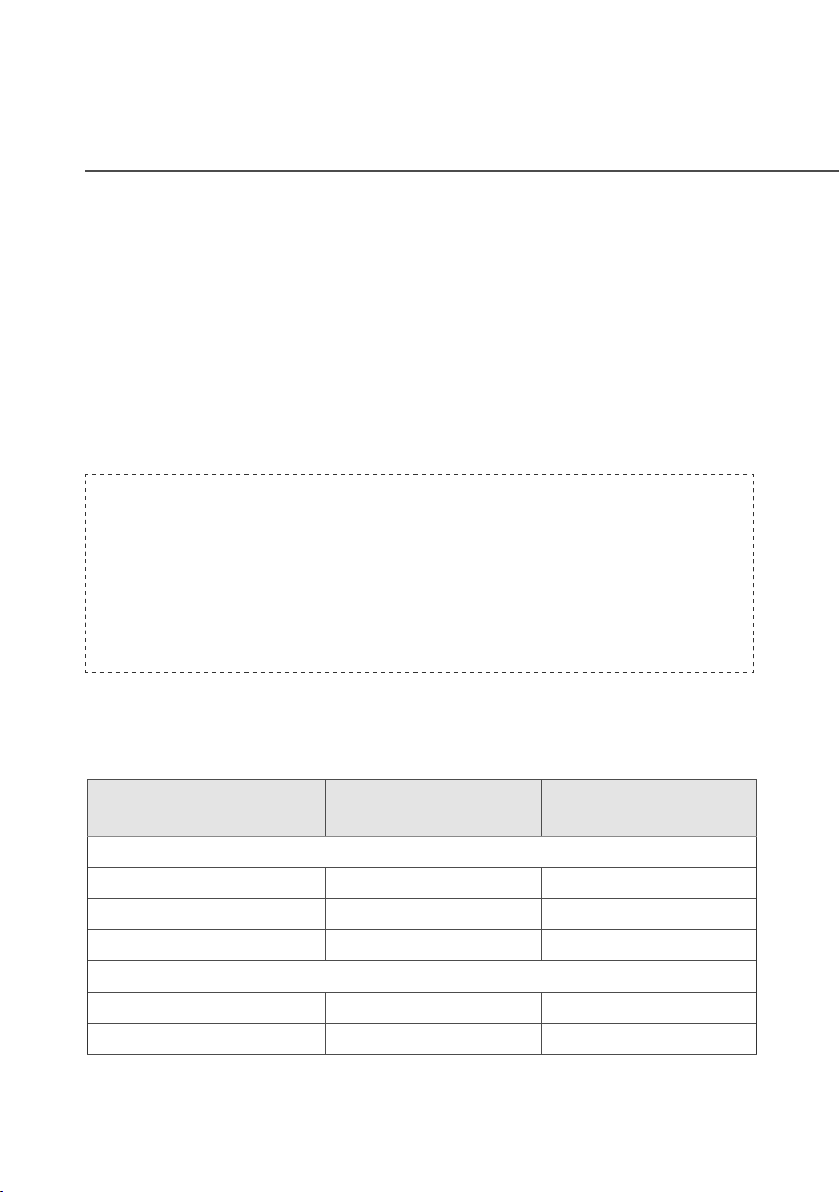

Temperature setpoint range and

ambient requirements

Model + temperature

setpoint range

Minimum ambient

operating temperature

Maximum ambient

operating temperature

BIOBASIC 210, 310, 410

RR with solid door: +2/+15ºC +10ºC +35ºC

RR with glass door: +2/+15ºC +10ºC +32ºC

RF: -25/-5ºC +10ºC +35ºC

BIOBASIC 600

RR: +2/+15ºC +10ºC +43ºC

RF: -25/-5ºC +10ºC +43ºC

The user must ensure that the cabinet is used in accordance with its

intended use. Abnormal use or use conicting with the intended use or

guidelines stipulated in the product documentation can lead to; danger

to patient safety, damage to stored items, damage to cabinet, danger to

user. Gram BIOBASIC equipment is designed to be used in a system with

monitored additional independent alarms to ensure timely reaction to

alarms and thereby maximum item safety.

BIOBASIC INSTRUCTIONS FOR USE | 7

Symbols used

Risk of burning / freezing

Risk of personal injury

Risk of material damage

Risk of electric shock

Hazard

Info

Riskofre/ammable materials

Risk of explosion/explosive materials

ATEX information

8 | BIOBASIC INSTRUCTIONS FOR USE

Installation

Initial setup steps

The cabinet is shipped with a protective

lm that shall be removed prior to use.

WARNING – POTENTIAL

ELECTROSTATIC CHARGING

HAZARD

Removing protective packaging

and lm may cause electrostatic

discharge. protective packaging and

lm shall not be removed in ATEX

zones.

The cabinet is only allowed to lay down for very short durations (for instance

handling through a doorway). If the cabinet has been laying down, the

cabinet must stand up-right for at least 24 hours prior to use. This enables

oil in the compressors to run back into place.

Avoid placement of the cabinet in a chloric/acidic environment due to risk

of corrosion.

Due to safety and operating considerations, the cabinet must not be used

outdoors. The cabinet should be installed in a dry and suciently ventilated

area. To ensure ecient operation, the cabinet should not be installed in

direct sunlight or close to heat sources.

The cabinet interior must not be exposed to corrosive atmospheres.

Clean the cabinet with a mild soap solution prior to use.

BIOBASIC INSTRUCTIONS FOR USE | 9

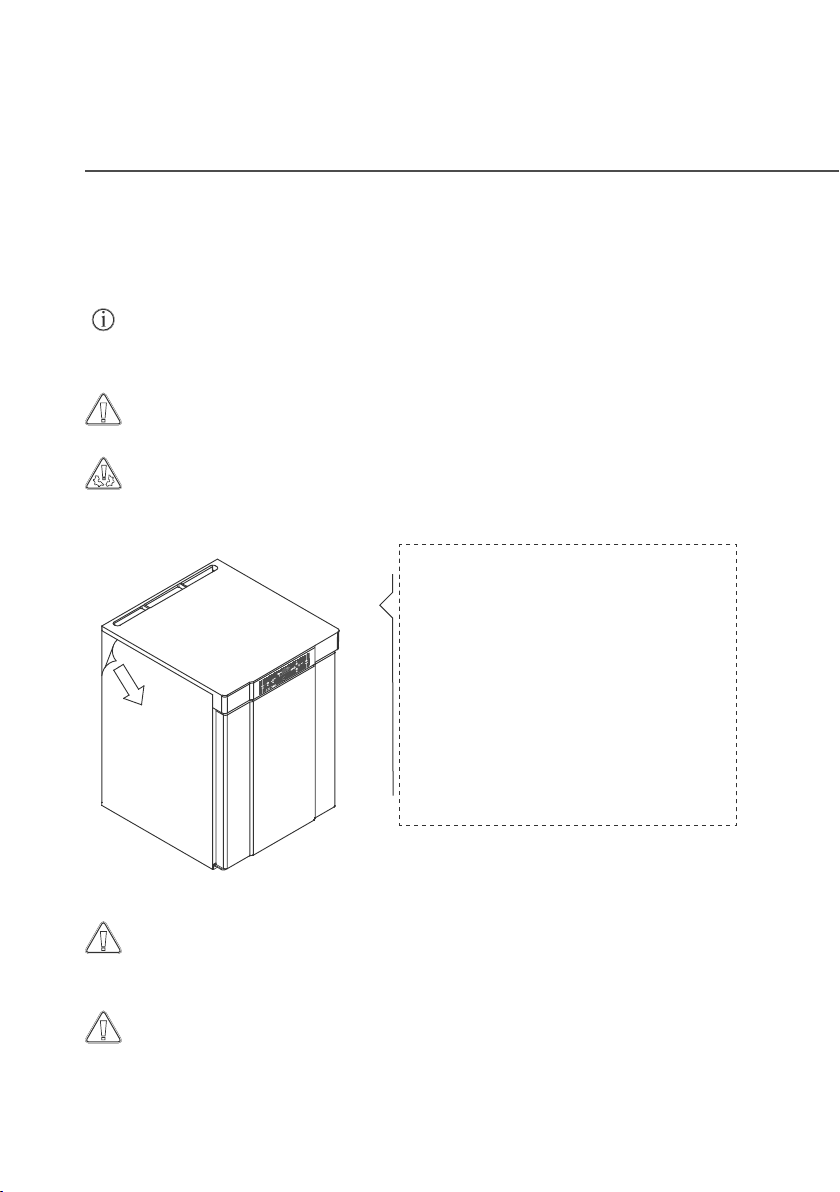

Cabinets equipped with legs

should be levelled as shown in the

illustrations to the left.

For cabinets equipped with

castors, the oor must be level

to ensure stable positioning and

safe use. When the cabinet is

positioned, the 2 front castors

should be locked.

Adjusting the base

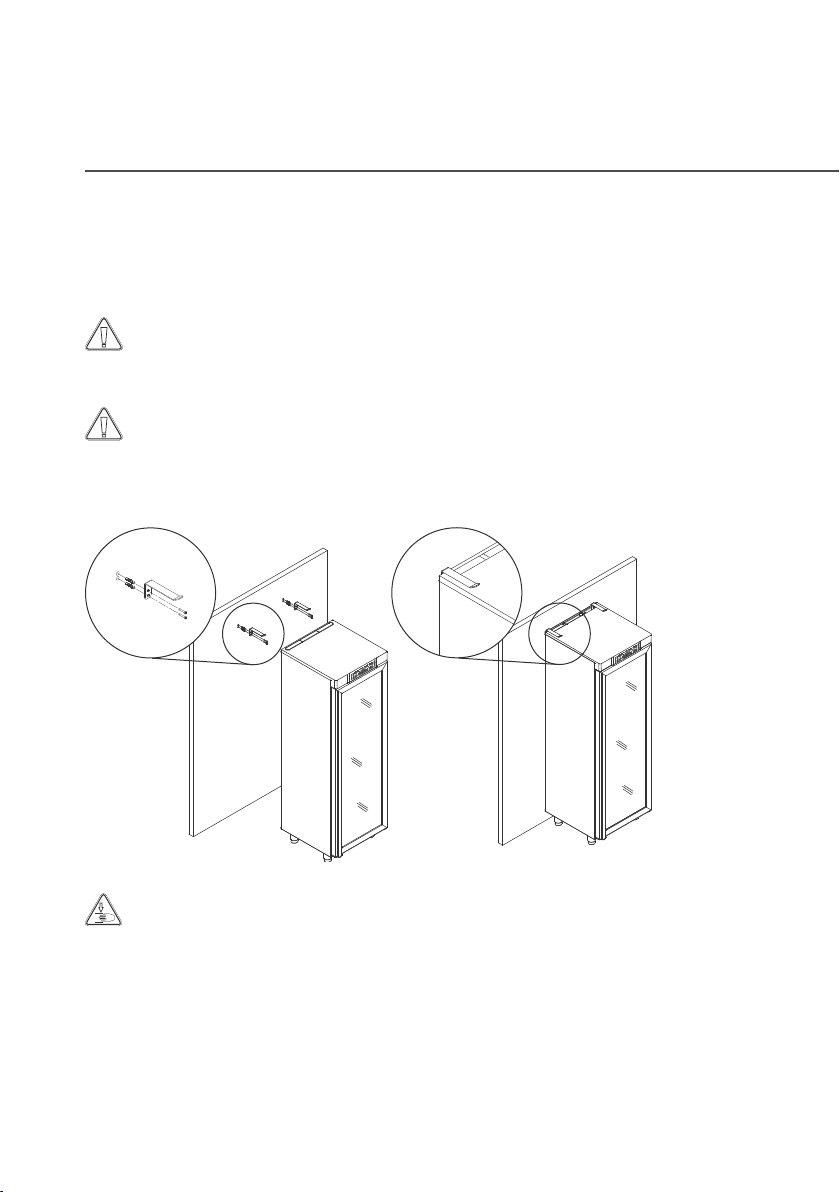

Cabinets with drawers and/or glass door must be secured to a stable vertical

surface, ensuring that the cabinet cannot tip over when the drawers are drawn

to the outermost position, or the door is open. Brackets for securing the cabinet

are included from the factory.

Find the instructions for the tilt bracket below.

The anti-tilt brackets must be tted when installing the cabinet, ensuring that

the users, surroundings and stored items are not damaged.

10 | BIOBASIC INSTRUCTIONS FOR USE

Anti tilt bracket

BIOBASIC INSTRUCTIONS FOR USE | 11

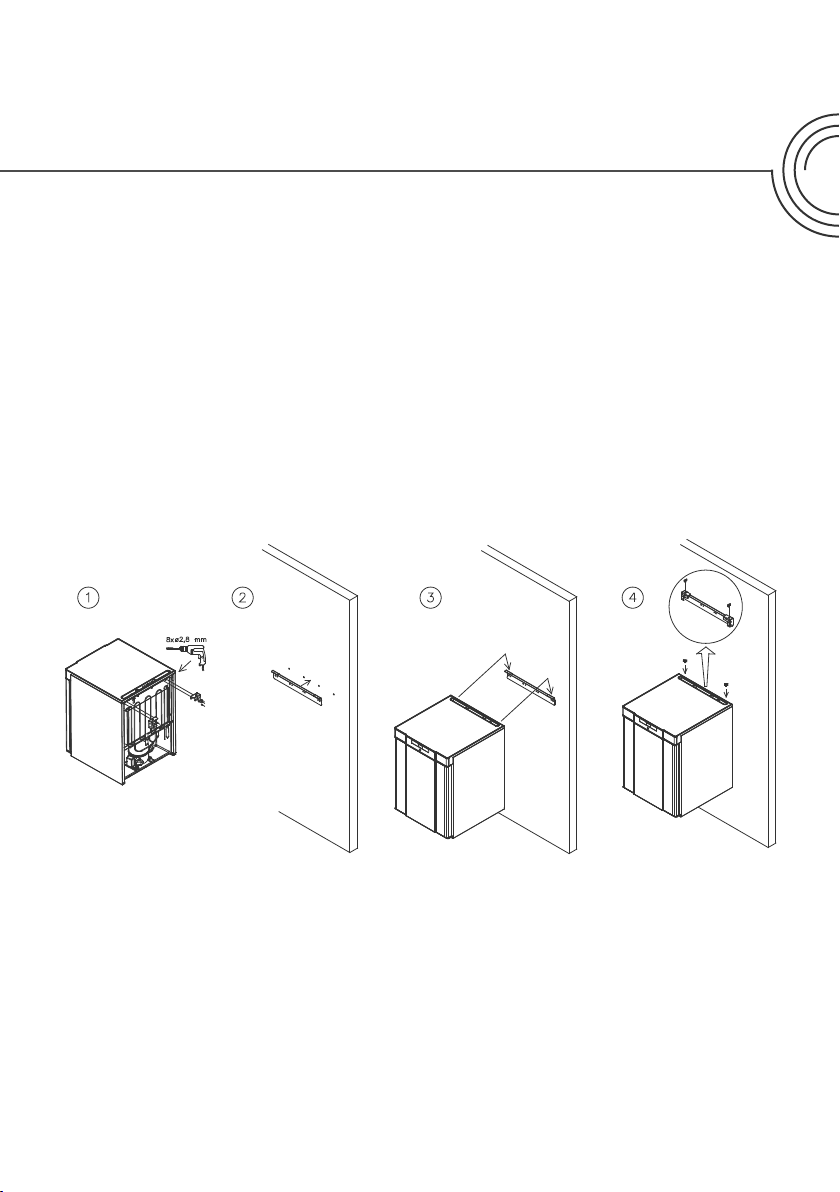

Wall mounting

Wall mounting brackets can be supplied if specied. Allowing the cabinet to be

lifted from the oor.

Find instructions on wall mounting of a BIOBASIC 210 below, the same

procedure applies for mounting 310 and 410.

NB: Applies for 210/310/410 models.

≥30mm

≥15mm

15-75 mm

12 | BIOBASIC INSTRUCTIONS FOR USE

Surroundings

The cabinet must be installed in accordance with the illustrations

below.

BIOBASIC INSTRUCTIONS FOR USE | 13

A visual inspection of the cabinet must be conducted prior to putting the

cabinet into service.

Check the cabinets structural integrity, that door frames and doors don’t

have deformities, gaskets seal properly and the doors sit ush up against

the door frame.

Product inspection

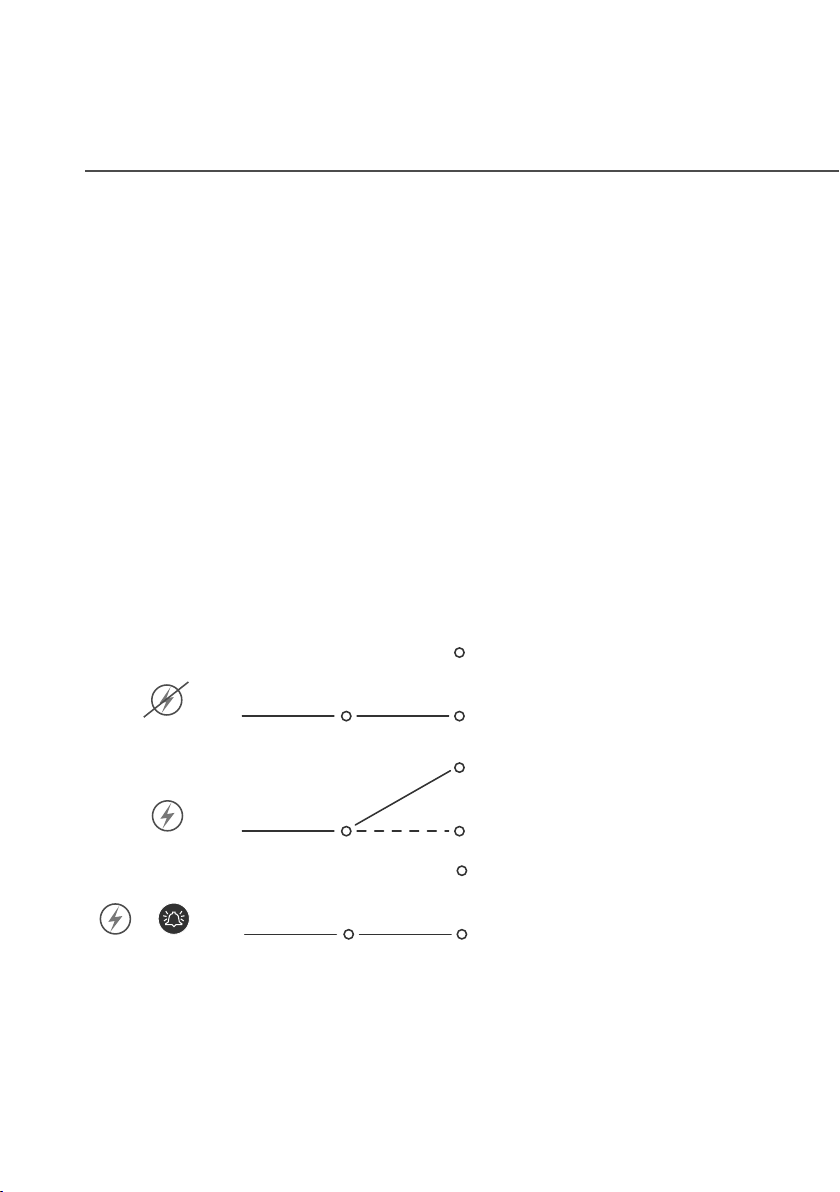

NC

Common

NO

Common

Normally Open (NO)

Normally Open (NC)

NC

Common

NO

Common

NC

Common

NO

Common

+

+NC

NO

NC

The illustration below shows the three connectors for the relay

(e.g. in connecting to CTS or other external monitoring systems).

The three connections are respectively Common, NO (Normally Open) and

NC (Normally Closed).

The moment voltage is applied, the controller draws the relay, this makes it

possible for the controller to respond to both high and low temperature alarms,

door alarms and power failures.

Find instructions on setting the alarms in the controller settings section.

Voltage free contact

Normally closed

circuit (NC)

14 | BIOBASIC INSTRUCTIONS FOR USE

Connection of the voltage free contact should be done by a qualied installer.

Location of the voltage free contact or 210/310/410

Location of the voltage free contact for 600

BIOBASIC INSTRUCTIONS FOR USE | 15

16 | BIOBASIC INSTRUCTIONS FOR USE

When setting up in an ordinary scenario that is not subject to

regulations for EN 60079-15 zone 2:

The appliance may be connected in accordance with applicable local

heavy current regulations.

Note that there are special regulations for products that are in

accordance with EN 60079-15 zone 2 and EN 60079-14: Explosive

atmospheres – Electrical installations design, selection and

erection.

The appliance has been manufactured in accordance with EN 60079-

15: Electrical apparatus for explosive gas atmospheres – Part 15: Type

of protection II 3G Ex ec nC ic IIB Tx Gc. Zone 2 is the applicable zone.

If the appliance is to be installed in a zone 2 environment, specialist

personnel should perform the installation, or be consulted beforehand,

in order to ensure that the appliance is installed in compliance with the

guidelines currently contained in the standard. The cabinet is intended

for connection to alternating current. The connection values for voltage

(V) and frequency (Hz) are given on the type/number plate.

BIOBASIC 210, 310, 410 – The mains terminal is accessed via the preload

cover on the back of the cabinet. Unscrew the preload cover to access

the mains supply terminal. Ensure that the preload cover is reinstalled

after plugging in the power cord. The leaf spring in the preload

cover must engage and preload the plug of the cord as shown in the

illustrations below.

BIOBASIC 600 – The power cord is plugged in the terminal box on the

back of the cabinet. The plug is then xated in place by the hanger that is

built into the terminal box. Please note that the hanger should be tted

tightly around the plug, as shown. In all cases, ensure that the mains

plug is seated completely in the terminal of terminal on the cabinet.

Connecting to power

BIOBASIC INSTRUCTIONS FOR USE | 17

Power cord plugged into 210/310/410 cabinets.

Power cord plugged into 600 cabinet.

18 | BIOBASIC INSTRUCTIONS FOR USE

The appliance must be connected to the external power supply using a suitable

device which mechanically prevents the plug and socket from being separated

unintentionally. The connection must be labelled:

”DO NOT SEPARATE WHEN ENERGIZED”.

Fuses and similar must never be removed or replaced while the appliance

is connected to a power source. The electrical terminal box must never be

opened while the appliance is connected to a power source. The compressor

starting equipment must never be dismantled while the appliance is connected

to a power source. The LED lighting must never be dismantled while the

appliance is connected to a power source. Whenever electrical components are

dismantled or replaced, the appliance must be moved to an area in which there

is no risk of ignition caused by the electrical components or gases contained in

the appliance. Never use the cabinet if the plug is damaged. The cabinet should

be examined by a Gram BioLine authorised service technician in such cases.

Please refer to EN 60079-14: Explosive atmospheres – Electrical installations

design, selection and erection for installation requirements in an ATEX

environment.

In both cases:

Use a three-wire plug, if the power outlet is intended for a three-wire plug,

the lead in green/yellow insulation should be connected to the ground

terminal. Power must be connected via a wall socket. The wall socket should

be easily accessible. All earthing requirements stipulated by the local electricity

authorities must be observed. The cabinet plug and wall socket should then

give correct earthing. If in doubt, contact your local supplier or authorized

electrician.

BIOBASIC INSTRUCTIONS FOR USE | 19

Technical support –

In the event of technical diculties always contact Gram BioLine

technical support or a Gram BioLine authorized service partner.

For Ex environments –

Special conditions for safe use may apply to this product when

installing in an EN 60079-14 environment.

Please see corresponding Ex certicate for specications.

For Ex environments –

Open containers inside the storage chamber may impact the ATEX

zone classication.

20 | BIOBASIC INSTRUCTIONS FOR USE

For installation in ATEX Cat. 3 Zone 2 areas, it is mandatory to have a

equipotential bonding, it is not sucient to use protective earth through

the mains connection.

To secure equipotential bonding of the unit – the mounted external

bonding conductor must be used in accordance with national installation

requirements e.g. EN 60079-14.

• Mounting of the bonding conductor should be done according to the

following illustrations.

• Please nd location for connection facilities on the back of the

cabinet marked with “Attention – Equipotential bonding”.

• The bonding conductor should be at least 4 mm2 gauge.

• Use a ring terminal to ensure adequate bonding.

• Use the supplied M5 machine screw and washer to attach the

bonding conductor to the cabinet. Tighten the machine screw to

3.2 Nm.

Bonding of the cabinet is illustrated on the following page.

Equipotential bonding

This manual suits for next models

3

Table of contents