Blue Diamond Heavy Duty Multi-Blade Manual

1

Heavy Duty Multi-Blade

Operation & Maintenance Manual

Date purchased:

REMEMBER: Register your product! No claims for warranty shall be considered

unless your product registration card is completed online within 30 days of

purchase!

Go to: bluediamondattachments.com/warranty-registration

Purchased From:

Model Number:

Serial Number:

2

Foreword

Congratulations on the purchase of your Heavy Duty

Multi-Blade, the finest snow plow on the market today!

Blue Diamond Attachments Snow Plows are designed by people

with years of experience. You can be sure that the quality and

innovation of the Multi-Blade is our first priority. Getting to know

your new snow plow should be the first step in learning its features

and limitations. This manual is designed to assist you in the

operation and maintenance of your Multi-Blade.

Document History

The list below shows all revisions of the Multi-Blade

Operation and Maintenance Manual.

Document Revision

Second Publication

Summary of Changes

First Revision

Publication Date

1/25/2017

Headquarters

Blue Diamond Attachments

4512 Anderson Road

Knoxville, TN 37918

toll free 888-376-7027

local 865-246-2006

fax 865-246-2007

info@bdattachments.com

www.bluediamondattachments.com

© 2017 – Blue Diamond Attachments. All Rights Reserved. 01/2017.All other brands, products, or

service names are trademarks or service marks of their respective owners, and are used to identify

products or services of their companies or organizations. Notice: This document is for informational

purposes only and does not set forth any warranty, expressed or implied, concerning any equipment,

equipment feature, or service offered or to be offered by Blue Diamond Attachments. Blue Diamond

Attachments reserves the right to make changes to this document at any time, without notice, and

assumes no responsibility for its use. This informational document describes features that may not be

currently available. Contact a Blue Diamond Attachments sales person for information on features and

product availability.

3

Contents

Document History 2

About This Manual 4

Hazard Notices Used 4

Terminology 4

Safety 4

Safety Notices 4

Modifications of

Equipment 4

About the Snow

Plow Equipment 5

Multi-Blade 5

Attaching the Plow

to Prime Mover 6

Removing the Plow

from Prime Mover 6

Operation & 7

Maintenance

Equipment 7

Inspection 7

Usage Guidelines 7

Inspection Checklist 7

Operation 7

Operation Continued 8

Maintenance 8

Detailed Parts Diagram 9

Detailed Parts List 10

Plow Specifications 11

Multi-Blade Available 11

Accessories

Manufacturer’s 12

Warranty

Two Year 12

Limited Warranty 12

Warranty Claim 12

Exclusions of Warranty 12

4

About this

Manual

This manual contains information

about the usage and maintenance

required for the equipment. This

document must be available for review

by the operator before using the

attachment to ensure proper safety,

maintenance and usage.

NOTE

Additional safety equipment may be

required depending on the operating

environment and worksite conditions.

Hazard Notices

Used in Manual

The following hazard notices are used in this document

NOTE

Notes are used to indicate important

information. This information may be

repeated in other areas of the manual.

CAUTION

Cautions are used to indicate a potentially

hazardous situation which, if not avoided,

may result in damage to the equipment or

other property.

WARNING

Warnings are used to indicate a potentially

hazardous situation which, if not avoided,

could result in serious injury or death.

DANGER

Danger is used to indicate a potentially

hazardous situation which, if not avoided,

will result in serious injury or death.

Terminology

Prime Mover:The Blue Diamond Attachments Multi-Blade Snow Plow can be attached

to many different pieces of equipment; therefore the term “prime mover” will be used. A

prime mover is any loader, tractor or equipment, providing power to the attachment.

Safety

Safety Notices

Before operating or conducting maintenance on this equipment, it is important

to wear proper protection. Recommended safety equipment when operating

and maintaining this equipment includes earplugs, eye protection, and a hard

hat.

Only qualified and trained personnel should operate, maintain, and service this

attachment. It is recommended that this equipment be inspected regularly for leaks,

cracks, or other conditions that may impair proper usage of the equipment. Verify that

all repairs have been completed and inspected prior to using the attachment under load.

It is the responsibility of the user to follow all local, state, and federal safety regulations.

Improper use of this equipment may result in personal injury, property damage, and/or

damage to the equipment.

Modifications to Equipment

Any modifications made to this equipment may void any warranty and

relieve the manufacturer of liability of any resulting injury or damage.

5

About the Heavy

Duty Multi-Blade

Attachment

The Multi-Blade attachment is intended for use in

snow removal. Use of this equipment in any other

manner is considered to be contrary to the

intended use of the attachment.

6

Figure 1 – ProPlow

Attaching the Snow Plow

to the Prime Mover

NOTE

Before attempting to attach

the Snow Plow to the prime

mover, verify that all hydraulic

couplings are compatible.

CAUTION

Hydraulics should operate in an

even and smooth manner.

Hydraulic movement that is not

even and smoo

th may indicate

that air is in the hydraulic lines.

WARNING

Improper

attachment to the prime

mover may cause personal injury.

CAUTION

All hydraulic connections must

be clean and free of debris

before making any connection.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Place the Snow Plow attachment on a level surface.

Position and align the prime mover to the rear of the

attachment, within proximity of the front of prime mover.

Insert and connect the prime mover into the

a

ttachment. Connect the hydraulic lines from the

attachment to the prime mover.

Close latches (or othe

r locking mechanism) to secure

the attachment to the prime mover.

Using the prime mover,

raise the attachment and move

the attachment to ensure h

ydraulic lines are clear of air

and operate properly.

Lower the attachment to ground level.

Route hoses away from pinch areas

– install cable

ties if necessary to assure extended hose life.

Inspect that the attachment is mounted properly and

securely. If t

he attachment does not meet this

requirement, follow the instructions to remove the Snow

Plow and re

-attach using the instructions above.

Multi-Blades

The Blue Diamond Attachments Multi-Blade attachment

has become a necessity among plowing contractors

today. This unique Snow Plow is offered for a variety of

applications.

Blue Diamond Attachments Multi-Blades

Snow plows are designed by people with years of

experience in harsh Minnesota winters. You can be sure

that the quality of the Multi-Blade is our first priority.

The Multi-Blade has been designed for absolute maximum

durability and efficiency, regardless of snow conditions.

Extra tight blade curl reduces horsepower requirements to

get snow rolling, 35° angle gives you the most efficient

snow discharge, and our patent pending spring-assisted

down pressure lets you scrape like no other! Simply put,

you’ve purchased the world’s finest snowplow!!

P.S. Wolves are not usually solitary animals.

They like to work in packs!

7

Removing the Snow Plow

from the Prime Mover

WARNING

Improper disconnection

may result person injury or

damage to t

he attachment

and prime mover.

CAUTION

All hydraulic connections must

be clean and free of debris

before disconnection.

NOTE

Hydraulic connections must be

disconnected before

disengaging latches to prevent

damage to the prime mover or

the attachment.

1. Using the prime mover, lower the attachment to the ground.

2. Relieve the pressure in the hydraulic system by following these

instructions:

a. Turn the ignition to off.

b. Turn the ignition back to the on position without starting the machine.

c. Move the auxiliary hydraulic function lever back and forth to relieve the

pressure in the hydraulic lines. (This will greatly assist you when

hooking the unit back up so that the hydraulic couplers connect easily)

3. Disconnect the hydraulic connection between the attachment and the prime

mover. To prevent contamination, remove any dirt and debris from the

couplings.

4. Disengage the prime mover latches (or other locking mechanism) from the

attachment.

5. Move the prime mover from the attachment.

8

Operation &

Maintenance

NOTE

Replace any damaged

hardware, hoses, and

fitting before using the

equipment.

WARNING

Do not use hands to check

for hydraulic leaks. Keep

body parts away from

leaking hydraulic lines and

couplings that are under

pressure.

DANGER

Keep all body parts away

from the Snow Plow

when in use. The

pivoting blade is

dangerous and

hazardous and could

potentially cause serious

bodily injury or death.

Inspection Checklist

√Are all safety

notices and warning

stickers in proper

locations and visible? √

Are there any visible

hydraulic leaks?

√Are any cracks

visible in Snow Plow

structure?

√Is the cutting edge

worn or bent?

√Are the bolts

holding blades

secure and tight?

√Has the prime

mover been properly

inspected for hydraulic

leaks and proper tire

inflation?

√Has the prime

mover been properly

maintained?

Equipment Inspection

It is recommended to inspect the equipment for damage and wear

before use. Use the following list as a guideline during equipment

inspection.

•Check all hardware connections to the prime mover for

damage or fatigue such as cracks or other structural flaws.

•Check that all latches or locks are closed.

•Check that all hydraulic fittings are tight and free of leaks

•Check that all hydraulic lines are free of leaks, holes, or

cracks.

Check that the tires on the prime mover are in good condition and have

proper load ratings.

Usage Guidelines

Before each use do the following:

•Perform the equipment inspection by performing a walk

around.

•Perform daily inspection as indicated in the Inspection

Checklist.

•Verify that the proper attachment is being used for the task.

Operation

Always be sure the A-frame of your Multi-Blade is level (perpendicular)

with the ground when plowing, to insure proper cutting edge wear. You

can regulate the scraping ability of your Multi-Blade by increasing or

decreasing the down pressure you apply via your tilt cylinders. The

angle of your Multi-Blade can be changed at any time by using your

auxiliary circuit. As you become experienced with the Multi-Blade, you

will find its productivity will amaze you.

If you are on extremely uneven ground, you may prefer to raise your boom

arms slightly, lower the Multi-Blade to the ground using your tilt cylinders,

then put your boom arms in the float position (if machine is equipped) to

better follow the contours of the ground. You will learn from experience

what works best for you in each situation.

Operation Continued

9

The Multi-Blade has been designed to

stack snow if you wish. This will not

damage the plow no matter how high you

push it into a pile of snow. Watch your

hose routing carefully so as not to stretch

and ruin your hoses.

DANGER – Always be aware of what is

overhead.

Maintenance

Disconnect the hydraulic connection between

the attachment and the prime mover before

performing any type of maintenance to the

Snow Plow.

Inspect the Snow Plow daily before use. It is also recommended to inspect the Snow

Plow after extreme use or damage. Us the following inspection checklist as a guideline.

•As with any power attachment, safety is critical. An enclosed cab prime mover

with the operator wearing safety protection is required.

•Never operate the Snow Plow with persons within 100 feet.

•Disengage Snow Plow and shut off engine before leaving the cabin of the

prime mover.

•Keep all body parts away from the Snow Plow when in use.

•Use caution on slopes and uneven terrain.

•Never carry passengers.

•Never leave machine running unattended.

•Never leave Snow Plow off the ground when out of operator’s seat.

•Never allow children or untrained personnel to operate the snowplow! STAY

CLEAR

Cutting Edge

Be certain to replace bolt-on cutting edge when it wears within 1/2” -3/4” of the

bolt head securing it to the trip-edge. Replace only with genuine Blue Diamond

Attachments cutting edge and hardware.

Cylinder Gland Nut

Periodically check cylinder gland nuts for tightness. Usually they will leak first if they

become loose. A large slip-joint pliers or pipe wrench can be used to tighten. Do not

over tighten!

Hoses

Check hoses occasionally for abrasion damage. This may save you from downtime. If

in doubt, replace with genuine Blue Diamond Attachments parts.

Pivot Pins

Pivot pins may be lubed with moly-type grease, same as used on your machine. Please

check the cotter pins that retain all pivot/anchor pins after each use. If missing,

replace! Severe damage could be caused by losing a pin.

Springs

Multi-Blade springs are adjusted by the two large jam nuts on the rod between each

spring. Springs are adjusted correctly when you can fit a business card between the

coils. It is very important to set them after your first use, then twice per year

thereafter. Use of grease or “Anti Seize” on the rod and jam nuts will keep them from

rusting to each other.

Storage

Lubrication of pivot pins is recommended if unit is stored outside. Be certain

hydraulic quick couplers are cleaned and joined together to keep dirt out. Put a light

coating of grease on exposed rod portion of cylinders to prevent corrosion. Touch-up

paint should be used on all scratches to prevent further rust.

10

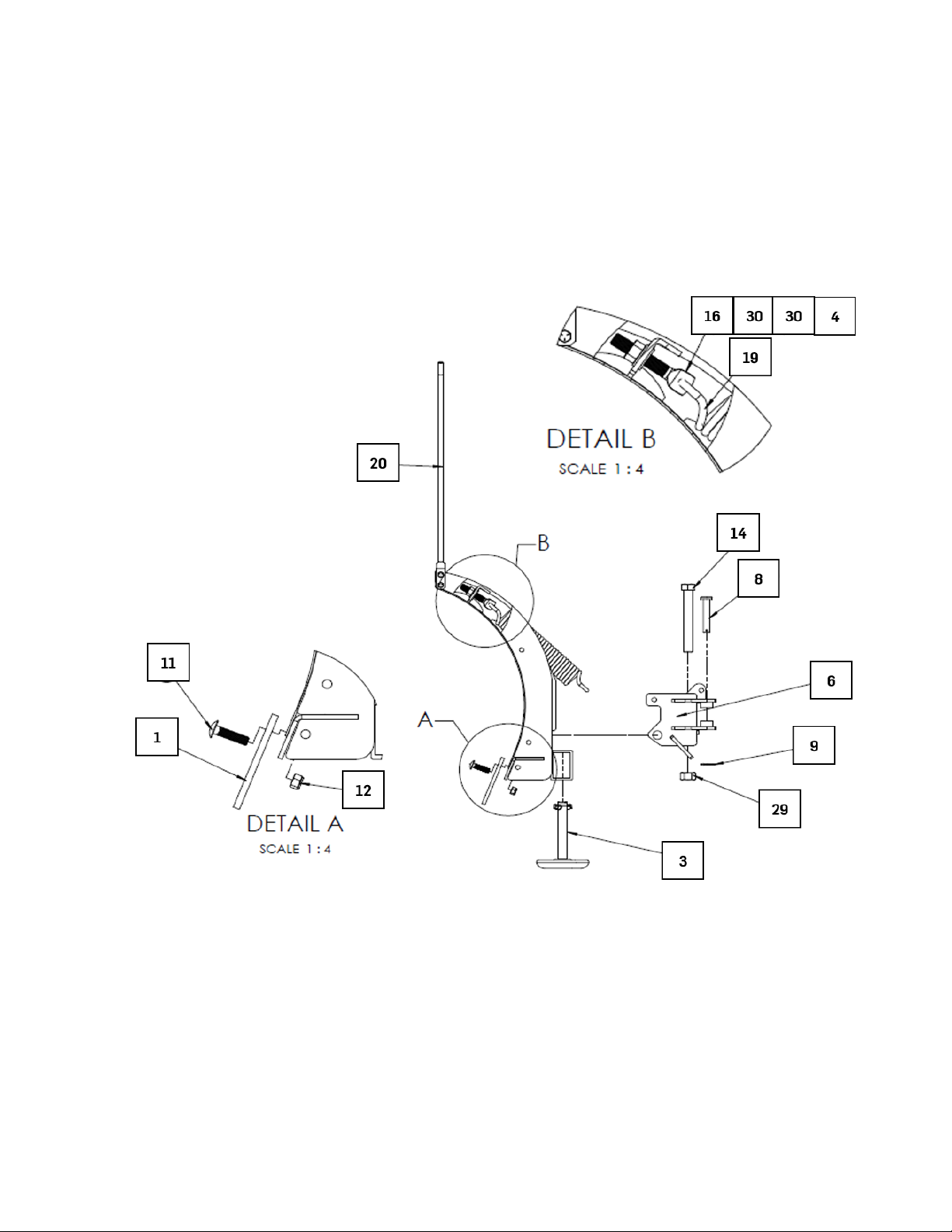

Detailed Parts Diagram

2

11

12

Detailed Parts List

Table 1 – Parts List

Item# Part#

Description

DC16

Blue Diamond Decal, Multi-Blade by Blue Diamond

DC17

Blue Diamond Decal

1

222043

Cutting Edge, 8’ with hardware

1

222042

Cutting Edge, 7’ with hardware

1

222041

Cutting Edge, 6’ with hardware

1

222040

Cutting Edge, 5’ with hardware

2

P20004-1

Moldboard Weldment, 8’, 2016 or newer

2

P20005-1

Moldboard Weldment, 7’, 2016 or newer

2

P20006-1

Moldboard Weldment, 6’, 2016 or newer

2

P20007-1

Moldboard Weldment, 5’, 2016 or newer

3

P20008

Wear Shoe Weldment

3

P20008-S

Wear Shoe Set, L & R, with Hardware

P20009

Spacer Kit for 20008

P20012

Klik Pin 20008

4

P20016

Locknut, 5/8 – 11

P20019

Decal, “DANGER PINCH AREA”

5

P20020-2

T-Frame Weldment , 2016 or newer

6

P20021-2

Quadrant Weldment, 2016 or newer

7

P20022-1

Universal Skid Steer Mount, 2016 or newer

8

P20029

Pin, ¾ x 3

9

P20030

Cotter Pin, 5/32 x 1¼

10

P20031

Angle Cylinder, Chrome rod

11

P20034

Carriage Bolt, 1/2 - 13 x 1-1/2", for Steel Cutting Edge

12

P20035

Hex Nut, 1/2", for Cutting Edge

13

P20036

Carriage Bolt, 1/2 - 13 x 2", for Poly Cutting Edge

P20037

8’ Polymer Cutting Edge Kit with hardware

P20038

7’ Polymer Cutting Edge Kit with hardware

P20039

6’ Polymer Cutting Edge Kit with hardware

P20040

5’ Polymer Cutting Edge Kit with hardware

14

P20041

Pivot Bolt, 1" x 7-1/2", 2016 or newer

15

P20042

Rubber Insert for T-Frame

16

P20043

5/8-11x4 Eyebolt

17

P25045

Grade C Locknut ½-13

18

P40007

Cotter Pin, 3/16 x 3

19

222133

Trip Spring, 6’-10’ New Style Ultra (15" long)

20

P50001

Blade Marker Guide Set

21

P50005

Ram Anchor Pin, Frame End

13

22

P50007

90° Restricted Angle Fitting

23

P50008

Hose Assembly, 78” long

P50008-B

Hose Assembly, 30" long, Crossover **

24

P50009-A

Adapter, #8 MJIC x #12 MORB, Hose to Coupler

25

P50009-B

Adapter, #6 MJIC x #10 MORB, Crossover to Hose **

P50010

ISO Flat Face Coupler Set

26

P50010F

ISO Flat Face Coupler, Female

27

P50010M

ISO Flat Face Coupler, Male

P60002

Crossover Relief Valve **

28

P60008

Carriage Bolt, 5/8-11 x 2-1/2 (for Poly Cutting Edge)

29

P60024

1" Grade C Locknut for Torsion and Parallel Plates

30

P60096

FLAT WASHER, 5/8" SAE

31

P50026

Hose Clamp Kit with hardware

32

P20048

Torsion Beam

33

P20049

Torsion Retainer Plate

34

P20047

Oscillation Lockout Kit, 2016 or newer **

**Optional upgrade items. Not on all Multi-Blades.

14

Snow Plow

Specifications

Table 2 – Specifications

Description

Pro-5.0

Pro-6.0

Pro-7.0

Pro-8.0

Blade Width

5’

6’

7’

8’

Blade Width at Full Angle

50”

59”

68.8”

78.6”

Blade Height

28”

28”

28”

28”

Weight

479#

541#

543#

638#

Gauge of Moldboard

12 Ga

12 Ga

12 Ga

12 Ga

Trip Springs

2 (4 opt.)

2 (4 opt.)

2 (4 opt.)

2 (4 opt.)

Wear Shoes

Yes

Yes

Yes

Yes

Cutting Edge (1085 High Carbon)

3/8” x 6”

3/8 x 6”

3/8 x 6”

3/8” x 6”

Angle Rams

1 ½” x 10

1 ½” x 10

1 ½” x 10

1 ½” x 10

Vertical Ribs

4

4

4

6

Moldboard Radius

15”

15”

15”

15”

Full Trip

Yes

Yes

Yes

Yes

Oscillation

Std.

Std.

Std.

St.d

Universal Skid Steer Mount

Std.

Std.

Std.

Std.

Trip Lock-Out

Std.

Std.

Std.

Std.

Blue Diamond Attachments Multi-Blade Accessories

Soft Touch Cutting Edge

Eliminate damage on brick, paver and other

delicate surfaces. Unlike rubber, there is no

maintenance required. Constructed of non-

marking and non-sparking proprietary high wear

polymer for maximum service life. Available for all

sizes of the Blue Diamond Attachments Multi-

Blades.

Poly Snow Deflector

Recommended for all light, fluffy snow conditions

and for all machines capable of 8 MPH or greater.

Available for all sizes of Blue Diamond

Attachments Multi-Blade.

15

Manufacturer’s

Warranty

Two-Year Limited Warranty

Warranty Claim

Exclusions of Warranty

B

lue Diamond Attachments LLC, hereinafter referred to as Blue Diamond

warrants new

Blue Diamond Multi-Blade at the time of delivery to the original

purchaser, to be free from defects in material and workmanship when properly

set up and op

erated in accordance with the recommendations set forth by Blue

Diamond

. Blue Diamond’s liability for any defect with respect to accepted

goods shall be limited to repairing the goods at a

Blue Diamond designated

location or at an authorized dealer location, or

replacing them as Blue Diamond

shall elect. The above shall be in accordance with

Blue Diamond warranty

adjustment policies.

Blue Diamond’s obligation shall terminate twenty-four (24)

months after the delivery of the goods to original purchaser including cutti

ng

edge breakage or wear. This warranty shall not apply to any machine or

attachment which shall have been repaired or altered outside the

Blue

Diamond

factory or authorized Blue Diamond dealership or in any way so as in

B

lue Diamond’s judgment, to affect its stability or reliability, nor which has been

subject to misuse, negligence or accident beyond the Company recommended

machine rated capacity.

To submit a warranty claim, a return authorization from

Blue Diamond must be

obtained. The failed part may then be

returned. Tampering with the failed part

may void the warranty. This warranty does not include freight or delivery charges

incurred when returning machinery for servicing. Dealer mileage, service calls,

and pickup/delivery charges are the customers’ res

ponsibility.

Except as otherwise expressly stated herein,

Blue Diamond makes no

representation or warranty of any kind, expressed or imp

lied, AND MAKES NO

WARRANTY

OF MERCHANTABILITY IN RESPECT TO ITS MACHINERY

AND/OR ATTACHMENTS ARE FIT FOR ANY PARTICULAR

PURPOSE. Blue

Diamond

shall not be liable for incidental or consequential damages for any

breach or warranty, including but not limited to inconvenience, rental of

replacement equipment, loss of profits or other commercial loss. Upon

purchase, the buyer a

ssumes all liability for all personal injury and property

resulting from the handling, possession, or use of the goods by the buyer.

No agent, employee, or representative of Blue Diamond has any authority to bind

Blue Diamond to any affirmation, representation or warranty concerning its

machinery and/or attachments except as specifically set forth herein.

This warranty does not cover abuse, modifications by others, or leaking hoses

due to improper routing, abrasion or pinching.

This warranty policy supersedes any previous documents.

No claims for warranty shall be considered unless warranty registration

has been completed within 30 days of purchase!

Table of contents

Other Blue Diamond Snow Blower Accessories manuals