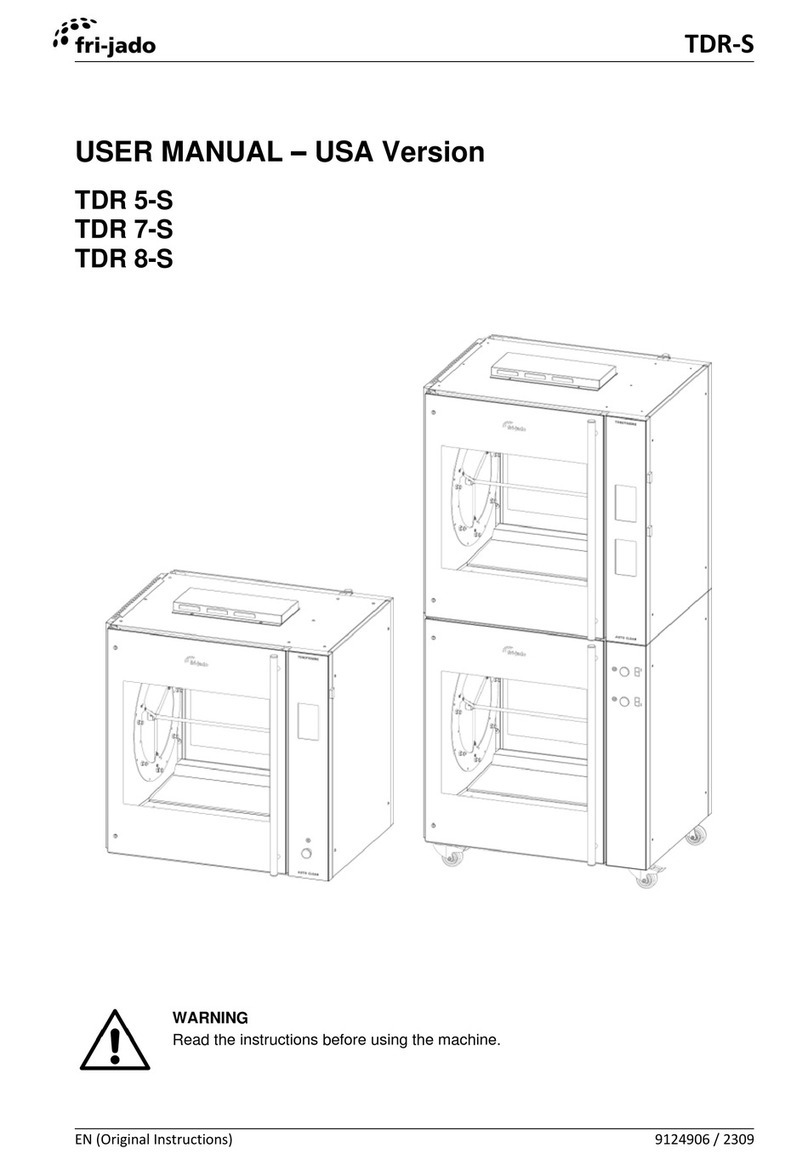

Blue Flame BFCO-1 User manual

1

INSTALLATION & OPERATION MANUAL

Gas Convection Oven

MODEL:BFCO-1

Blue Flame

223 W. Rosecrans Ave.

Gardena CA 90248 USA

Tel : 1.866.677.8500 / 1.310.808.0102

Fax :1.310.808.0242 /1.310.808.0262

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

DANGER

If you smell gas:

• Shut off gas to the appliance.

• Extinguish any open flame.

• If odor continues, keep away from the appliance and immediately call your gas supplier or your

fire department.

2

death.

NOTICE

! WARNING

! CAUTION

SAFETY

PRECAUTIONS

Beforeinstallingandoperatingthisequipment,besureeveryoneinvolvedinitsoperationisfullytrained

andawareofprecautions.Accidentsandproblemscanbecausedbyfailuretofollowfundamentalrules and precautions.

Thefollowing symbols,foundthroughoutthismanual,alertyouto potentiallydangerousconditionstothe operator,

service personnel, or to the equipment.

!DANGERThissymbolwarnsofimmediatehazardswhichwillresultinsevereinjuryor

Thissymbolreferstoapotentialhazardorunsafepracticewhichcouldresultin injury or death.

Thissymbolreferstoapotentialhazardorunsafepracticewhichcouldresultin injury, product

damage, orproperty damage.

Thissymbolreferstoinformationthatneedsspecialattentionormustbefully understood, even

though not dangerous.

!WARNING

FIRE HAZARD

FOR YOUR SAFETY

Donotstoreorusegasolineorotherflammablevaporsandliquidsinthevicinityofthisoranyother appliance.

Keep area around appliances free and clear of combustibles.

Purchaserofequipmentmustpostinaprominentlocationdetailedinstructionstobefollowedinthe event the

operatorsmells gas. Obtain theinstructionsfrom the local gas supplier.

!WARNING

Electrical GroundingThis appliance is equipped with a three-prong (grounding) plug for your protection

against shockhazard and should be plugged directly into a properly grounded three-prong receptacle.

And Do not cut orremove the grounding prong from the plug.

!WARNING

Asphyxiation canresult from improper ventilation. Do notobstruct the flow of combustion and ventilation air to

and from your cooking equipment.

NOTICE

BesurethisOperator’sManualandimportantpapersaregiventotheproperauthoritytoretainfor futurereference.

NOTICE

This product is intended for commercial use only. NOT FOR HOUSEHOLD USE.

Copyright © 2017 byBLUE FLAME.

All rights reserved.

Published in the United States of America.

3

TABLE OF CONTENTS

Congratulations! You have purchased one of the finest pieces of heavy-duty commercial cooking

equipment.

Youwill findthatyournew equipment,hasbeen designedand manufactured

tomeetthetougheststandardsintheindustry.Each pieceofequipmentiscarefullyengineered

anddesignsareverified throughlaboratorytestsandfieldinstallations.Withproper careandfield

maintenance,youwillexperienceyearsofreliable, trouble-free operation.Forbestresults,read this manual

carefully.

RETAIN THISMANUAL FOR FUTUREREFERENCE.

Table of Contents

Specifications.........................................................................................................................4

Installation..............................................................................................................................8

Operation..............................................................................................................................13

Cooking Hints.......................................................................................................................14

Cleaning...............................................................................................................................17

Adjustments..........................................................................................................................19

Troubleshooting....................................................................................................................22

Parts...................................................................................................................................26

Replacing Oven lamp............................................................................................................30

Natural to LP gas conversion Procedure...................................................................................31

Readtheseinstructionscarefullybeforeattempting installation. Installationandinitialstartupshouldbe

performedby aqualifiedinstaller.Unlesstheinstallationinstructionsforthisproductarefollowedbya

qualifiedservicetechnician (apersonexperiencedinandknowledgeable withtheinstallation ofcommercial gas )

then the terms and conditions on the Manufacturer’s Limited Warranty will be renderedvoid and

nowarranty of any kind shallapply.

Please contact a local service company to perform maintenance and repairs

In the event you have questions concerning the installation, use, care, or serviceof the product, write to:

4

SPECIFICATIONS

NOTICE

Localcodesregardinginstallationvarygreatlyfrom oneareatoanother.TheNationalFire Protection

Association, Inc.statesinitsNFPA 96latesteditionthatlocalcodesarethe“authorityhaving jurisdiction”

whenit comestoinstallationrequirementsfor equipment.Therefore,installations should comply with all

local codes.

Producerreservestherightto changespecificationsandproductdesign withoutnotice.Such revisionsdo

notentitlethebuyertocorrespondingchanges,additions,orreplacementsforpreviously purchased

equipment.

This product is intended for commercial use only, not for householduse.

Theinstallationmustconformwithlocalcodes,orintheabsenceoflocalcodes,withtheNational

FuelGasCode,ANSIZ223.1,Natural GasInstallationCode,CAN/CGA-B149.1,orthePropane

InstallationCode CAN/CGA-B149.2,asapplicable, including:

1. Theapplianceanditsindividualshutoffvalvemustbedisconnectedfromthegassupplypiping

systemduringanypressuretestingofthatsystemattestpressuresinexcessof1/2psi(3.45 kPa).

2. Theappliancemustbeisolatedfrom thegas supplypiping system byclosingitsindividual manual

shutoffvalveduringanypressuretestingofthegassupplypipingsystemattestpressuresequal to or less

than 1/2 psi (3.45 kPa).

ELECTRICITY SUPPLY

Convection ovens require connection toa supplyofelectricity. Theappliance,wheninstalled,mustbe

electricallygroundedinaccordance withlocalcodes,orintheabsenceoflocalcodes,withtheNational Electrical

Code,ANSI/NFPA70, orthe CanadianElectrical Code,CSA C22.2, asapplicable.Anelectrical

diagramislocatedonthe sideofthecontrolpanelassembly(see drawingonpage20).Electricaldiagrams can

also be found in this manual beginning on page21.

Power Option

Power

# of Ovens

Maximum Amps

120/60/1 120Volts,60Hz,SinglePhase Single-Deck 9.3

Single-deckovenswillhaveone120 volt single phase powercord.

GAS SUPPLY

The serial plateindicatesthetype of gasthe unitisequippedto burn. All equipment is adjusted at the factory.

Check type of gas on serial plate.

Thesemodelsaredesign-certified foroperationon naturalorpropanegases.Fornatural gas,theregulator is set to

deliver a 4" W.C. pressure to the manifold.For propanegas, it is set to deliver 10"W.C.

Ifapplicable,theventlinefromthegasappliancepressureregulatorshallbe installedtotheoutdoorsin

accordancewithlocalcodes,orintheabsenceoflocalcodes,withtheNationalFuelGasCode,ANSI

Z223.1,NaturalGasInstallationCode, CAN/CGA-B149.1, orthe PropaneInstallationCodeCAN/CGA-

B149.2,as applicable.

This appliance should beconnected ONLY to the type of gas forwhich it is quipped.

A3/4"NPTlineisprovidedattherearforthegasconnection.Anadequategassupply isimperative. Undersizedorlow

pressurelines willrestrictthevolumeofgasrequiredfor satisfactory performance.

Fluctuationsofmorethan25%onnaturalgasor10%onpropanegaswillcreateproblemsandaffect burner operating

characteristics.

5

Anadequate gas supplylinetotheunit shouldbe nosmallerthantheinsidediameterofthepipefromthe unit to

which it is connected.

Purge thesupply line to clean out dust, dirt, or other foreign matter beforeconnecting the lineto the unit.

Allpipejointsandconnectionsmustbetestedthoroughlyforgasleaks.Useonly soapywaterfortestingon

allgases.NEVERuseanopenflametocheckforgasleaks.Allconnectionsmustbecheckedforleaks after the unit

has been put into operation.Test pressure should notexceed 1/4" W.C.

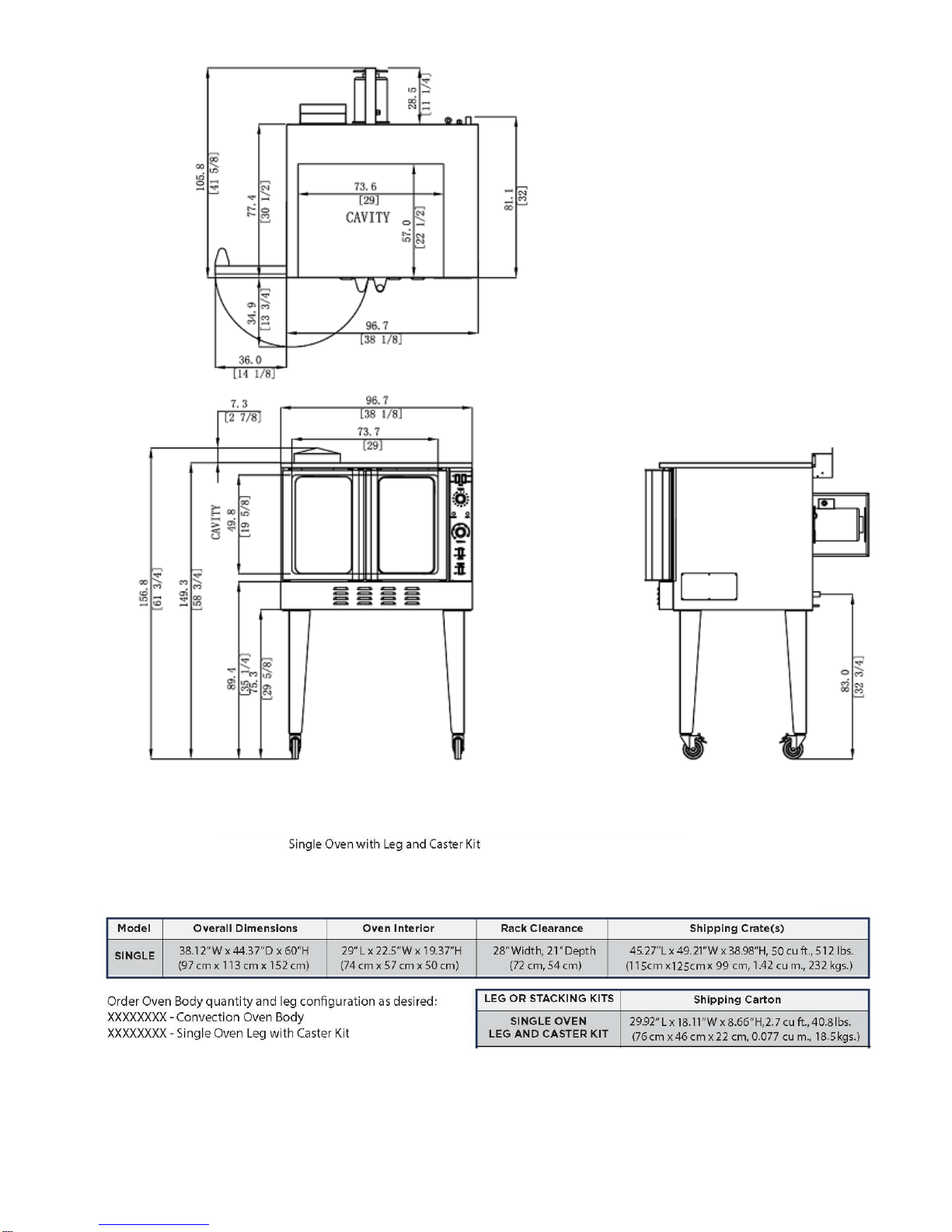

Model # of Ove

ns

Oven

Depth

Type ofGas Orifice Size

# of Burners Total BTU

Convection oven

Single-

Deck 22.5” Natural Gas 45 3 @ 18,000 BTU

54,000

LP 55

THIS APPLIANCE IS EQUIPPED FOR NATURAL GAS.

All oven shipped for Natural Gas.

Each oven is shipped with an LP Gas Conversion kit,

--Regulation spring (FS Part # 001)

--LP orifices (FS Part # 002)

For conversion to LP gas see the conversion instruction(Page.29).

6

7

MINIMUMCLEARANCES

!WARNING

There must be adequate clearance between the left side of the ovens and combustibleconstruction.

Minimum Clearance from

Combustible

C i

Minimum Clearance from

Non-Combustible

C i

Back

6"

6"

Right Side

6"

0"

Left Side

6"

0"

Adequate clearancemustbeprovidedintheaisletoallowthedoorstoopensufficientlytopermitthe removal of

the racks and for serviceability.

Althoughno clearanceisrequiredbehindthemotorontherear oftheoven,caremustbe takento provide

adequate air circulation to prevent the motor from overheating.

Donotlocate theovenadjacenttoanyhighheator grease-producingpieceofequipment,suchasa

rangetop,griddle,fryer,etc.,thatcouldallowradiantheattoraise theexteriortemperatureof theoven above

130°F(54°C). DO NOT MOUNTABOVE OTHER COOKING EQUIPMENT.

VENTILATION

! WARNING

Improperventilationcan resultinpersonalinjuryordeath.Ventilationwhichfailstoproperly remove flue

products cancause headaches, drowsiness, nausea, orcould result in death.

Allunits mustbeinstalled in such amannerthat theflowof combustionandventilation airare not

obstructed.Provisionsfor adequateair supplymust beprovided.Donotobstructthefrontorrear of the unit as

combustion airenters through these areas.

Besureto inspectand cleanthe ventilationsystemaccordingtothe ventilationequipment manufacturer’s

instructions.

NOTICE

Properventilationistheowner’sresponsibility.Anyproblemduetoimproperventilationwillnotbe covered by the

warranty.

Ifaventilationcanopyisused,itisrecommendedthatacanopy extend6"pasttheapplianceandthatthe

bottomedge belocated6'6"fromthefloor.Filtersshould beinstalledatanangleof45°ormorefromthe horizontal.

Thispositionprevents drippinggreaseandfacilitatescollectingtherun-off greaseinadrippan, unusually

installed with a filter.

Ifanexhaust fanisused,itshouldbeinstalledatleast2"abovetheflueopeningatthetopoftheunit.A

strongexhaustfantendstocreateavacuumintheroomandmay interferewithburnerperformance.Fresh

airopeningsapproximatelyequaltothefanareawillrelievesuchavacuum. Incaseofunsatisfactory performance

onanyappliance,checktheappliance withtheexhaustfaninthe “OFF”position.Dothisonly longenough

tocheckequipmentperformance.Then turnthe exhaustfan backonandletitrunto remove any exhaust that

may have accumulatedduring the test.

Iftheovenflueisconnecteddirectly toanoutside flue,aCSAInternational designcertifieddowndraft diverter

mustbe installed atthe flue outlet of the oven and connected to the outside flue.

8

INSTALLATION

NOTICE

These installation procedures must be followed by qualified personnel or warranty will be void.

Localcodesregardinginstallationvarygreatlyfrom oneareatoanother.TheNationalFire Protection

Association, Inc.statesinitsNFPA 96latesteditionthatlocalcodesarethe“authorityhaving jurisdiction” whenit

comestoinstallationrequirementsfor equipment.Therefore,installations should comply with all local codes.

Theinstallationmustconformwithlocalcodes,orintheabsenceoflocalcodes,withtheNational

FuelGasCode,ANSIZ223.1,Natural GasInstallationCode,CAN/CGA-B149.1,orthePropane

InstallationCode CAN/CGA-B149.2,asapplicable, including:

1. Theapplianceanditsindividualshutoffvalvemustbedisconnectedfromthegassupplypiping

systemduringanypressuretestingofthatsystemattestpressuresinexcessof1/2psi(3.45 kPa).

2. Theappliancemustbeisolatedfrom thegas supplypiping system byclosingitsindividual manual

shutoffvalveduringanypressuretestingofthegassupplypipingsystemattestpressuresequal to or less

than 1/2 psi (3.45 kPa).

Step 1: Unpacking

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

Allcontainersshould be examined for damage before and during unloading.Thefreight carrierhas

assumedresponsibilityforitssafe transitand delivery.Ifdamagedequipmentisreceived,either apparent or

concealed, a claim must bemade with the delivering carrier.

Apparentdamageorloss mustbenotedonthefreightbillatthetimeofdelivery.Thefreight billmust

thenbesignedbythecarrierrepresentative(Driver).Ifthebillisnotsigned,thecarriermayrefuse the claim. The

carrier can supply the necessary forms.

Arequestforinspectionmustbe made tothecarrier within15daysifthereisconcealeddamage or lossthatis

notapparentuntilaftertheequipment isuncrated. Thecarriershouldarrangean inspection. Be certain to hold all

contents plus all packing material.

1. Cut bandingstraps and remove packing material.

2. Cut bandingstrap holding oven to wooden skid.

Step 2: Installation ofLegs on Single-Deck Ovens (For Stacking kit, refer to instructions

included with kit)

1. Raiseovensufficientlytoallowclearanceforthelegstobeattached.Use ofalifttruckorother mechanicalliftingmeans

isrecommended.For safety,“shoreup”and supporttheoven withan adequateblockingarrangementstrong

enoughtosupporttheload.(Ifitisabsolutelynecessarytorest theovenonitsside,restit onitsleftside.)

2. Attachthelegstothebottomcornersoftheoven usingtheprovidedmachinescrewsand lock washers. Each leg

issecured by 3 screws. The mounting holes are pre-drilled and threaded.

3. Lower the oven gently onto a level surface. Never drop or allow the oven to fall.

4. Makesurethattheovenislevel.

5. Install required cable restraint connecting oven to wall.

9

Step 3: Installation of Restraint (Only for Ovens with Casters)

NOTICE

When this appliance is installed with casters, it must be installed with the caster supplied, a

connector complying with either ANSI Z21.69 or CAN/CGA-6.16 and a quick-disconnect

device complying with either ANSI Z21.41 or CAN1-6.9. It must be installed with a restraining

means to guard against transmission of strain to the connector, as specified in the appliance

manufacturer’s installation instructions.

!WARNING

To avoid accidental gas disconnection and potential explosion:

Ifdisconnectionofthisrestraintisnecessarytomovetheapplianceforcleaning,etc.,reconnectit when the

appliance is moved to its originally installedposition.

10

Step 4: Connect Electricity

!WARNING

ELECTRIC GROUNDING INSTRUCTIONS

Thisappliance(120Vovensonly)isequipped withathree-prong(grounding)plugforyourprotection against shock

hazard and should be plugged directly into a properly grounded three-prong receptacle. Do not cut or

remove the grounding prong from this plug.

NOTICE

Thisappliance,wheninstalled,mustbe electrically groundedinaccordance withlocal codes,orinthe

absence of local codes, with the National Electrical Code, ANSI/NFPA 70or the Canadian Electrical

Code, CSA C22.2, as applicable.

Wiringdiagramsarelocatedonthesideofthecontrol panelassembly,aswellasinthismanual(beginning onpage 21).

Besurethat theinputvoltageandphasematchthe requirementsshownontheserial plate, which is located inside

thelower front panel.

Ovensorderedtooperateon120Vpowerhaveathree-wirecord.Single-ovenunitsrequirea15amperesupply.

Step 5: Connect Gas Supply

NOTICE

Theinstallationmustconformwithlocalcodes,orintheabsenceoflocalcodes,withtheNational

FuelGasCode,ANSIZ223.1,Natural GasInstallationCode,CAN/CGA-B149.1,orthePropane InstallationCode

CAN/CGA-B149.2,asapplicable, including:

1. Theapplianceanditsindividualshutoffvalvemustbedisconnectedfromthegassupplypiping

systemduringanypressuretestingofthatsystemattestpressuresinexcessof1/2psi(3.45 kPa).

2. Theappliancemustbeisolatedfrom thegas supplypiping system byclosingitsindividual manual

shutoffvalveduringanypressuretestingofthegassupplypipingsystemattestpressuresequal to or less than

1/2 psi (3.45 kPa).

A 3/4" NPT line is provided atthe rear for the gas connection.

Ifthisequipmentisbeinginstalledatover2,000feetaltitudeandthatinformationwasnotspecified when ordered,

contact the appropriate authorized Service Representative or the Service

Department.Failuretoinstallwithproperorificesizingwillresult inpoorperformanceandmayvoidthe warranty.

The serial plateislocatedinsidethefrontlowerpanel.Itindicatesthetypeofgastheunit is equipped to burn. All

equipment is adjusted at the factory. Check type of gas on serial plate.

Thesemodelsaredesign-certified foroperationon naturalorpropanegases.Fornatural gas,theregulator is set to

deliver a 3.5" W.C. pressure to the manifold.For propanegas, it is set to deliver 11"W.C.

ThisapplianceshouldbeconnectedONLYtothetypeofgasforwhichitisequipped.The inletpressure before

theregulatorshould be 6-10" W.C. for natural gas or 11-14"W.C. for LP gas.

11

Anadequategassupplyisimperative.Undersized orlowpressurelineswillrestrictthevolumeofgas

requiredforsatisfactoryperformance.Fluctuationsofmorethan25%onnaturalgasor10%onpropane gaswill create

problems and affect burner operating characteristics.

AnadequategassupplylinetotheunitshouldbenosmallerthantheI.D.ofthepipefromtheunittowhich it is connected.

Purge thesupply line to clean out dust, dirt, or other foreign matterbeforeconnecting the lineto the unit.

! CAUTION

ALLPIPEJOINTSANDCONNECTIONSMUSTBETESTEDTHOROUGHLYFORGASLEAKS. USEONLY

SOAPYWATERFORTESTINGONALLGASES. NEVER USEANOPENFLAMETO

CHECKFORGASLEAKS.ALL CONNECTIONS MUSTBE CHECKEDFORLEAKSAFTERTHE UNITHAS

BEEN PUT INTO OPERATION. TEST PRESSURESHOULDNOTEXCEED1/4"W.C.

Step 6: Check the Installation

1. Check that all screws and bolts are tightened.

2. Move the oven into the position at which it will be operated.

3. Check that the oven is level. If not, adjust the legs.

4. Check that the appropriateclearances are satisfied (see page 7)

12

Control Panel

FanSpeed

Use to select fan speed (HI or

LOW).The appropriate speed is

determined bythe type of food

being cooked.

Cook Timer

Turn knob to set a time duration.

An alarmwill soundwhen the timer

runs out. The timer is a reminder

to the user; the timer does not

control theoven

Power on Light

Power Switch

Switch ON to use the oven, switch

OFFwhen done using the oven.

FanMode

In COOK mode, the fan runs

continuouslyexceptwhen thedoors are

open. The fan does NOTcycle with the

operation of the burners. In COOL

mode, the fan runs

continuouslyeven if the doors are

open. Since the burnerswill not

operate if the oven doors areopen, to

rapidlycool the oven after cooking is

completed, open the doors and switch

the fan mode to COOL.

Heat-OnIndicator

Indicator is lit when the burners are

operating.

Cook Temperature Control

Turn knob to select desired cooking

temperature. The Heat On indicator will

go outwhen the oven reaches the set

temperature, andwill cycle on and off

as the burners operate to maintain the

set cooking temperature.

OvenInteriorLightSwitch

On ovens equippedwith an oven

interior light, press to turn on the

light. The light remainson for as

long as the switch is held.

13

OPERATION

!

DANGER EXPLOSION HAZARD

Intheeventagasodorisdetected,shutdownequipmentatthemainshutoffvalve.Immediatelycall the

emergency phone number of your gas supplier.

!CAUTION

Toeliminategasbuildupwhichcouldresultinanexplosion,intheeventofmainburnerignition failure a five minute

purgeperiod must be observed prior to re-establishing ignition source.

NOTICE

Foranapplianceequippedwithaconvectionoven,noattemptshouldbemadetooperateoven during a power

failure.

LIGHTING, RELIGHTING, AND SHUTDOWN INSTRUCTIONS

Tolighttheoven,just switchthepower switch atthe bottom ofthe control paneltothe “ON”position. (The oven

isequipped with a direct hot surface ignition system. There is no pilot to light.)

If the burners fail to ignite within four seconds, the oven will automatically shut offthe gas, wait five

minutes toallowthegasthatwasreleasedtodissipate,andtrytolighttheburnersagain.Iftheburners stillfailto

igniteafterthree suchattempts,theovenwill stoptrying,eventhoughthepowerswitchisinthe “ON” position. To

continue to attempt to light the burners, turn the power switch “OFF” and then “ON” again.

Toshutdown theoven,switchthepowerswitchtothe“OFF”position.

OPERATING THE CONTROLS

Aconvection ovenis adifferenttype ofoventhatoffersmanyfeaturesandadvantagestothe foodservice

operation.Theadditional capabilitiesandfeaturesoftheovenrequiresomelearning. However,the operation

of the oven is notdifficult to understand orcontrol onceyou have some practice.

Operation of STANDARD Models

Models withStandard Controls operatemuch like a standard oven:you turn the oven ON andselect a

cooking temperature. Twoadditional controls are used to control the fan (as described below).

The timer is areminder to you of when to remove foodfrom the oven.The timer does NOT control the

temperature of the oven.

To cook, do the following:

1. Turn the oven ON using the Power Switch at the bottom of the control panel.

2. SelectthedesiredfanspeedusingtheFanSpeedswitch.Theappropriatefanspeed(HIorLOW)depends on

the type of food beingcooked.

3. SwitchtheFanModeswitchtoCOOK. Thefan will run continuouslywhenthe ovendoorsareclosed (thefan

doesnotcycleon andoffwiththeburners).(IfthisswitchissettoCOOLtheonlydifferenceis that the fan will

continue torun when theoven doors are open.)

4. Setthecookingtemperaturebyturning theCookTemperatureControl untiltheindicatormarkonthe

knobispointedtothedesired cookingtemperature.TheHeatOn indicatorwill lightwhentheburners are on,

and will remain on while the oven preheats.

14

5. Waituntilthe HeatOnindicator hascomeonandgoneoutthree times.Atthattimetheovenwillhave reached the set

cooking temperature.

6. Open the oven doors, loadthe product into the oven, and close thedoors.

7. Youcanuse theCookTimerasa reminderofwhentheremovetheloadfromtheoven.Ifsodesired,

turntheCookTimerknob untiltheindicatormarkpointstothedesired cookingtime(upto55 minutes).

Thetimerknobwillrotate counterclockwiseasthetimerrunsdown,indicating howmuchtimeremains. Youcanturn

theknob whilecookingto increase or decreasetheremainingtime.Whenthe timer runs

out,abuzzerwillsoundforashorttime,thenturnitself off.(Toimmediatelysilencethebuzzer,turnthe

CookTimerknobtotheOFFposition.)Thetimerisareminderto you;thetimerdoesnotcontrolthe oven.

Ifyouopentheovendoors,theburnersandfanwillshutoffuntilthedoorsareclosed.However,the timer will continue

running even if the doors are open.

Toturnontheinterior oven lights,use the switch located at the bottom of the control panel.

8. Whentheloadhasfinishedcooking,youcanrapidlycooltheloadbyopeningtheovendoors(which

willshutofftheburners)andswitching theFanModetoCOOL(whichwill causethefantoruneven though the doors

are open). For the most rapid cooling, also switchthe Fan Speed switch toHI.

9.Whenyou are donecooking,turntheCookTemperaturecontroltothelowest setting(fully counterclockwise) and

switch the PowerSwitch to OFF.

COOKINGHINTS

Ina convectionoven,thefan-blown circulatingairstripsawaythisinsulatinglayer allowingthe

heattopenetratefasterforquickerbakingandroasting.Hence,in aconvection oven cooking procedures

andtechniquesmay requiresomemodificationfor successful results.As ageneral rule,the cooking time will be

shorter and the cooking temperature will be 25°F to 75°F lower than those called for in recipes for

astandard oven.

TIME & TEMPERATURE

Timeandtemperature areimportant.The“GuidetoTimesandTemperatures”laterinthissectionisa

startingpoint.Theactualbestcookingtimeandtemperaturewilldependonsuchfactorsassizeofload andmixture

ofrecipe(particularlymoisture).Onceanappropriatetime andtemperaturehasbeen established for a particular

product and load, you willfind the result of succeeding loads to be similar.

OVERLOADING

Do NOToverloadtheoven.The size oftheloadthatcan be cooked satisfactorilydependslargelyon the

particularproduct.Asa rule,fiveracks can be successfullyusedforshallowcakes,cookies, pies,etc.For deeper

cakes(suchasangelfood),useonlythree racksbecauseofthesize ofthepanandthespace requiredforrising.

Forhamburgerpatties,fish sticks,cheese sandwiches,etc.,afull complementof racks and pans is usually

satisfactory.

HELPFULSUGGESTIONS

Herearesomesuggestionsthatwillassistingettingthebestpossibleperformancefromaconvection oven:

•

Pre-heat the oven thoroughly before use.

•

Whenre-thermalizingfrozenproducts,pre-heattheovento50°Fhigherthantheplannedcooking temperature.After

loading,reduce the temperaturesetting to the appropriatecooking temperature.

•

Space theracks and pans as evenly as possible to allow aircirculation.

•

Centertheloadontherackstoallowforproperaircirculationaroundthesides.Donotcovertheracks completely with

pans.

•

Donotuseadeeppanforshallowcakesorcookies,etc.Aircirculationacrossthesurfaceofthe product is essential.

15

!WARNING

THE USEOFALUMINUMFOIL CAN CAUSE HEATDISTRIBUTIONPROBLEMSINOVENS.

EXTREMECAREMUST BEUSEDWHENPLACINGALUMINUMFOILINTHEOVEN TOENSURE THATIT

DOESNOTBLOCKOR CHANGETHE AIRFLOW. THEUSE OFALUMINUMFOILMAY VOID THE

PRODUCTWARRANTY IF ITS USEISASCERTAINEDTOBEAPROBLEM.

HOLDING FOOD BEFORE SERVING

AnyfooditempreparedinsteamtablepanscanbehelduntilbeingservedbysettingtheHoldthermostat to 160°F.

Examples includestuffed porkchops,oysters Rockefeller, and any vegetable entree.

COOKING PROBLEMSAND SOLUTIONS

If…

then…

Cakes are dark on the sides andnot done in the

t

lower oven temperature.

Cake edges are too brown… reduce numberof pans or loweroven temperature.

Cakes have a light outer color… raise temperature.

Cakes settle slightly in the center…

bake longer or raise oven temperature slightly.

Do not open doors except to load or unload

product

Cakes ripple… do not overload pans or use batter that is too thin.

Cakes are too coarse… lower oven temperature.

Pies have uneven color… reduce numberof pies per rack or eliminate useof

bake pans

Brown sugar topping or meringue blows off…

after oven is preheated, turn off oven and put

product in oven until topping sets, then turn oven

back on

Rolls have uneven color… reduce numberor size of pans.

Meats are browned and not done in center… lower oven temperature and roast longer.

Meats are well done and not browned… raise temperature. Limit amount of moisture.

Meats develop hard crust… reduce temperature or place pan of water in oven.

Excessive meatshrinkage occurs… lower oven temperature.

GUIDE TO TIMES AND TEMPERATURES

Asa guide,setoventemperatures25°F to75°Flowerthan called forin recipesfornon-convection ovens, (i.e.,

range ordeck ovens).

Timeandtemperaturewillvarydependinguponload,mix,size,portion,initialtemperatureoffood,and

otherfactors.Usethefollowingchartasastarting pointtodevelopyourown cookingtechniques.Rack loading and

position may affect results. Experimentation may be necessary to suitindividual requirements.

Cooking Time Temperature Number of Racks

Meat and Fish

Top Round, 18-20 lbs. (medium) 5 hours 275°F 1

Prime Ribs (rare) 4 hours 225°F 1

Burger Patties, 4 oz. 10 min. 350°F 5

16

Fish Cakes 10-12 min. 375°F 5

Turkey, 10-12 lbs. 3 hr. 20 min. 225°F 1

Cooking Time Temperature Number of Racks

Baked Goods

Bread, 2 lb. loaf 35 min. 375°F 3

Biscuits 5-10 min. 400°F 5

Cornbread 18 min. 400°F 5

French Bread 10 min. 375°F 5

Sheet Cake 18-20 min. 300°F 5

Cream Puffs 20 min. 375°F 5

Brown & ServeRolls 6 min. 400°F 5

Ginger Bread 18 min. 300°F 5

Yeast Rolls,sheet pan 16-18 min. 325°F 5

Pineapple Upside Down Cake 25-30 min. 325°F 5

Apple Turnovers 15-18 min. 350°F 5

Fruit Cobbler 22-25 min. 375°F 5

Brownies 15 min. 350°F 5

Danish Pastry 12 min. 325°F 5

Pie Shells 12 min. 350°F 5

Fresh Fruit Pies 25-30 min. 350°F 5

Pumpkin Pies 25-30 min. 275°F 5

Fresh Apple Pies 35 min. 375°F 5

Frozen Berry Pies 40 min. 375°F 5

Frozen Fruit Pies 45 min. 375°F 5

Potatoes

Baked Potatoes,10 oz. 50-55 min. 450°F 5

Baked Potatoes,6-8 oz. 40-45 min. 450°F 5

Scalloped Potatoes 35 min. 325°F 5

Miscellaneous

Macaroni and Cheese 30 min. 350°F 5

Stuffed Peppers 18 min. 350°F 5

Toasted Cheese Sandwiches 8 min. 375°F 5

17

CLEANING

Equipmentissturdilyconstructedofthebestmaterialsandisdesignedtoprovidedurable

servicewhentreatedwithordinarycare.Toexpectthebestperformance, yourequipmentmustbe maintainedin good

conditionand cleaneddaily.Naturally,theperiodsforthis careand cleaningdepend on the amount and degree

ofusage.

Following daily and periodic maintenance procedures will enhance long life for your equipment. Climatic

conditions(such as saltair) mayrequiremorethorough and frequent cleaning orthelife of theequipment could be

adversely affected.

Theoveninteriorisfinishedwithaporcelainenamelcoating.“Spillovers”shouldbecleanedfromthe

interiorbottomsurfaceassoonaspossibletopreventcarbonizing andaburnt-oncondition.Greaseorany

residueshould be cleaned from interior surfaces assoon as it accumulates.

! WARNING

FOR YOUR SAFETY, DISCONNECT THE POWER SUPPLY TO THE APPLIANCE BEFORE CLEANING.

WHENCLEANINGTHEBLOWERWHEEL,BESURETOHAVETHEPOWERSWITCHINTHE “OFF” POSITION.

DAILY CLEANING

1. Turn the power switch to OFF and allowthe oven to cool.

2. Removethe oven-interiorracksandrackslideframes.(Therackslideframesarereadilyremovableby

merelyraisingtodisengagethemfromtheirsockets.) Washtheracksandrackslidesinasinkwith mild detergent and

warm water. Dry them thoroughly with a clean cloth.

3. Looktoseeif anyforeign matterhasaccumulatedonthe wire grate in front of the fan blower wheel on the wheel

itself(whichwillreduce aircirculation).Ifnecessary,removethe rearpanelof theoven,whichis securedbybolts

near eachcorner.Useastiffbrushtoremoveaccumulationsfromtheblowerblades,thenwash withsoap and water.

4. Washtheinteriorsurfaceswithmild detergentandwarmwater.Rinse withcleanwater,anddry thoroughly with a

cleancloth. For stubborn accumulations, a commercial ovencleaner may be used.

5. Clean thecontrol panel with warm water and mild soap. Never usecleaning solvents with a hydrocarbon

base.

6. Wipetheotherexteriorsurfaceswitha cleandamp cloth.Iftheexteriorsurfacesrequiremore thorough cleaning,

see“Cleaning Stainless SteelSurfaces” onthe next page.

7. Return the rackslides and racks to theirappropriate locations insidethe oven.

8. LEAVETHE DOOR OPENATNIGHTAFTER CLEANING.Thisallowsthe oventodrythoroughlyafter cleaning

andalso prolongsthe life of thedoor gasket.

MONTHLYCLEANING

Cleanaroundrearofmotor(wheretheventscreenislocated),louveredpanels,andprimaryairholesin the rear of

the oven wheregrease or lint may have accumulated.

SEMI-ANNUAL CLEANING

Atleasttwicea yearhaveyourAuthorized ServiceAgency oranotherqualified service technician clean and

adjust the unit for maximum performance.

At least twicea year the oven’s venting system shouldbe examinedand cleaned.

CLEANING STAINLESS STEEL SURFACES

To remove normal dirt, grease and product residue from stainless steel that operates at LOW temperature,

18

useordinarysoapandwater(withorwithoutdetergent)appliedwithaspongeorcloth.Drythoroughlywith a clean

cloth.

Toremovegreaseandfoodsplatter,orcondensed vapors,thathaveBAKEDontheequipment,apply

cleansertoadampclothorspongeandrub cleanseronthemetalinthedirectionofthepolishinglineson the metal.

Rubbingcleanser, asgently as possible, in the direction of the polished lineswill not mar the finish of the

stainless steel. NEVER RUB WITH A CIRCULAR MOTION. Soil and burnt deposits which do

notrespondtotheaboveprocedurecanusuallyberemovedbyrubbingthesurface withSCOTCH-BRITE

scouringpadsorSTAINLESSscouringpads.DONOTUSEORDINARYSTEELWOOL,asanyparticles

leftonthesurfacewillrust andfurtherspoiltheappearanceofthefinish.NEVERUSEAWIREBRUSH, STEEL

SCOURING PADS (EXCEPT STAINLESS), SCRAPER, FILE OR OTHER STEEL TOOLS.

Surfaceswhich aremarredcollectdirtmore rapidlyand becomemore difficultto clean. Marring also increases

thepossibility of corrosive attack. Refinishing may then be required.

Toremoveheat tint – Darkenedareas sometimes appearonstainless steel surfaceswherethearea has

beensubjectedtoexcessiveheat.Thesedarkenedareasarecausedbythickeningoftheprotective

surfaceofthestainless steelandarenotharmful.Heattintcannormallyberemovedbytheforegoing,but

tintwhichdoesnotrespondtothisprocedurecallsforavigorousscouringinthedirectionofthepolish

lines,usingSCOTCH-BRITE scouring padsoraSTAINLESS scouring padin combination withapowered

cleanser.Heattintaction maybelessenedbynotapplying,or byreducingheattoequipmentduring slack periods.

19

ADJUSTMENTS

!WARNING

ADJUSTMENTSANDSERVICEWORKMAY BEPERFORMED ONLYBYA QUALIFIED TECHNICIAN

WHO IS EXPERIENCED IN, AND KNOWLEDGEABLE WITH, THE OPERATION OF

COMMERCIALCOOKINGEQUIPMENT.HOWEVER,TOASSURE YOUR CONFIDENCE, CONTACT

YOUR AUTHORIZED SERVICE AGENCY FOR RELIABLE SERVICE, DEPENDABLE ADVICE

OROTHER ASSISTANCE, AND FOR GENUINE FACTORY PARTS.

NOTICE

Warrantywillbevoidandthemanufacturerisrelievedofallliabilityifserviceworkisperformedby other than

aqualified technician, or if other than genuine replacement parts are installed.

LUBRICATION

Motor lubrication information can be found on permanent label located on motor. Casters are providedwith

a Zerk fittingfor proper lubricationwhen required.

ADJUSTING GAS PRESSURE REGULATOR

Thepressureregulatorisfactorysetat3.5"W.C.fornaturalgasand11"W.C.forpropanegas.Tocheck the

manifoldpressure:

1. Turn all thermostats andburner valvesto “OFF” position.

2. Turn main gas valve to entire unit off.

3. Remove valve panels and locate 1/8" plug in manifold.

4. Remove plugand install afitting appropriate to connect a manometer.

5. Turn on maingas to unit and light pilots.

6. Turn all burners and ovens to full “ON” position and read manometer.

7. Ifmanometerdoesnotread3.5"W.C.fornaturalgas,or11"W.C.forpropanegas,adjustregulator(if gas pressure is

O.K. go to Step 10).

8. Removecapfrom top of regulator.

9. Withascrewdriverrotateregulatoradjustmentscrewclockwisetoincrease,orcounterclockwiseto decrease,

pressure until manometer showscorrect reading.

10.Repeat steps 1 and .

11.Remove manometer fitting and replace plug in manifold.

12.Repeat step.

13.Replace valve anels.

20

ADJUSTING DOOR SWITCH

Thedoorswitchdetectswhenthe oven doors areopen.Asadjustedatthefactory,when thedoorsare

openedmorethan2to4inches,theburnersandfanshouldshut off(unlessthefanisswitchedto “COOL” mode). To

adjust the door switch, do thefollowing:

1. Remove lower front panel that covers the doorchain mechanism.

2. Close both doors.

3. Checkthatthedoor switch cam is operating the door switch.

!CAUTION

DoNOTadjustthedoorswitchsothattheplungerarmiscompletelydepressedandishittingthe switch body.

Thiscould distort the arm and cause the switch to operate poorly.

TEMPERATURE CONTROLLER

Temperaturecontrolleris set at the factory and should only be changed or adjust by a qualified service

technical.

TROUBLESHOOTING

! WARNING

ADJUSTMENTSANDSERVICEWORKMAY BEPERFORMED ONLYBYA QUALIFIED TECHNICIAN WHO

IS EXPERIENCED IN, AND KNOWLEDGEABLE WITH, THE OPERATION OF

COMMERCIALCOOKINGEQUIPMENT.HOWEVER,TOASSURE YOUR CONFIDENCE, CONTACT YOUR

AUTHORIZED SERVICE AGENCY FOR RELIABLE SERVICE, DEPENDABLE ADVICE OROTHER

ASSISTANCE, AND FOR GENUINE FACTORY PARTS.

NOTICE

Warrantywillbevoidandthemanufacturerisrelievedofallliabilityifserviceworkisperformedby other than

aqualified technician, or if other than genuine replacement parts are installed.

Incaseofproblemsinoperationatinitialinstallation,checktypeofgasandmanifoldpressureand compare

withinformation listed on theserial plate. The serial plateis located inside the lower front panel.

PERFORMANCE STANDARD

Thetypicaltimefortheoventoheatfrom75°Fto350°Fis5to6minutesforovensusingnaturalgas,and 7 to 8 minutes

for ovens using propane.

Theburnersshouldcome onwhentheactualoventemperaturedropsto10°Fbelowthetemperature setting.

Table of contents

Popular Convection Oven manuals by other brands

UNITED

UNITED CO7120 quick start guide

Blodgett

Blodgett ZEPHAIRE-G Operating and troubleshooting guide

Fisher & Paykel

Fisher & Paykel MINIMAL OB24SM16PLB1 user guide

KRAFTE

KRAFTE NC-60305 instruction manual

Black & Decker

Black & Decker CTO7100B Use and care book

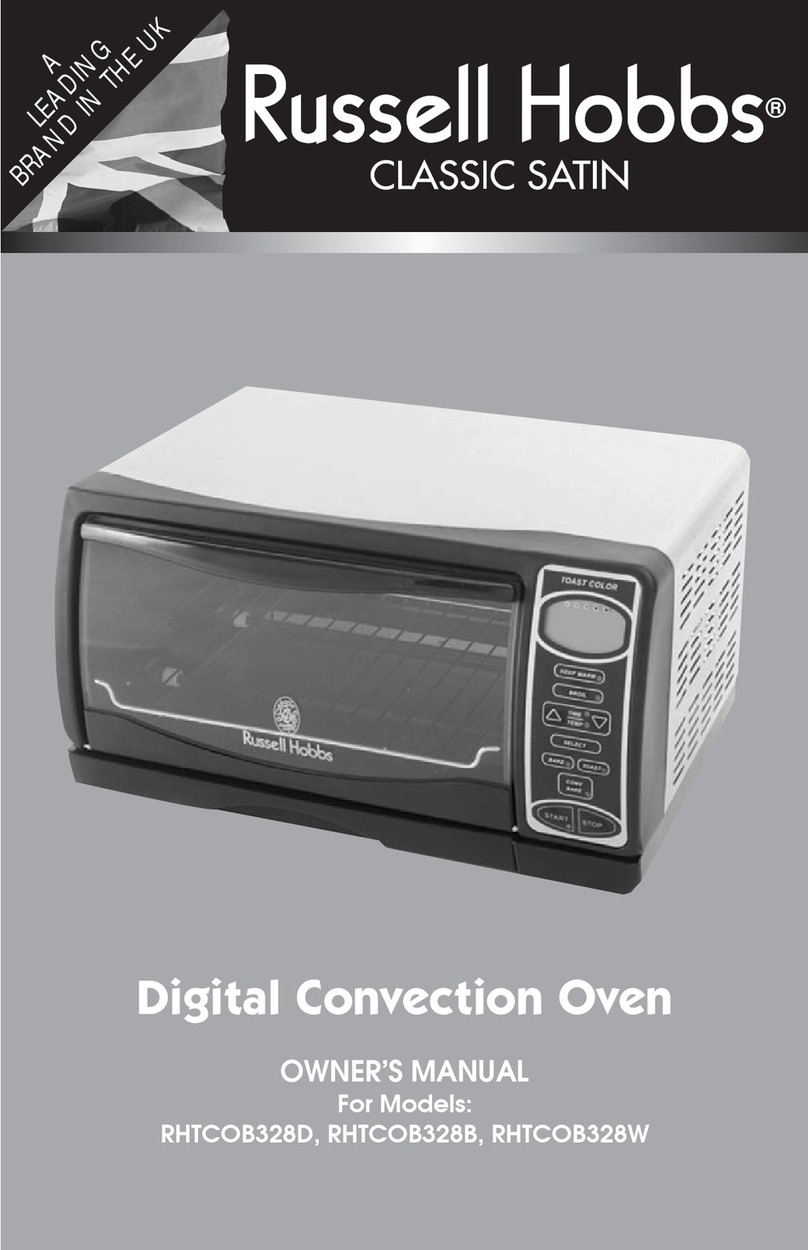

Russell Hobbs

Russell Hobbs RHTCOB328B owner's manual