CPG 351COHD3A User manual

www.cookingperformancegroup.com 1

User Manual

Electric Countertop

Convection Ovens

REVISED 04/2023

351COHD3A, 351COHT3A, 351COHD4M, 351COHT4M, 351COFT4M, 351COFD4M

. www.cookingperformancegroup.com

2

User Manual

Congratulations on your purchase of Cooking Performance Group commercial cooking equipment!

At Cooking Performance Group, we take pride in the design, innovation, and quality of our products.

To ensure optimal performance, we have outlined the following instructions and guidelines in this manual

carefully for your review. Cooking Performance Group declines any responsibility in the event users do

not follow the instructions or guidelines stated here.

Contents

Product Overview.........................................2

Safety Precautions ........................................3

Installation ...............................................5

General Operating Procedures .............................7

Manual Cooking ..........................................8

Cleaning Care .......................................... 11

Warning & Alarms ...................................... 12

Troubleshooting ........................................ 13

Stacking Instructions .................................... 14

5008969

Conforms to UL STD. 197

Conforms to CSA C22.2

Conforms to NSF/ANSI STD. 4

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY, OR DEATH. READ THE INSTALLATION, OPERATING,

AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEOFRE INSTALLING OR SERVICING THIS

EQUIPMENT.

5008969

www.cookingperformancegroup.com 3

User Manual

CAUTION:

Equipment is designed to provide safe and productive processing, cooking, and warming of food products as

long as the equipment is used in accordance with the instructions in this manual and is properly maintained.

Failure to comply with the following operation instructions could lead to potential hazards and/or unsafe

practice and could result in injury and damage to product and property. Owners of this equipment bear the

responsibility to make certain that this equipment is used properly and safely, and to strictly follow all the

instructions contained in this manual and the applicable requirements of applicable local, state, or federal law.

Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this or any other

equipment. Improper installation, adjustment, alteration, service, or maintenance could lead to property

damage, injury, or death. Read the installation, operating, and maintenance instructions thoroughly before

installing or servicing CPG equipment. This manual must be retained for future reference. A factory authorized

agent must handle all maintenance and repair.

Owners should not permit anyone to touch this equipment unless they are over 18 years old, are adequately

trained and supervised, and have read and understood this manual. Repairs and conversions are to be made

solely by an authorized servicer. Owners should also ensure that no customers, visitors, or other unauthorized

personnel come in contact with this equipment. Please remember that the vender cannot anticipate every

circumstance or environment in which its equipment will be operated. It is the responsibility of the owner and

the operator to remain alert to any hazards posed by the function of this equipment. If you are ever uncertain

about a particular task or the proper method of operating this equipment, ask your supervisor.

This manual contains a number of precautions to follow to help promote safe use of this equipment.

Throughout the manual you will see additional warnings to help alert you to potential hazards.

Safety Precautions

Warnings affecting your personal safety are indicated by:

OR

WARNING

Warnings affecting your possible damage to the equipment and property are indicated by:

CAUTION

Please remember that this manual or the warning labels do not replace the need to be alert, to properly train

and supervise operators, and to use common sense when using this equipment.

. www.cookingperformancegroup.com

4

User Manual

NOTE: The serial plate is located on the back of the unit.

The serial plate provides important technical information that is essential in case of a request for

intervention for a maintenance or a repair of the equipment. Do not remove, damage, or modify it.

Serial Plate

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If equipment is received damaged, either apparent

or concealed, a claim must be made with the delivering carrier.

Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be signed

by the carrier representative (ie: driver). If this is not done, the carrier may refuse the claim. The carrier

can supply the necessary forms.

For concealed damage or loss if not apparent until after equipment is uncrated, a request for inspection

must be made to the carrier as soon as possible. Please conrm the time frame with the carrier as this

can vary. The carrier should arrange an inspection. Be certain to hold all contents and packaging material.

Installation and service should be performed by an authorized service agency. All CPG ranges should

also be installed under an approved hood. CPG Limited Warranty Does NOT cover equipment that fails

to follow these guidelines or has been altered, modied, or repaired by anyone other than an authorized

service agency. If you have questions concerning the installation, operation, maintenance, or service of

your equipment, visit CPG’s website at www CookingPerformanceGroup.com.

Make sure that the oor where you plan to locate the commercial range can support its weight along with

any accessories. Adequate clearance should be provided for proper operation and servicing. Level the

commercial range once you’ve uncrated it in your facility using the adjustable feet.

Proper ventilation is crucial to safe and optimum performance. Ensure that the oven is installed

underneath a ventilation hood according to all applicable local and national codes. Keep adequate

clearance for air openings into the combustion chamber.

www.cookingperformancegroup.com 5

User Manual

Installation

• These units are designed for commercial use and not for household use.

• Installation must conform to all applicable codes. Improper installation will void the

manufacturer’s warranty.

• Do not obstruct or reduce the air ow rate of the natural ventilation openings on the

oven or the vent located at the rear of the oven.

• Discontinue use if power cord or electrical wires are frayed or worn.

• This product conforms to UL-197 standards and is required to be installed under a

ventilation hood in accordance with all applicable codes.

Combustiable Clearance Requirements: 20" Sides, 28" Back

Non-Combustiable Clearance Requirements: 2" Sides, 2" Back

Installation Instructions

The place of installation must be indoors, well ventilated, and the ambient temperature must be at least

40 degrees Fahrenheit. The unit is required to have at least 2" of clearance on the sides and back from

non-combustible surfaces, or at least 20" and 28" of clearance on the sides and back, respectfully, from

combustible surfaces. Ensure that all four legs are installed correctly before the operation of this oven.

The unit is required to be installed on a non-combustible surface with 4" legs, or a combustible oor with

a stand. For full-size models, level unit by adjusting the (4) feet which have an adjustment of 1¾" for

accurate leveling.

This product conforms to UL-197 standards and requires it to be

under an exhaust hood. A vertical distance of not less than 48"

shall be provided between the top of the appliance and lters

or any other combustible material. Exhaust installation must

conform to applicable local codes.

Do not obstruct or reduce the air ow rate of the natural

ventilation openings on the oven or the vent located at the rear

of the oven. To ensure proper ventilation and clearance, the

provided spacer is required to be installed.

The spacer must be installed by screwing (2) self-threading

screws on the back of the unit immediately below the cooling

fan.

NOTE: For Oven Stacking Instructions, please see page 14.

WARNING: DO NOT OBSTRUCT THE VENT OR COOLING FAN LOCATED AT THE REAR OF

THE OVEN.

. www.cookingperformancegroup.com

6

User Manual

Electric Connection

• The power supply must comply with the rated voltage, frequency, and plug specic to the data plate.

• All installation types require a dedicated circuit protected by a fuse or circuit breaker. Do not use an

extension cord with plug and cord models.

• All electrical connections must be carried out by a qualied and authorized technician.

• This device should be safely and adequately grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical code, ANSI/NFPA 70, Latest Edition to protect

the user from electrical shock. It requires a grounded system and a dedicated circuit, protected by a

fuse or circuit breaker of proper size and rating. Canadian installation must comply with the Canadian

Electrical Code, CSA C22.2, as applicable.

• To prevent any damages to property and/or people, unplug the appliance from the electrical

connection prior to carrying out any type of maintenance, installation, and/or cleaning operation.

Water Connection

ATTENTION: Using water that does not meet the requirements listed below may cause severe

damage to the heating elements, to the fans, and to the cooking chamber. Additionally, it may cause

considerable performance degradation.

A ¾” water connection is required for installation. The inlet water pressure has a requirement (min/max)

of 150-200 kPa or 22-29 psi. To reduce calcium/mineral build-up, a water ltration system

is recommended.

• Maximum acceptable water hardness = 60-90 ppm

• Minimum water PH = 7.5 PH

• Chlorides = less than 30 ppm

• Silica = less than 12 ppm (mg / L)

• Free chlorine = less than 0.1 ppm (mg / L)

• Total dissolved solids (tds) = 50-125 ppm

Before First Use

Remove all packing material and protective plastic from the surfaces of the unit. Ovens should be

cleaned before operation (see below). Make sure to clean the bafe, wire shelving, and support racks

before installing. The 240V full size and half size models feature (7) rack positions and the 120V half size

models feature (5) rack position. Make sure the tray support and shelves are correctly positioned inside

the cooking chamber and securely installed. Only load the rated number of trays per oven size. Do not

overload the chamber or it will affect cooking performance and results.

It is normal for an unpleasant smell to be noticeable the rst time the oven is used. This is caused by

burning off residue from the manufacturing process. Set the oven to 450 degrees Fahrenheit until the

smell dissipates, for about 30 minutes.

www.cookingperformancegroup.com 7

User Manual

General Operating Procedures

NOTE: This convection oven is not a replacement for a Combi Oven.

NOTE: For all models, the bi-directional fans reverse direction of rotation every two minutes.

NOTE: All models feature a micro safety switch which shuts off the oven when the door is open.

Exterior surfaces on unit will get hot during use and at the end of the cooking process. Use caution

when touching these areas. Do not touch any surfaces labeled CAUTION HOT while the product is

in use.

For timed use, the timer does control the baking operation of the oven. Start by rotating the

‘Temperature’ control clockwise to the desired temperature. Then rotate the 120-minute ‘Timer’ control

clockwise to set the desired time. The ‘Power On’ indicator light should now illuminate. When the timer

reaches ‘0’ minutes, the buzzer will sound and the heating will stop. To ensure the oven is ‘Off’ at the end

of service, rotate the ‘Temperature’ and ‘Timer’ controls to the ‘0’ position.

For continuous use and without interruption, rst rotate the ‘Timer’ control counterclockwise to the

‘ ’ symbol to turn the timer ‘Off‘. Then rotate the ‘Temperature‘ control clockwise to the desired

temperature. The ‘Power On‘ indicator light should now illuminate. The oven will continue to run until you

turn it ‘Off‘ by rotating the ‘Temperature‘ and ‘Timer‘ controls to the ‘0‘ position.

Steam can be added to the chamber at any point by pressing and holding the steam button.

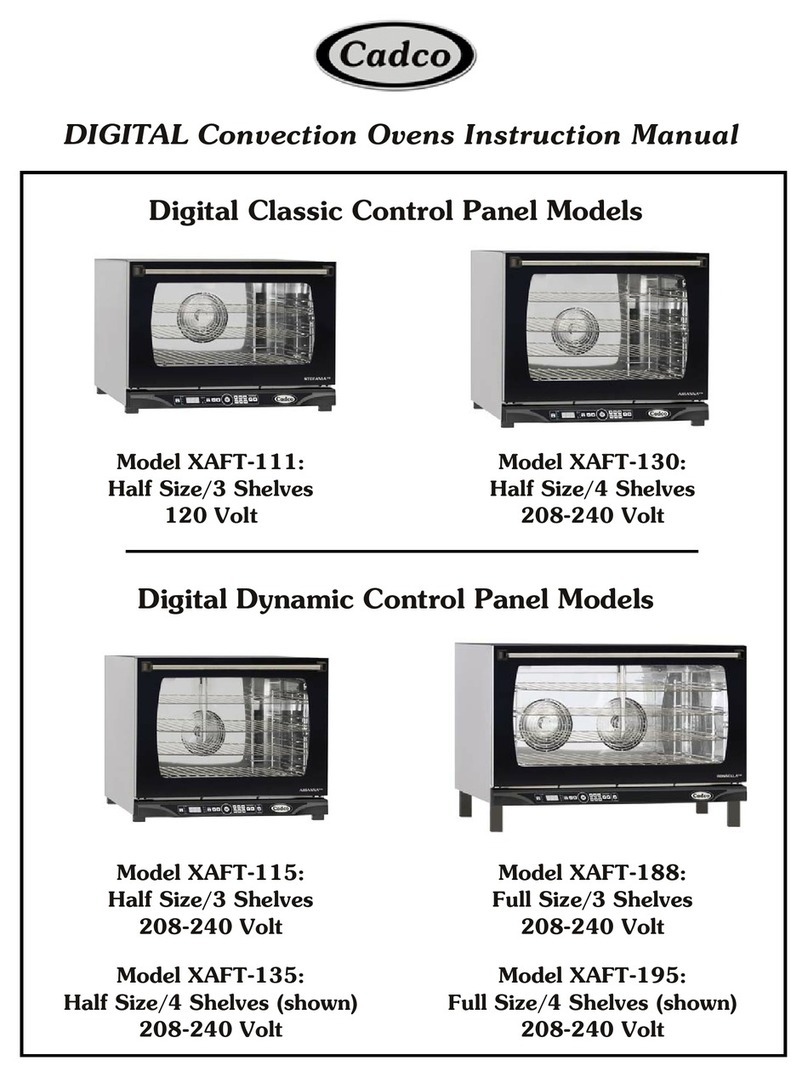

THERMOSTATIC MODELS

DIGITAL MODELS

ON/OFF:

Press once to turn 'On' the

oven. Press and hold to

turn 'Off' the oven.

START/STOP:

Use this button to start or stop a manual

or programmable cooking cycle.

TEMPERATURE:

When the oven is cycling ‘On’ and heating, the LED will light

up. The actual temperature of the chamber will appear on the

display. If you want to display the set temperature, please

press this button.

SELECTING BUTTONS:

Plus or minus selecting buttons.

TIMER:

The adjustable time range is

999 minutes. Timer will be

displayed as a countdown

timer.

STEAM/HUMIDITY:

This button allows you to add steam during manual or programmable

cooking modes. The adjustable humidity range is: OFF – 20% - 40% -

60% - 80% - 100%. The LED will illuminate when steam is being added

to the chamber. Note: This unit is not a substitute for a Combi oven.

PHASE

These LEDs inform

you about which

phase is operating at

the time.

COOKING

CYCLE

For programmable

mode, this button

allows you to cycle

through the (3)

different cooking

phases when

creating a program.

. www.cookingperformancegroup.com

8

User Manual

Manual Cooking

For manual timed use, the timer does control the baking operation of the oven. Turn ‘On’ the oven by

pressing the ‘On/Off’ button. Manual cooking mode is the default and ‘MAN’ will appear on the display.

To set the temperature press the ‘ ’ button and then select your desired set temperature using the ‘+’ or

‘-‘ buttons. Pressing the ‘ ’ button again, or waiting 5-seconds, will conrm set temperature. Similarly, to

set the 999-minute timer press the ‘ ’ button and then set timer using the ‘+’ or ‘-‘ buttons. Then press

the ‘ ’ button again to conrm set timer. To start the cooking cycle, press the ‘Start/Stop’ button to start

the cooking cycle. The unit will now pre-heat (see below). When the timer reaches 0 minutes, ‘END’ will

ash on the display and the unit will ‘beep’ for 40-seconds at the end of the cooking cycle and the oven

will stop heating.

For manual continuous use and without interruption, turn ‘On’ the oven by pressing the ‘On/Off’ button.

Manual cooking mode is the default and ‘MAN’ will appear on the display. Press the ‘ ’ button and use

the ‘-‘ button to go below the minimum timer value and select “- -“. To set the temperature press the

‘ ’ button and then select your desired set temperature using the ‘+’ or ‘-‘ buttons. Pressing the ‘ ’ button

again, or waiting 5-seconds, will conrm set temperature. The timer will be displayed as a countdown.

The oven will continue to run until you turn it ‘Off‘ by pressing and holding ‘On/Off’ button or ‘Start/Stop’

at any point to stop cooking program.

Note: At any point during the cooking process, you can change the temperature and time. Manual steam

can be added to the chamber at any point by pressing and holding the steam button.

Note: The actual temperature of the chamber will appear on the display. If you want to display the set

temperature, please press the ‘ ’ button.

NOTE: When using the steam functions, if the Oven Temperature is BELOW 212°F (100°C ), water

may pool in oven as temperature will be too low to create steam.

Pre-Heating

All digital models feature an automatic pre-heat setting, where ‘PRE’ will appear on the display and

the oven will heat the chamber to a temperature of 20% higher than the set one. This is necessary to

compensate for heat loss that occurs when opening the door to load product. The oven will ‘beep’ and

ash when product is ready to be loaded. The unit will not stop ‘beeping’ or ‘ashing’ until you open the

door and load product. Once you close the door, your cooking cycle will begin automatically.

In programmable mode, you can create and set 99 programs with 3 stage cooking. In each stage, you can

set temperature, time, and humidity. Please refer to the supporting videos on the program page for added

visualization of recipe and program creation.

NOTE: For further instruction on programmable cooking, please view the online product page for a

'How-to' video.

www.cookingperformancegroup.com 9

User Manual

To create a new cooking program:

Press the button

COOKBOOK and

“P01” will appear

on the display

Then act on the

PLUS and MINUS

buttons

Press the button

COOKBOOK

to confirm

Now the oven is positioned on the rst phase (LED lit on N.1) and you can set the time, temperature, and

steam in the various stages as follows:

Press the button

TEMPERATURE

Then act on the

PLUS and MINUS

buttons

Press the button

TEMPERATURE to

confirm

Set the temperature value:

Press the button

TIME

Then act on the

PLUS and MINUS

buttons

Press the button

TIME to confirm

. www.cookingperformancegroup.com

10

User Manual

Cleaning Care

• DO NOT use abrasive or ammable cleaning uids.

• DO NOT hose down, immerse, or pressure wash any part of the oven.

• NEVER use a scrubber pad, steel wool or abrasive material, or cleaners containing chlorine, iodine,

ammonia, or bromine chemicals, as these will deteriorate the stainless steel and shorten the life of the unit.

• NEVER use steel wool pads to clean oven, as small bers may be left behind in cooking chamber.

• ALWAYS turn off the oven and allow time to cool prior to cleaning and/or maintenance.

Set the timer value:

Press the button

HUMIDITY

Then act on the

PLUS and MINUS

buttons

Press the button

HUMIDITY to

confirm or wait 5

seconds and the new

value will be stored

Set the steam/humidity value:

Select the cooking phase button to go to the second phase

(in the case of the cooking process with several phases) and

you will see the second LED on

C

To save a program with 3 steps, after setting them, press and hold the COOKBOOK button until the LED

ashes. If you only have 1 or 2 steps, enter ‘0’ for the time in the unused steps and save.

- When the program is stored, you can press START/STOP to activate the cooking process.

If needed, you can skip a phase in your recipe during the cooking cycle by pressing and holding the

‘Cooking Cycle’ button to continue to the next step. Note: The timer will reset to the next step's set time.

Return to manual cooking mode by turning the oven ‘Off’ and ‘On’.

www.cookingperformancegroup.com 11

User Manual

Internal Cleaning

Allow the oven to cool completely. To use the ‘cool down’ program for digital models, see below:

• Press ‘ ’ and using the MINUS button, go below the minimum temperature value and select “C00".

• Press ‘Start’ and the temperature will start to ash in the display, and then you will see the temperature

start to decrease.

• To expediate the cooling process, open the door of the oven.

Once the unit is cool, remove stainless steel bafe, wire shelves, and support racks. These parts are

dishwasher safe. Clean any buildup of grease from the oven interior using a mild detergent, a hot water

solution, and a soft bristle brush. We recommend Noble Chemical Sunbright for daily cleaning, and Noble

Chemical Knockout, or Blast, for deep clean or carbon build up. Dry the oven thoroughly with a soft, dry cloth.

Then reinstall steel bafe, wire shelves, and support racks.

External Cleaning

Clean any buildup of grease on the exterior of the oven using a mild detergent, a hot water solution, and

a soft bristle brush. We recommend Noble Chemical Sunbright for daily cleaning. We recommend using

Noble Chemical Excel to polish external stainless steel surfaces, as well as Noble Chemical Kleer View to

clean the door glass.

NOTE:

everything back in its original location.

Door Cleaning

Strictly adhere to the following procedure in order to avoid electrocution or

injury: To clean the inner glass of the door, start a rapid cooling cycle of the oven

chamber (for digital models) or wait until the ambient temperature is reached (for

mechanical models).

• This procedure should be performed with the door ajar (inclined about 30°).

• Remove the two external screws “A” as shown in the gure, unscrewing

counterclockwise.

• Pull out the sheet metal prole “B” carefully.

• Remove the inner glass very gently.

• Place the glass on a suitable surface, such as a soft cloth.

• Clean the surface using a soft cloth just moistened with a neutral product, specic for glass,

following the instructions of the manufacturer of the detergent

. www.cookingperformancegroup.com

12

User Manual

Warning and Alarms

All alarms are indicated by a buzzer. The buzzer can be silenced by pressing a key.

• ERR = CHAMBER PROBE ALARM

This is triggered if the chamber probe fails. Everything is deactivated except for the light. The cycle in

progress is interrupted. Once the alarm is silenced, press the ON/OFF button for 1 second to reset the

alarm (the control panel is set to OFF).

• "ALL" = MOTOR ALARM

This is triggered if the motor overheats. Everything is deactivated except for the light. The cycle in

progress is interrupted. Once the alarm is silenced, press the ON/OFF button for 1 second to reset the

alarm (the control panel is set to OFF).

• "H-t" = CONTROL BOARD TEMPERATURE ALARM

This is triggered if the control board overheats. The cycle in progress is interrupted. Once the alarm is

silenced, press the ON/OFF button for 1 second to reset the alarm (the control panel is set to OFF).

Operator and Factory Parameters Table

Parameter Description Default

Value Limits Unit Level

P01 Temperature unit: 0=C, 1=F 0 0-1 Flag Operator

P03 Min. cooking temperature setpoint 30 30-200 C/F Factory

P06 Preheating superheating

(% value of the set above the cooking setpoint) 20 0-100 % Operator

P15 Light Mode: 0= timed on button pressure, 1= always

ON during cooking, 2= Always ON 2 0-2 Flag Operator

P16 Light activation time 45 0-120 Seconds Operator

P17 Enable Preheating 1 0-1 Flag Operator

P40 Default Setpoint for Cooling 50 30-70 C/F Operator

P52 Time of inactivity to switch to standy mode

(function disabled with 0) 10 0-60 Minutes Factory

Access the parameter menu with the oven set to "OFF", indicated by the top display of the

appliance. Press down the ‘ ’ key until the upper display shows "PAS" and the lower display shows "0",

ashing. Press the ‘+’ key to set the value shown on the lower display to "30". Conrm by pressing

START/STOP. The upper display will show the name of the parameter, whereas the lower one will show

the value of that parameter. Scroll through the list of editable parameters using the ‘+’ and ‘-’ buttons.

Once the parameter to be edited has been found, press the START/STOP button: the value shown on the

lower display will start to ash, and then press ‘+’ and ‘-’ buttons to change the value. Once the desired

value has been set, according to the table below, press START/STOP to conrm the change. When the

desired parameters have been changed, press the ‘ ’ key to set the appliance back to "OFF".

www.cookingperformancegroup.com 13

User Manual

Troubleshooting

PROBLEM CAUSE RESOLUTION

In START mode

the oven does not

turn on

Door open Make sure the door is closed

The micro-switch does not signal that

the door is closed

Contact a specialist technician for repairs (Cus-

tomer Service)

Oven light off

Loose lamp Insert the lamp correctly into the lamp holder

Blown lamp Replace the lamp

(refer to ordinary maintenance)

The oven does not

cook uniformly

The fans no longer

execute inversion

Contact a specialist technician for repairs (Cus-

tomer Service)

One of the fans has stopped

One of the heating elements

is broken.

The oven is

completely off

No power supply Restore the power supply

Incorrect connection to the mains power

supply Check connection to the main power supply

Safety thermostat triggered Contact a specialist technician for repairs

(Customer Service)

The water is input

into the steam

pipes

Water inlet closed Open Water inlet

Incorrect connection to the main water

supply Check connection to the mains water supply

Water inlet lters obstructed by dirt. Clean the lters

Water leaks out

from the washer

when the doors is

closed

Dirty washer Clean the washer with a damp cloth

Damaged washer Contact a specialist technician for repairs

(Customer Service)

Door closing mechanism problem

The fan stops

during

operation

Motor safety thermostat

triggered

Switch the oven off and wait for the motor's

thermal protection to restore automatically. If the

problem persists, contact a specialist technician

for repairs (Customer Service)

Motor condenser breakage Contact a specialist technician for repairs (Cus-

tomer Service)

NOTICE: The above examples are provided for your reference. Provided a failure occurs, stop using the oven and

consult an authorized service agency. All maintenance should be done after the power supply is shut off.

. www.cookingperformancegroup.com

14

User Manual

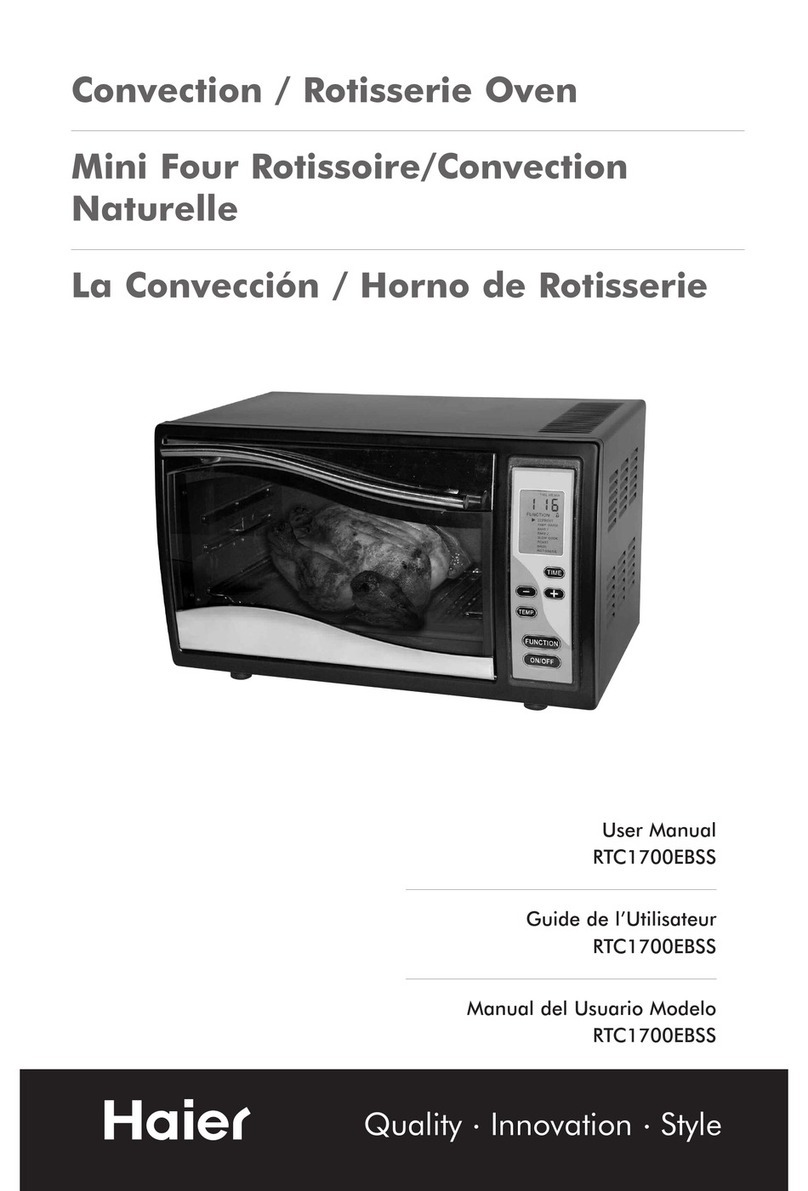

Stacking Kit Instructions

1. Screw the front prole with provided screws.

2. Screw the rear plates with provided screws.

65

65

65

3. Place the oven on top.

Fig. 1 Fig. 2

1

2

2

4. Place the bracket on the back of the oven

on top.

Fig. 3

5. Connect the pipe and use the bracket provided.

Fig. 4

This manual suits for next models

5

Table of contents

Other CPG Convection Oven manuals

Popular Convection Oven manuals by other brands

Cosori

Cosori CO125-TO Quick reference guide

GE

GE Profile J2S968 SERIES owner's manual

Kleenmaid

Kleenmaid SMC4530 Instructions for use and warranty details

STARFRIT

STARFRIT 024615 Instructions for use and care

Vulcan-Hart

Vulcan-Hart SG4D Specifications

Lang

Lang 2F11-CLS-S Installation, operation, maintenance, & troubleshooting