Blue Hawk 3275.1 User manual

Questions, problems, missing parts? Before returning to your retailer, call our customer

service department at 1-877-888-8225, 8 a.m. - 6 p.m., EST, Monday - Thursday, 8 a.m. - 5 p.m.,

EST, Friday.

1

ATTACH YOUR RECEIPT HERE

Serial Number ____________ Purchase Date ____________

Lowes.com

ITEM #0067272

12 AMP CIRCULAR SAW

MODEL #3275.1

Español p. 42

Français p. 21

2

Lowes.com

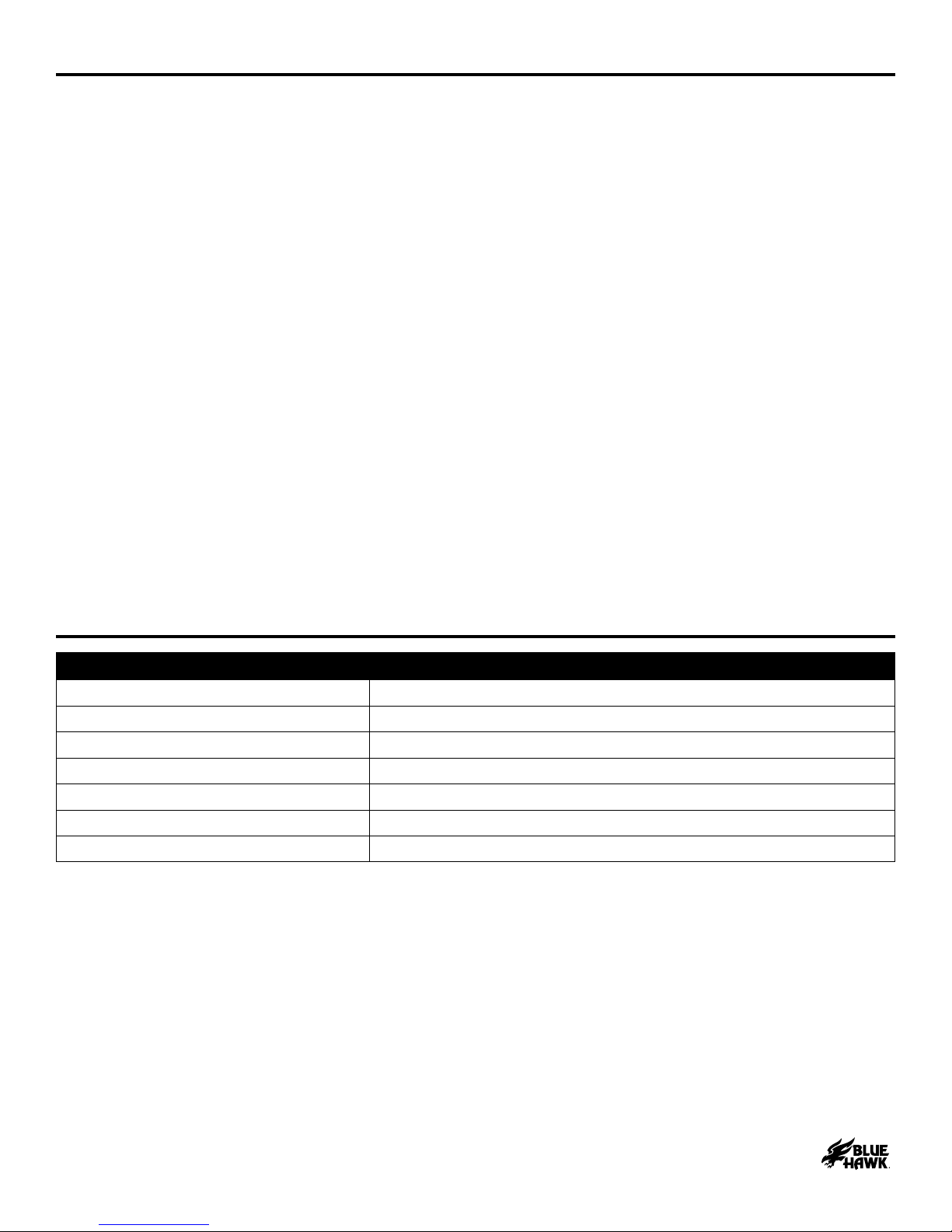

PRODUCT SPECIFICATIONS

COMPONENT SPECIFICATION

Rated Voltage 120 V ~ 60 Hz

Rated Power Input 12 A

No-Load Speed, n05,500 RPM

Saw Blade Size 7-1/4 in.

Cutting Angle 0° – 45°

Depth of Cut at 90° 2-7/16 in.

Depth of Cut at 45° 1-3/4 in.

TABLE OF CONTENTS

Product Specications ...........................................................2

Safety Information ..............................................................3

Package Contents ..............................................................9

Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Glossary of Terms for Woodworking ...............................................11

Assembly Instructions ..........................................................12

Operating Instructions ..........................................................13

Care and Maintenance..........................................................19

Troubleshooting ...............................................................20

Warranty.....................................................................20

3

Lowes.com

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble or operate this product.

If you have any questions regarding the product, please call the customer service department at

1-877-888-8225, 8 a.m. - 6 p.m., EST, Monday - Thursday, 8 a.m. - 5 p.m., EST, Friday.

CAUTION: Read and understand all instructions. Failure to follow all instructions listed below

may result in electric shock, re and/or serious personal injury.

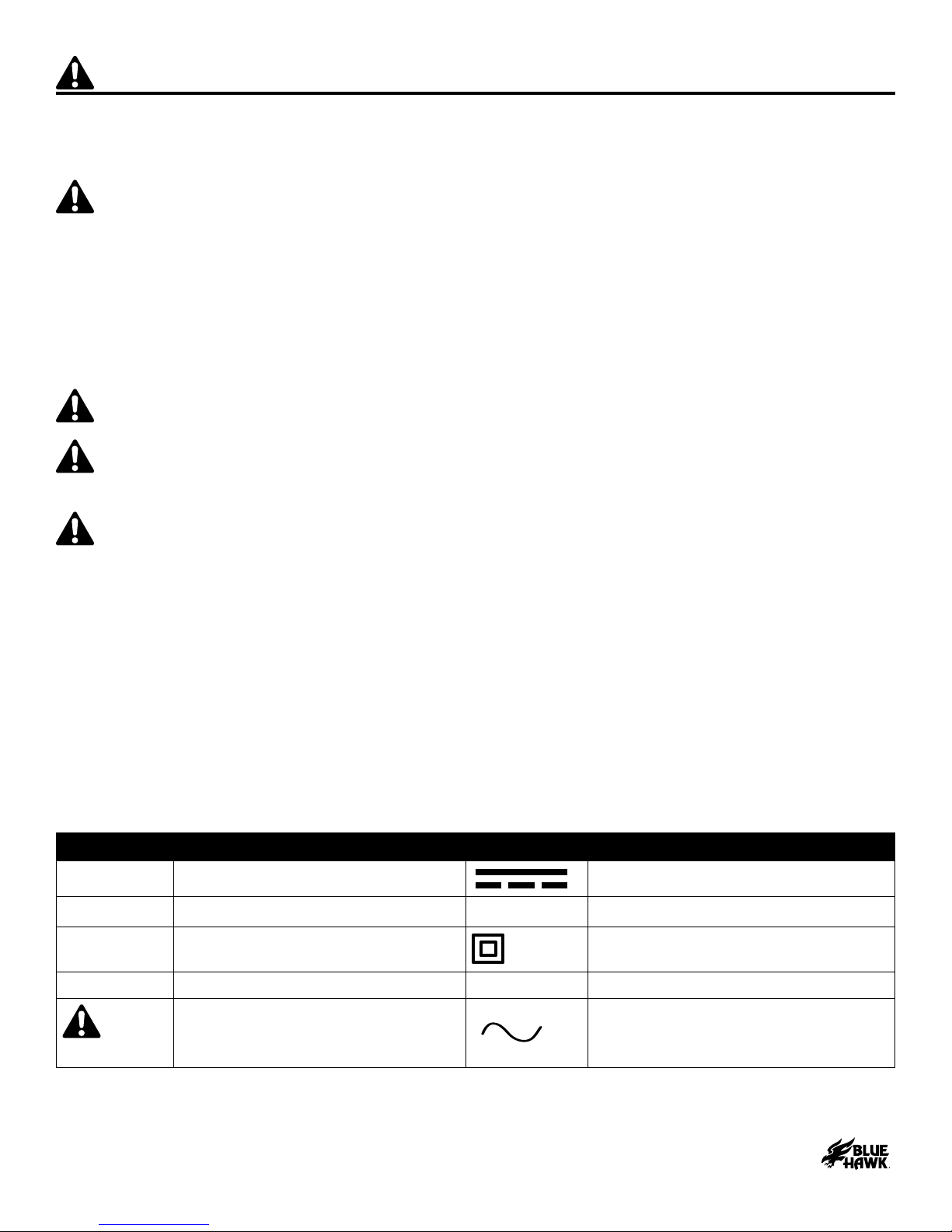

SAFETY SYMBOLS

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols

and the explanations that accompany them deserve your careful attention and understanding. The

safety warnings DO NOT, by themselves, eliminate any danger. They are not substitutes for proper

accident-prevention measures.

DANGER: Someone will be seriously injured or killed if the safety information is not followed.

WARNING: Someone could be seriously injured or killed if the safety information is not

followed.

CAUTION: Someone may be injured if the safety information is not followed.

DAMAGE PREVENTION AND INFORMATION MESSAGES

These inform the user of important information and/or instructions that could lead to equipment or

other property damage if they are not followed. Each message is preceded by the word “NOTE,” as in

the example below:

Note: Equipment and/or property damage may result if these instructions are not followed.

KNOW THE TOOL

To operate this tool, carefully read this manual and all labels afxed to the circular saw before using it.

Keep this manual available for future reference.

Some of the following symbols may be used on this tool. Please study them and their meaning.

Proper interpretation of these symbols will allow you to operate the tool better and more safely.

SYMBOL DEFINITION SYMBOL DEFINITION

V Volts Direct Current

A Amps n0No-load Speed

Hz Hertz Class II Construction

W Watts /min. Revolutions or Strokes per Minute

A danger, warning, or caution.

It means ‘Attention! Your safety is

involved.’

Alternating Current

Important: This tool should only be serviced by a qualied service technician.

4

Lowes.com

SAFETY INFORMATION

WORK AREA SAFETY

• Keep your work area clean and well-lit. Cluttered benches and dark areas invite accidents.

• Do not operate power tools in explosive environments, such as in the presence of ammable

liquids, gases, or dust. Power tools create sparks that may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating a power tool. Distractions can cause

you to lose control.

• Make the workshop childproof with padlocks, master switches, or by removing starter keys.

• Use the right tool. Do not force a tool or attachment to do a job for which it was not designed.

ELECTRICAL SAFETY

• Double-insulated tools are equipped with a polarized plug (one blade is wider than the other). This

plug will t in a polarized outlet only one way. If the plug does not t in the outlet, reverse the plug.

If it still does not t, contact a qualied electrician to install a polarized outlet. Do not change the

plug in any way. Double insulation eliminates the need for a three-wire, grounded power cord and

grounded power-supply system.

• Avoid contact with grounded surfaces, such as pipes, radiators, ranges, and refrigerators. There is

an increased risk of electric shock if your body is grounded while using the tool.

• Do not expose power tools to rain or wet conditions. A wet power tool will increase the risk of

electric shock.

• Do not abuse the cord. Never use the cord to carry the tool or to pull the plug from an outlet. Keep

the cord away from heat, oil, sharp edges, or moving parts.

• Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

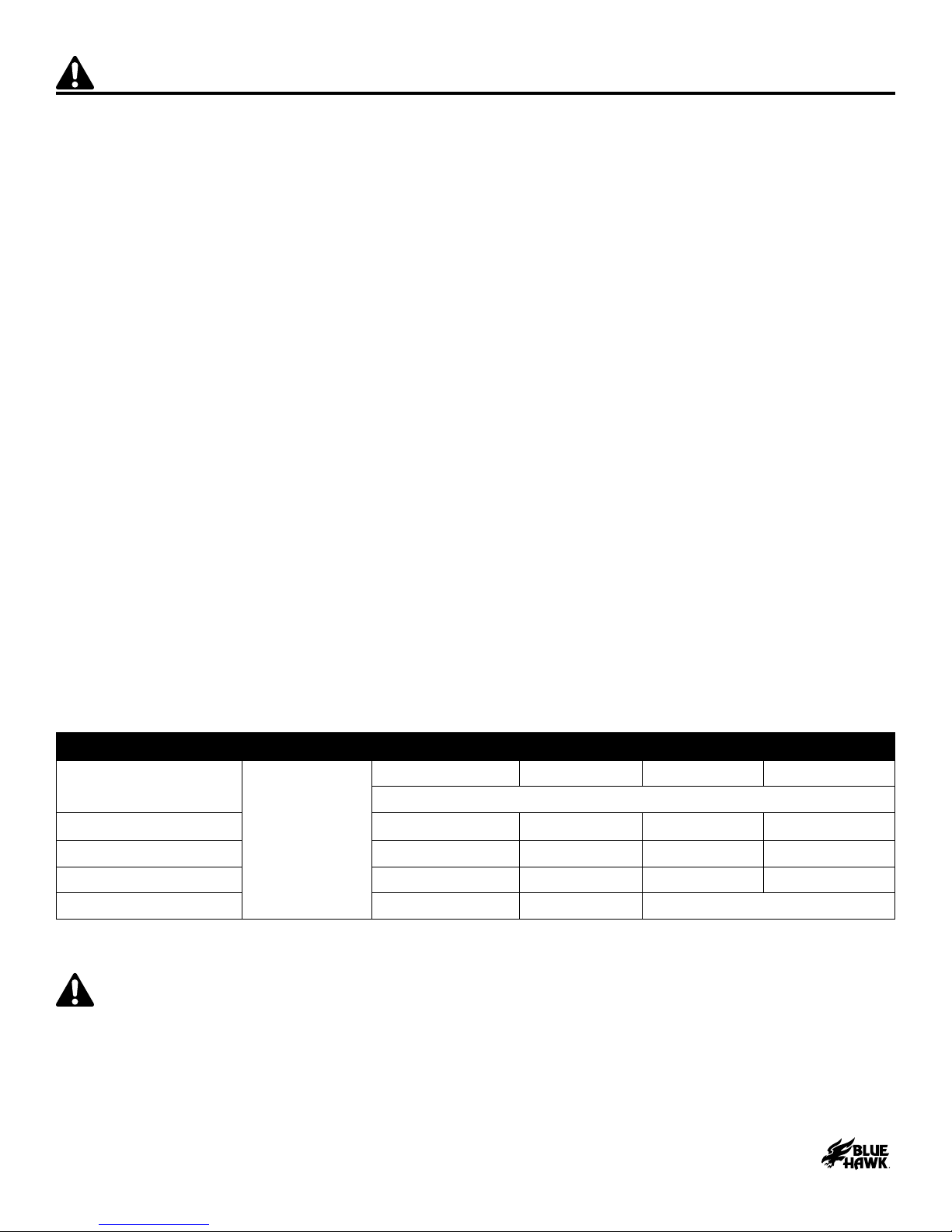

• When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W”. These

cords are rated for outdoor use and reduce the risk of electric shock. The following table shows

the correct size to use, depending on the cord length and nameplate amperage rating of the tool.

When in doubt, use the next heavier gauge. Always use UL and CSA listed extension cords:

RECOMMENDED SIZES OF EXTENSION CORDS

AMPERE RATING VOLTS TOTAL LENGTH OF CORD IN FEET

120 V~ 25 ft. 50 ft. 100 ft. 150 ft.

A. W. G.

0~6 18 16 16 14

6~10 18 16 14 12

10~12 16 16 14 12

12~16 14 12 not recommended

PERSONAL SAFETY

WARNING: The operation of any power tool can result in foreign objects being thrown into

your eyes, which can result in severe eye damage. Before beginning power-tool operation, always

wear safety goggles or safety glasses with side shields and a full-face shield, when needed. It is

recommended to use a wide vision safety mask over eyeglasses or standard safety glasses with

shields. Always use eye protection, which is marked to comply with ANSI Z87.1.

5

Lowes.com

SAFETY INFORMATION

• Stay alert, watch what you are doing, and use common sense when operating a power tool. Do

not use the tool while tired or under the inuence of drugs, alcohol, or medication. A moment of

inattention while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

• Avoid accidental startups. Ensure that the switch is off before plugging the tool in. Carrying tools

with your nger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and balance

enables better control of the tool in unexpected situations.

• Use safety equipment. A dust mask, non-skid safety shoes, a hard hat, or hearing protection must

be used for appropriate conditions.

• Before connecting the tool to a power source (receptacle, outlet, etc.), ensure that the voltage

supplied is the same as that specied on the nameplate of the tool. A power source with voltage

greater than that specied for the tool can result in serious injury to the user as well as damage to

the tool.

POWER TOOL USE AND CARE

• Use clamps or another practical means to secure and support the workpiece to a stable platform.

Holding the workpiece by hand or against your body is unstable and may lead to loss of control.

• Do not force the tool. Use the correct tool for your application. The correct tool will do the job better

and more safely at the rate for which it is designed.

• Do not use the tool if the switch does not turn it on or off. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments, changing accessories,

or storing the tool. Such preventive safety measures reduce the risk of starting the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the

hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools with sharp

cutting edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any other condition that

may affect the tool’s operation. If damaged, have the tool serviced before using. Many accidents

are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model. Accessories that

may be suitable for one tool may become hazardous when used on another tool.

• Do not alter or misuse the tool. This tool is precision built. Any alteration or modication not

specied is misuse and may result in a dangerous condition.

SERVICE

• Tool service must be performed only by qualied repair personnel. Service or maintenance

performed by unqualied personnel could result in a risk of injury and/or property damage.

• When servicing a tool, use only identical replacement parts. Follow instructions in the maintenance

section of this manual. Use of unauthorized parts or failure to follow maintenance instructions may

create a risk of electric shock or injury.

6

Lowes.com

SAFETY INFORMATION

SPECIFIC SAFETY RULES FOR CIRCULAR SAWS

• Do not use the circular saw near fumes or combustible liquids.

• Never slow the blade down with your hands, or by applying pressure to the side of the blade.

• Never apply force! Move the circular saw forward gently and steadily.

• Use of accessories that are not recommended for use with this tool may create hazardous

conditions.

DANGER: Keep hands away from the cutting area and blade. Keep your second hand on the

auxiliary handle or motor housing. If both hands are holding the saw, they cannot be cut by the blade.

• Keep your body positioned to either side of the saw blade, but not in line with the saw blade.

Kickback could cause the saw to jump backward.

• Do not reach underneath the workpiece. The guard cannot protect you from the blade below the

work surface.

• Check the lower guard for proper closing before each use. Do not operate the saw if the lower

guard does not move freely and close instantly. Never clamp or tie the lower guard into the open

position. If the saw is accidentally dropped, the lower guard may be bent. Raise the lower guard

with the retracting handle and make sure it moves freely and does not touch the blade or any other

part, in all angles and depths of cut.

• Check the operation and condition of the lower guard spring. If the guard and the spring are not

operating properly, they must be serviced before use. The lower guard may operate sluggishly due

to damaged parts, gummy deposits, or a buildup of debris.

• The lower guard should be retracted manually only for special cuts, such as “Pocket Cuts” and

“Compound Cuts.” For these specialized cuts, raise the lower guard with the retracting handle. As

soon as the blade enters the material, the lower guard must be released. For all other sawing, the

lower guard should operate automatically.

• Always observe that the lower guard is covering the blade before placing the saw down on the

bench or oor. An unprotected, coasting blade will cause the saw to walk backward, cutting

whatever is in its path. Be aware of the time it takes for the blade to stop after the switch is

released.

• NEVER hold the piece being cut in your hands or across your body. It is important to support the

work properly to minimize body exposure, blade binding, or loss of control.

• Hold the tool by the insulated gripping surfaces when performing an operation where the cutting

tool may contact hidden wiring or its own cord. Contact with a “live” wire will also make exposed

metal parts of the tool “live” and shock the operator.

• When ripping, always use a rip fence or straight edge guide. This improves the accuracy of the cut

and reduces the chance of blade binding.

• Always use blades with the correct size and shape (diamond vs. round) holes. Blades that do not

match the mounting hardware of the saw will cause a loss of control.

• Never use damaged or incorrect blade washers or bolts. The blade washers and bolts were

specially designed for the saw, for optimum performance and safety of operation.

WARNING: Use of this tool can generate dust-containing chemicals known to the state of

California to cause cancer, birth defects, or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paints.

7

Lowes.com

SAFETY INFORMATION

• Crystalline silica from bricks, cement, and other masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending upon how often you do this type of work. To reduce

your exposure to these chemicals:

• Work in a well-ventilated area.

• Work with approved safety equipment, such as dust masks that are specially designed to lter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other

construction activities. Wear protective clothing and wash exposed areas with soap and water.

• Allowing dust to get into your mouth or eyes or to lie on the skin may promote the absorption of

harmful chemicals.

KICKBACK

Kickback is a sudden reaction to a pinched, bound, or misaligned saw blade, causing an uncontrolled

saw to lift up and out of the workpiece toward the operator.

When the blade is pinched or bound tightly by the kerf closing down, the blade stalls and the motor

reaction drives the unit rapidly back toward the operator.

If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade can dig

into the top surface of the wood, causing the blade to climb out of the kerf and jump back toward the

operator.

Kickback is the result of tool misuse and/or incorrect operating procedures or conditions and can be

avoided by taking the proper precautions as given below:

DANGER: Release the switch immediately if the blade binds or the saw stalls. Kickback could

cause loss of control of the saw. Loss of control can lead to serious personal injury.

To guard against kickback, avoid dangerous practices such as the following:

• Setting the blade depth incorrectly.

• Sawing into knots or nails in the workpiece.

• Twisting the blade while making a cut.

• Making a cut with a dull, gummed up, or improperly set blade.

• Supporting the workpiece incorrectly.

• Forcing a cut.

• Cutting warped or wet lumber.

• Operating the tool incorrectly or misusing the tool.

To reduce the chance of kickback, follow these safety practices:

• When the blade is binding, or when interrupting a cut for any reason, release the trigger and

hold the saw motionless in the material until the blade comes to a complete stop. Never attempt

to remove the saw from the workpiece or pull the saw backward while the blade is in motion or

kickback may occur. Investigate and take corrective actions to eliminate the cause of blade binding.

• When restarting a saw in the workpiece, center the saw blade in the kerf and check that saw teeth

are not engaged into the material. If the saw blade is binding, it may walk up or kickback from the

workpiece as the saw is restarted.

8

Lowes.com

SAFETY INFORMATION

• Blade depth and angle-locking knob levers must be tight and secure before making a cut. If the

blade adjustment shifts while cutting, it may cause blade binding and kickback.

• Use extra caution when making a “Pocket Cut” into existing walls or other blind areas. The

protruding blade may cut objects that can cause kickback.

• Keep the blade at the correct depth setting. The depth setting should not extend more than 1/4 in.

(6.5 mm) below the material that is being cut.

• Inspect the workpiece for knots or nails before cutting.

• Make straight cuts. Always use a straight edge guide when rip cutting. This helps prevent the blade

from twisting.

• Use clean, sharp, and properly set blades.

• Support the workpiece properly before beginning a cut.

• Use steady, even pressure when making a cut.

• Do not cut warped or wet lumber.

• Hold the saw rmly with both hands and maintain a balanced position in order to resist the force if

kickback should occur.

WARNING: When using the saw, always stay alert and exercise control. Do not remove the

saw from the workpiece while the blade is moving.

SAW BLADES

• The best saw blades will not cut efciently if they are not kept clean, sharp, and properly set. Using

a dull blade will place a heavy load on the saw and increase the danger of kickback. Keep extra

blades on hand so sharp blades are always available.

• Gum and resin on blades will slow the saw down. Remove the saw blade from the saw and use

gum and resin remover, hot water, or kerosene to remove these accumulations. DO NOT USE

GASOLINE.

9

Lowes.com

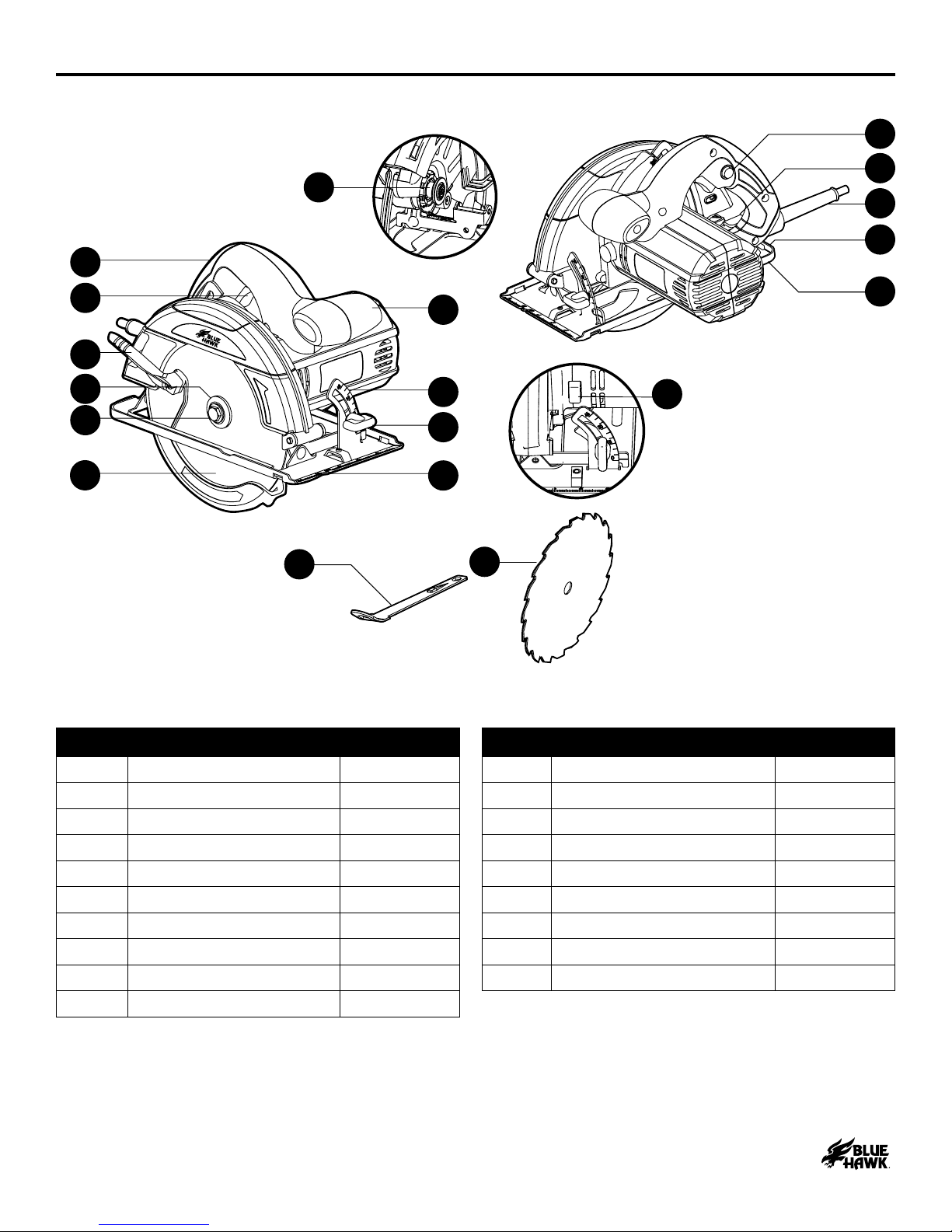

PACKAGE CONTENTS

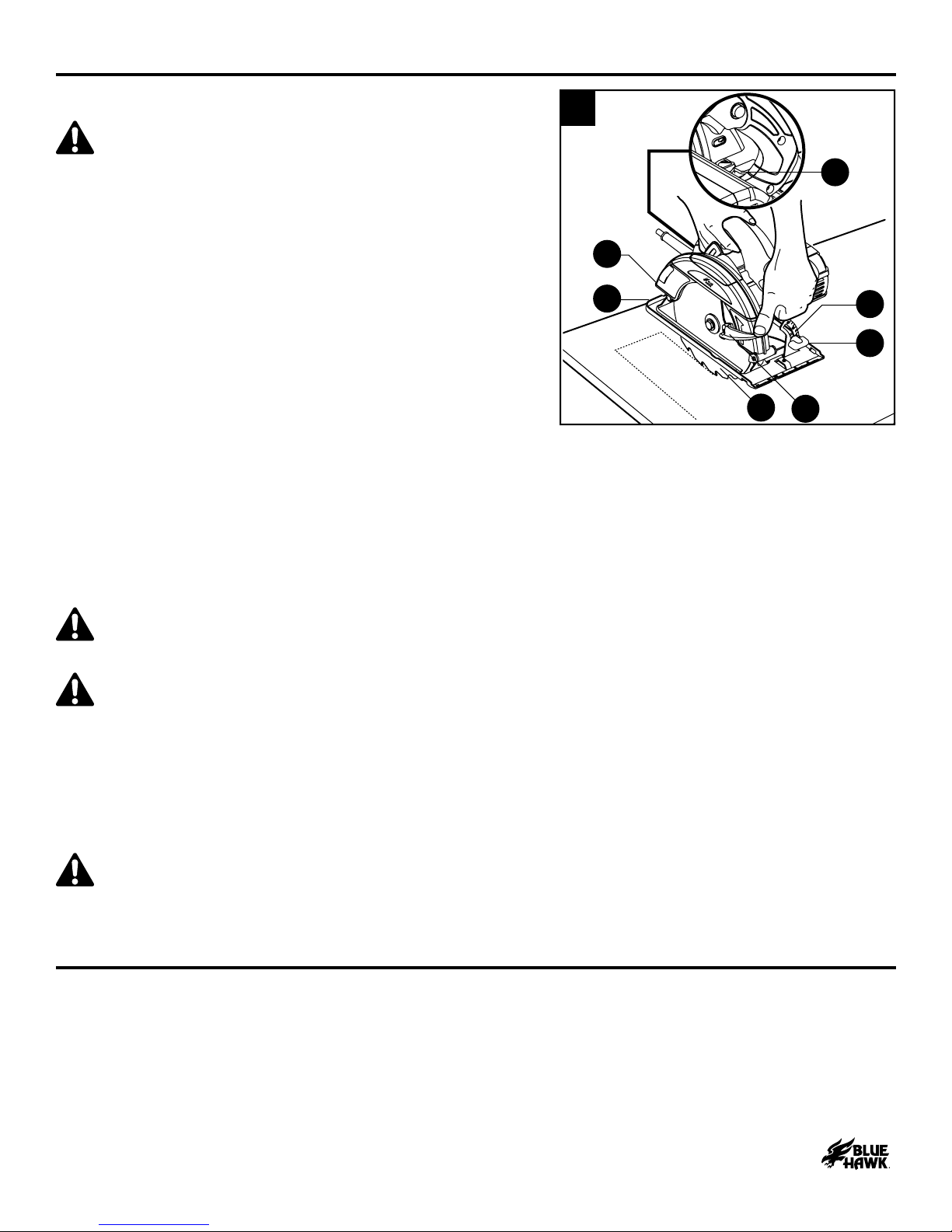

R

B

P

Q

M

G

N

O

K

E

J

L

H

S

I

D

F

A

C

PART DESCRIPTION QUANTITY PART DESCRIPTION QUANTITY

A Trigger Switch 1 K Base Plate 1

B Spindle-lock Button 1 L Outer Flange (D-Washer) 1

C Main Handle 1 M Cord Guard 1

D Front Handle 1 N Lock-off Button 1

E Lower Blade Guard 1 O Blade Wrench Storage 1

F Blade Guard Lever 1 P Blade 1

G Depth-locking Lever 1 Q Wrench 1

H Angle-locking Knob 1 R Spindle 1

I 0° – 45° Bevel Gauge 1 S Kerf Indicator 1

J Hexagon Blade Screw 1

10

Lowes.com

PREPARATION

Before attempting to use any tool, be sure to become familiar with all of the operating features and

safety instructions.

WARNING: DO NOT allow familiarity with the saw to cause carelessness. Remember that one

careless moment is enough to cause severe injury.

APPLICATIONS

This saw can be used for the purpose listed below:

• Cutting all types of wood and wood products.

Note: The use of abrasive cut-off wheels is not recommended with this saw.

11

Lowes.com

GLOSSARY OF TERMS FOR WOODWORKING

TERM DEFINITION

Bevel Cut A cutting operation made with the blade at any angle other than 90° to the

miter table.

Chamfer Cut A cut removing a wedge from a block of wood so that the end (or part of the

end) is angled at other than 90°.

Compound-Miter Cut A cut made using a miter angle and a bevel angle at the same time.

Cross Cut A cutting or shaping operation made against the grain of the workpiece.

Dado Cut A non-through cut that produces a square-sided notch or trough in the

workpiece (requires a special blade).

Freehand Cut Performing a cut without using a fence, miter gauge, xture, work clamp, or

other proper device to keep the workpiece from twisting or moving during the

cut. Freehand cuts are dangerous and should be avoided.

Gum A sticky, sap-based residue from wood products.

Kerf The material removed by the blade in a through cut or the slot produced by

the blade in a non-through or partial cut.

Kickback A hazard that can occur when the blade binds or stalls, throwing the

workpiece back toward the operator.

Leading Edge The end of the workpiece pushed into the tool rst.

Miter Cut A cutting operation made with the blade at any angle other than 90° to the

fence.

Non-Through Cuts Any cutting operation where the blade does not extend completely through

the thickness of the workpiece, like a dado cut.

Resin A sticky, sap-based substance that has hardened.

Revolutions Per

Minute (RPM)

The number of turns completed by a spinning object in one minute.

Ripping or Rip Cut A cutting operation along the length of the workpiece.

Saw-Blade Path The area over, under, behind, or in front of the blade, as it applies to the

workpiece. The area that will be or has been cut by the blade.

Set The distance that the saw blade tooth is bent (or set) outward from the face of

the blade.

Spindle The shaft on which a blade or cutting tool is mounted. Also called the arbor.

Through Sawing Any cutting operation where the blade extends completely through the

thickness of the workpiece.

Workpiece or

Material

The item on which the cutting operation is being done. The surfaces of a

workpiece are commonly referred to as faces, ends, and edges.

12

Lowes.com

ASSEMBLY INSTRUCTIONS

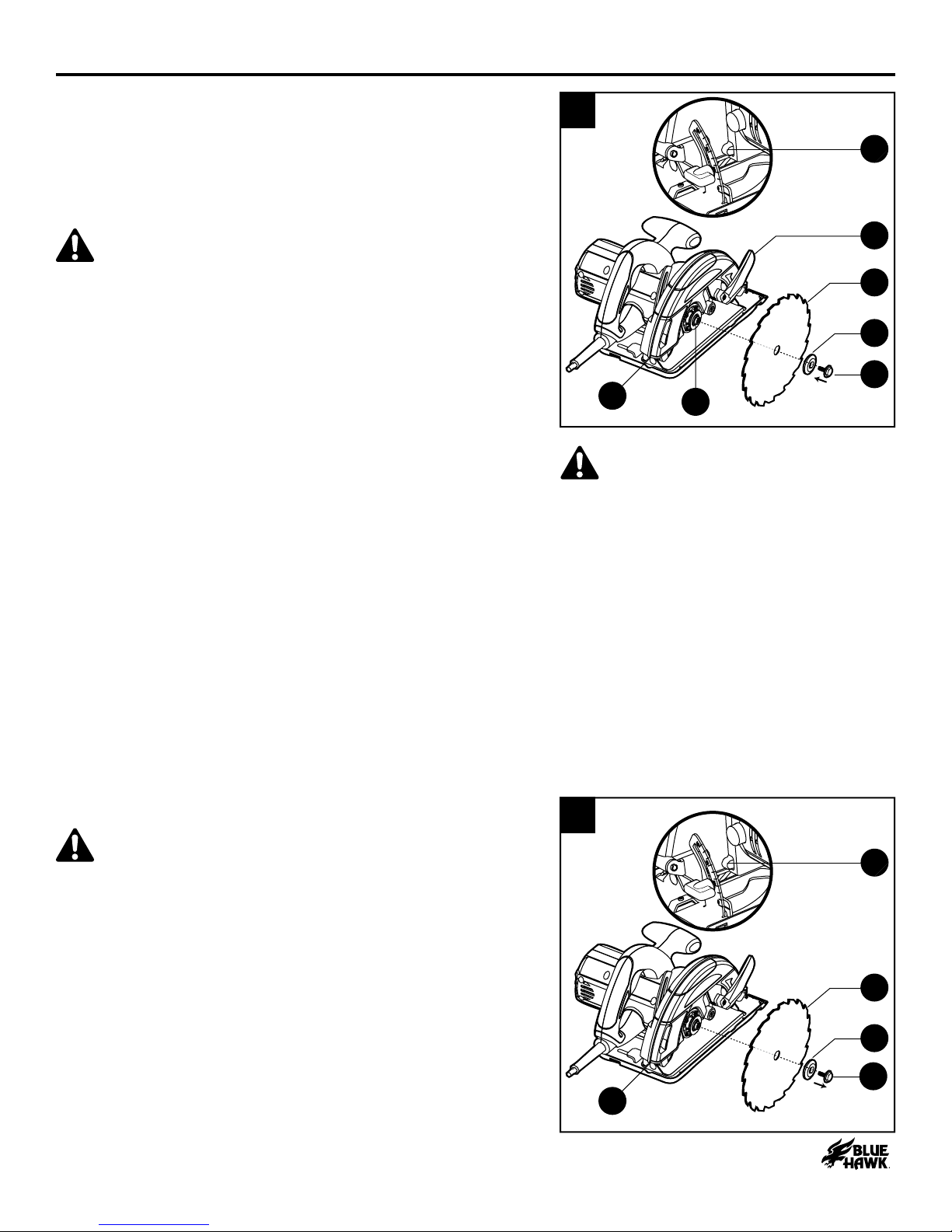

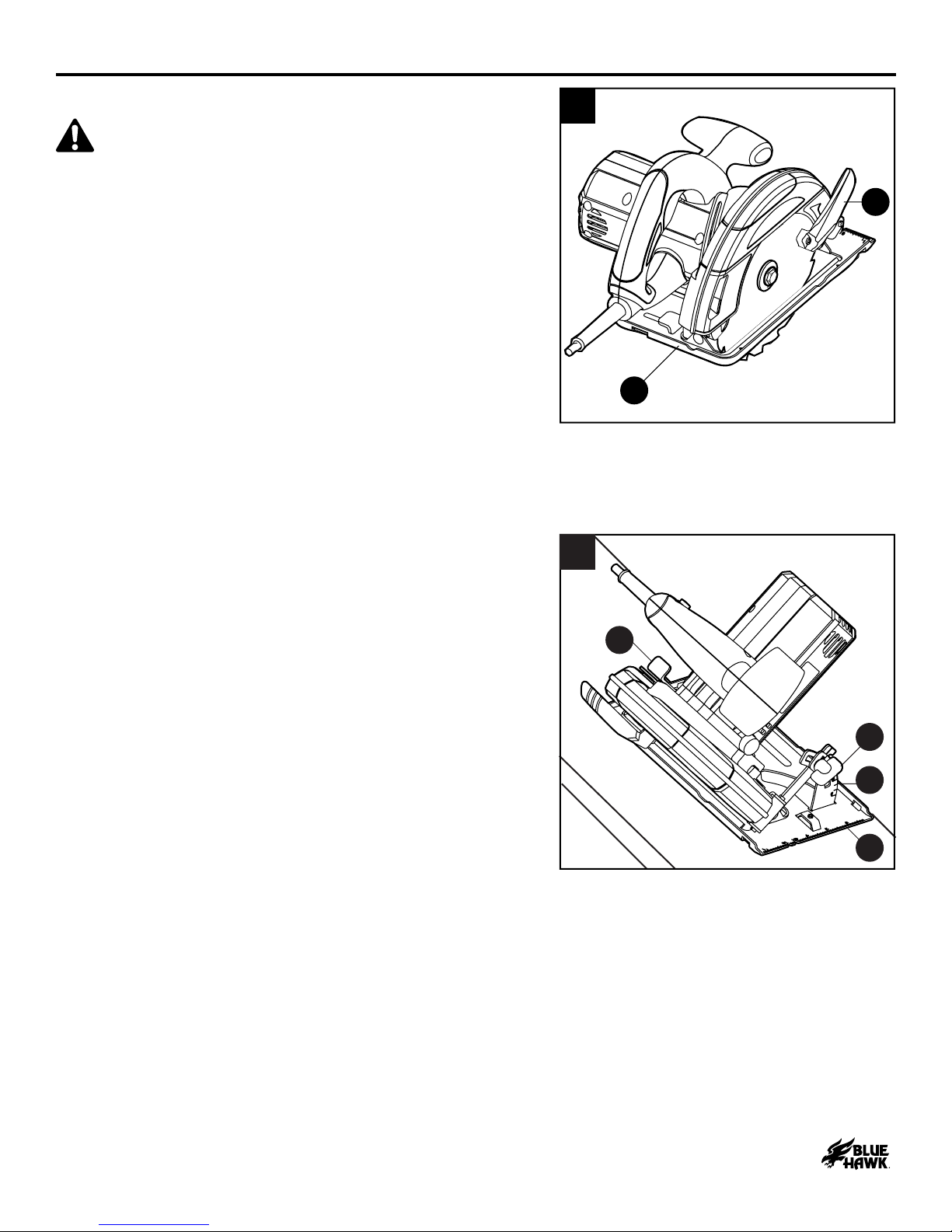

1. Installing a Saw Blade

a. Unplug the saw.

b. Press and hold the spindle-lock button (B)

and remove the blade screw (J) by turning it

counterclockwise with the wrench (Q).

c. Remove the outer ange (D-Washer) (L).

WARNING: If the inner ange bushing has been

removed, replace it before placing the blade on the

spindle. Failure to do so will prevent the blade from

tightening properly, and could result in serious personal

injury.

d. Use the blade guard lever (F) to retract the lower

blade guard (E) into the upper blade guard. Make

sure that the lower guard works properly and

allows the guard to move freely.

e. Verify that the blade teeth and the arrow on the

blade (P) and the arrow on the lower blade guard

(E) are pointing in the same direction.

Note: The blade teeth should point upward at the front of

the saw.

f. Fit the blade (P) inside the lower blade guard (E)

and onto the spindle (R).

g. Replace the outer ange (D-Washer) (L).

h. Press and hold the spindle-lock button (B) and

replace the blade screw (J). Then tighten the

blade screw (J) securely by turning it clockwise

with the wrench (Q).

Note: Never use a blade that is too thick to allow the

outer ange (D-Washer) (L) to engage with the at

section of the spindle.

1

ER

J

L

P

F

B

WARNING: To prevent personal

injury, always disconnect the plug from

the power source before installing or

removing the saw blade.

2. Removing a Saw Blade

WARNING: To prevent personal injury, always

disconnect the plug from the power source before

installing or removing the saw blade.

a. Unplug the saw.

b. Press and hold the spindle-lock button (B)

and remove the blade screw (J) by turning it

counterclockwise with the wrench (Q).

c. Remove the outer ange (D-Washer) (L).

d. Lift the lower blade guard (E) and remove the

blade (P).

2

E

J

L

P

B

13

Lowes.com

OPERATING INSTRUCTIONS

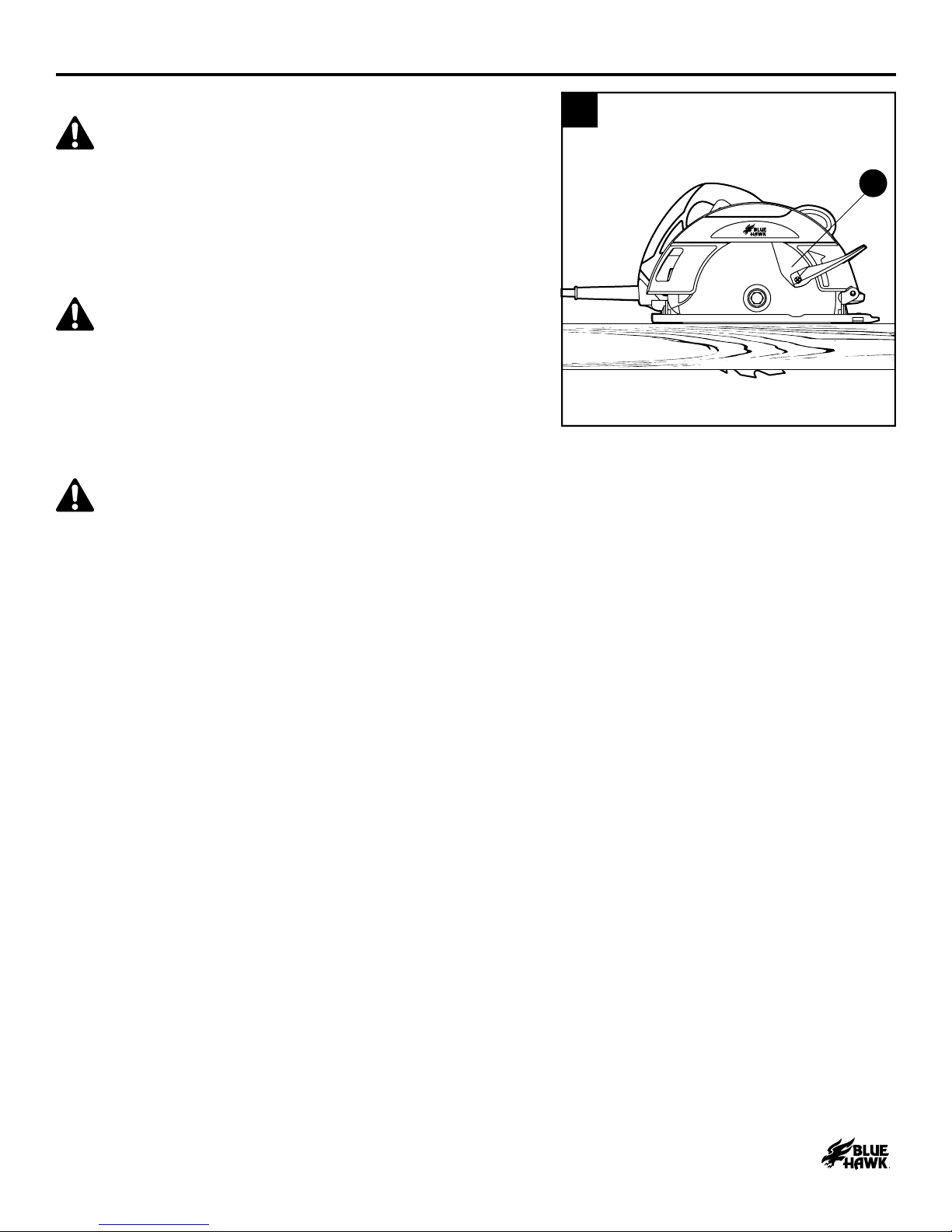

1. Blade Guard System

DANGER: When sawing through a workpiece,

the lower blade guard does not cover the blade on the

underside of the workpiece. Since the blade is exposed

on the underside of the workpiece, ALWAYS keep hands

and ngers away from the cutting area. Serious injury will

result if any part of the body comes into contact with the

moving blade.

WARNING: The lower blade guard on the circular

saw is there for the operator’s protection and safety. Do

not alter it for any reason. If it becomes damaged or if the

blade begins to run slowly or sluggishly, DO NOT operate

the saw until the damaged part has been repaired

or replaced. ALWAYS leave the guard in its correct

operating position when using the saw.

WARNING: To avoid possible serious injury, never

use the saw when the guard is not operating correctly.

Check the guard for correct operation before each use.

The guard is operating correctly when it moves freely

and instantly returns to the closed position. If the saw is

dropped, check the lower blade guard and bumper for

damage at all depth settings before using it.

a. Ensure that the lower blade guard (E) is in the

up position when making a cut. If the lower blade

guard (E) does not snap closed at any time,

unplug the saw from the power supply.

b. Exercise the lower guard (E) by moving it rapidly

back and forth from the full open position to

the closed position several times. This will

usually restore the guard to its normal operating

condition. If this does not correct a slow or

sluggishly closing lower guard (E), do not use the

saw. Take it to an authorized service technician

for repair.

E

1

14

Lowes.com

OPERATING INSTRUCTIONS

2. Starting the Saw

WARNING: The blade should reach full speed

before it comes into contact with the workpiece.

a. Press lock-off button (N) and then press and hold

the trigger switch (A).

b. Always allow the blade (P) to reach full speed,

then guide the saw into the workpiece.

P

N

A

2

3. Stopping the Saw

Release the trigger switch (A) and allow the blade (P)

to come to a complete stop.

P

A

3

15

Lowes.com

OPERATING INSTRUCTIONS

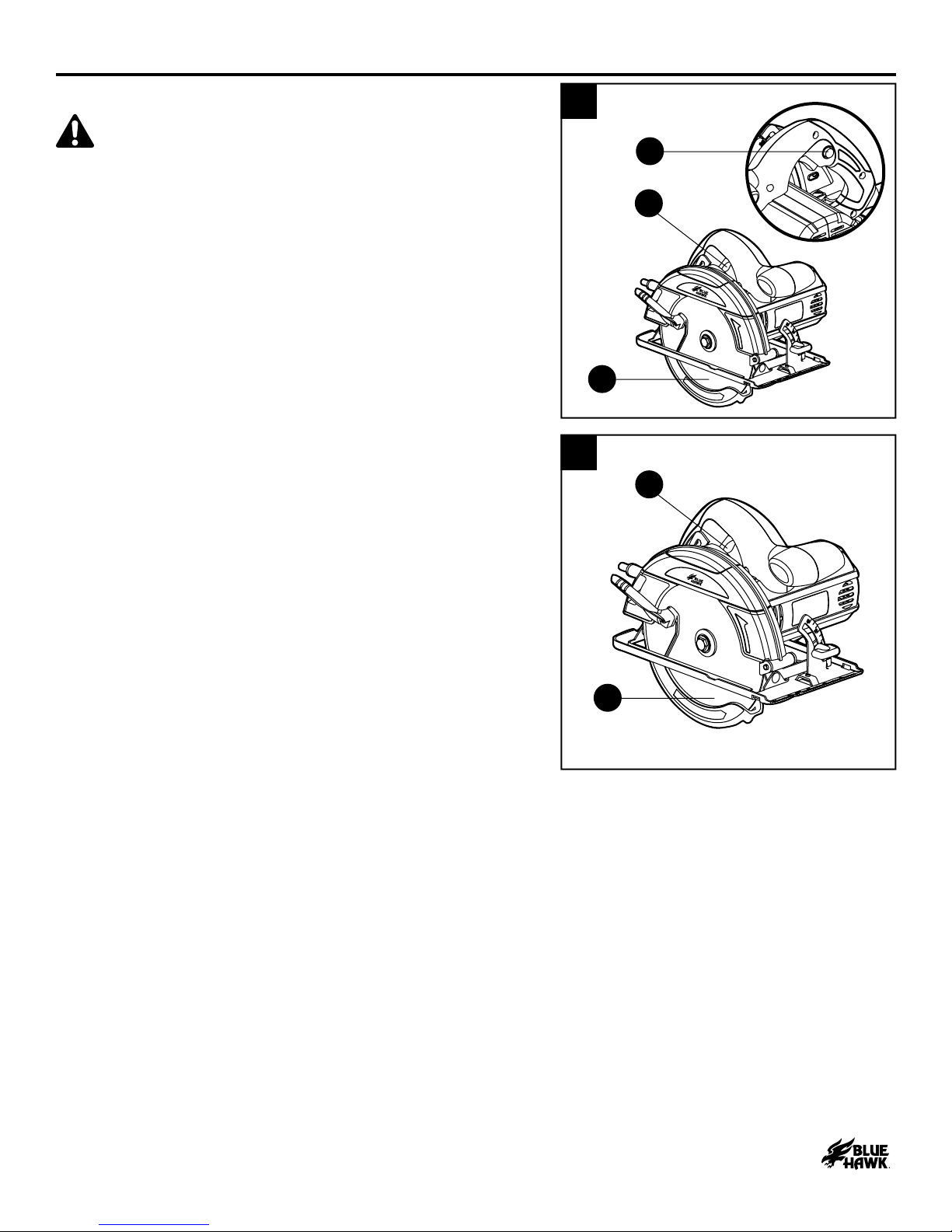

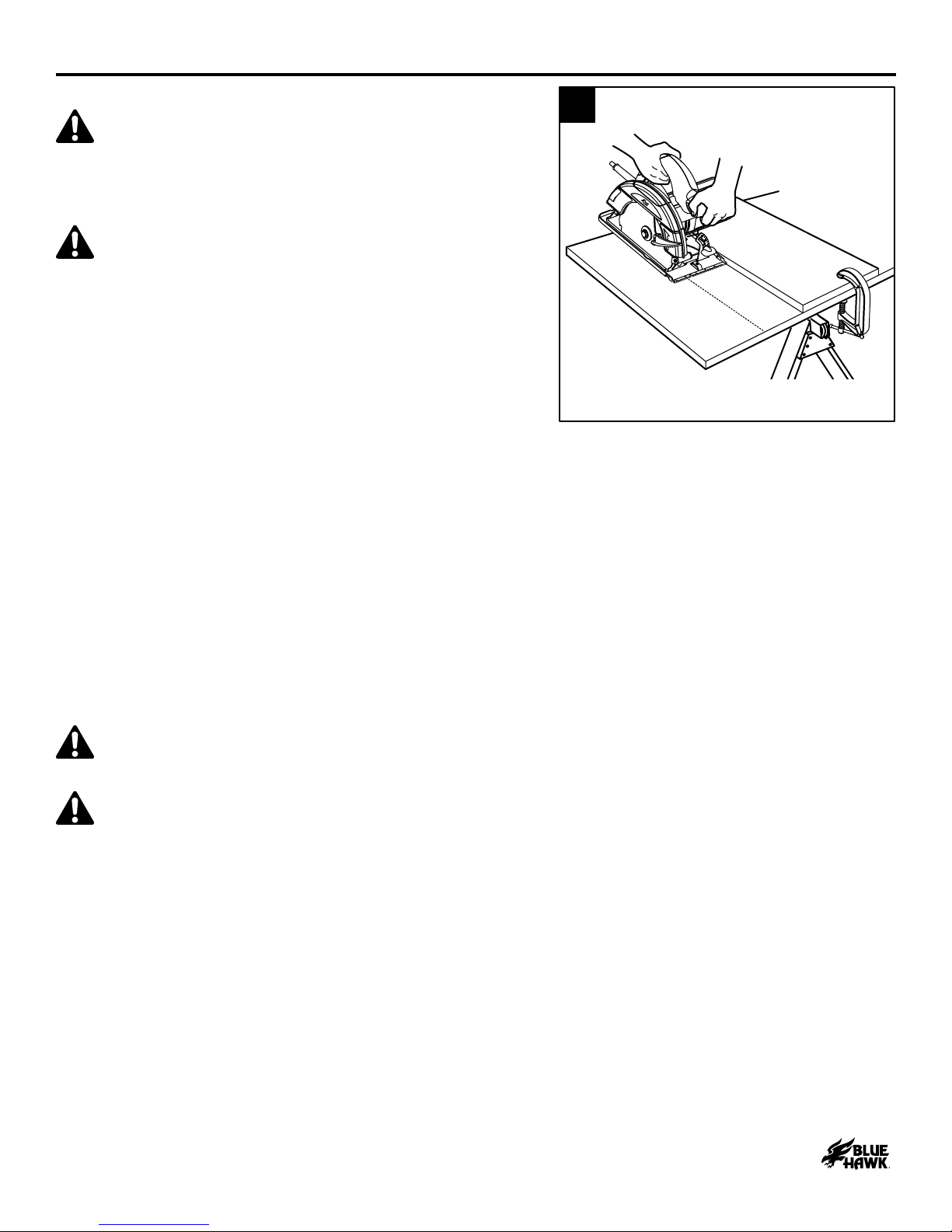

4. Depth-of-Cut Adjustment

WARNING: ALWAYS maintain the correct blade-

depth setting. The correct blade-depth setting for all cuts

should not exceed the thickness of the material being cut

by more than 1/4 in. (6.5 mm). Greater blade depth will

increase the chance of kickback and cause the cut to be

rough.

a. Unplug the saw.

b. Pull the depth-locking lever (G) upward to

release it.

c. Determine the desired depth of cut.

d. Hold the base plate (K) at against the workpiece

and raise or lower the saw until the indicator mark

on the saw aligns with the desired depth on the

scale.

e. Push down on the depth-locking lever (G) to lock

it into position.

G

K

4

5. Adjusting the Cutting Angle

a. Loosen the angle-locking knob (H), located on the

0°~45° bevel gauge (I) on the base plate (K).

b. Tilt the body of the saw until the required angle is

reached. Refer to the scale on the 0°~45° bevel

gauge (I).

c. Tighten the angle-locking knob (H) to secure the

saw and angle.

H

G

K

I

5

16

Lowes.com

OPERATING INSTRUCTIONS

6. General Cutting

DANGER: When lifting the saw from the workpiece,

the blade is exposed on the underside of the saw until

the lower blade guard closes. Ensure that the lower blade

guard is closed before setting the saw down.

WARNING: To make sawing easier and safer,

always maintain proper control of the saw. Loss of control

could cause an accident resulting in possible serious

injury.

To make the safest and best possible cut, follow these

steps:

a. Hold the saw rmly with both hands. Avoid placing

your hand on the workpiece while making a cut.

b. Support the workpiece so that the cut is always to

the operator’s side and not directly in line with the

operator’s body; support the workpiece near the

cut.

6

DANGER: If the cord hangs up on the workpiece during a cut, release the trigger switch

immediately. Unplug the saw and reposition the cord in order to prevent it from hanging up again.

DANGER: Using a saw with a damaged cord could result in serious injury or death. If the cord

has been damaged, have it replaced before using the saw again.

c. Place the workpiece with the good side facing down.

d. Clamp the workpiece securely so that the workpiece will not move during the cut.

Note: Always place the saw on the portion of the workpiece that is supported and not on the “cut off”

piece.

e. Draw a guideline along the desired cutting line before beginning the cut.

f. Keep the cord away from the cutting area. Always place the cord so that it is not hanging up

on the workpiece while making a cut.

17

Lowes.com

OPERATING INSTRUCTIONS

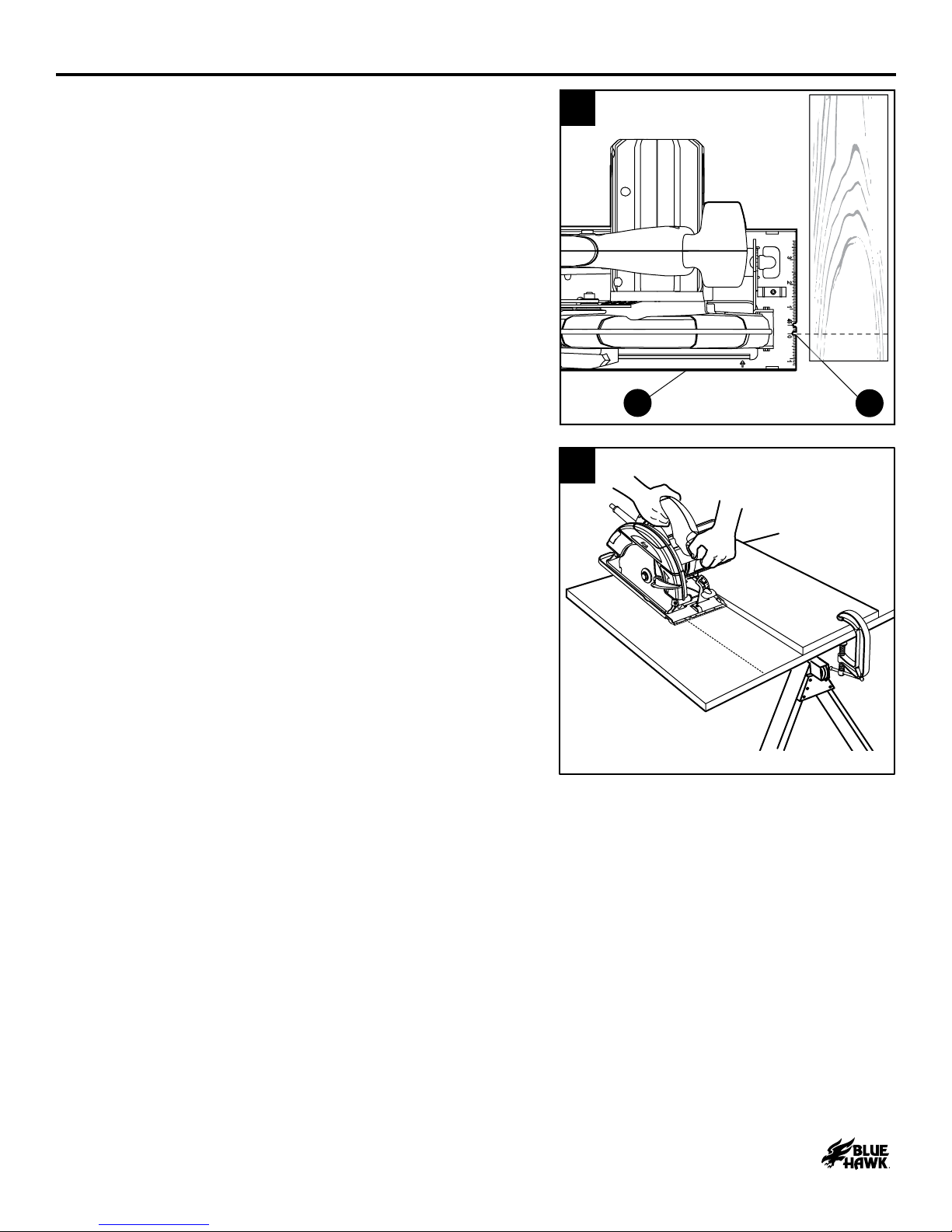

7. Cross Cutting/Rip Cutting

When making a cross-cut or a rip cut, align the

guideline on the workpiece with the full-length kerf

indicator (S) on the base plate (K). The distance from

the saw blade to the saw base is approximately 4-1/4

in. (10.8 cm) on the left side of the saw and 1-1/2 in.

(3.8 cm) on the right side.

Note: Blade thicknesses vary. Always make a trial cut in

scrap material along a guideline to determine how

much the guideline must be offset from the guide

to produce an accurate cut.

Note: The distance from the cutting line to the guideline

is the amount by which the guide should be offset.

Use a guide when making long or wide rip cuts. KS

7

8. Rip Cutting Using a Straight Edge

a. Secure the workpiece.

b. Clamp a straight edge to the workpiece using

C-clamps (not included).

Note: Position the C-clamps so that they will not interfere

with the saw housing during the cut.

c. Saw along the straight edge to achieve a straight

rip cut.

Note: Do not bind the blade in the cut.

8

18

Lowes.com

OPERATING INSTRUCTIONS

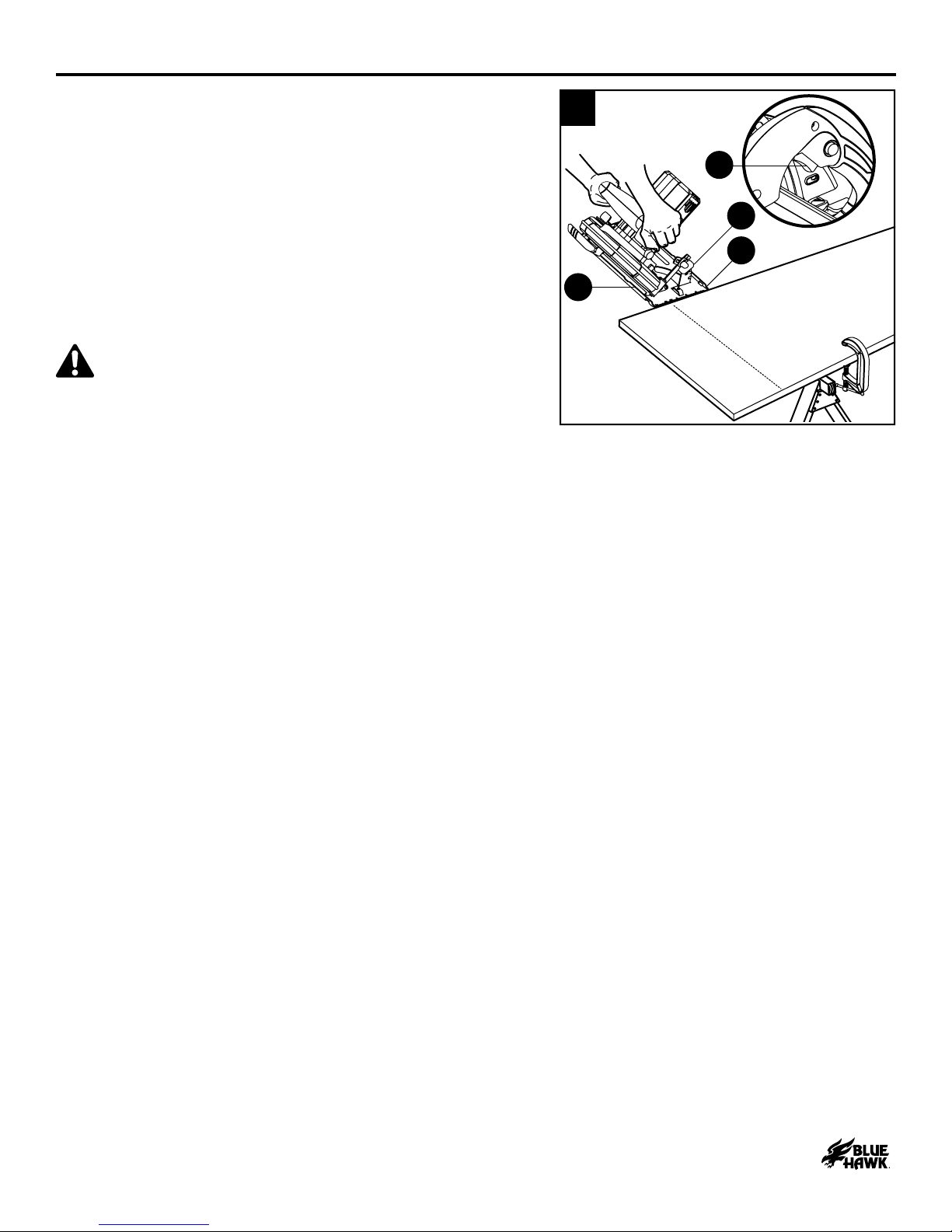

9. Bevel Cutting

To make the best possible cut bevel cut:

a. Align the cutting line with the inner-blade-guide

notch on the base plate (K) when making 45°

bevel cuts.

b. Make a trial cut in scrap material along a

guideline to determine the amount to offset the

guideline on the cutting material.

c. Adjust the angle of the cut to any desired setting

on the bevel gauge (I) between 0° and 45°.

WARNING: Attempting a bevel cut without having

the angle-locking knob securely locked in place can result

in serious injury.

d. Hold the saw rmly with both hands.

e. Rest the front edge of the base plate (K) on the

workpiece without touching the blade (P) to the

workpiece.

f. Start the saw and allow the blade (P) to reach full

speed.

g. Guide the saw into the workpiece and make the

cut.

h. Release the trigger switch (A) and allow the blade

(P) to come to a complete stop.

i. Lift the saw from the workpiece.

9

K

P

A

I

19

Lowes.com

OPERATING INSTRUCTIONS

10. Pocket Cutting

WARNING: Always adjust the bevel setting to 0°

before making a pocket cut. Attempting a pocket cut at

any other setting can result in loss of control of the saw

and possible serious injury.

a. Adjust the bevel gauge (I) to 0° and tighten the

angle-locking knob (H).

b. Set the blade (P) to the correct blade-depth

setting and tighten the depth-locking lever (G).

c. Swing the lower blade guard (E) up using the

blade guard lever (F).

d. Hold the lower blade guard (E) in place with the

blade guard lever (F).

e. Rest the front of the base plate (K) at against the

workpiece, with the rear of the handle raised, so

that the blade (P) does not touch the workpiece.

f. Start the saw, allowing the blade (P) to reach full

speed.

g. Guide the saw into the workpiece and make the

cut.

H

I

P

G

E

K

F

10

CARE AND MAINTENANCE

CAUTION: Before performing maintenance or cleaning, pull the plug from the main socket.

• Never use water or chemical liquids to clean the electrical parts of the machine.

• Keep the ventilation slots clean in order to prevent overheating of the motor.

WARNING: Always cut in a forward direction when pocket cutting. Cutting in the reverse

direction could cause the saw to climb up on the workpiece and kick back toward the operator.

WARNING: As the blade starts cutting the material, release the lower guard immediately. When

the foot of the guard rests at on the surface being cut, proceed cutting in a forward direction to the

end of the cut.

a. Release the trigger switch (A) and allow the blade (P) to come to a complete stop.

b. Lift the saw from the workpiece.

c. Clear the corners out with a hand saw or jigsaw.

WARNING: Never tie the lower blade guard in a raised position. Leaving the blade exposed

could lead to serious injury.

20

Lowes.com

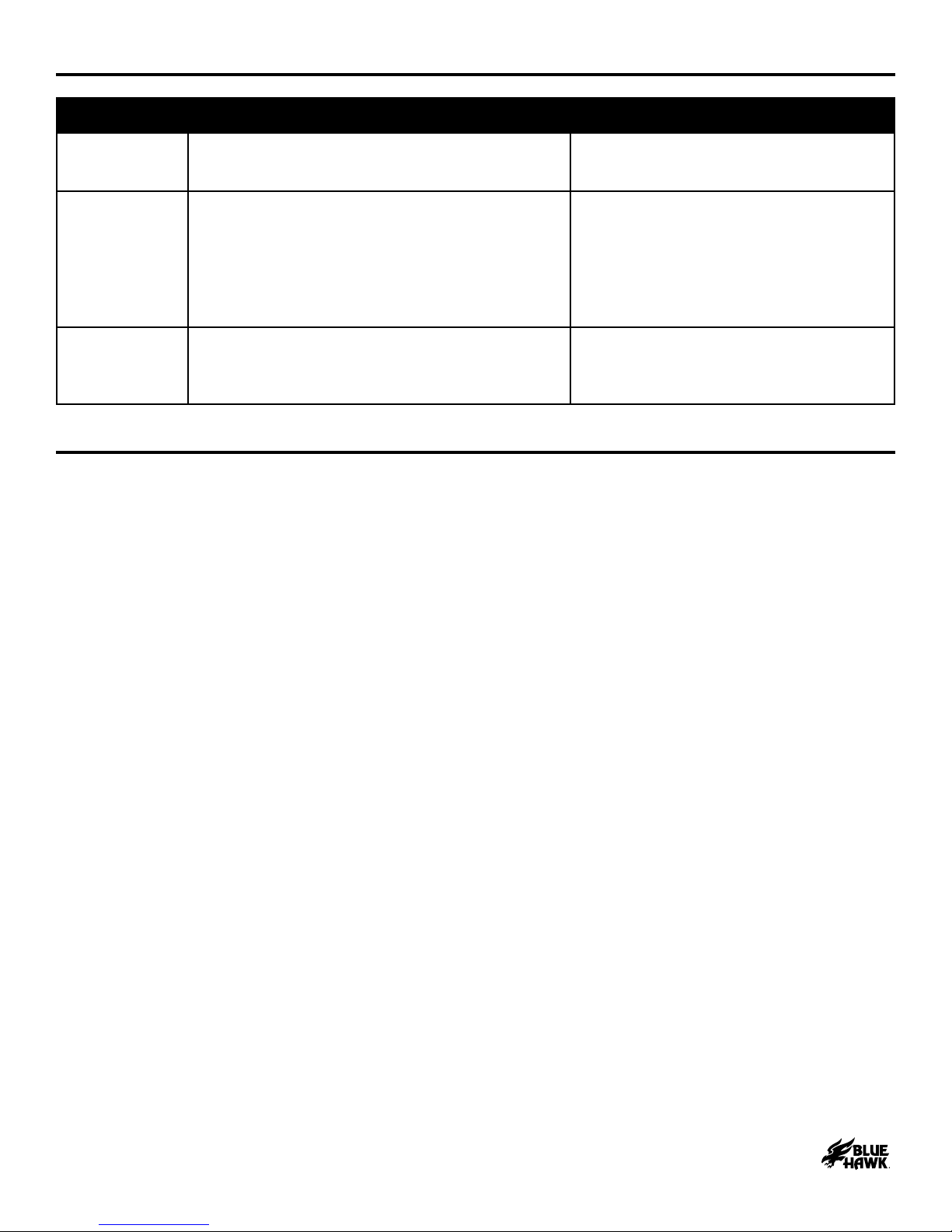

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

The motor

does not start.

1. There is a blown fuse. 1. Check the time-delayed fuse or

circuit breaker.

The blade

binds, jams,

or burns the

wood.

1. The blade is not operating properly.

2. The blade is dull.

3. The wrong type of blade is being used.

4. The blade is warped.

1. See the Operating Instructions

section of this manual.

2. Replace or sharpen the blade.

3. Replace the blade.

4. Replace the blade.

The saw

vibrates or

shakes.

1. The blade is damaged.

2. The blade is loose.

1. Replace the blade.

2. Tighten the hexagon blade

screw bolt.

WARRANTY

The manufacturer warrants to the original purchaser that each new product is free from defects

in material and workmanship and agrees to replace under this warranty any defective product as

follows from the original date of purchase.

• Three (3) Year Limited Warranty.

• THIS WARRANTY IS NOT TRANSFERABLE AND DOES NOT COVER:

• Products sold damaged or incomplete, sold “as is,” sold reconditioned or used as rental

equipment.

• Products that have ever been used while providing commercial services or have been rented to

another person.

• Delivery, installation or normal adjustments explained in the owner’s manual.

• Damage or liability caused by shipping, improper handling, improper installation, incorrect

voltage or improper wiring, improper maintenance, improper modication, or the use of

accessories and/or attachments not specically recommended.

• Repairs necessary because of operator abuse or negligence, or the failure to install, operate,

maintain and store the product according to the instructions in the owner’s manual.

• Damage caused by cold, heat, rain, excessive humidity, corrosive environments and materials,

or other contaminants.

• Expendable items that become worn during normal use.

• Cosmetic defects that do not interfere with tool functionality.

• Freight costs from customer to vendor.

• ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT

MAY RESULT FROM ANY DEFECT, FAILURE OR MALFUNCTION OF THE PRODUCT.

Some states do not allow the exclusion or limitations on how long an implied warranty lasts, so the

above limitations may not apply to you.

Printed in China

Blue Hawk & Design®is a registered trademark of LF, LLC. All rights reserved.

Table of contents

Popular Saw manuals by other brands

Bosch

Bosch GKS 165 Professional Original instructions

Draper

Draper MS250A instructions

Huvema

Huvema HU 250 CS-4 quick start guide

Harbor Freight Tools

Harbor Freight Tools Admiral Owner's manual & safety instructions

Homelite

Homelite WF10MSP Operator's manual

Parkside

Parkside PTS 20-Li A1 Original instructions