BM2 BIEMMEDUE BMP 26 C Specification sheet

Gas fired room sealed unit heaters

centrifugal

TECHNICAL INFORMATION, ASSEMBLY

INSTRUCTIONS, USE AND MAINTENANCE

BMP C BMP CS BMP C-2 BMP C-2S

2

Dear Customer

Thank you for choosing a BMP C series air heater, an innovative and modern, quality and high performance product which

will assure safe and silent working for a long time. This is particularly the case if the generator is put in the hands of

Biemmedue’s Technical Assistance Department whichis specially trained and equipped to keep it working at

maximum efficiency with low running costs and has a large number of original spares in stock.

This instruction manual contains important instructions and suggestions for simple installation and making the best

possible use of the BMP C air heater.

Thank you again

BIEMMEDUE S.p.A.

COMPLIANCE NOTICES

The warm air heaters comply with the following directives:

• EEC machine directives 98/37/CEE

• EEC gas directive 90/396

• EEC low tension directive 73/23

PIN NUMBER

Notified Body PIN Reference is 0694BN3750

SINGLE STAGE TWO STAGE

STANDARD UP RATED FAN STANDARD UP RATED FAN

Type Model Model Model Model

1 BMP 26 C BMP 26 CS BMP 26 C -2 BMP 26 C -2S

2 BMP 36 C BMP 36 CS BMP 36 C -2 BMP 36 C -2S

3 BMP 46 C BMP 46 CS BMP 46 C -2 BMP 46 C -2S

4 BMP 66 C BMP 66 CS BMP 66 C -2 BMP 66 C -2S

5 BMP 86 C BMP 86 CS BMP 86 C -2 BMP 86 C -2S

6 BMP 106 C BMP 106 CS BMP 106 C -2 BMP 106 C -2S

VERSION SINGLE STAGE

The heater has a single stagegas valve, and a standard centrifugal fan. An optional uprated fan version is availablefor

installations that require higher static pressures.

VERSION TWO STAGE

The heater has a two stage Hi /Lo gas valve, and a standard centrifugal fan. An optional uprated fan version is available

for installations that require higher static pressures.

GUARANTEE

Warm air heaters series BMP C are covered by aSPECIFIC GUARANTEE that starts on the dateof purchase of the

device, which date the buyer should document; if he cannot do this, the guarantee starts on the date of manufacture of

the device.

The guarantee conditions are specified in detail in the GUARANTEE CERTIFICATE, supplied with the device, and we

suggest you read them carefully.

3

INDEX

GENERAL

Description of equipment page. 6

Identification “ 7

Description “ 8

Technical data “ 10

Wiring diagram “ 11

Remote control connections “ 15

FOR THE USER

Operation “ 16

Servicing “ 16

Heater indication lights “ 17

Receipt of product and transport “ 17

Dimension and weight “ 18

FOR THE INSTALLER

Installation “ 20

Installation clearances “ 21

Examples of installation “ 22

Accessories “ 23

Gas connection “ 24

Flue and combustion options “ 25

Electrical control panel and circuit board “ 29

Electrical connections “ 29

TECHNICAL ASSISTANCE SERVICE

Duct connection “ 30

Return air connections “ 31

Protection “ 31

Pre commissioning checks “ 31

Initial start up “ 32

Gas conversion “ 33

Thermostat “ 35

Fan “ 36

Control “ 36

Maintenance “ 37

Fault finding “ 39

The following symbols are used in the manual:

WARNING = where the work to be carried out requires

special care and suitable training

FORBIDDEN = where the action MUST NOT be carried

out

This manual consists of 44 pages.

4

GENERAL NOTES

This Instruction Manual is an integral part of the device

and as such must always be kept with the device. This

also when the heater is sold to another user. The

Manual must therefore be conserved carefully and

consulted attentively before any action. In the case of

damage or loss, you can at any time ask the local After

Sales Service for a copy of the Manual.

After removing the packing, first make sure that the

contents are complete and undamaged.

If the heater does not correspond in any way, contact

the Agency that sold the heater.

Installation of warm air heaters must be carried out by

qualified companies. On completion of the job, they

provide the owner with a declaration of conformity of the

installation correctly carried out, that is according to the

requisites of current applicable Norms and according to

the indications provided by the Manufacturer in this

Instruction Manual.

The heaters have been manufactured for room heating

and they must be used for this purpose, compatibly with

their performance characteristics.

The Manufacturer takes no contractual or extra-

contractual responsibility for damage caused to

persons, animals or property, due to errors in

installation, adjustment and maintenance or due to

improper use.

Excess temperature is damaging to health and

represents a waste of energy.

Avoid leaving rooms closed for long periods of time.

Open the windows periodically to ensure adequate air

change.

During the first start-up, there may be formation of

smells and smoke due to evaporation of the liquid used

to protect the heat exchanger during storage; this is a

normal phenomenon that will disappear after a brief

operation time.

The rooms must be adequately aerated.

On leaving the heater unused for a long period, you

should carry out at least the following operations:

• Turn off the main heater switch and the main plant

switch;

• Close the main fuel supply valve.

If the heater is not used for a long period of time, we

suggest you contact the After Sales Service or other

professionally qualified personnel for restarting.

All heaters must be fitted exclusively with original

accessories. The Manufacturer is not responsible

for any damage caused by improper use of the

heater and by the use of accessories that are not

original.

All references to Law, standards, directives and

technical rules in this manual are to be considered

as informative only and valid at the date of printing

of the Manual. The enforcing of new dispositions or

the alteration of current ones do not create any

Manufacturer obligations towards third parties.

Repairs and maintenance must be carried out by

the After Sales Service or by qualified personnel as

specified in this Manual. Do not alter or tamper with

the heater: this can create dangerous situations and

the Manufacturer will not be responsible for any

damage.

The systems that must be installed (gas or oil pipes,

electrical supplies etc) must be suitably fastened

and must not create obstacles that could cause

tripping.

The Manufacturer is responsible for conformity of

his product to laws, directives and construction

standards current at the date of sale. Knowledge

and observation of legislative instruments and of

standards for the design of systems, and for

installation, operation and maintenance are the

exclusive responsibility of respectively the designer,

the installation personnel and the user.

The Manufacturer is not responsible for failure to

observe the instructions in this Manual, for the

consequences of any operation carried out that is

not specifically foreseen, or for any translations

causing erroneous interpretations.

The heater id designed for operation at the thermal

power and the airflow rate as specified in the

Technical Data Chapter. A thermal power that is too

low and/or an airflow that is too high can lead to

condensation in the fluegases, with consequent

irreparable corrosion to the heat exchanger. A

thermal power that is too high and/or an airflow that

is too low cause abnormal overheating of the heat

exchanger with consequent actuation of the safety

systems and damage to the heat exchanger.

5

GENERAL NOTES

The use of devices that employ electrical energy and/or fuel oil requires the observance of some fundamental safety

rules such as:

Children ad unassisted disabled persons must not use

the warm air heaters.

Do not operate electrical equipment such as switches,

electric household equipment etc if you can smell gas,

fuel or other combustibles.

In this case:

• Open the doors and windows to aerate the room

• Close the fuel supply valves

• Call in quickly the After Sales Service or other

professionally qualified personnel

Do not touch the heater if you are barefoot or if parts of

your body are wet.

Do not carry out any cleaning or maintenance operation

without first deactivating the heater by setting the main

system switch to "OFF" and without first closing the fuel

supply.

Do not alter the safety and adjustment systems without

prior authorisation and indications by the heater

Manufacturer.

Do not pull, detach or twist the electric cables that exit

the heater, even if the heater is not connected to the

electrical supply.

Do not open any doors that access the inside of the

heater without turning the main system switch to "OFF".

Do not abandon or leave available to children the

heater packing materials (cartons, nails, plastic bags

etc), as these are a potential source of danger.

Do not install the heater near flammable material, or in

areas where there is a corrosive atmosphere.

Do not place any object on the heater or push anything

through the grilles in the casing nor in the fluegas ducts.

Do not touch the fluegas ducts as during normal

operation these can reach high temperatures and

represent a hazard.

Do not use any adapters, multiple sockets and cable

extensions for the electrical connection of the heater.

Do not install the heater in the open air nor where it

could be subject to atmospheric events.

Do not install the heater directly in limited spaces

without adequate ventilation, as the burner air suction

can create a pressure drop in the room and

consequently cause serious problems.

6

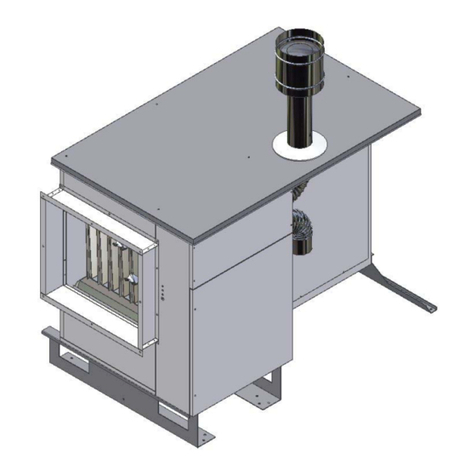

DESCRIPTION OF EQUIPMENT

Heat exchanger

• Stainless steel construction easily accessible for

inspection and cleaning and maintenance operations.

• Patented exchange elements made in stainless steel

modular sections with large surface area, trapezoidal in

section with swirl impressions for which give thermal

yields of over 90%. The exchange elements have no

welded joints or seams near to the burner flame so as

to avoid exposure of any weak points.

Flue outlet with integral flue venter to assist dispersal of

combustion gasses.

External casing

Encloses all controls giving a good aesthetic appearance

and streamlined look whilst allowing for easy inspection.

The casing consists of removable panels and also

includes:

A burner compartment which is totally sealed off, with an

inspection door;

Radiant heat insulation on the surfaces closest to the heat

exchanger;

Outlet grille for directing the warm air.

Fan assembly

One or two centrifugal fans operated by a single electric

motor via pulleys and belts the motor pulley is adjustable to

give effective cooling of the combustion / heat exchanger.

The position of the fan(s) produce greater effective cooling

of the combustion chamber, optimising the heat exchange

and avoiding overheating.

An up rated fan is also available.

Control and protection equipment

This is electronic with ionisation flame detection and

ignition controls.

The equipment controls and monitors the operation of the

burner in the following sequence.

Checks the differential pressure switch operated by the

flue venter is in the closed position and the flue venter is

working;

Checks the air temperature of the combustion chamber

(below 100ºC)

Opens the gas solenoid valve;

Starts burner ignition;

Detects flame signal from flame probe and allows normal

heater operation.

Failure in any of the above sequence will result in the

control box shutting the gas valve and stopping the heater.

The Heater will go to lockout and can be only be reset

manually by pressing the red light on the front of the

equipment.

Gas solenoid valve

The multifunctional 1 stage gas valve (Single Stage)

and 2 Stage gas valve (Two Stage ) consists of:

• Safety solenoid valve

• A regulatory solenoid valve

• A pressure regulator

• A gas filter

Atmospheric multigas burner assembly

Consisting of:

• Galvanised steel manifold

• Visual monitoring aperture for the electrodes and flame

observation

• 3 or 6 stainless steel burner bars

• Ignition and Detection electrodes

Note: the type 4-5-6 are equipped with two gas manifolds,

each manifold has an ignition electrode.

Control and safety thermostat

The heater is controlled by three thermostats pre set to the

following.

LM Limit thermostat (100°C)

Capillary type. Manual Reset

Act as a safety device and shuts down the burner if the

heater goes to overheat. The yellow light will flash when in

overheat. The LIMIT thermostat is reset by the removal of

the plastic cap situated on the control panel inside the

heater, and manually pressing the reset button, after first

ensuring that the fault has been rectified. (calibrated

at100°C). Replace cap after resetting thermostat.

TR Regulatory thermostat (0 – 90°C)

Capillary type. Automatic reset.

The thermostat monitors the temperature of the airflow and

will shut down the burner if the set level is exceeded

(calibrated at 70°C). Once the fan has sufficiently cooled

the heat exchanger, the burner will automatically relight.

The yellow indication light will flash untill the burner

relights. If this fault persists the cause should be

investigated.

SND Control probe (0 – 40°C)

Connected in series with the thermostat TR. The probe will

start the fan when the temperature reaches 30°C

(approximately 30 seconds from burner ignition). When the

desired room temperature is reached and the burner shuts

down, the probe will allow the fan to run for approximately

3- minutes until the heat exchanger has cooled

sufficiently.

The probe also monitors the operation of the TR

thermostat and if a fault is detected will change the yellow

flashing light to a continous on light. In addition to this the

SND probe monitors the temperature of the return air and

will switch off the fan prior to the 3-4 minute run on time if

the heat exchanger has cooled sufficiently (this avoiding

cold air flow from the heater).

Differential air pressure switch

This switch will shut the gas valve if the flue venter fails or

there is an obstruction in the flue, or in the air inlet

preventing the flue venter from operating.

Flue venter

This consists of a centrifugal fan which

Is run by an electric motor with self-cooling rotor the

cooling air is supplied through a duct pipe situated in the

axial fan air flow.

Indication lights

These consist of three different coloured lights on the front

of the heater:

• Green light – indicates normal working. Illuminates

when the gas solenoid valve opens

• Yellow light – indicates the operation of the LM, TR

and SND thermostat.

• Red light - to indicate lockout of the heater by the

control circuit failure.

• Reset button to reset the lockout

Flue spigot

A flue spigot (100mm) is situated at the rear of the heater

for connection of flue pipes.

Combustion air spigot

A combustion air spigot (100/150mm) with a safety mesh

of less than 16 mm Ø on the rear of the heater allow for

connection of combustion air pipe.

7

IDENTIFICATION

If the TECHNICAL DATA is lost or damaged ask

Manufacturer Technical Department for

duplicate.

Check code and model is as data plate.

Position of data plate

Manufacturer

AIR HEATER

Model

Serial Number

Country PIN

Category Code

Type Year

Nominal Heat INPUT kW

Nominal Heat OUTPUT kW

Air Flow (+15°C) m3/h

Electrical Supply

Electrical Power W

Protection Rating

GAS TYPE

Supply Pressure mbar

Head Pressure mbar

Injector Diameter mm

Gas Consumption m3/h

Packing label position

Code

Model

SerialNo

8

DESCRIPTION

Type 1÷4

NOTE:

Heaters type 1, 2, 3 have a single burner manifold.

Heaters type 4 have two burner manifolds

1. Regulation thermostat SND

2. FAN thermostat TR

3. LIMIT thermostat LM

4. Flue venter inspection door

5. Flue pipe

6. Flue manifold

7. Outlet Grille

8. Controls compartment

9. Heat exchanger

10. Burner plate insulation

11. Gas injector

12. Combustion chamber

13. Gas manifold

14. Burner bars

15. Flue ducting

16. Deflector

17. Green power on light

18. Yellow limit indication light

19. Red light lockout indication

20. Lockout reset

21. Gas inlet connection

22. Electrical connections

23. Combustion intake air spigot

24. Flue spigot

25. Inlet casing

26. Fan Motor

27. Centrifugal Fan

28. Gas Solenoid valve

29. Ignition electrode

30. Gas pressure manifold test nipple

31. Flame detection electrode

32. Flame check aperture

33. Flue venter

34. Air inlet grille

35. Base plate front

36. Rear support

9

Type 5and 6:

NOTE:

Heaters type 5 are supplied with 2 opposing burner manifolds

Heaters type 6 are supplied with 4 opposing burner manifolds

1. Regulation thermostat

2. LIMIT thermostat

3. FAN thermostat

4. Flue venter inspection door

5. Flue pipe

6. Flue manifold

7. Outlet Grille

8. Controls Compartment

9. Heat exchanger

10. Gas manifold

11. Gas injector

12. Combustion chamber

13. Burner plate insulation

14. Burner tubes

15. Ignition transformer

16. Left burner casing

17. Flue ducting

18. Deflector

19. Green power light

20. Yellow limit indication light

21. Red light lockout indication

22. Lockout reset

23. Gas inlet connection

24. Cable grips

25. Combustion intake air spigot

26. Flue spigot

27. Inlet casing

28. Fan Motor

29. Centrifugal Fan

30. Gas Solenoid valve (2 on type 5 and 6)

31. Ignition electrode

32. Gas pressure manifold test nipple

33. Flame detection electrode

34. Flame check aperture

35. Gas pressure manifold test nipple

36. Air inlet grille

37. Rear support

38. Base plate

10

TECHNICAL DATA

DESCRIPTION TYPE UNIT

1 2 3 4 5 6

HEAT OUTPUT 25,4 33,8 46,3 65,0 85,0 104,7 KW

21.844 29.068 39.818 55.900 73.100 90.042 kcal/h

HEAT INPUT 23,0 30,5 41,7 58,6 76,6 94,3 KW

(Nett) 19.780 26.230 35.862 50.396 65.876 81.098 kcal/h

EFFICIENCY 90,1 90,2 90,1 90,1 90,1 90,1 %

AIR FLOW +15°C 1.820 2.920 4.130 5.900 7.900 8.750 Nm3/h

MAX AIR OFF (∆T) 37 31 30 30 29 32 °K

HEAT INPUT MIN (two stage) 15,8 21,0 28,8 40,5 52,9 65,2 KW

MIN AIR OFF (∆T) (two stage) 25 21 20 20 20 22 °K

STATIC PRESSURE (standard) 200 Pa

STATIC PRESSURE (uprated) 500 450 440 470 440 500 Pa

THERMOSTAT CALIBRATION

- TR (auto reset) 70 °C

- LM (manual reset) 100 °C

- SND (auto reset) 70 °C

FAN OPERATION

- Fan on 30 sec

- Fan off 3 min’

Air pressure switch setting 0,85 0,90 0,85 1,95 0,40 0,70 mBar

Maximum flue resistanceI 70 70 70 70 160 115 Pa

CENTRIFUGAL FAN

- Type AT 10-8 AT 12-9 AT12-12 AT 12-9 AT12-12 AT12-12

- Number 1 1 1 2 2 2 N°

ELECTRICAL SUPPLY 230V 230V 230V 400V 3N 400V 3N 400V 3N 50Hz ∼

RATED INPUT standard motor) 0,5 0,5 0,5 0,750 1,100 1,500 KW

RATED INPUT (up rated motor) 0,5 0,75 1,1 1,5 2,2 3,0 KW

RUNNING CURRENT MAX( standard motor) 3,7 3,7 4,0 2,0 2,8 3,6 A

RUNNING CURRENT MAX (up rated motor) 4,0 4,7 7,5 3,6 5,0 6,5 A

ELECTRICAL PROTECTION 40 IP

GAS CATEGORY II 2H3B/P

INSTALLATION TYPES B22 – C12 – C32

OPERATIONAL LIMITS

- Temperature -15 / +40 °C

- Relative humidity (non condensing) 70 %

WEIGHT (standard) 122 133 156 200 267 311 Kg

WEIGHT (up rated) 122 135 159 204 274 318 Kg

NUMBER OF INJECTORS 1 1 1 2 2 4 N°

NATURAL GAS G20

- Diameter of injectors 410 480 555 500 540 450 mm/100

- Inlet pressure 20 mBar

- Head pressure max 13,0 13,0 13,0 10,0 13,0 10,5 mBar

- Head pressure (two stage) 7,0 6,5 6,5 7,0 6,5 5,0 mBar

- Consumption max (1) 2,55 3,39 4,65 6,52 8,53 10,51 Nm3/h

- Consumption min (1) (two stage) 1,79 2,38 3,25 4,57 5,97 7,36 Nm3/h

PROPANE GAS G31

- Diameter of injectors 250 280 335 285 320 255 mm/100

- Inlet pressure 37 m/Bar

- Maximum gas head pressure 35,0 35,5 35,5 34,5 35,5 34,5 mBar

- Minimum gas head pressure (two stage ) 18,0 18,5 18,0 18,0 18,0 18,5 mBar

- Consumption max (2) 0,98 1,30 1,78 2,50 3,27 4,03 Nm3/h

1,97 2,63 3,60 5,05 6,60 8,13 Kg/h

3,88 5,16 7,07 9,92 12,97 15,98 Litri/h

- Consumption min (2) (two stage) 0,68 0,91 1,25 1,75 2,29 2,82 Nm3/h

1,38 1,84 2,52 3,53 4,62 5,69 Kg/h

2,72 3,62 4,94 6,04 9,08 11,19 Litri/h

BUTANE GAS G30

- Diameter of injectors 250 280 335 285 320 255 mm/100

- Inlet pressure 30 m/Bar

- Maximum gas head pressure 29,0 29,0 28,5 29,0 29,0 28,5 mBar

- Minimum gas head pressure (two stage ) 16,5 16,5 16,5 16,5 16,5 16,5 mBar

- Consumption max (3) 0,74 0,99 1,36 1,91 2,49 3,07 Nm3/h

2,00 2,67 3,65 5,13 6,70 8,26 Kg/h

3,48 4,62 6,34 8,89 11,63 14,33 Litri/h

- Consumption min (3) (two stage) 0,52 0,69 0,95 1,33 1,74 2,15 Nm3/h

1,40 1,87 2,56 3,59 4,69 5,78 Kg/h

2,08 3,24 4,43 6,23 8,14 10,03 Litri/h

Mass products of combustion max 0,0139 0,0185 0,0253 0,0356 0,0465 0,0573 kg/s

References:

1) 2) 3) Atmospheric pressure 1013 mBar

Gas temperature 15°C

1) P.C.I. 8.570 kcal/Nm3

2) P.C.I. 22.360 kcal/Nm3– 11.070 kcal/kg – 5.635 kcal/litro

3) P.C.I. 29.330 kcal/Nm3– 10.905 kcal/kg – 6.285 kcal/litro.

11

WIRING DIAGRAM

Schematic layout:

Heaters type 1-2-3

EF

SE

J4

J8

IGN1

PA

COMCOM

NA NC

ION

EA1

J11

J17

J2

J14

VM

TA

J16 J13

J7

RSTR

MS

EVG1-I°

EVG1-II°

RST

LB

LL

LF

J10

J9 J12

SND

LM

TR

J15J18

J1

IMT

J6

NL

F2

F1

N

J5

II°

I°

SF

FAN

C

KEY:

SND Temperature control probe

TR Regulatory control thermostat(auto reset)

LM LIMIT thermostat (manual reset)

EVG1-I° Gas solenoid valve

EVG1-II° Gas solenoid min (two stage)

CCapacitor / centrifual fan

FAN Centrifugal fan

F1-F2 Line fuse

LF Green working light

LL High temperature indication

LB Lockout indication

RST Lockout reset

EF Flue venter

PA Differential pressure switch

IGN1 Ignition transformer

EA1 Ignition electrode

ION Ionisation probe

SE Control board

IMT (*)Fused isolator

MS (*)Fire switch

RSTR (*)Remote reset

TA (*)Room thermostat

VM (*)Fan switch

SF (**)Second stage gas valve connection

(*)External to heater customer supply.

(**)Two stage only, External wiring customer

supply.

Electrical supply

single phase 230V 50Hz

12

Heater type 2-3 up rated fan

SE

EF PA

COM

NA

J4

J8

J17

J10

J9

LM

J12

J18

NC

IGN1

ION

EA1

J16

J11

J2

J14

J7

J13

RSTR

TA

VM

MS

NL

J15

J1

J6

CNT

F2

J5

F1

II° SF

I°

RT

FAN

SND

TR

EVG1-I°

EVG1-II°

LF

LL

LB

RST

F

KEY:

SND Temperature control probe

TR Regulatory control thermostat(auto reset)

LM LIMIT thermostat (manual reset)

EVG1-I° Gas solenoid valve

EVG1-II° Gas solenoid min (two stage)

CCapacitor / centrifual fan

FAN Centrifugal fan

F1-F2 Line fuse

LF Green working light

LL High temperature indication

LB Lockout indication

RST Lockout reset

EF Flue venter

PA Differential pressure switch

IGN1 Ignition transformer

EA1 Ignition electrode

ION Ionisation probe

SE Control panel

RT Relay fan motor

CNT Fan contactor

F Line fuse

IMT (*)Fused isolator

MS (*)Fire switch

RSTR (*)Remote reset

TA (*)Room thermostat

VM (*)Fan switch

SF (**)Second stage gas valve connection

(*)External to heater customer supply.

(**)Two stage only, External wiring customer

supply.

Electrical supply

single phase 230V 50Hz

13

Heater type 4

LF

LL

LB

RST

NC

IGN1

ION

EA1

J16

J11

J2

J14

J7

J13

RSTR

TA

VM

MS

L3

NL1L2

IMT

F

J15

J1

J6

CNT

F2

J5

F1

II° SF

I°

RT

FAN

SND

TR

EVG1-I°

EVG1-II°

SE

EF PA

COM

NA

J4

J8

J17

J10

J9

LM

J12

J18

KEY:

SND Temperature control probe

TR Regulatory control thermostat(auto reset)

LM LIMIT thermostat (manual reset)

EVG1-I° Gas solenoid valve

EVG1-II° Gas solenoid min (two stage)

CCapacitor / centrifual fan

FAN Centrifugal fan

F1-F2 Control fuse

LF Green working light

LL High temperature indication

LB Lockout indication

RST Lockout reset

EF Flue venter

PA Differential pressure switch

IGN1 Ignition transformer

EA1 Ignition electrode

ION Ionisation probe

SE Control panel

RT Relay fan motor

CNT Contactor fan motor

F Line fuse

IMT (*)Fused isolator

MS (*)Fire switch

RSTR (*)Remote reset

TA (*)Room thermostat

VM (*)Fan switch

SF (**)Second stage gas valve connection

(*)External to heater customer supply.

(**)Two stage only, External wiring customer

supply.

Electrical supply

threephase 400V 50Hz 3N

14

Heaters type 5-6

LF

LL

LB

RST

TR

J16

IGN2 EF PA

EA2

SE

NA

COM

J4

J17

J8

NC

IGN1

EA1

ION

J11

J14

J2

J7

VM

RSTR

TA

L3NL1L2

IMT

J10

J9 J12

J1

J13 J18

MS

J15

CNT

F

J6 J5

F2

F1

II° SF

I°

RT

FAN

SND

LM

EVG2-I°

EVG1-I°

EVG2-II°

EVG1-II°

KEY:

SND Temperature control probe

TR Regulatory control thermostat(auto reset)

LM LIMIT thermostat(manual reset)

EVG1-I° Gas solenoid valve 1

EVG2-I° Gas solenoid valve 2

EVG1-II° Gas solenoid min 1. (two stage)

EVG2-II° Gas solenoid min2(two stage)

FAN Centrifugal fan

F1-F2 Control fuse

LF Green working light

LL High temperature indication

LB Lockout indication

RST Lockout reset

EF Flue venter

PA Differential pressure switch

IGN1 Ignition transformer 1

IGN2 Ignition transformer 2

EA1 Ignition electrode 1

EA2 Ignition electrode 2

ION Ionisation probe

SE Control panel

RT Relay fan motor

CNT Contactor fan motor

FLine fuses

IMT (*)Fused isolator

MS (*)Fire switch

RSTR (*)Remote reset

TA (*)Room thermostat

VM (*)Fan switch

SF (**)Second stage gas valve connection

(*)External to heater customer supply.

(**)Two stage only, External wiring customer

supply.

Electrical supply

threephase 400V 50Hz 3N

15

REMOTE CONTROL CONNECTIONS

Remote switchboard with thermostat (Optional) connection scheme

VERSION SINGLE STAGE

VERSION TWO STAGE

DESCTIPTION:

SE Multifunction electronic plate

QCD Remote control switchboard

MS (*)Fire dumper’s switch (if necessary)

(*)Not included in the apparatus, to be supplies and

assembled by the Customer.

READ THE INSTRUCTION MANUAL BEFORE

PROCEEDING WITH THE INSTALLATION.

THIS HEATER IS NEUTRALLY SWITCHED

ENSURE THAT THE WIRING IS CORRECT

TO THE DIAGRAMS PROVIDED.

INCORRECT WIRING WILL DAMAGE THE

ELECTRICAL CONTROL PANEL

16

Remote switchboard with thermostat and timer (Optional) connection scheme

VERSION SINGLE STAGE

VERSIONE BISTADIO

DESCTIPTION:

SE Multifunction electronic plate

QCD Remote control switchboard

MS (*)Fire dumper’s switch (if necessary)

(*)Not included in the apparatus, to be supplies and

assembled by the Customer.

READ THE INSTRUCTION MANUAL BEFORE

PROCEEDING WITH THE INSTALLATION.

THIS HEATER IS NEUTRALLY SWITCHED

ENSURE THAT THE WIRING IS CORRECT TO

THE DIAGRAMS PROVIDED.

INCORRECT WIRING WILL DAMAGE THE

ELECTRICAL CONTROL PANEL

17

OPERATION

To switch ON the heater

• Switch the fused isolator switch ON (supply

customer)

• Switch the heater ON/OFF selector to “ON”

• Turn the thermostat to the desired temperature

• The heater will start automatically

To switch OFF the heater

• Turn the thermostat to its lowest temperature setting

or alternatively switch the heater ON/OFF selector

switch to OFF

• The burner will switch off but the fan will continue to

operate for 3 to 4 minutes to cool the combustion

chamber before stopping

• Finally switch the fused isolator to OFF

To switch ON fan only

• Switch the fused isolator to ON

• Set ON/STANDBY switch to ON

• Set VENT/HEAT switch to VENT position

• The fan only will run

To switch OFF fan

• Set ON/STANDBY switch to STANDBY

Stop

• Turn the selector switch to STOP

IF HEATER IS TO BE SWITCHED OFF FOR A LONG

PERIOD

• Set ON/STANDBY switch to STANDBY

• Isolate at mains electrical supply

• Isolate the gas supply

WARNING! UNLESS IN AN EMERGENCY

Never stop the heater by switching off at the mains

isolator. The residual heat accumulated in the heat

exchanger may trigger the LIMIT safety device

resulting in the need to reset manually.

If this is repeated it will damage the heat exchanger

and will invalidate the warranty on the heater.

VERSION SINGLE STAGE

In the single stage version the heater has a standard maximum heat output and a fixed air flow capacity the heater can

be operated manually via a switch or automatically by a remote thermostat.

VERSION TWO STAGE

In the two stage version the heater has a two stage high low gas valve and can be operated in either high fire or low fire

but with a fixed air flow capacity the heater can be operated manually via a switch or automatically via a remote

thermostat.

SERVICING

• Switch the fused isolator switch ON (supply

• Turn the thermostat to its lowest temperature setting

or alternativly switch the heater ON/OFF

• The burner will switch off but the fan will continue to

operate for 3 to 4 minutes to cool the heater.

WARNING!

It is a requirement that only qualified personnel are

allowed to carry out installation commissioning or

servicing. In addition only spare parts recommended by

the manufacturer may be fitted, and the installer should

provide a list of recommended spare parts that are

available through the manufacturer or his agent.

Before commencing any maintenance or servicing work

the heater must be shut down and allowed to cool, and

have the gas and electric supplies to it turned off at the

supply cock and isolator respectively.

Always test for gas soundness after completing any

service work particularly if this has necessitated

the removal and / or replacement of gas carrying

components

It is advisable that routine inspections are carried out on

a frequent basis, servicing must also be carried out

regularly, and in accordance with the manufacturers

recommendations i.e. at a maximum interval of one

year. In certain applications the frequency of servicing

will have to be increased, this to a large extent is

governed by the working environment, and both the

manufacturer and the installer will be able to offer

further advice.

A safe working platform giving good access to the

heater is required.

Clean all accessible surfaces including the outside of

the heat exchanger by removal of the fan assembly and

the louvres. Check for panel damage and that all

fasteners are present and secure.

Visually check all electrical wiring for signs of damage,

possibly through contact with hot surfaces, check

conduit for signs of chaffing and for security . Check all

terminals are secure and free from escaped / stray

conductor strands

CLEAN EXTERNAL PANELS

This cleaning should only be carried out with damp

cloths with soap and water. In If there are stubborn

stains dampen The cloth with a 50% mixture of water

and white spirit.

After cleaning dry the surfaces carefully.

CLEANING

Filters should be cleaned regularly as required.

18

HEATER INDICATOR LIGHTS

If a fault should occur with the heater the lights situated

at the right hand side of the heater will be illuminated

indicating the fault

• Red Lockout indication (1).

This will be illuminated if the heater has gone to

lockout due to the loss of flame sensing by the flame

probe situated in the burner assembly in order to reset

the heater the RESET Button (2) should be pressed (if

fitted with remote controls the remote reset button will

reset this switch).

• Yellow overheat indication (3).

This will be illuminated if the heater has exceeded the

temperature set on the thermostat. The thermostat will

shut down the burner until the fan(s) have cooled the

chamber sufficiently and the burner will re light.

If the yellow light is flashing this means that the heater

has gone to overheat and the LIMIT thermostat has

operated and shut down the burner The heater will not

re light until the LIMIT (4) has been reset this can be

done by removing the plastic cap covering the reset

button and pushing the reset replace cap

The cause of the overheat should be investigated

RECEIPT OF PRODUCT AND TRANSPORT

Delivery & pre installation checks

The heater is supplied wrapped in heavy duty

protective polythene, mounted on a pallet. On receipt

of the heater, the following checks should be carried

out:

a) The model is as per order

b) That it is undamaged

c) That it is suitable for the gas supply and pressure

d) That it is suitable for the electrical supply

If any of these points are not satisfied then contact

should be made with the Manufacturer. In the case

of claims for damage this must be reported in

writing within 24Hrs of delivery, in order to comply

with insurance criteria

WARNING

The instruction manual is an integral part of the

equipment and so, after the packaging has been

removed, make sure that it has been collected and

stored safety.

When moving the heater ensure that the

equipment used is capable of lifting and

supporting the weight of the heater

When lifting by fork truck ensure that the

forks support the weight

20

DIMENSION AND WEIGHT

Type 1 – 2 – 3 – 4

Type 1 2 3 4

A [mm] 665 745 925 1170

B [mm] 745 745 745 793

C [mm] 435 515 695 940

D [mm] 563 563 555 510

E [mm] 140 140 140 185

F [mm] 132 132 132 115

G [mm] 132 132 132 132

H [mm] 710 791 971 1216

J [mm] 335 415 595 840

K [mm] 910 910 910 960

L [mm] 1225 1225 1225 1273

∅1 [mm] 100 (1) 100

(1) 100

(1) 100

(2)

∅2 [mm] 100 (1) 100

(1) 100

(1) 150

(2)

∅[inch] ½ ½ ½ ¾

Nett weight [kg] 122 133 156 200

(1) female

(2) male

Note: heater type 5 is equipped with 2 centrifugal fans.

19

20

Type – 5 – 6

Type 5 6

A [mm] 1720 1960

C [mm] 1300 1540

H [mm] 1644 1885

J [mm] 1200 1440

∅[inch] ¾ ¾

Nett weight [kg] 267 311

20

male

male

This manual suits for next models

23

Table of contents

Other BM2 BIEMMEDUE Gas Heater manuals

Popular Gas Heater manuals by other brands

Qlima

Qlima GH 438 B-2 Directions for use

Qlima

Qlima GH 142 RV Directions for use

Heatmaster

Heatmaster ENVIRO Operating information & installation instructions

Rinnai

Rinnai brivis StarPro SP4UN installation manual

Clarke

Clarke 900DV User instructions

FMI

FMI MF42INR OWNER'S OPERATION AND INSTALLATION MANUAL