8| English

1 609 92A 1VD | (22.8.16) Bosch Power Tools

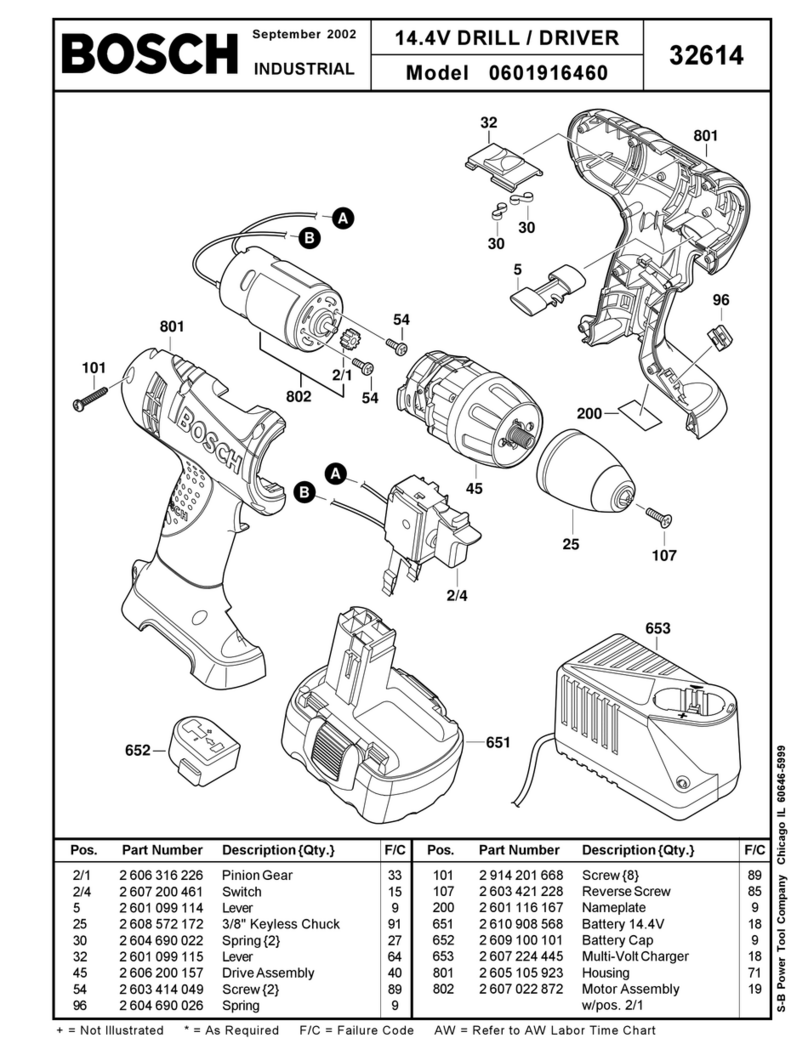

To mount the key type drill chuck 1turn the nut on the drive

spindle in clockwise direction to the stop. Place the key type

drillchuckwithoutforceontothe drivespindleuntilitis tightly

seated. Apply light blows with a rubber hammer onto the face

side of the key type drill chuck 1to ensure tight seating of the

chuck. Pay attention that the clamping jaws of the keytype

drill chuck do not project, in order not to damage them.

Mounting the securing screw

Screw the securing screw 10 anticlockwise into the open key

chuck. Always use a new securing screw, as their thread is ap-

plied with a securing adhesive substance, which is rendered

ineffective after several uses.

Dust/Chip Extraction

Dusts from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful to

one’s health. Touching or breathing-in the dusts can cause

allergic reactions and/or lead to respiratory infections of

the user or bystanders.

Certain dusts, such as oak or beech dust, are considered

as carcinogenic, especially in connection with wood-treat-

ment additives (chromate, wood preservative). Materials

containing asbestos may only be worked by specialists.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the mate-

rials to be worked.

Prevent dust accumulation at the workplace. Dusts can

easily ignite.

Operation

Starting Operation

Observe correct mains voltage! The voltage of the pow-

er source must agree with the voltage specified on the

nameplate of the machine. Power tools marked with

230 V can also be operated with 220 V.

Reversing the rotational direction (see figure D)

The rotational direction switch 7is used to reverse the rota-

tional direction of the machine. However, this is not possible

with the On/Off switch 6actuated.

Right rotation: For drilling and mixing, push the rotational di-

rection switch 7to the left until it stops.

Left rotation: For loosening or mixing, push the rotational di-

rection switch 7to the right until it stops.

Switching On and Off

To start the machine, press the On/Off switch 6and keep it

pressed.

Tolockthe pressedOn/Offswitch 6, pressthelock-onbutton

5.

To switch off the machine, release the On/Off switch 6or

when it is locked with the lock-on button 5, briefly press the

On/Off switch 6and then release it.

Adjusting the Speed

The speed of the switched-on power tool can be variably ad-

justed, depending on how far the On/Off switch 6is pressed.

Light pressure on the On/Offswitch 6resultsin a low rotation-

al speed. Further pressure on the switch results in an increase

in speed.

Work Instructions for Drilling

Use drilling lubricant or cutting oil for cooling and lubrication,

and to avoid overheating or jamming of the drill bit.

Whendrillingdiameters>10 mm,drillapilothole witha small

drilling diameter. This allows you to reduce the feed pressure

and the power tool is strained less.

For drilling in metal, use only perfectly sharpened HSS drill

bits (HSS=high-speed steel). The appropriate quality is guar-

anteed by the Bosch accessories program.

The machine vice, which is available as an accessory, enables

secure clamping of workpieces. This prevents the workpiece

from turning and any accidents this would cause.

Work Instructions for Mixing

Do not use the power tool in a stand.

Avoid splashing around the material being stirred. Oth-

erwise, you could slip and lose control over the power tool.

Avoid continuous operation of the power tool at re-

ducedspeed. Otherwisethemotorof the power toolcould

overheat.

To release the lock-on button 5, briefly press the on/off

switch 6and then let it go. This will prevent the power tool

from restarting unintentionally (risk of injury).

Selection of the stirrer paddle is dependent on the material

that is to be stirred.

For materials with low viscosity, e. g. emulsion paint, varnish-

es, adhesive, grouting compound, cement slurry, use a stirrer

paddle with a left-hand spiral. The material is moved from the

top downwards in a stirrer paddle with a left-hand spiral. The

stirrer paddle ispushed upwards. Materialswith lowviscosity

are mixed in a way which minimises splattering.

For materials with high viscosity, e. g. plaster, concrete, ce-

ment, screed, filler, epoxy resin, use a stirrer paddle with

right-hand spiral. The material is moved from the bottom up-

wards in a stirrer paddle with a right-hand spiral. The stirrer

paddle works its way into the mixture. Materials with high vis-

cosity are mixed thoroughly.

While mixing, move the power tool in an up and down motion.

Clean the stirror paddle after use.

Store the power tool in a safe place. Ensure that it can-

not fall over. Otherwise, the machine may become dam-

aged.

Maintenance and Service

Maintenance and Cleaning

Before any work on the machine itself, pull the mains

plug.

OBJ_BUCH-2233-004.book Page 8 Monday, August 22, 2016 3:47 PM