BOSSCO SNR24023 User manual

FormNo.MSC25235RevA

Owner'sManual

V-BladePlowKit

SnowratorMAG

PartNo.SNR24023—SerialNo.400000000andUp

Registeratwww.bossplow.com.

OriginalInstructions(EN)*MSC25235*

BOSSProductslimitedconsumerwarrantyandBOSS

Productscommercialwarrantypoliciesarelocatedat

www.bossplow.com.

Patentswww.ttcopats.com.

Introduction

Note:ThisplowattachestotheSnowratorMAG.

TheV-bladeplowisintendedtobeusedonaBoss

stand-on,multi-purposemachine.Thebladeis

designedtohydraulicallychangeitsangleasneeded

forsnowremoval.Usingthisproductforpurposes

otherthanitsintendedusecouldprovedangerousto

youandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.bossplow.comforproductsafetyand

operationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineBOSSparts,or

additionalinformation,contactanAuthorizedBOSS

DealerorBOSST echnicalService(1-800-286-4155)

andhavethemodelandserialnumbersofyour

productready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethe

numbersinthespaceprovided.

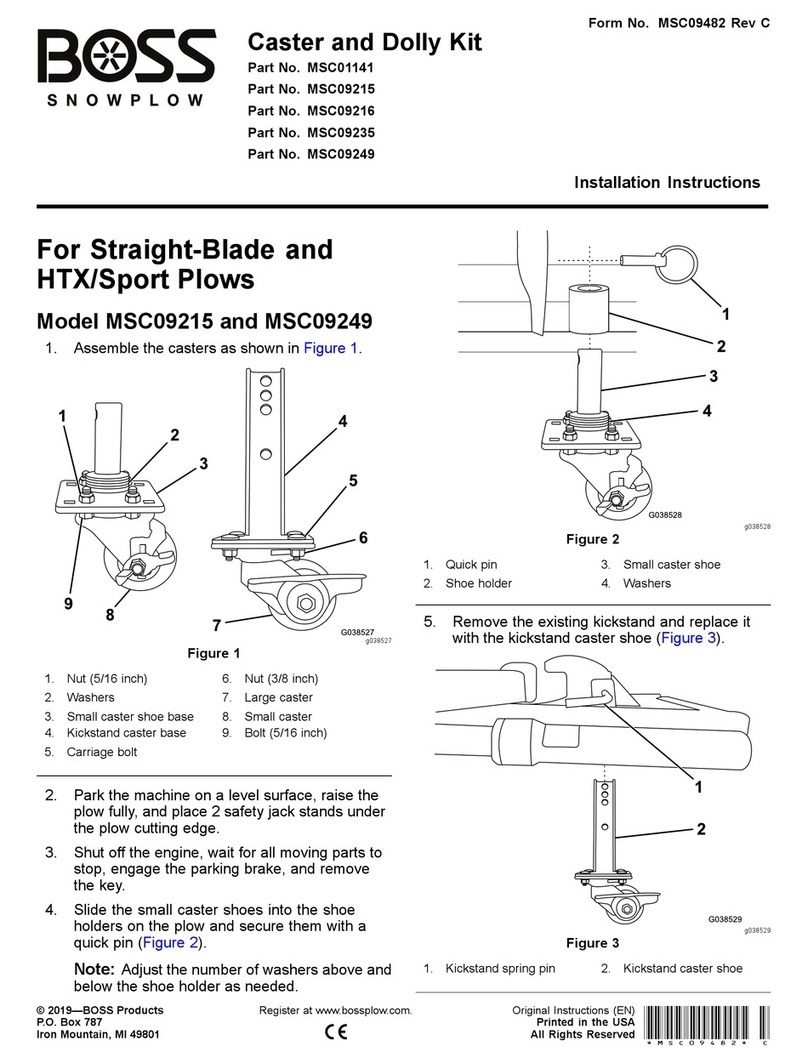

g373489

Figure1

1.Modelandserialnumberlocation

Date

Purchased

ModelNo.

SerialNo.

BladeCrate

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2022—BOSSProducts

P .O.Box787

IronMountain,MI498012

Contactusatwww.bossplow.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................3

Preparation.........................................................3

Operation............................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................5

MountingthePlow..............................................5

ProductOverview.....................................................6

Controls.............................................................6

Operation..................................................................8

MountingthePlow..............................................8

RemovingthePlow.............................................8

OperatingTips...................................................8

Maintenance.............................................................9

RecommendedMaintenanceSchedule(s).............9

...........................................................................9

Maintenance..........................................................9

ReplacingtheCuttingEdge....................................9

Storage...................................................................10

StoringthePlow...............................................10

RemovingthePlowfromStorage......................10

Troubleshooting.......................................................11

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alert

symbol,whichmeans:Caution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

Preparation

•ReadtheOwner’sManualbeforeoperatingor

servicingtheplow.

•Ensurethatonlytrainedpersonnelinstallsand

performsmaintenanceontheequipmentand

hydrauliccomponents.

•Alwayswearappropriatepersonalprotective

equipmentwhenloading,unloading,andservicing

theplow.

Operation

•Usea500kg(1/2ton)minimumliftingdeviceto

moveheavyplowcomponents.

•Donotexceed8km/h(5mph)whileoperating.

•Neverputanypartofyourbodybetweentheplow

andthevehicle.

•Wearappropriateclothing,includinghearingand

eyeprotection,protectivegloves,andsubstantial,

slip-resistantfootwear.Tiebacklonghair,secure

looseclothing,anddonotwearloosejewelry.

•Whentransportingtheplow,ensurethatitis

properlysecured.Instructionsareavailableat

www.bossplow.com.

•Whentransportingthevehicle,positiontheplow

soasnottoblockyourvisionorheadlights.

•Donotchangethebladepositionwhentraveling.

•Alwayslowerthebladewhenthevehicleisnotin

use.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•RefertotheOwner’sManualforproperparking

procedures.

•Turnthevehicleandplowoffbeforelling,

servicing,orcleaningit.

•Donotclimbintoorrideontheplow.

•Keepyourhands,feet,andclothingawayfrom

movingpartsandmountingpoints.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

3

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatetheplowwithin8m(25ft)of

bystanders.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

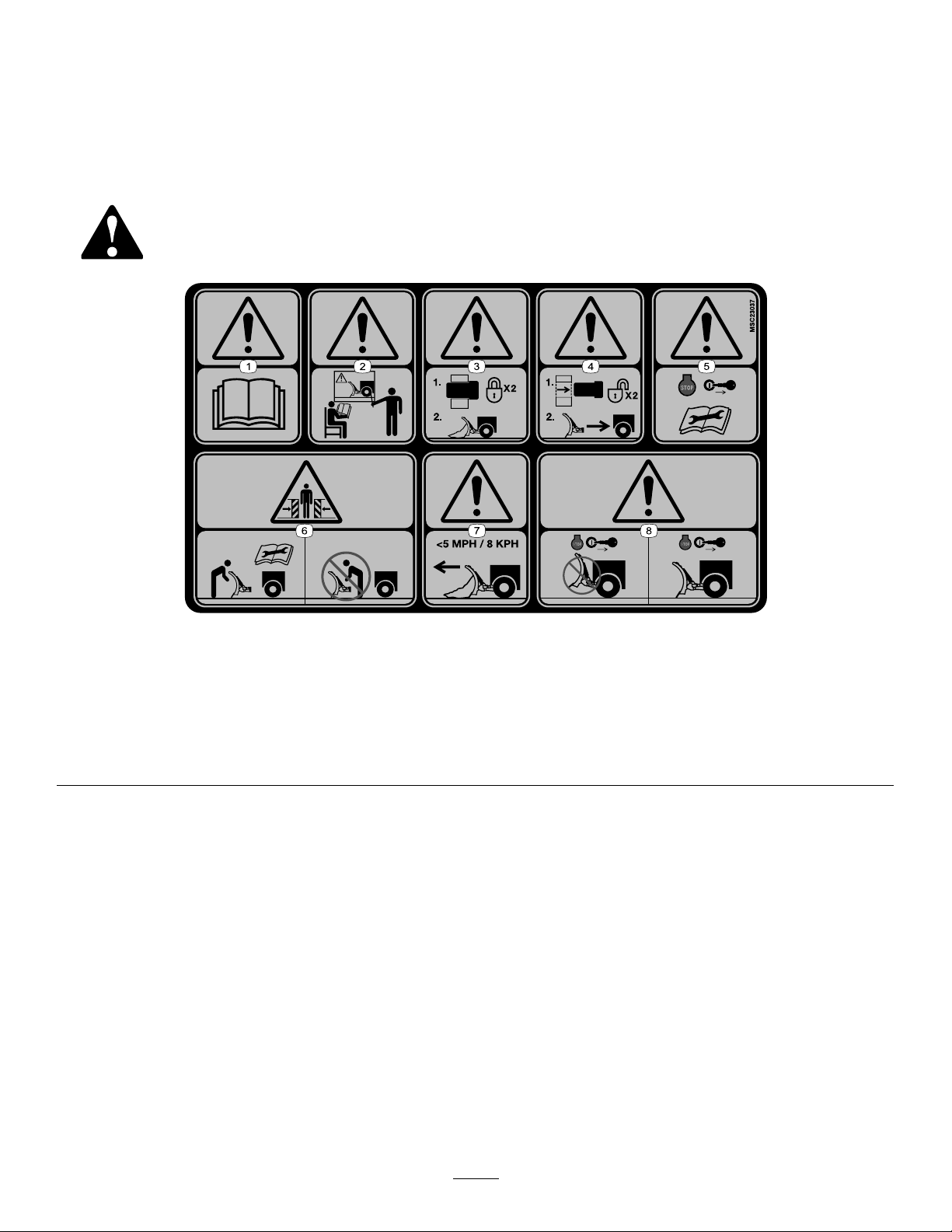

decalmsc23037

MSC23037

1.Warning—readtheOwner’sManual.5.Warning—shutofftheengine,removethekey,andreadthe

Owner’sManualbeforeperformingmaintenance.

2.Warning—alloperatorsshouldbetrainedbeforeoperating

themachine.

6.Crushinghazard—donotstandbetweentheplowandvehicle

duringmaintenance.

3.Warning—couplermustbelockedbeforeplowing.7.Warning—donotexceed8km/h(5mph)whenplowing.

4.Warning—couplermustbeunlockedtoremovetheplow.8.Warning—lowertheplowwhenthevehicleisnotinuse.

4

Setup

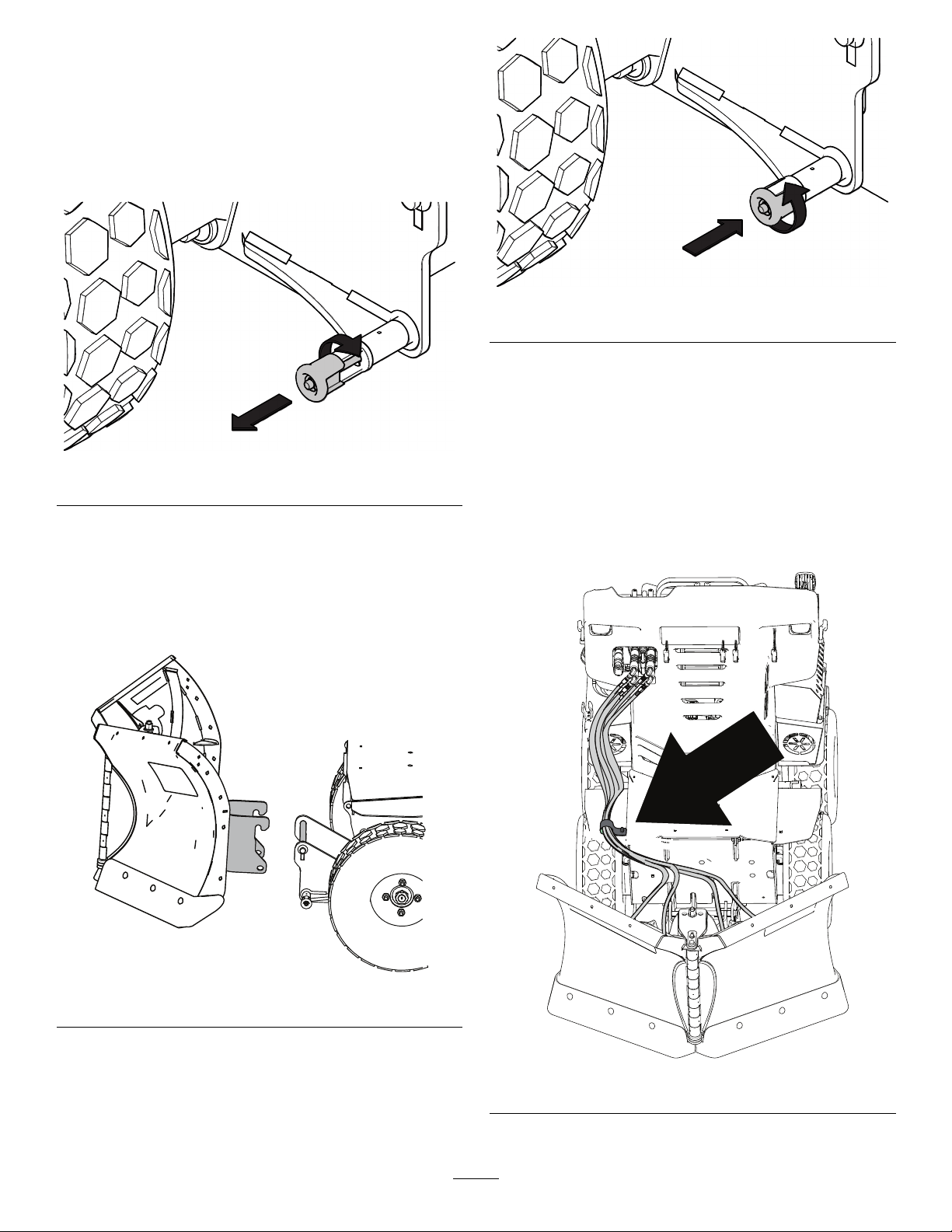

MountingthePlow

1.Parkthemachineonalevelsurface.

2.Pullthecouplerpinsoutwardandrotate90°to

lockinthedisengagedposition.

g373475

Figure3

3.Makesurethatthehydraulichosesdonotblock

theplowattachmentpoint.

4.Startthemachine.

5.Slowlydriveforwarduntilthecouplermeetsthe

plowhooks.Raisethecouplertohookitonto

theplow.

g381690

Figure4

6.Rotatethecouplerpin90°sothatitengages

withtheplowassembly.

Note:Ensurethatthecouplerpinalsoinserts

throughtheholeinthepinchannelontheplow

coupler.

g373477

Figure5

7.Lowertheattachmentcoupleruntiltheplow

restsontheground.

8.Shutoffthemachineengine,waitforallmoving

partstostop,ensurethattheparkingbrakeis

engaged,andremovethekey.

9.Routethehydraulichosesfromtheplow,

throughthehosestrap,totheconnectionson

themachine

Note:Theleftlowowhosesarecoloredyellow

andconnecttothecenterports.

g381686

Figure6

10.Startthemachine.

5

11.Usethecontrolstomovetheplowinall

directionstocyclethehydraulicuid.

12.Lowertheplowandshutoffthemachine.

13.Checkandllthehydraulicuid;refertothe

machineOwnersManual.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.

•Ifhydraulicuidisinjectedintothe

skin,itmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliar

withthistypeofinjury.Gangrenemay

resultifthisisnotdone.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertond

hydraulicleaks.

•Safelyrelieveallpressureinthe

hydraulicsystembeforeperforming

anyworkonthehydraulicsystem.

•Makesurethatallhydraulic-uid

hosesareingoodcondition,and

allthatthehydraulicconnections

andttingsaretightbeforeapplying

pressuretothehydraulicsystem.

ProductOverview

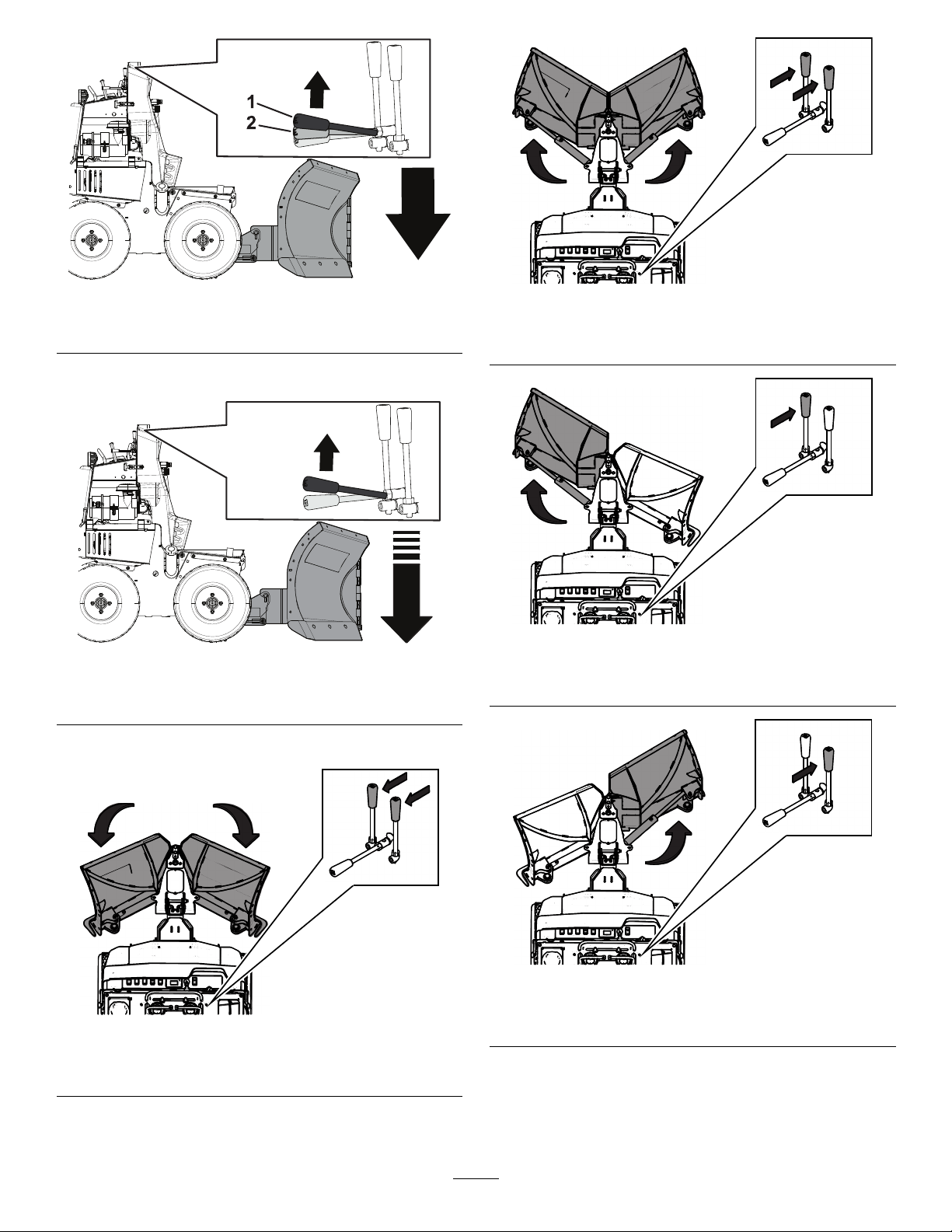

Controls

g381687

Figure7

1.Anglelevers2.Attachmentcouplerlever

•Usetheattachmentcouplerlevertoraise,lower,

oroattheplow.

g381689

Figure8

6

g381688

Figure9

1.Float2.Lower

Note:Donotplowforwardindownforce.

g381948

Figure10

DownForce

•Usetheangleleverstoangletheplowblades.

g373490

Figure11

Vposition

g373488

Figure12

Scoopposition

g373487

Figure13

Rightangle

g373483

Figure14

Leftangle

7

Operation

MountingthePlow

RefertotheMountingthePlow(page5)section

above.

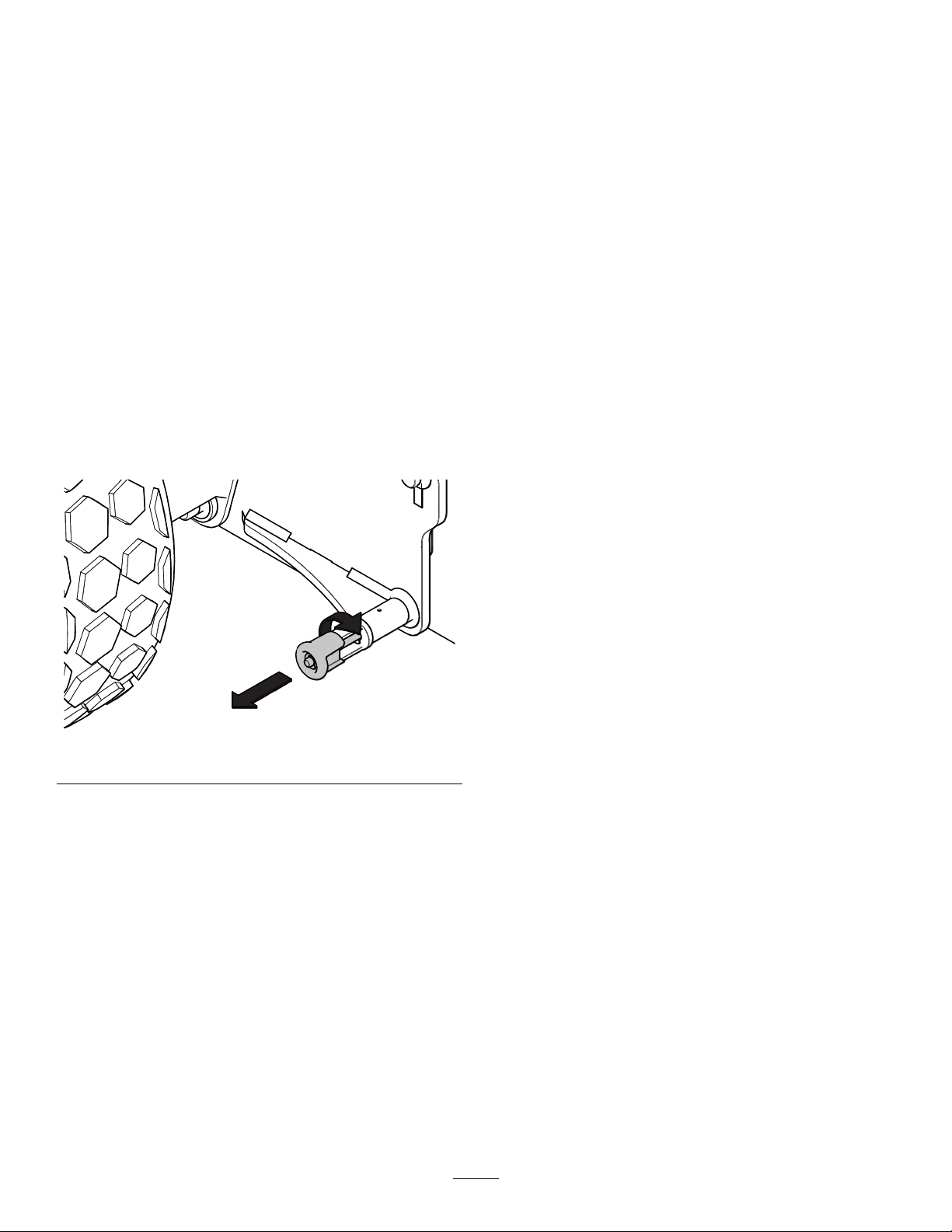

RemovingthePlow

1.Stopmachineonalevelsurface.

2.PlacetheplowintheVposition

3.Lowertheplowuntilthecuttingedgeis2.5to5

cm(1to2inches)fromtheground.

4.Shutofftheengine,waitforallmovingpartsto

stop,engagetheparkingbrake,andremove

thekey.

5.Disconnectthehydraulics.

6.Pullthecouplerpinsandturnit90°untiltheplow

isdisconnectedfromthemachine.

g373484

Figure15

7.Startmachine,lowerattachmentcoupler,and

slowlybackawayfromplow.

8.Arrangethehydraulichosesanddisconnectsso

thattheyarenotrestingontheground.

OperatingTips

•Becomefamiliarwiththeareayouareplowing;

hiddenobstructionssuchascurbsandpipescan

damageyourplowormachine.

•Donotletsnowaccumulate;alwaysplowwiththe

storm.

•Lowertheplowwhennotinusetopreventpossible

injury.

•Alwaysplowatasafespeedincaseyouhithidden

obstructions.

•Whentransportingthemachine,donotblockyour

visionwiththeplow.

•Donotchangetheplowpositionwhileplowing.

•Ensurethatthekickstandisraisedbeforeplowing

topreventdamagetotheplowormachine.

•Formoreplowingtips,visitwww.bossplow.com.

8

Maintenance

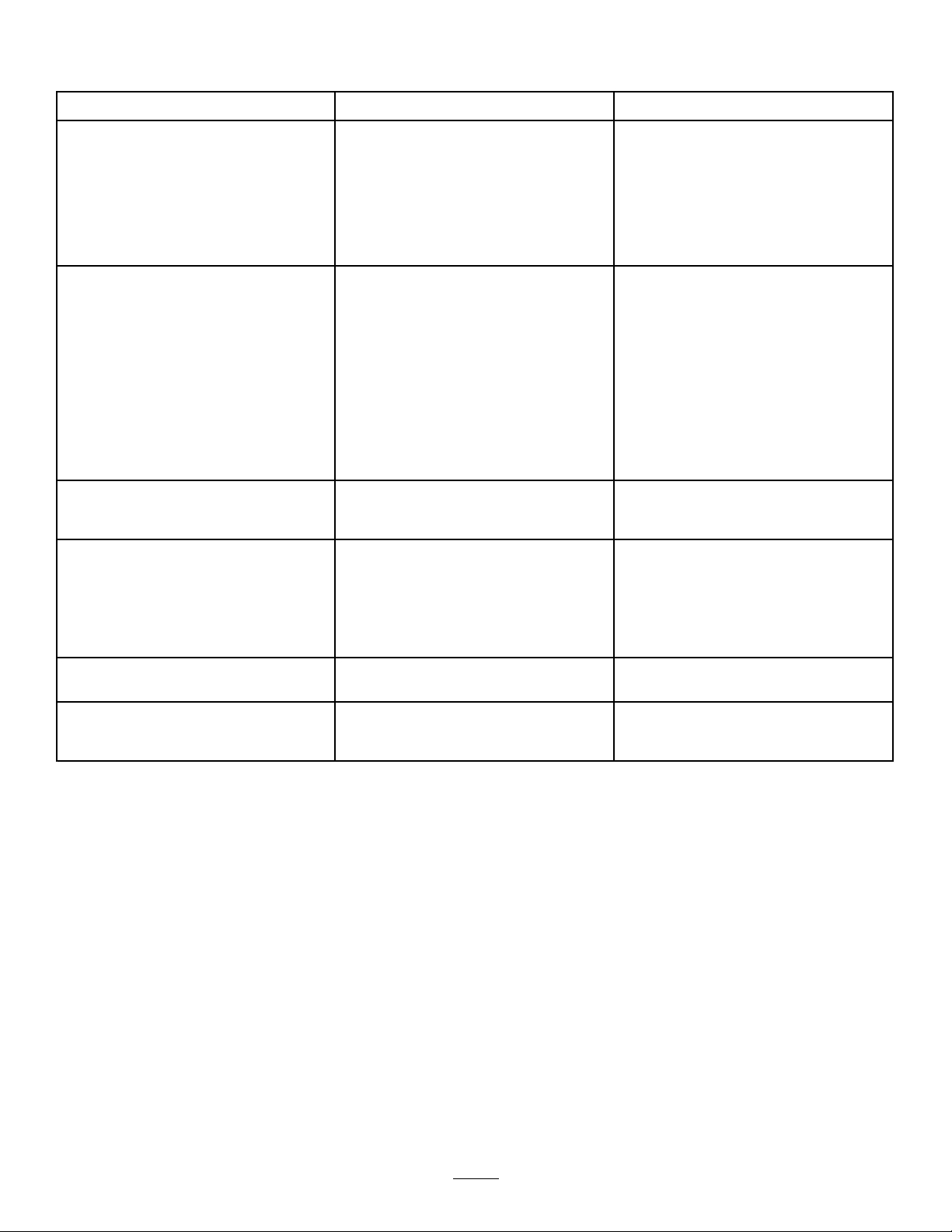

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst2hours•Tightenallhardware.

Beforeeachuseordaily

•Checkthehydrauliccylinders.

•Checkthehydrauliclinesandhoses.

•Checkallfasteners,pins,retainers,nuts,andbolts.

•Checkthecuttingedgeforwear.

Beforestorage

•Lightlysandandusetouch-uppaintonpaintedareasthatarescratched,chipped,

orrusted.

•Greasethehydrauliccylinderrods.

•Lightlysandandusetouch-uppaintonpaintedareasthatarescratched,chipped,

orrusted.

Maintenance

•Checkthehydrauliclinesandhosesdailyfor

leaks,kinkedlines,loosemountingsupports,wear,

loosettings,weatherdeterioration,andchemical

deterioration.Makeallnecessaryrepairsbefore

operating.

•Checkthehydrauliccylindersdailyforleaks,rust,

orpittingontherods.Makeallnecessaryrepairs

beforeoperating.

•Checkthecuttingedgedailyforwear.Replacethe

cuttingedgeifitisworndown.

•Checkallfasteners,pins,retainers,nuts,andbolts

dailytoensurethattheyaresecure.T orquethem

totheappropriatevalueiftheyareloose.

ReplacingtheCutting

Edge

Note:Replacementhardwareisavailablethroughan

AuthorizedBossDealerorBossTechnicalService.

1.Removeanddiscardthe3nutsand3washers

holdingthecuttingedgetotheblade.

g373480

Figure16

2.Removeanddiscardthe3carriageboltsand

cuttingedge.

9

g373481

Figure17

3.Installnewcuttingedgewithnewhardware.

Torqueto101N·m(75ft-lbs).

Storage

StoringthePlow

1.Drivetheplowtoyourstoragelocationand

removetheplow;refertoyourmachine

Operator’sManual.

2.Greaseanyexposedmetalonthehydraulic

cylinderrods.

3.Lightlysandandusetouch-uppaintonpainted

areasthatarescratched,chipped,orrusted.

RemovingthePlowfrom

Storage

1.Checkthetorqueofallfasteners;tightenas

necessary.

2.Checkthehydrauliclinesandhosesforcracks

orleaks.

3.Checkthecuttingedgeforwear.

4.Lightlysandandusetouch-uppaintonpainted

areasthatarescratched,chipped,orrusted.

5.Attachtheplowtothemachine;refertoyour

machineOperator’sManual.

6.Movetheplowthroughitsrangeofmotionto

checkthehydrauliccylinderrods.

10

Troubleshooting

ProblemPossibleCauseCorrectiveAction

1.Acylinderorhoseisbad.1.Checkthecylinders,hoses,andall

ttingsforleaks.Tightenanyloose

connections.Replaceanydamaged

components.

Theplowwingsretractwhileplowing.

2.Thepressurereliefvalveisbad.2.Checkthepressurereliefvalve,

locatedontheSnowratorMAGtraction

unit.Ifthevalveiscontaminated,clean

orreplaceit.

1.Thehydraulicuidlevelislow.1.Checkthehydraulicuidlevel;referto

yourSnowratorMAGOwner'sManual.

2.Thepressurereliefvalveisbad2.Checkthepressurereliefvalve,

locatedontheSnowratorMAGtraction

unit.Ifthevalveiscontaminated,clear

orreplaceit.

3.Acylinderorhoseisbad.3.Checkthecylinders,hoses,andall

ttingsforleaks.Tightenanyloose

connections.Replaceanydamaged

components.

Theplowwing(s)donotextend,retract,

ortheymoveslowly.

4.Thehydrauliccouplingsarenot

attachedtothevehicle.

4.Connecttheplowhydraulicstothe

vehiclehydraulics.

Theleftwingextends/retractswhenthe

rightcontrolleverisactuated,orvice

versa.

1.Thehosesareconnectedtothewrong

controlvalves.

1.Disconnectthehosesandconnect

themtothecorrectcontrolvalves.

1.Ahoseisbad.1.Checkhosesforleaks.Tightenany

looseconnections.Replaceany

damagedcomponents.

2.Acylinderisbad.2.Replacethecylinder.

Oilleaksfromthehydrauliccylinders.

3.Thecylinderrodispitted.3.Polishtherodwithsteelwool.Replace

thecylinderisthepittingistoobad.

Thebladetripstooeasily.1.Thetrip-springsneedadjustment.1.Tightenthesprings.Replacethemif

theyaredamaged.

Theplowdoesnotfollowthecontourof

theground.

1.Theattachmentcouplerleverisnotin

theoatposition.

1.Ensurethattheattachmentcoupler

leverisintheoatpositionwhile

plowing.

11

Table of contents

Other BOSSCO Snow Blower Accessories manuals