TECHNICAL HANDBOOK

Index

SPECIFICATIONS ...........................................1

BS 50 Sport ................................................1

BS 60 Sport ................................................1

90 cc ......................................................3

175 Dual Twin .............................................5

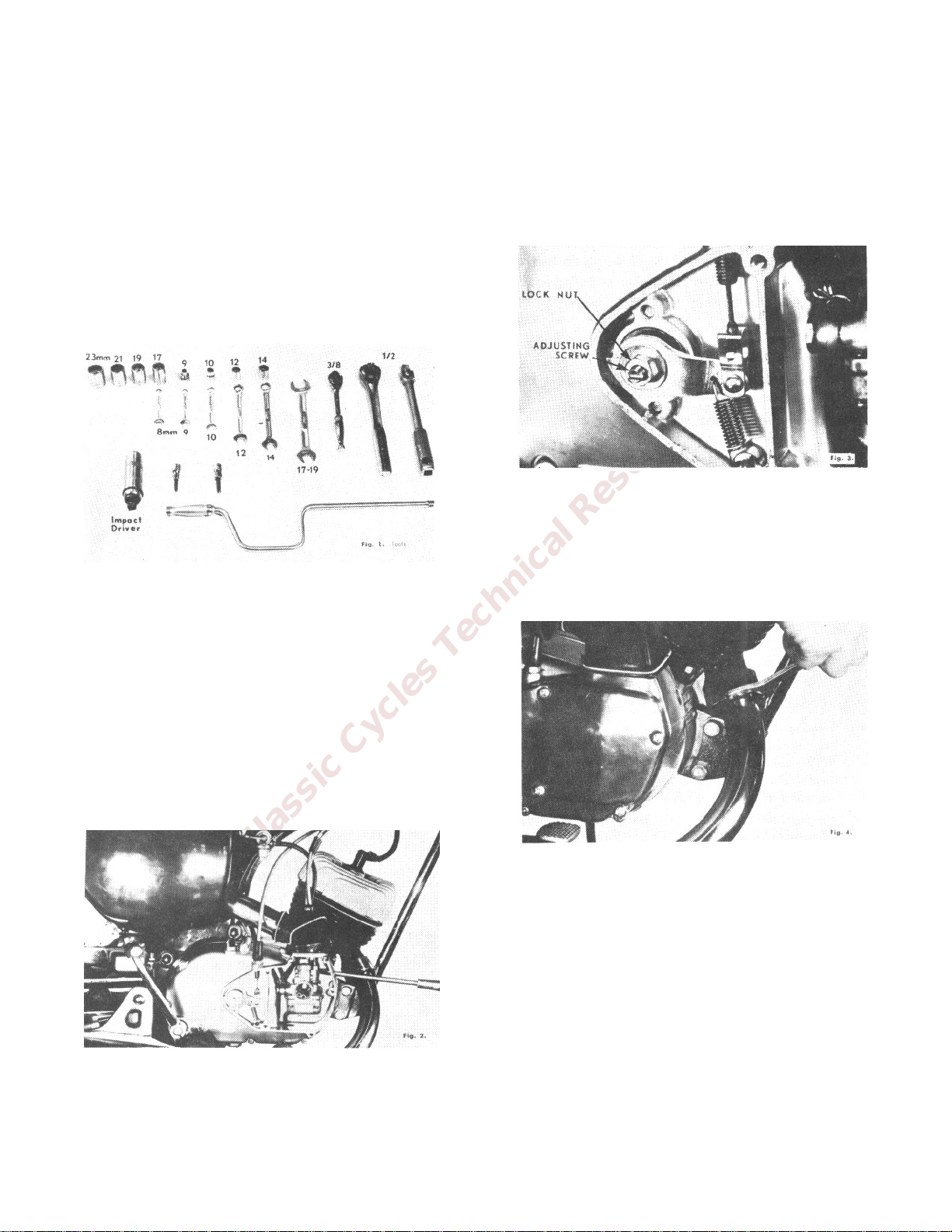

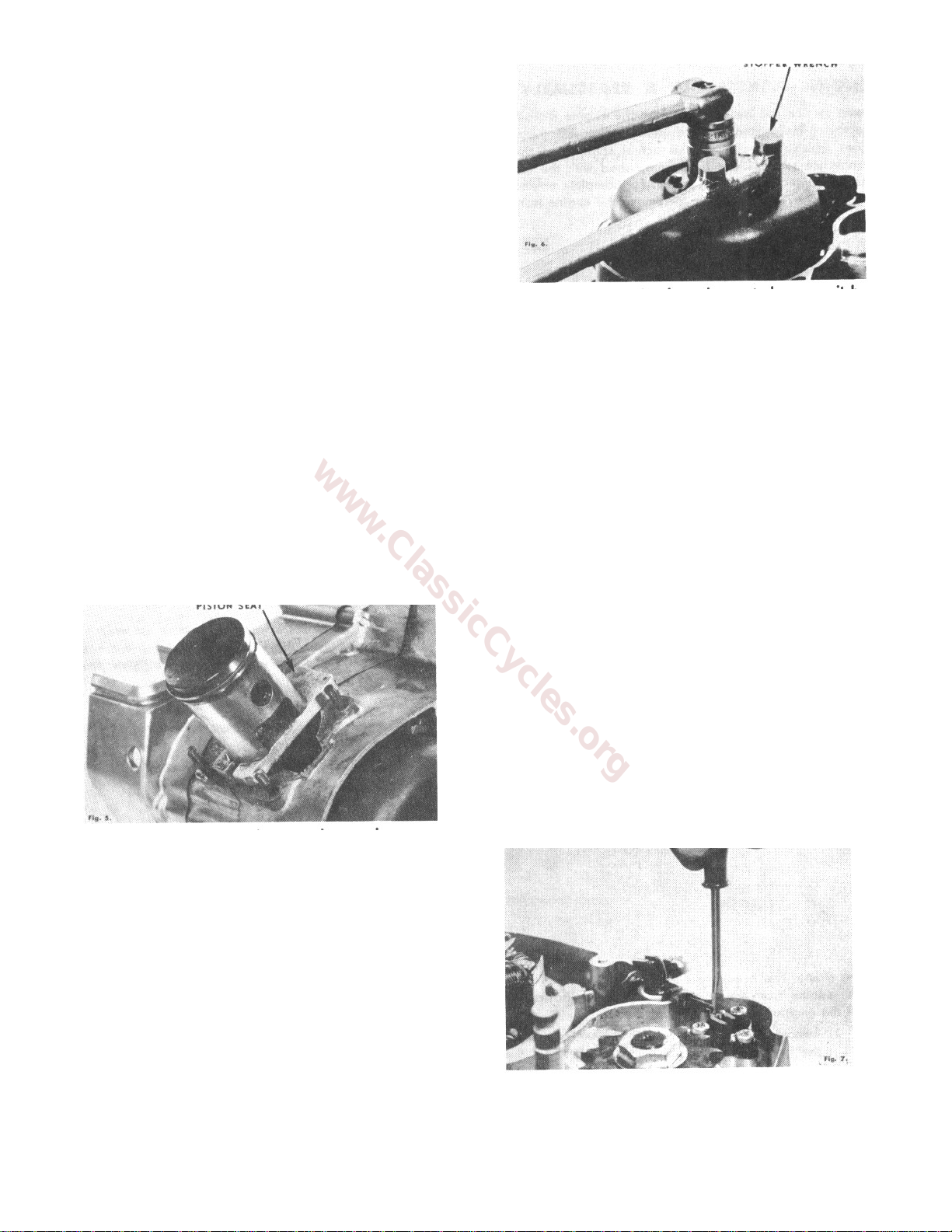

I. ENGINE DISASSEMBLY & REASSEMBLY ..................7

50 Sport, 60 Sport and 90cc models ...........................7

II. REASSEMBLY ........................................12

175 DT ...................................................15

II. ENGINE DISASSEMBLY ...............................16

III. ENGINE REASSEMBLY ..............................19

IV. INSTALLING ENGINE INTO FRAME ..................24

CYLINDERS AND PISTONS .................................26

A. Construction and Operation: .............................26

CRANKSHAFT AND ROTARY DISC VALVES ................27

A. Construction and Operation .............................27

B. Rotary Valve Modification ...............................28

50-60 SPORT, 90 & 90 SPORT ...........................28

175 DUAL TWIN .......................................29

KICK STARTER MECHANISM ..............................29

Construction and Operation ................................29

CLUTCH ...................................................31

A. Construction ...........................................31

B. Operation ..............................................32

C. Adjustment ............................................32

TRANSMISSION ............................................34

A. Construction and Operation .............................34

B. Gear Shift Mechanism ...................................35

C. Gear Shift Operation ....................................37

D. Gear Ratios ............................................41

CARBURETOR .............................................42

A. Construction and Operation .............................42

B. Functions of Various Parts ...............................44

C. Adjustment ............................................45

TO ADJUST FLOAT LEVEL: ............................46

OIL INJECTION SYSTEM – 90cc .............................47

A. Construction and Operation .............................47

B. Adjustment ............................................48

C. Special Attention to the Oil Injection System ..............49

OIL INJECTION SYSTEM – 175DT ..........................50

A. Construction and Operation .............................50

B. Adjustment ............................................51

C. Special Attention — Pump Modification ...................52

ELECTRICAL EQUIPMENT – 50, 60 Sport, 90cc ...........53

A. Ignition System ........................................53

Contact Breaker ........................................53

Ignition Timing .........................................53

TO SET TIMING .....................................53

Condenser .............................................54

Spark Plug .............................................54

B. Testing the Ignition Coil ................................55

C. Technical Standards ....................................55

D. Lighting System ........................................55

E. Testing the Lighting Coil ................................56

F. Selenium Rectifier ......................................56

G. Battery Charging (50-60 Spt) ............................56

ELECTRICAL EQUIPMENT – 175 DT .......................57

Contact Breakers .......................................57

Ignition timing .........................................57

TO CHECK TIMING - RIGHT CYLINDER ...............57

RIGHT CYLINDER TIMING ADJUSTMENT .............58

TO CHECK TIMING-LEFT CYLINDER ..................58

LEFT CYLINDER TIMING ADJUSTMENT ..............58

B. Ignition Coils ...........................................58

C. Technical Standards ....................................59

D. Generator ..............................................59

E. Selenium Rectifier ......................................60

F. Battery ................................................60

G. Headlight ..............................................60

H. Spark plugs ............................................60

Dry Charged Storage Batteries ...............................61

FRONT FORK .............................................63

Operation ................................................63

Maintenance ..............................................63

Assembling Front Fork ....................................63

REAR SUSPENSION .......................................64

FRONT WHEEL ...........................................65

Removing Front Wheel ....................................65

Adjusting Front Brake .....................................65

REAR WHEEL ..............................................66

Removing Rear Wheel .....................................66

Adjusting Rear Brake .....................................67

PRE-DELIVERY SERVICE .................................68

B/S 90 w/Oil Injection ......................................68

175 DT ...................................................69

TROUBLESHOOTING: ENGINE ...........................71

I. PRELIMINARY CHECK ................................71

II. SPARK PLUG .........................................71

III. ENGINE OVERHEATING .............................74

TROUBLESHOOTING: TRANSMISSION ...................75

I. MISSED GEARS ........................................75

TROUBLESHOOTING: ELECTRICAL ......................76

50, 60 Spt; 90cc ............................................76

I. KEY SWITCH ........................................76

II. CHARGING SYSTEM ................................76

III. BRAKE LIGHT SWITCH ............................76

IV. HEAD LIGHT .......................................77

V. HORN CIRCUIT .....................................77

VI. SELENIUM RECTIFIER ............................77

175 DT ...................................................77

ALL MODELS ............................................78

INSPECTION AND MAINTENANCE .......................79

SERVICE STANDARDS ....................................80

APPENDIX .................................................81

USEFUL FORMULAS AND TABLES .....................81

CONVERSIONS ........................................82

EXAMPLES OF CONVERSIONS ........................83

TEMPERATURE .......................................83

PISTON DISPLACEMENT ..............................83

COMPRESSION RATIO ................................84

HORSEPOWER AND TORQUE .........................85

PISTON SPEED ........................................85

GEAR RATIO ..........................................86

BOLT TORQUE ........................................87