4. If you touch ungrounded objects (recharge your body with

static electricity), firmly touch furnace again before touch-

ing control or wires.

5. Use this procedure for installed and uninstalled (un-

grounded) furnaces.

6. Before removing a new control from its container, dis-

charge your body’s electrostatic charge to ground to protect

the control from damage. If the control is to be installed in

a furnace, follow items 1 through 5 before bringing the

control or yourself into contact with the furnace. Put all

used AND new controls into containers before touching

ungrounded objects.

7. An ESD service kit (available from commercial sources)

may also be used to prevent ESD damage.

INTRODUCTION

The model 330AAV Series B or C Furnace is available in sizes

40,000 through 133,000 Btuh input capacities.

The design of the upflow gas-fired furnace is CSA (A.G.A. and

C.G.A.) design-certified for use with natural and propane gases

and for installation on combustible wood flooring, in alcoves,

attics, basements, closets, or utility rooms. The design of this

furnace line is not CSA (A.G.A. and C.G.A.) design-certified for

installation in mobile homes, recreation vehicles, or outdoors.

Before installing the furnace in the United States, refer to the

current edition of the NFGC/NFPA 54/Z223.1 and the NFPA 90B.

For further information, the NFGC/NFPA 54/Z223.1 and NFPA

90B are available from National Fire Protection Association Inc.,

Batterymarch Park, Quincy, MA 02269; or American Gas Asso-

ciation, 1515 Wilson Boulevard, Arlington, VA 22209.

Before installing the furnace in Canada, refer to the current edition

of the NSCNGPIC. Contact Standard Sales CSA International

Approval Services of Canada, 178 Rexdale Boulevard, Etobicoke,

(Tronto) Ontario, Canada M9W 1R3.

Canadian installations must be made in accordance with NSCNG-

PIC and all authorities having jurisdiction.

Installation must comply with regulations of serving gas supplier

and local building, heating, plumbing or other codes in effect in the

area in which installation is made. In absence of local codes,

installation must conform with NFGC.

These instructions cover minimum requirements for a safe instal-

lation and conform to existing national standards and safety codes.

In some instances, these instructions exceed certain local codes

and ordinances, especially those that may not have kept pace with

changing residential construction practices. We require these

instructions as a minimum for a safe installation

CAUTION: Application of this furnace should be in-

doors with special attention given to vent sizing and

material, gas input rate, air temperature rise, and unit

sizing. Improper installation or misapplication of the

furnace can require excessive servicing or cause prema-

ture component failure.

To aid in installation, troubleshooting, and service, a status code

label is located on the blower compartment door. This label

explains how to use the LED status indicator on the furnace control

which is viewed through the sight glass on the door.

WARNING: Improper installation, adjustment, alter-

ation, service, maintenance, or use can cause carbon

monoxide poisoning, explosion, fire, electrical shock, or

other conditions which may cause personal injury or

property damage. Consult a qualified installer, service

agency, local gas supplier, or your distributor or branch

for information or assistance. The qualified installer or

agency must use only factory-authorized and listed kits or

accessories when modifying this product. A failure to

follow this warning can cause electrical shock, fire,

personal injury, or death.

For high-altitude installations, the high-altitude conversion kit

MUST be installed at or above 5500 ft above sea level. Obtain

high-altitude conversion kit from your area authorized distributor.

For accessory installation details, refer to applicable installation

literature.

NOTE: Remove all shipping brackets and materials before oper-

ating furnace.

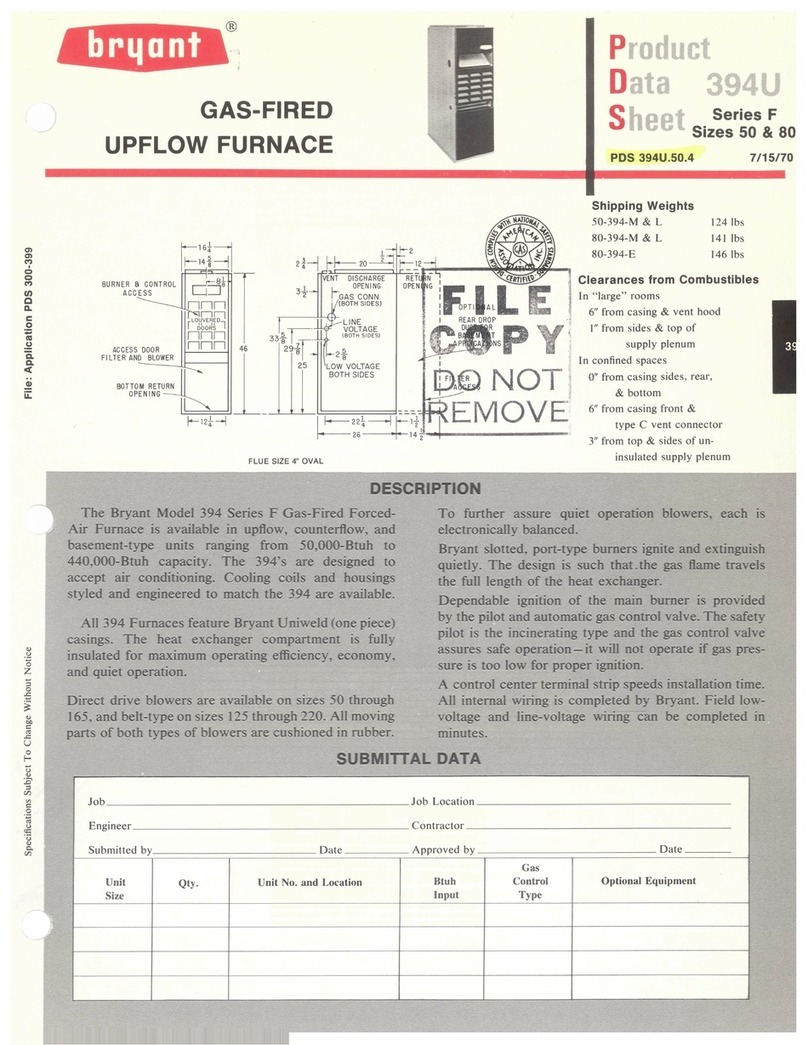

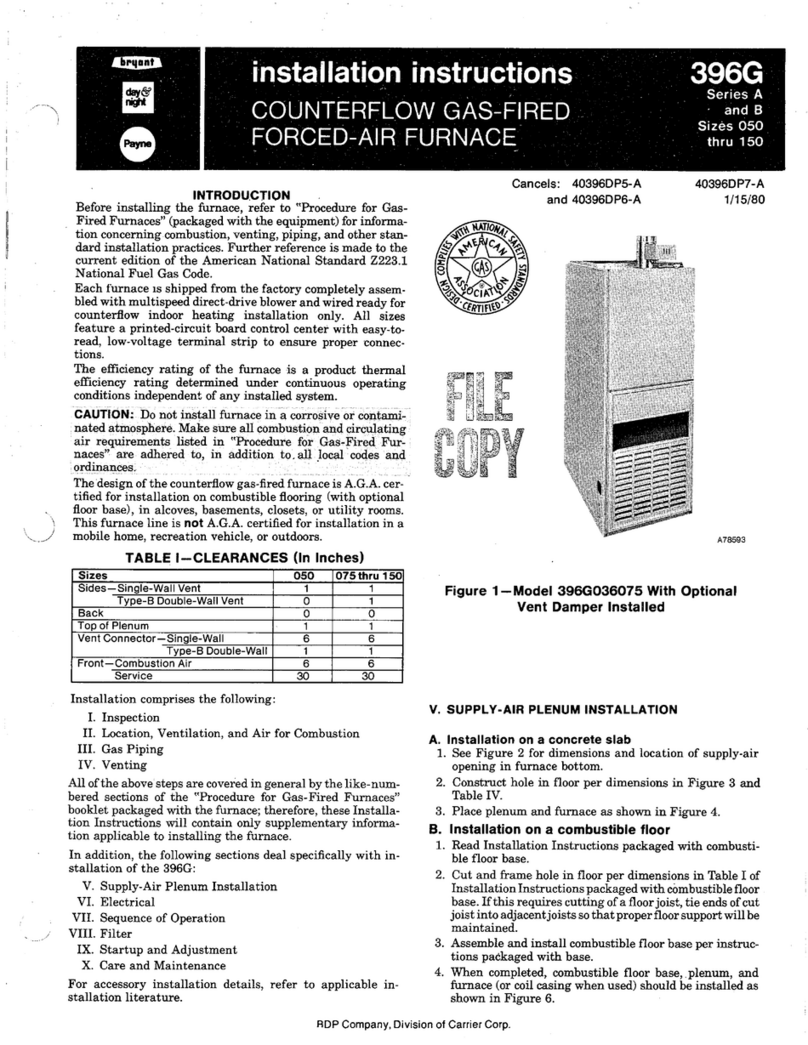

Fig. 2—Clearances to Combustibles A98122

320325-101 REV. H

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

his forced air furn

nace is equipped for use with

atural gasat altitudes 0 - 10,000 ft (0-3,050m).

n accessory kit, supplied by the m

m

anufacturer,

all be used to convert to propane gas use or

y be required for some natural gas applications.

his

s

furnace is for indoor installation in

uilding constructed onsite.

his f

f

f

urnace may be install

led on combustible

oor

ring in alcove or closet at minimum clearance

mcombustible material.

his furnace ma

a

a

y be used with a Type B-1 Vent

nd may be vented in common with other gas-fired

pliances.

Clearance in inches.

0"

##

1" #

0"

1"

1"

30"

MIN

SIDE

FRONT

BCK

A

SERVIE

C

FRONT

SIE

U

FRNACE

#

TOP / PLENUM

D

For furnaces wider than 14.25 inches

(362mm) may be 0 inches.

For single wall vent type 6inches.

For Type B-1 vent type 3 inches.

#

#

Vent Clearance to combustibles:

For Single Wall vents 6 inches (6 po).

For Type B-1 vent type 1 inch (1 po).

This furnace is approved for UPFLOW installations only.

BOTTOM

DESSOUS

—3—