C-Tech Floor Machine Service manual

WARN ING ATENCION ATTENTION

4275 N.W. PACIFIC RIM BLVD. ■CAMAS, WA 98607 ■USA

For technical assistance or the Dealer nearest you, call (360) 833-1600

OPERATING INSTRUCTIONS

AND PARTS MANUAL

2

Model Number ______________________________

Serial Number ______________________________

Date of Purchase ____________________________

The model and serial numbers will be found on a decal attached to

the Cyclone.You should record both serial number and date of pur-

chase and keep in a safe place for future reference.

CONTENTS

3

Cyclone System Manual • Form #96-619 • Revised 10/01

Introduction ................................................................................................................................... 4

Important Safety Information ......................................................................................................... 4

General Operating Techniques...................................................................................................... 4

Alignment Tool, #95-0728030........................................................................................................ 5

Exploded View .............................................................................................................................. 6

Parts List, Exploded View ............................................................................................................. 7

Troubleshooting ............................................................................................................................ 8

Nozzle Chart ................................................................................................................................. 8

Warranty ....................................................................................................................................... 9

Spanish..................................................................................................................................10-12

4

CYCLONE SYSTEM OPERATOR’S MANUAL

INTRODUCTION

The Cyclone is designed to attach to a pressure washer

which rotates two high pressure nozzles in the Cyclone.

The nozzles produce spray as well as determine the size

of the swath when cleaning surfaces such as parking

lots, driveways and sidewalks.

Owner/User Responsibility:

The owner and/or user must have an understanding of the

manufacturer’s operating instructions and warnings before

using this Cyclone.Warning information should be empha-

sized and understood. If the operator is not fluent in En-

glish, the manufacturer’s instructions and warnings shall

be read to and discussed with the operator in the operator’s

native language by the purchaser/owner, making sure that

the operator comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and

serial number.

IMPORTANT SAFETY

INFORMATION

CAUTION:To reduce the risk of in-

jury, read operating instructions

carefully before using.

1. Read the owner’s manual thor-

oughly. Failure to follow instruc-

tions could cause malfunction

of the machine and result in

death, serious bodily injury and/

or property damage.

WARNING: High pressure stream of

fluid that equipment can produce

can pierce skin and its underlying

tissues, leading to serious injury.

2. High pressure developed by

these machines will cause per-

sonal injury or equipment dam-

age. Use caution when operat-

ing. Do not direct discharge

stream at people or animals or severe injury or death

will result.

3. Never make adjustments on machine while it is in

operation.

4. Eye safety devices and foot protection must be worn

when using this equipment.

5. The best insurance against an accident is precau-

tion and knowledge of the machine.

6. Never expose any parts of the body, such as feet or

fingers, to the underside of base when spray arms

are rotating. Never tilt or attempt to work on under-

side of base while pressure washer is running or

spray arms are rotating.

WARNING: High pressure spray

can cause paint chips or other par-

ticles to become airborne and fly

at high speeds.

7. Safety clothing and protective

eye covering must be worn.

8. The Cyclone comes equipped

with two #3 nozzles in the ro-

tating swivel. Check your ma-

chine nozzle size before using.

9. We will not be liable for any alterations made to our

standard machines, or the application of any com-

ponents not purchased from us.

10. Pressure must NOT exceed 4,000 PSI. Tempera-

ture must NOT exceed 200°F. Flow rate must NOT

exceed 6 GPM.

11. To protect from freezing, squeeze the trigger lever

after you turn off the pressure washer and have dis-

connected the high pressure hose from the Cyclone.

This will allow water to drain through the nozzles.

GENERAL OPERATING

TECHNIQUES

1. Disconnect pressure washer spray gun from high pres-

sure hose. These items are not included, but are pro-

vided with the soon to be attached pressure washer.

2. Attach the female nipple, supplied with the Cyclone,

to the pressure washer high pressure hose.

NOTE: We recommend using no mar hose to

prevent black marks from appearing on the clean-

ing surface.

3. Couple pressure washer high pressure hose to Cyclone.

4. Inspect your pressure washer nozzle size. The Cy-

clone surface cleaner comes with two #3 nozzles. If

your pressure washer requires a nozzle larger than

a #6, consult with your local dealer.

NOTE: For ideal cleaning, the Cyclone must be

attached to a minimum 4 gpm at 3,000 psi pres-

sure washer.

5. Turn on water supply and start pressure washer.

6. Pull the trigger for water to start cleaning surface.

NOTE: Never stop moving the Cyclone while trig-

ger is engaged and surface is being sprayed or

damage to surface could occur.

WARNING

HIGH PRESSURE

STREAM CAN

PIERCE SKIN

AND TISSUE

WARNING

USE PROTECTIVE

CLOTHING WHEN

OPERATING.

READ OPERATOR’S

MANUAL

THOROUGHLY

PRIOR TO USE

CAUTION

CYCLONE SYSTEM OPERATOR’S MANUAL

5

15°

20°

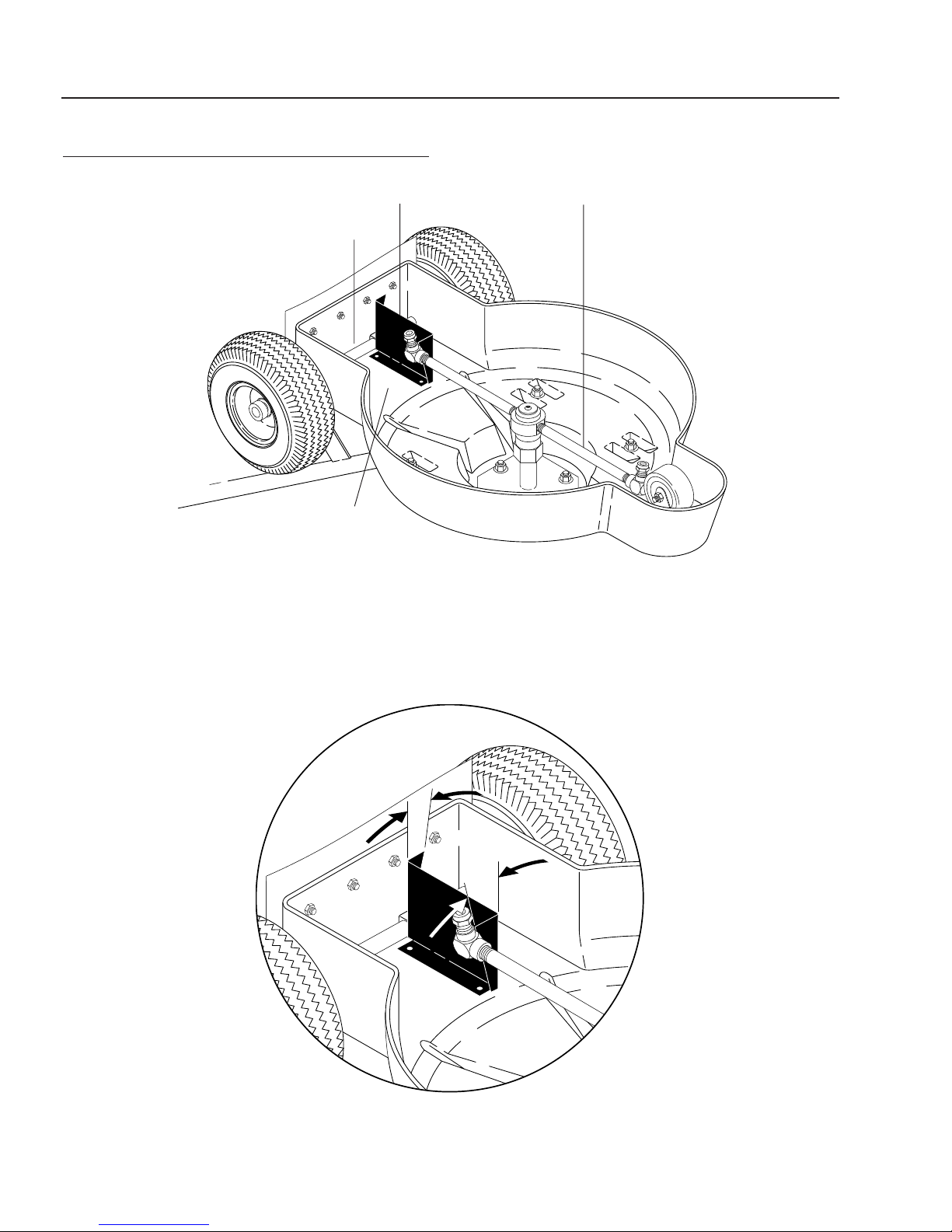

ALIGNMENT TOOL

95-0728030

STEP 1: Disconnect water to Cyclone, then turn

entire machine over to allow access to

nozzle jets.

STEP 2: Place base of alignment tool flat against

bottom of Cyclone plastic body. Press end

of tool (opposite of desired angle) against

axle, then rotate nozzle arm to alignment

tool as shown.

STEP 3: Use either the 20°or the 15°end of tool, adjust nozzle to align with angled

surface of tool. NOTE: 20°is the factory setting. Nozzles can be set at 15°if a

slower rotational speed is desired.

Axle

Alignment

Tool

Nozzle Arm

Plastic Body

6

CYCLONE SYSTEM OPERATOR’S MANUAL

WARNING ATENCION ATTENTION

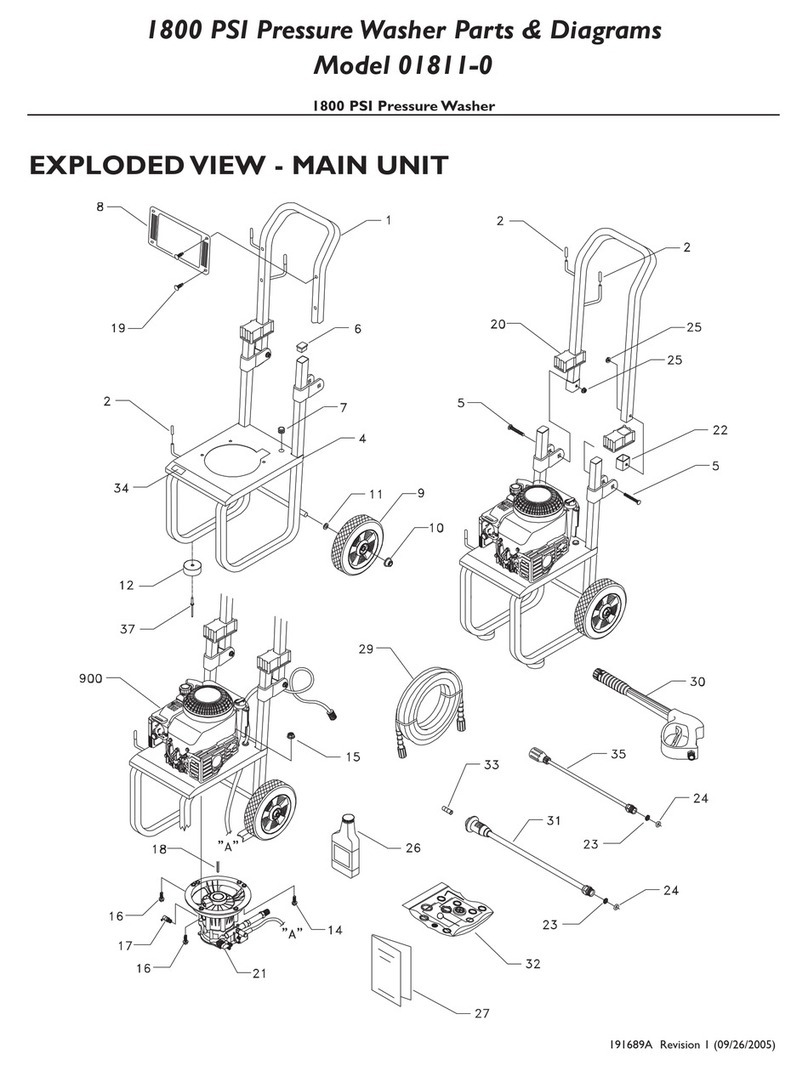

EXPLODED VIEW

24

41 1

31

32 17

22

20

35

21 16

21

2

16

21

14

40

29

12

11

21

18

6

11

29

12

30

21

18

3

33

23

13

19

9

34

28

26

10

27

36

7

8

5

25 4

15

37

38

39

CYCLONE SYSTEM OPERATOR’S MANUAL

7

ITEM PART NO. DESCRIPTION QTY

1 2-00260 Elbow, 1/4", Male Pipe 1

2 2-01080 Cap, Black Vinyl 4

3 2-011049 Base, Polyethylene, Red 1

4 2-0003 Nipple, 1/4" Close Sch 80 Steel 1

5 2-1104 Connector, 1/4" Anchor 1

6 2-11055 Swivel, Rotary Union URF400 1

7 2-11059 Swivel, 1/4" High Pressure 1

8 2-2003 Coupler, 3/8" Male Brass 1

9 2-4006 Guard, Splash 1

10 2-99071 Filter, High Pressure 1

2-990710 ▲Screen, High Press Filter S/S 1

2-990711 ▲Gasket, Nylon 1

11 4-0111320 Wand, 8" Rotary 2

12 4-01803015 Nozzle Only, SA, 1/8",

MEG-1503 2

13 4-0303 Wheel & Tire Assy, 4" w/Tube 2

14 4-031509 Wheel, Caster 3 Grey 1

15 81-21007L Valve, Acuator, Assy 1

16 90-10182 Bolt, 3/8" x 1-3/4", HH NC

Stainless 5

17 90-1042 Screw, 1/4" x 2" Carriage, ZN 4

18 90-20021 Nut, 3/8" Stainless, ESNA NC 8

19 90-20041 Collar, 5/8" Bore Shaft 3010 4

20 90-20054 Nut, Wing 1/4-20 ZN 4

21 90-40021 Washer, 3/8", SAE,

Stainless Steel 13

22 90-40089 Washer, Split-Lock 1/4" ZN 4

EXPLODED VIEW

PARTS LIST

ITEM PART NO. DESCRIPTION QTY

23 95-0728018 Axle, 5/8" x 18.5", Stainless 1

24 95-0728022 Handle, Trigger Bar 1

25 95-0728023 Adapter, Valve, Trigger Bar 1

26 95-0728026 Handle, Lower Assy 2

27 95-0728027 Handle, Upper Assy 1

28 95-0728029 Plate, Backup, Splash Guard 1

29 2-10410 Elbow, 1/4" x 1/8", Brass,

90 Degree 2

30 95-0728025 Nipple, Bulkhead, 1/2" x 4-1/2",

304 SS, SCH. 40 1

31 4-02021234 Hose, 3/8" x 34" Pressure,

1/2" FJIC x 1/4" FNPT 1

32 2-00602 Elbow, 1/2" JIC x 1/2" FEM

90 DGR 1

33 90-020 Nut, 10/32" NF ST ST KEP 4

34 90-10141 Screw, 10/32" x 1/2" SHCS SS 4

35 90-10162 Bolt, 3/8" x 1" HH/NC, 316 SS 3

36 2-00301 Elbow, Street, 1/4" x 3/8", Steel 1

37 90-50035 Pin, Roll M2.5" x 24 mm

5395A277 1

38 90-1700 Screw, 8/32" x 1/4" SS,

SOL SET 1

39 90-50168 Hook, 10/24" x 2" 1

90-20044 ▲Nut, 10/24" HEX, Whiz Loc

M/S Zinc 2

40 10-020310 Label, Warning 2

10-08014 ▲Label, Made in USA 1

41 11-0477 Label, Cyclone 1

▲Not Shown

8

CYCLONE SYSTEM OPERATOR’S MANUAL

NOZZLE CHART

Correct nozzle size is important for optimum cleaning efficiency. The Cyclone is shipped with two #3, 15°nozzles in rotary swivel. Review

correct nozzle size for your pressure washer. See chart below for correct nozzle size. To obtain the correct nozzle size in the rotary swivel, divide

the minimum nozzle size for the pressure by two. Round this figure up to the nearest half nozzle size. These are the 1/8" nozzles only (two

needed) for the rotary swivel on the Cyclone.

TROUBLESHOOTING

MELBORPESUACELBISSOPNOITULOS

RELPUOCKCIUQ

SKAEL

gniR-OnroW.)1210-2#traP(gniR-OecalpeR

REHSAWERUSSERP

SELCYCREDAOLNU

dezisgnorwroretliferusserphgiH

rehsawerusserpdehcattarofselzzon

.)s(elzzon,retliftuonaelcdnaevomeR

.eziselzzonkcehC

YLBMESSAELZZON

WOLSOOTGNINNIPS

TSAFOOTRO

yltcerrocnidelgnaeraselzzoN.selzzontsujdaeR :ETON elgnaeroM

.°03tuobaotelgnA.noitatorretsafsnaem

GNINNIPSSELZZON

WOLSOOT

dehcattarofemulovretawhguonetoN

selzzonetatorotrehsawerusserp

.rehsawerusserpmpgregraladeeN

GNINAELCTON

ECAFRUS

erusserpro,gnorwelgnaelzzoN

bojrofllamsootrehsaw

othcattaroelgnaelzzonegnahC

.rehsawerusserpregral

elzzoN

eziS

ecifirO

.maid

).ni(

04

ISP

001

ISP

052

ISP

005

ISP

006

ISP

007

ISP

008

ISP

0001

ISP

0021

ISP

0051

ISP

0002

ISP

0052

ISP

0003

ISP

0053

ISP

0004

ISP

2430.02.23.05.17.77.08.98.0.11.12.14.16.17.19.10.2

3240.03.74.57.70.161.152.143.15.16.18.11.24.26.28.20.3

4250.04.36.00.104.106.107.108.10.22.25.28.21.35.38.30.4

5.4550.54.17.01.105.107.109.100.22.24.28.20.36.39.33.40.5

5750.05.97.03.108.109.101.202.25.28.21.36.30.44.47.40.5

5.560.55.78.04.109.101.203.205.28.234.38.34.48.42.55.5

6260.06.59.05.101.203.205.207.20.32.37.32.48.42.57.50.6

5.6460.56.00.107.103.205.207.209.23.36.30.46.42.57.50.6

7760.07.01.108.105.207.209.201.35.38.33.40.56.5

5.770.57.02.109.107.209.202.304.38.31.46.43.50.6

8270.08.03.100.208.201.304.306.30.44.40.56.5

5.8470.58.03.102.200.303.306.308.33.46.43.50.6

9670.09.04.103.202.305.308.300.45.40.55.5

5.9870.59.05.104.204.307.300.403.48.42358.5

0180.00.106.105.205.309.302.405.40.54.5

21780.02.109.100.302.406.400.504.50.6

51490.05.104.208.303.508.5

02901.00.202.300.5

03141.00.307.4

04651.00.4

CYCLONE SYSTEM OPERATOR’S MANUAL

9

LIMITED MINIMUM 90 DAY WARRANTY

We warrant to the original consumer that each new part and accessory sold by C-Tech will be free from manufacturing defects

in materials or workmanship in normal service for the duration specified by the original component manufacturer with a 90 day

minimum from date of purchase, provided it is installed properly and the equipment is maintained in accordance with C-Tech's

instructions and manuals. Components manufactured by C-Tech, such as frames and handles, have a one year warranty from

date of purchase.

Our obligation under this warranty is expressly limited as to the replacement or repair, at our option, at C-Tech, Camas,

Washington 98607, or at a service facility designated by us, for such part or parts as inspection shall disclose to have been

defective.

EXCLUSIONS:

This warranty does not apply to defects caused by casualty or unreasonable use, including faulty repairs by others and

failure to provide reasonable and necessary maintenance.

THE FOLLOWING ITEMS ARE NOT COVERED BY THIS WARRANTY:

WE SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND,

including but not limited to labor costs or transportation charges in connection with the replacement or repair of defective parts.

ANY IMPLIED OR STATUTORY WARRANTIES, INCLUDING WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, ARE EXPRESSLY LIMITED TO THE DURATION OF THIS WRITTEN WARRANTY. We make no

other express warranty, nor is anyone authorized to make any on our behalf.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

TO OBTAIN WARRANTY SERVICE:

Purchaser must bring the accessory parts to an authorized C-Tech Dealership. For the dealership nearest you write:

C-Tech, 4275 NW Pacific Rim Blvd, Camas, WA 98607.

Cyclone System

WARRANTY

10

SYSTEME DE CHORRO DE AGUA MANUAL DEL OPERADOR

INTRODUCCION

El Sistema de Cyclone de agua estádiseñado para

adaptarse a una lavadora de presión haciendo rotar dos

boquillas de alta presión para producir el rociado y así

mismo determinar el tamaño del ancho de corte cuando

se limpian superficies de playas de estacionamiento,

pistas de acceso y veredas.

Responsabilidad del Dueño/Usuario

El dueño/usuario debe entender las instrucciones de

operación y las advertencias del fabricante antes de usar

el Sistema de Chorro de agua. La información de

advertencia debe ser enfatizada y entendida. Si el

operador no habla inglés, las instrucciones y

advertencias del fabricante deberán ser leídas y

discutidas en la lengua nativa del operador por el

comprador/dueño, asegurándose que el operador

entienda su contenido.

El dueño y/o usuario deben estudiar y mantener las

instrucciones del fabricante para futuras referencias.

Este manual deberáser considerado como una

parte de la máquina y debe permanecer asíen

caso que se revenda la unidad.

Cuando ordene repuestos, por favor especificar

el modelo y el número de serie.

SEGURIDAD DE LA MAQUINA

ADVERTENCIA: Para reducir el

riesgo de accidentes, leer

cuidadosamente las instrucciones

de operación antes de usar la

unidad.

1. Leer cuidadosamente el

manual deldel operador. El

incumplimiento de las

instrucciones puede causar unoperación defectuosa

e inadecua- da de la unidad y puede provocar la

muerte, causar heridas serias

y/o daños a la propiedad.

ADVERTENCIA: El flujo de líquido

de alta presión del equipo puede

producir perforaciones en los

tejidos de la piel, causando heridas

graves.

2. La alta presión desarrollada por

estas unidades causará

accidentes personales o daños

al equipo. Sea precavido al operar. No descargar el

flujo directamente en personas o animales ya que

puede causar heridas graves o la muerte.

3. Nunca hacer ajustes a la máquina mientras esté

operando.

4. Deben usarse accesorios de seguridad para los ojos

y protección de los pies cuando se use este equipo.

5. El mejor seguro contra un accidente es la precaución

y el conocimiento de la máquina.

6. Nunca diriga la varilla del chorro de agua a cualquier

parte de su cuerpo o alguna persona a 10 pies de

distancia ya que podría producir heridas graves.

ADVERTENCIA: El chorro de alta

presión puede ocasionar que trozos

de pintura y otras partículas vuelen

por los aires a altas velocidades.

7. Debe usarse ropa de seguridad

y protección para los ojos.

8. El ensamble del Sistema de chorro de agua viene

equipado con una boquilla #6 en la pistola de

apagado y dos boquillas #3 en la placa giratoria.

Revise la boquilla de su equipo antes de usarlo.

9. No seremos responsable por cualquier cambio

hecho a nuestras unidades estándar o la aplicación

de cualquier otro componente no comprado de

nosotros.

10. La presión NO debe exceder 4,000 PSI. La

temperatura NO debe exceder 200°F.

11. Para protegerla del congelamiento, apriete la

palanca del disparador después de apagar la

máquina para lavado a presión y después de haber

desconectado el tubo flexible de alta presión de

Cyclone. Esto permitiráque el agua desagüe a

través de los tubos flexibles.

TECNICAS GENERALES

DE OPERACION

1. Desconectar la pistola de alta presión de la

manguera de alta presión. Estos artículos no se

incluyen, pero serán provistos cuando se requieran

acoplar a la lavadora de presión.

2. Conectar la boquilla hembra, incluída con la

lavadora, a la manguera de agua de alta presión.

NOTA: Recomendamos no usar manguera tipo

mar para prevenir que aparezcan marcas negras

en la superficie que se estálimpiando.

3. Acoplar la manguera de alta presión de la lavadora

al Sistema de chorro de agua.

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

SYSTEMA DE CHORRO DE AGUA MANUAL DEL OPERADOR

11

4. Inspeccionar el tamaño de la boquilla de la lavadora

de presión. El Sistema de chorro de agua viene con

dos boquillas #3. Si su lavador de presión requiere

una boquilla más grande que la #6, consulte con su

vendedor local.

NOTA: Para un lavado ideal, el Sistema de chorro

de agua debe adaptarse a un lavador de un mínimo

de 4 gpm y 3,000 psi de presión.

5. Prender el suministro de agua y arrancar la lavadora

de presión.

NOTA: Siempre es importante probar en una área

pequeña para la correcta regulación de la altura

necesaria de tal manera que la superficie a ser

limpiada no sea dañada.

6. Tirar del gatillo para que el agua empiece a limpiar

la superficie.

NOTA: Nunca deje de mover el Sistema de chorro

de agua mientras el gatillo estáaccionado y la

superficie estásiendo limpiada o podrían ocurrir

daños en la superficie.

12

SYSTEME DE CHORRO DE AGUA MANUAL DEL OPERADOR

HERRAMIENTA DE ALINEAMIENTO

95-0728030

15°

20°

PASO 1: Desconecte el agua de Cyclone, luego gire

la máquina completa para permitir el acceso

a las toberas de chorro.

PASO 2: Coloque la base de la herramienta de ajuste

plana contra la parte inferior de la carrocería

plástica de Cyclone. Presione el extremo de

la herramienta (opuesto al ángulo deseado)

contra el eje y luego gire el brazo de la tobera

hacia la herramienta de ajuste tal como se

muestra.

PASO 3: Utilizando el extremo de la herramienta en 20°o en 15°, ajuste la tobera para alinearla

con la superficie en ángulo de la herramienta. NOTA: 20°es ajuste de fábrica. Las

toberas se pueden fijar en 15°si desea una velocidad de rotación más despacio.

Carrocería Plástica

Brazo de la

Tobera

Herramienta de Ajuste

Eje

4275 N.W. Pacific Rim Blvd. •Camas, WA 98607 •(360) 833-1600

Form #97-6138 •Revised 10/01 •Printed in U.S.A.

This manual suits for next models

1

Table of contents

Languages:

Popular Pressure Washer manuals by other brands

Black Max

Black Max BM80920 Operator's manual

Clarke

Clarke Power Wash EHD130 Operating & maintenance instructions

Echo

Echo PW-3100 Operator's manual

Black Max

Black Max BM802711 Operator's manual

Craftsman

Craftsman 580.752011 Operator's manual

Amazing Machinery

Amazing Machinery 5.5-24HP GAS & DIESEL ENGINEPRESSURE WASHER manual