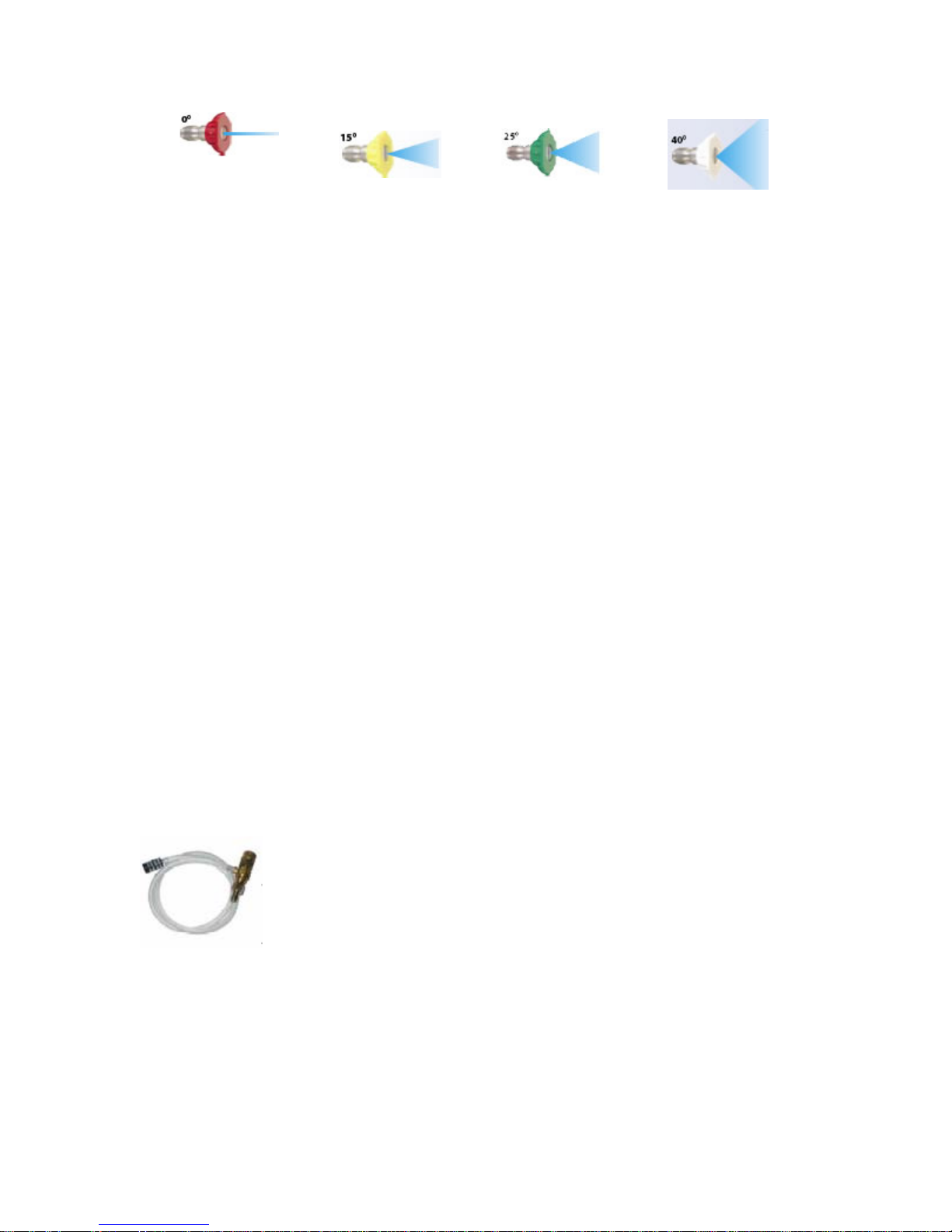

Spray Nozzle

A spray nozzle is located on the end of your wand and is interchangeable to create different angle fans. As

you use different nozzles you will increase or decrease the width of the fan.

Typical Pressure Washing Spray Nozzles

•0° Spray Tip – RED - This tip is not recommended for wood applications, its

stream of water is to narrow and concentrated. This tip would be ideal for concrete, and metal.

•15° Spray Tip – YELLOW - This tip is a heavy duty cleaning or stripping tip. You

can use this tip for cleaning concrete, loose paint, and driveways.

•25° Spray Tip – GREEN - This tip is for general washing purposes. You will find yourself using

this tip for your deck, siding, and your car.

•40° Spray Tip – WHITE - This tip has the least amount of impact. The white tip is great for

rinsing, cleaning out your gutters, and other sensitive jobs.

How do I clean a clogged nozzle?

Remove the nozzle from your system, using a small piece of wire like a paper clip clear the clog. Flush

water backwards through the nozzle and replace it on your pressure washer. If it is still partially clogged try

again.

How often should I replace my nozzles?

This depends on much time you use your machine. A good rule of thumb is if you notice a gradual pressure

lose you should replace that tip. Not all tips will wear out at the same time.

Why should I keep my nozzles clean?

A clogged nozzle can increase the back pressure on your pump causing damage.

Chemical Injectors

Depending on your machine you may have an integrated or separate chemical injector which draws at a

20% mixture. If you have a separate injector it needs to be attached at the high pressure out port of your

pump and then attach the hose gun and wand. On single wand systems you must use the black QC spray

tip that is included with your machine in order for the injector to draw. Place your feed tube with filter

attached into the chemical of choice and pull trigger. On Dual wand systems you will need to rotate your

grip to the low pressure tube with the ¼” meg tip for chemical application.