2

Us 4 Slush Limited RTB Warranty. (See also Oponal On Site Extended Warranty appendix 4)

Please keep a record of your Order ID as this forms part of the warranty validaon.

Within 5 working days of delivery the Slush machine must be unpacked, examined and fully tested with product for a minimum of 3

hours. Faults must be reported immediately.

1. Us 4 Slush Limited warranes against manufacturer’s defects for all of our Slush machines and equipment including

accessories and parts listed in appendix 2.

2. The warranty period is 12 months and is valid on Mainland UK, Isle of Wight and Isle of Man only.

3. The warranty period begins on the delivery date unless otherwise stated in wring by Us 4 Slush Limited.

4. The Warranty type is RTB. (return to base)

5. In the event that the Slush Machine needs to be returned under the terms of the Warranty the shipping cost will be borne by Us 4

Slush Limited. (See appendix 1)

6. In the event that the slush machine has arrived with a fault the only course of acon will be repair or replace at the discreon of Us 4

Slush Limited. In this instance Us 4 Slush Limited must be informed of the fault within ve working days of the delivery and we will take

care of the shipping fees and arrangements for the Slush Machine to be collected, repaired and returned within 7 working days.

7. The Warranty is valid only when the Slush Machine is purchased direct from Us 4 Slush Limited.

8. The Slush Machine or its warranty is not transferable.

9. The Slush Machine is not to be repaired by any party other than us 4 slush limited, its agents or persons authorised by

Us 4 Slush Limited.

10. The model and serial number label must not be defaced or removed from the slush machine.

11. The Warranty does not cover damage or loss caused by modicaon, alteraon or repair by any unauthorised persons.

12. The warranty does not cover normal wear and tear.

13. The Warranty is void if the owner or user neglects to do roune cleaning and maintenance as outlined in the user manual on the fol-

lowing pages

14. The Warranty is void if the product used is not a product either supplied by or approved by Us 4 Slush Limited.

15. The Warranty is void if the product is used in any way other than directed by the manufacture.

16. The Warranty is void is if the electric power used to power the Slush Machine is anything other than mains electricity supplied

through UK naonal grid unless otherwise stated in wring by Us 4 Slush Limited on headed paper,

17. The Warranty is void if the Slush Machine is connued to be used when there is a known fault.

18. The warranty does not cover aesthec components or any plasc or electronic parts that present defects due to incorrect handling,

modicaon, and/or servicing or repair by unqualied personnel.

19. The warranty does not cover defects due to inadequate transportaon or shipping.

20. Parts may be supplied to third party engineers chosen by the customer at the discreon of Us 4 Slush Limited.

Appendix 1 :

In the event that the Slush Machine needs to be returned under the terms of the warranty a purpose built grate will be sent and ar-

rangements will be made for collecon.

We will send you an informaon pack regarding packing and arrange collecon for you.

We can make arrangements for shipping however it will be the customer’s reasonability to have adequate

insurance cover during transit. In the event that your machine cannot be repaired and returned within 10 working days we will supply

a 2 bowl machine free on loan unl the repair can be made.

Appendix 2:

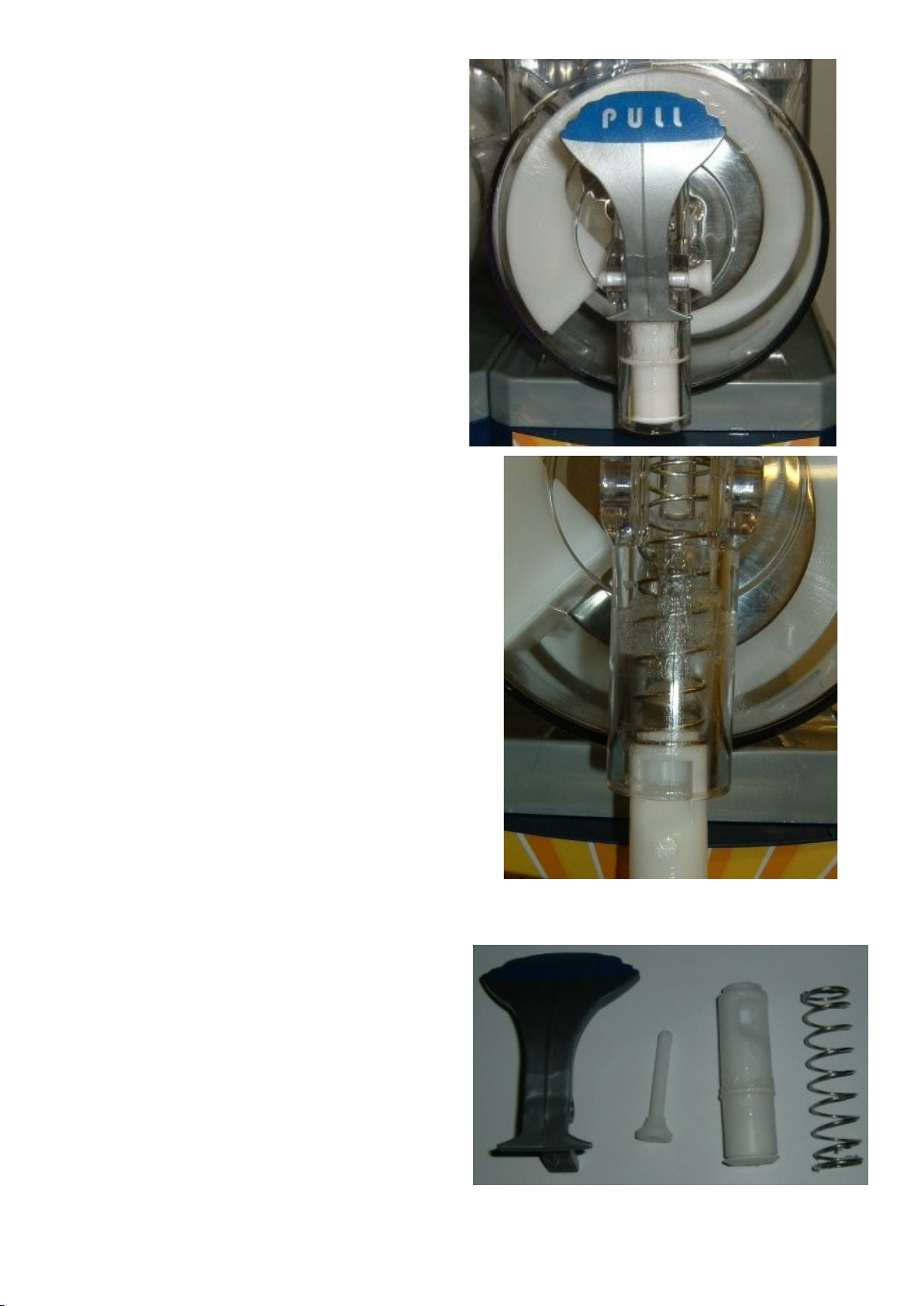

The Slush machine parts listed below are covered by this warranty for ng by the customer as part of roune maintenance. We

may request the return of the damaged parts at our discreon.

Plasc parts including Tanks, mixing auger, Lids, Dispensing Handles and assemblies including rubber seals, Drip trays, light bulbs,

supporng feet, aesthec components or any plasc or electronic parts that present defects due to incorrect handling, modicaon,

and/or servicing or repair by unqualied personnel.

Appendix 3:

If the machine is covered by the oponal on site or extended warranty an engineer will visit your business premises

within 5 working days.

In the event the machine cannot be repaired on site a 2 bowl loan machine will be provided while your machine is being repaired.

Excluding parts listed in appendix 2 as these can be ed by the user.