Caleffi North America, Inc.

3883 West Milwaukee Road

Milwaukee, WI 53208

T: 414.238.2360 F: 414.238.2366

6-17-19

LEAVE THIS GUIDE WITH USER

2

Dimensions

1

1

2

2

3

3

4

4

A A

B B

SCALE

TOLERANCES UNLESS NOTED

SHEET

DIMENSIONING AND TOLERANCING PER ASME Y14.5M-1994

PROJECT:

DWN

CHKD

DATE

DATE

THIRD ANGLE

NOTICE ON REPRODUCTIONS

ANGLESDECIMALS

FINISH

MATERIAL

TITLE

PN

SIZE

Legiomix Station 1"

THIS DRAWING, THE DE SIGN AND THE PATE NTS IT COVERS, A RE THE PROPERTY OF

CALEFFI INC. THEY ARE LOANED MERELY A ND ON THE BORROW ER'S EXPRESS AGRE EMENT

THAT THEY W ILL NOT BE REPROD UCED, COPIED, LO ANED, EXHIBITED , NOR USED EXCEP T

IN THE LIMITED WAY A ND THE PRIVATE US E PERMITTED BY WR ITTEN CONSENT GIV EN BY

THE LENDER TO THE BORROWE R.

10/29/2018

PATH:

C:\InventorWork\Workspace\Mix Valves\LegioMix station\LegioMixStation 1 inch.iam

Mike

2

REV

.X ±

.XX ±

.XXX ±

X° ±

B

CALEFFI NORTH AMERICA

3883 West Milwaukee Road

Milwaukee, WI 53208

A

B C

D

E

F

H

I

G

LegioMix Station Assembly Dimensions

LegioMix As

mDESCRIPTION A B C D E F G H I

600066AS

1" 24.75 7.5 8.25 5.25 35.25 32 39 3.5 3.5

600076AS

1.25" 27 7.5 9 6.25 39.25 36 43 3.5 3.5

600086AS

600096AS

Code connec-

tions A B C D E F G H/I Wt

(lb)

600066AS 1" copper 24¾" 7½" 8¼" 5¼" 35¼" 32" 39" 3½" 27.3

600076AS 1¼" copper 27" 7½" 9" 6¼" 39¼" 36" 43" 3½" 28.2

600086AS 1½" copper 33¾" 8½" 13¼" 5" 43¼" 40" 48" 4" 41

600096AS 2" copper 36¾" 87/8" 14¼" 53/8" 47¼" 50" 60" 5" 42

*to ensure stable operation and accurate temperature control.

Minimum flow rate is 0 gpm when recirculation flow rate is greater than or

equal to the valve size minimum flow rating.

Provide with optional Modbus-to-BACnet gateway for BAS integration,

code NA10520.

Recommended Flow Rates (gpm/lpm)

Size 1" 1¼" 1½" 2"

Minimum* 3.1 / 11.7 4.4 / 16.6 6.6 / 25 8.8 / 33.3

Maximum 94 / 356 107 / 405 152 / 575 215 / 814

Cv 21 24 34 47

Technical specifications

Mixing valve body

Materials: - Body: DZR low-lead brass

- Ball: low-lead brass, chrome-plated

- Hydraulic seals: peroxide-cured EPDM

Max. body pressure rating (static): 230 psi (16 bar)

Max. operating pressure: 150 psi (10 bar)

Max. inlet temperature: 212°F (100°C)

Temperature gauge scale: 30 - 210°F

Suitable fluids: water

Max. water hardness: 10 grains

Main connections: -NPT male and sweat union

1", 1¼", 1½" and 2"

Actuator, 3-wire floating

Electric supply: 24 VAC - 50/60 Hz

Power consumption: 6 VA

Protection cover: self-extinguishing VO

Protection class: IP 65 (NEMA 4/4X)

Ambient temperature range: 14 - 130°F (-10 - 55°C)

Electric supply cable length: 31½” (0.8 m)

Max. distance for control signal wire:

500 ft (150 m) cable 2 conductor x AWG 18

800 ft (250 m) cable 2 conductor x AWG 16

Station components

Frame: steel uni-strut

Pipes: copper type L

Ball valves: low-lead brass

Check valves: stainless steel

Main connections: -copper

1”, 1¼”, 1½” & 2”

Controller, LCD user interface/display

Materials: - Housing: self-extinguishing ABS, color white RAL 1467

- Cover: self-extinguising SAN, smoked transparent

Electric supply: 24 VAC (min 21.6, max 26.0 VAC) - 50/60 Hz

Power consumption: 6.5 VA

Adjustment temperature range: 70 - 185°F (20 - 85°C)

Disinfection temperature range: 100 - 185°F (40 - 85°C)

Ambient temperature range: 32 - 120°F (0 - 50°C)

Protection class: IP 54 (wall mounting)

(Class II appliance)

Mounting bracket: DINrail

Contact rating (R1, R3, R4): 5 A resistance, 2 A inductance / 24 V

Mixing valve control: 5 A resistance, 2 A inductance / 24 V

Alarm relay (R2): 5 A resistance, 2 A inductance / 24 V

Fuses: 1 (main): 80 mA

Fuses: 2 (mixing valve): 1 A

Charge reserve: 15 days in the event of electric supply failure,

with a 3 cell rechargeable 3.6 V 140 mAh buffer battery

Battery recharging time: 72 hours

Approvals: CE, FCC part 15

Temperature sensors

Body material: stainless steel

Type of sensitive element: NTC

Working temperature range: 14 - 260°F (-10 - 125°C)

Resistance: 1000 Ohms at 77° F (25° C)

Time constant: 2.5

Max. distance for mixed outlet or return (recirculation) sensor:

500 ft (150 m) cable 2 conductor x AWG 18

800 ft (250 m) cable 2 conductor x AWG 16

Mixing valve performance

Accuracy: ± 3º F (± 2º C)

Max. operating differential pressure (dynamic): 75 psi (5 bar)

Max. ratio between inlet pressures (H/C or C/H): 2.1

Certifications

1. ASSE 1017/CSA B125.3, certified by ICC-ES, file PMG-1357.

2. NSF/ANSI 372-2011, Drinking Water System Components-Lead

Content Reduction of Lead in Drinking Water Act, California Health and

Safety Code 116875 S.3874, Reduction of Lead in Drinking Water Act,

certifed by ICC-ES, file PMG-1360.

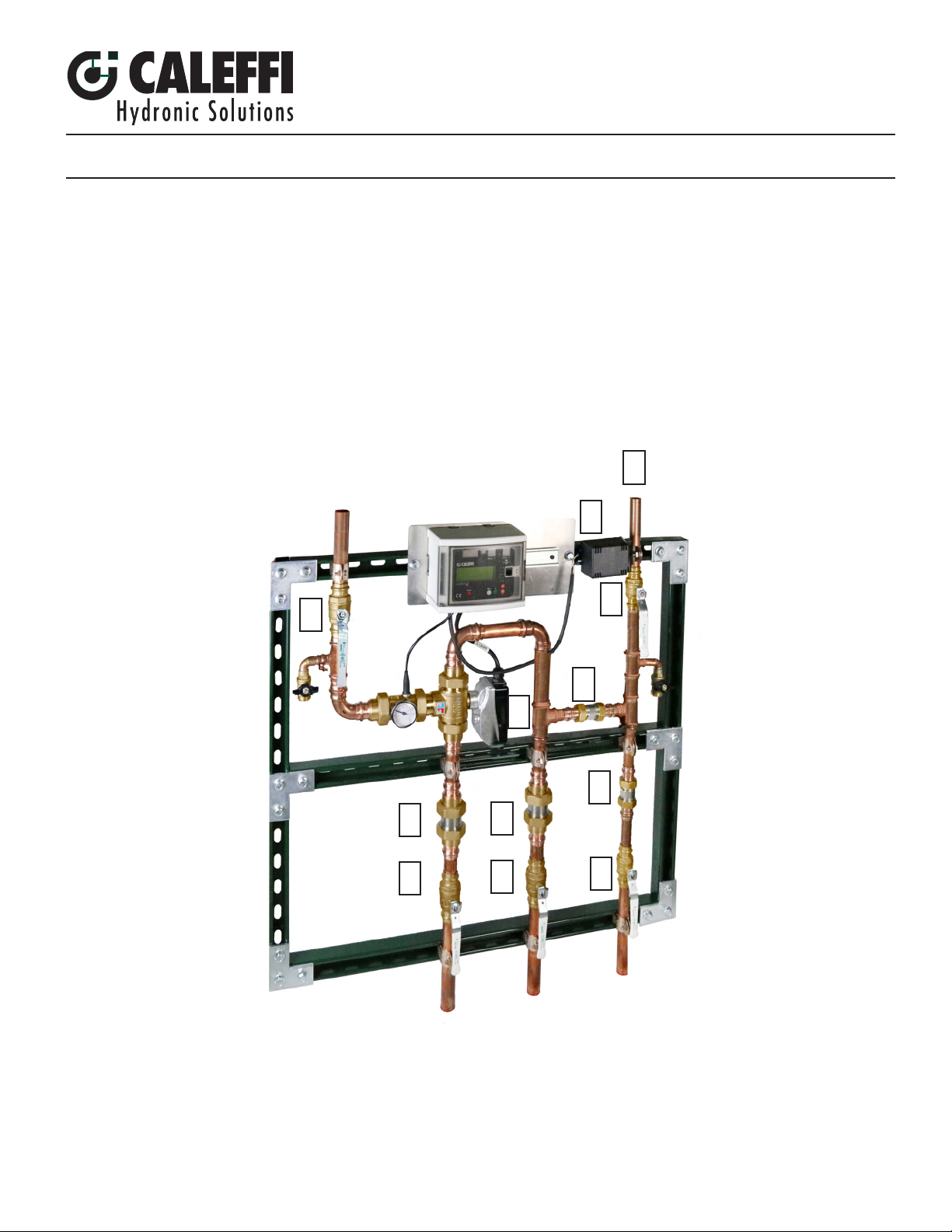

Station assembly

Includes pre-piped LEGIOMIX 3-way mixing valve with union connections,

serviceable low-lead stainless steel check valves, a recirculation connection

and isolation valves for fast and simple installation. The LEGIOMIX controller is

pre-mounted and pre-wired and includes a return water temperature sensor,

in a packaged wall mount configuration with steel uni-strut frame that can bolt

to the wall through any of the perforations. The assembly also includes copper

type L pipe, low lead ball valves and a plug-in 24 VAC transformer with 10

feet of wire.

Mix Out

Cold In To Tank

Hot In

Recirc

Return

pump not included