>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

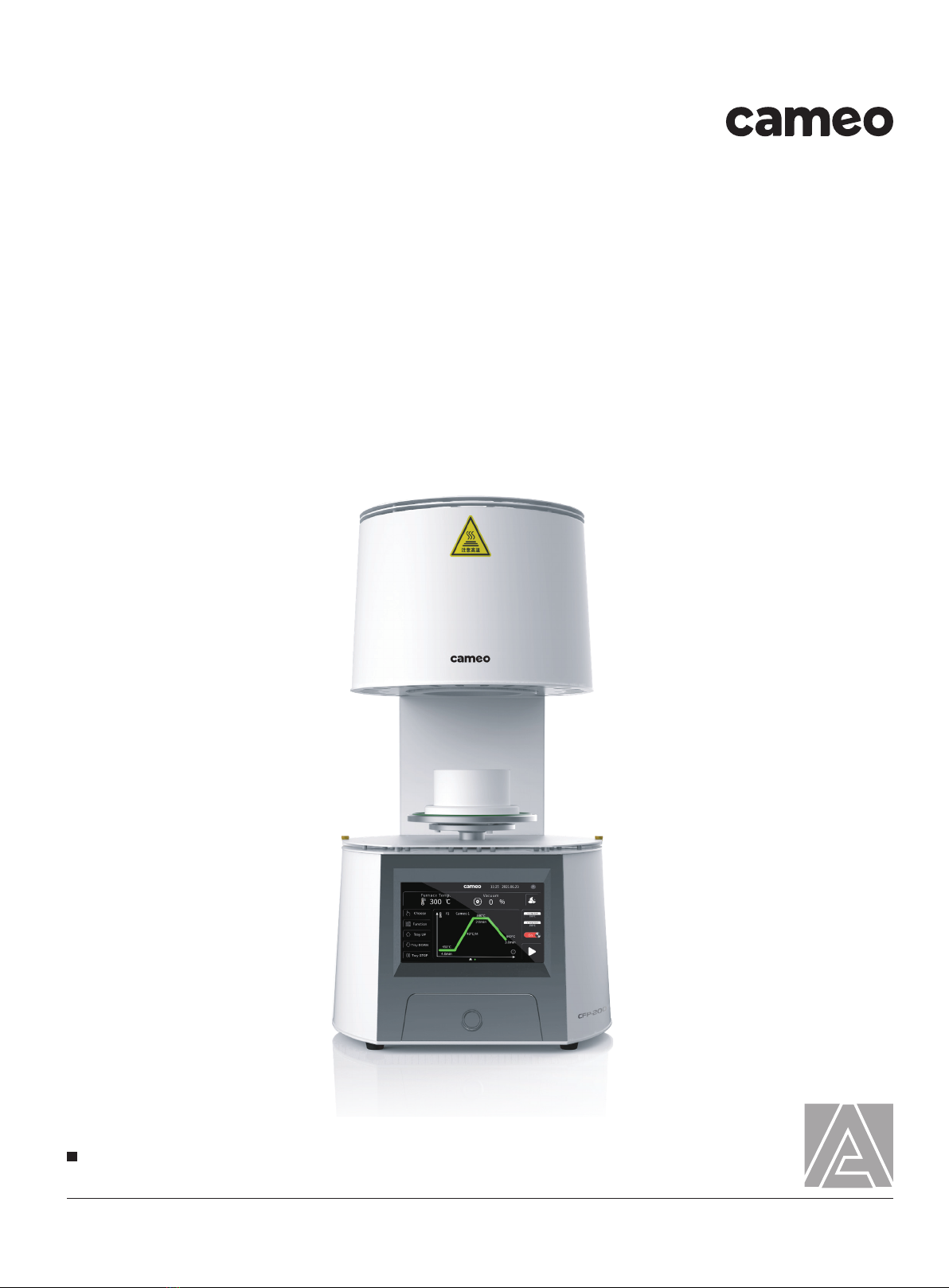

| Aidite

01

Disclaimer

Disclaimer

The information contained in this manual belongs to Aidite(Qinhuangdao)Technology Co., Ltd. and

is only intended for users. Without our written permission, any part of this manual are not allowed to be

duplicated, stored or disseminated in an electronic, mechanical, photocopying or recording way. Because

this manual has been prepared with great care, the publisher declares that it is not liable for errors and

omissions in this manual and losses caused by the use of the information contained therein.

Aidite(Qinhuangdao)Technology Co., Ltd reserves the right to change without further notice. For this

manual and the product it describes, we are neither liable for technical or editorial errors and omission,

nor for accidents and losses arising out of the use of this manual.

This manual is made by Aidite(Qinhuangdao)Technology Co., Ltd. to the best of its ability, and only

for reference. Because we are not able to predict all possible situations, this manual does not include all

technical and safety information. If you have any questions during installation, conguration and use,

please contact us.

Foreword

Dear Users:

Firstly, thank you for purchasing our product! Please conrm the furnace according to the order, invoice

and the serial number directly installed in the furnace. The production processes of all products in the

table of contents all conform to high-quality control procedures, which are under strict control from order

processing to after-sales technical service, ensuring the product quality standards.

We will provide users with free service of the entire furnace (except for man-made damage), if the

product is damaged due to quality problems and cannot work normally within 12 months from the

date of delivery, on the premise of observing relevant requirements of storage, use, installation and

transportation. We will continue to carry out paid lifelong maintenance according to user's requirements,

after the warranty period expires.

You must read through this manual and obey requirements contained herein because this manual

contains additional information on intended use and safe operation of the furnace. If Users follows

precautions related to this furnace in this manual, operations on this furnace are safe.