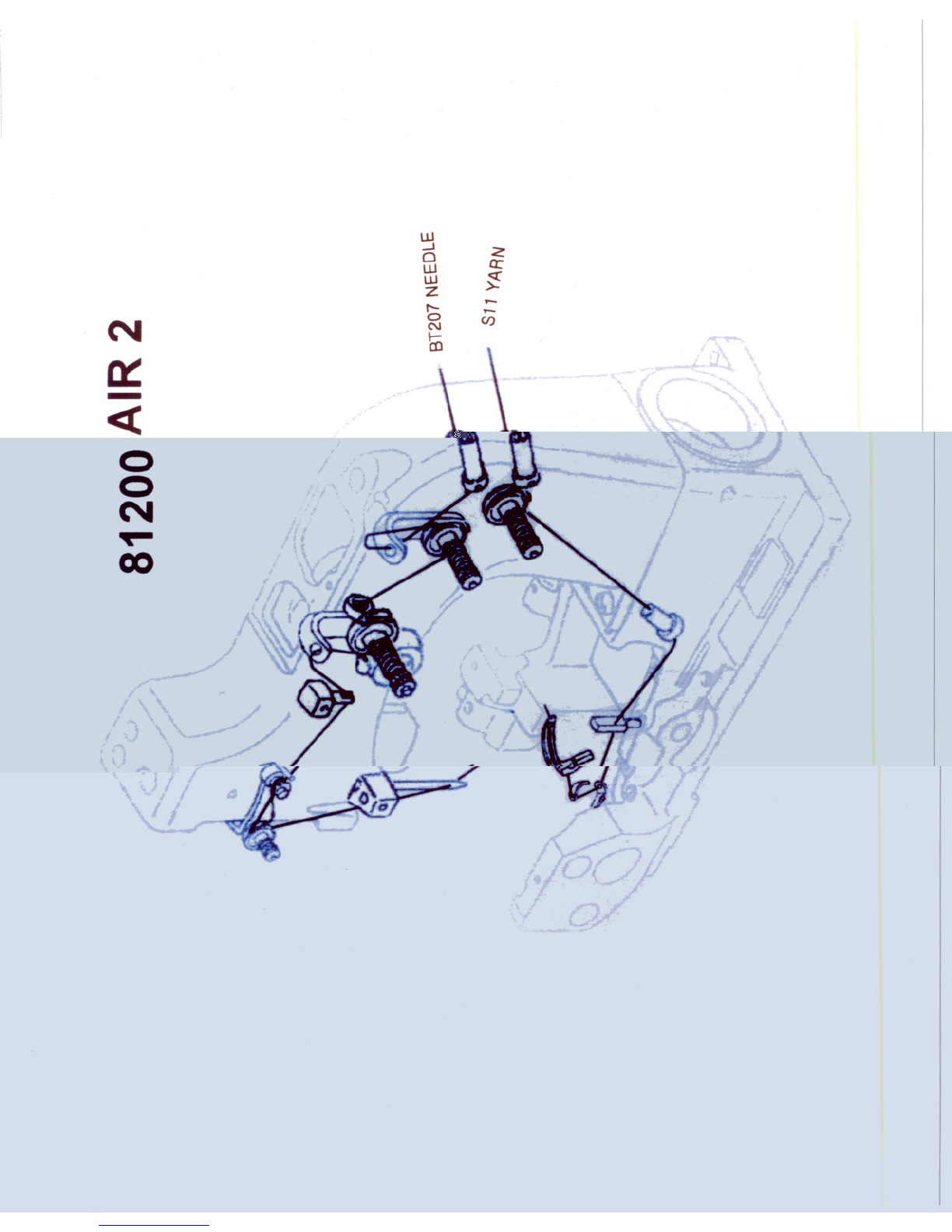

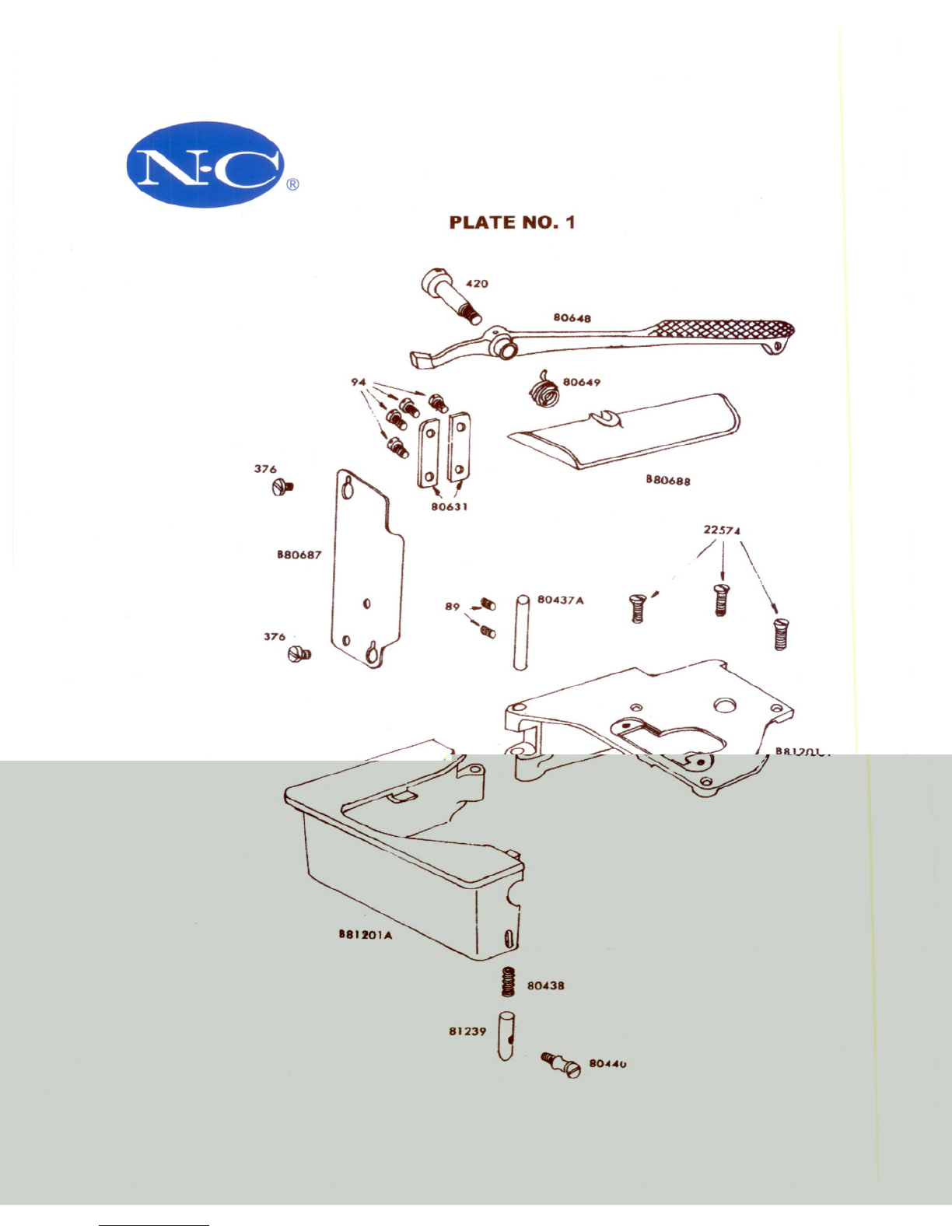

Figure 1 ADJUSTING THE LOOPER

For convenient access, remove the presser foot, throat plate and feed dog.

Insert the looper into the looper rocker. Set the looper so that the distance

from the center line of the needle to the point of the looper is 6.5 mm '" 1/4" in

the lowest position of needle bar just before moving upwards (Fig. 1). Then,

loosen the nut at the right side of looper rocker and the ball stud till the speci-

fied dimension is obtained. As the looper moves to the right, its point should

pass behind the needle as close as possible without contacting it. Adjustment

can be made by loosening the fastening screws of looper rocker and replacing

the looper rocker axially till this adjustment be obtained.

Figure 2

ADJUSTING THE SPREADER

The spreader should closely pass behind the looper and behind the nee-

dle so that its point just brushes, without deflecting them. Set the dis-

tance of 5mm '" 13/64" between speader and needle (Fig. 2). If adjust-

ment is necessary, turn the connecting rod, as required to obtain the de-

sired dimension.

THIS ADJUSTMENT IS FOR WRAP AROUND SERGERS ONLY.

Figure 3

5mm

ADJUSTING THE UPPER LOOPER

Will be done like machines with spreader. But the distance between the

needle and looper are to be adjusted like (Fig. 3).

THIS ADJUSTMENT IS FOR ALL 81200 CLASSES EXCEPT WRAP

AROUND SERGERS.

/2 mm

SETTING THE NEEDLE BAR

Set the needle bar so that the top of the needle eye is even with the underside of the looper, when the

looper point in its travel to the left projects 1 - 1.5 mm =0.04 - 0.06" from the left side of the needle. If ad-

justment is necessary, loosen the clamping screw in the needle bar connection and move the needle bar

up or down as required and retighten screw.