downflowinstallations,afactoryaccessoryfloorbasemustbe

usedwheninstalledoncombustiblematerialsandwoodflooring.

Specialbaseisnotrequiredwhenthisfurnaceisthstalledonthe

mmmthcturer'scoilassemblyorwhenthemanufacturer'scoilbox

isused.Thedesignofthe5gMTAfurnaceisnotC.S.A,(A.G.A.

andC.G.A.)certifiedforinstallationinmobilehomes,recreational

vehicles,oroutdoors.This furnace is suitable for installation in a

structure built on site or a manufactured budding completed at

final site.

1. Combustion products must be discharged outdoors, Connect

this furnace to an approved vent system only, ,'tqspecified in

the "Venting" section of these instructions

2. Never test for gas leaks with an open flame. Use a commer-

cially available soap solution made specifically for the detec-

tion of leaks to check all connections, as specified in the "Gas

Piping" and "Stari-Up, Adjustment, and Safety Cbeck" sec-

tion.

3. Always install furnace to operate within the furnace's intended

temperature-tise range with a duct system which has an

external static pressure within the allowable range, as speci-

fied in the "Adjustments" section. See furnace rating plate.

4. When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space containing

the furnace, the return air shall also be handled by duct(s)

sealed to the furnace casing and terminating outside the space

containing the furnace.

5. Agas-fired furnace for installation in a residential garage must

be installed as specified in the warning box in the "'Location"

section.

6. The furnace is not to be used for temporary heating of

buildings or structures under construction.

This furnace is designed lk,r continuous return-air minimum

temperature of 60 °F db or intermittent operation down to 55°F db.

Return-air temperature must not exceed 85°F db, See Fig. 4.

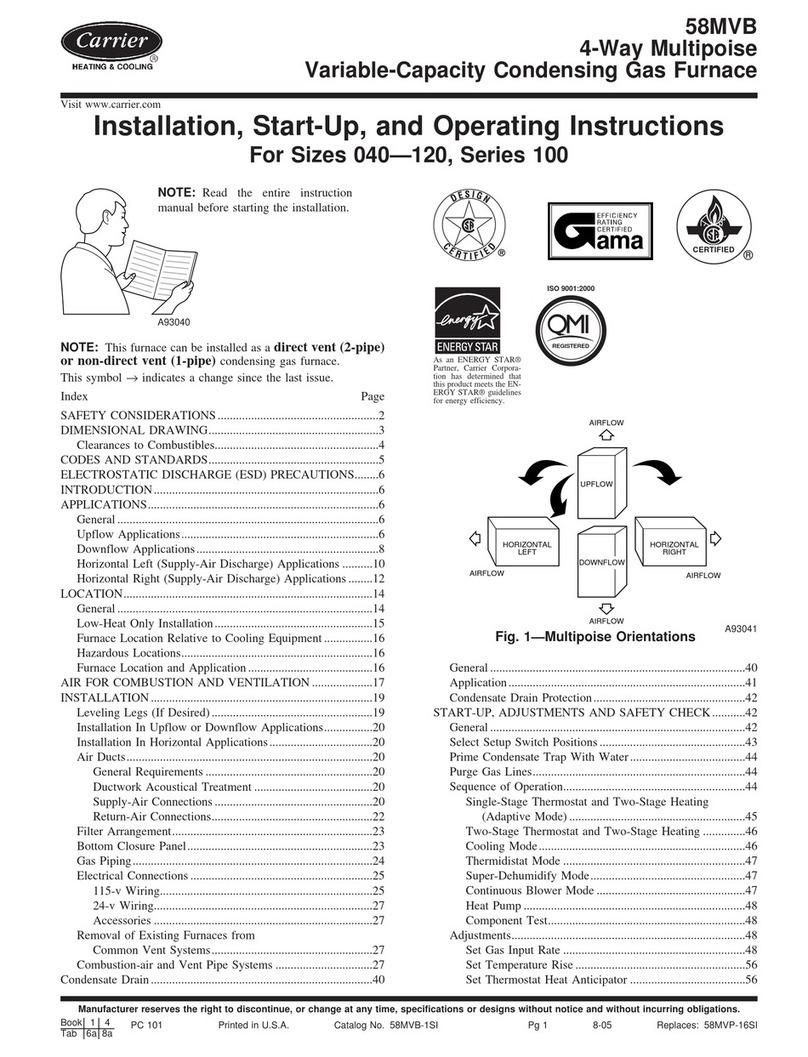

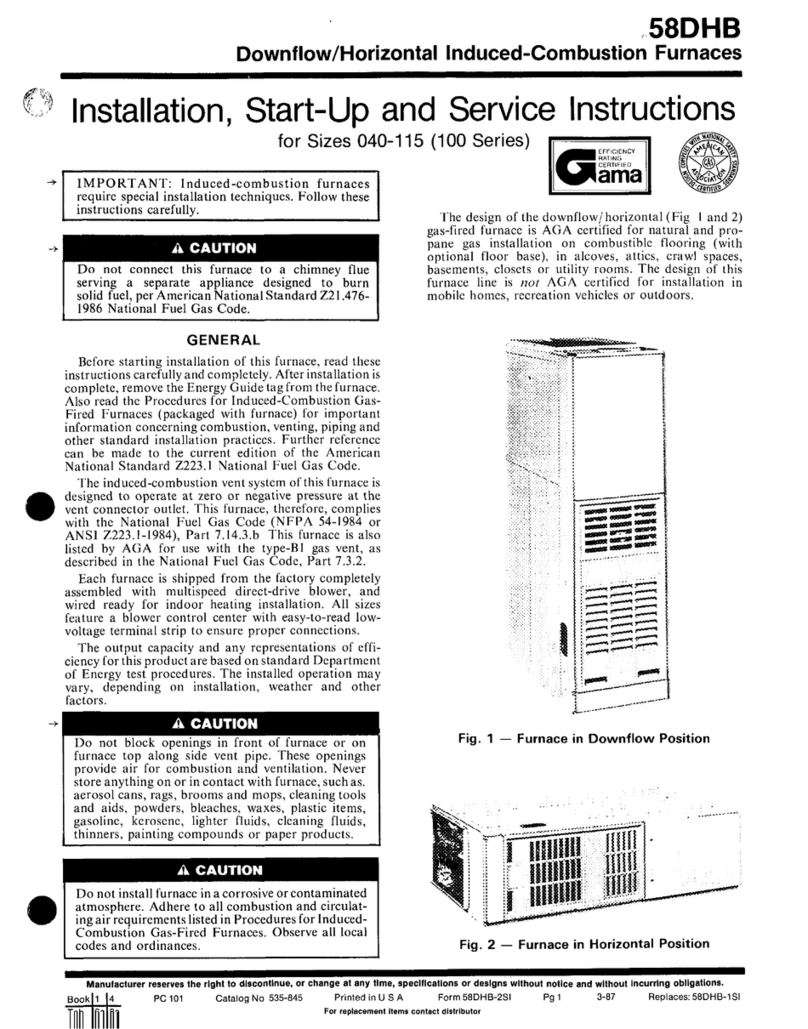

This furnace is shipped with the drain and pressure tubes con-

nected for UPFLOW applications. Minor modifications are re-

quired when used in DOWNFLOW, HORIZONTAL RIGHT,

or HORIZONTAL LEFT Isupply-air discharge direction) appli-

cations as shown in Fig. 1. See details in Applications section.

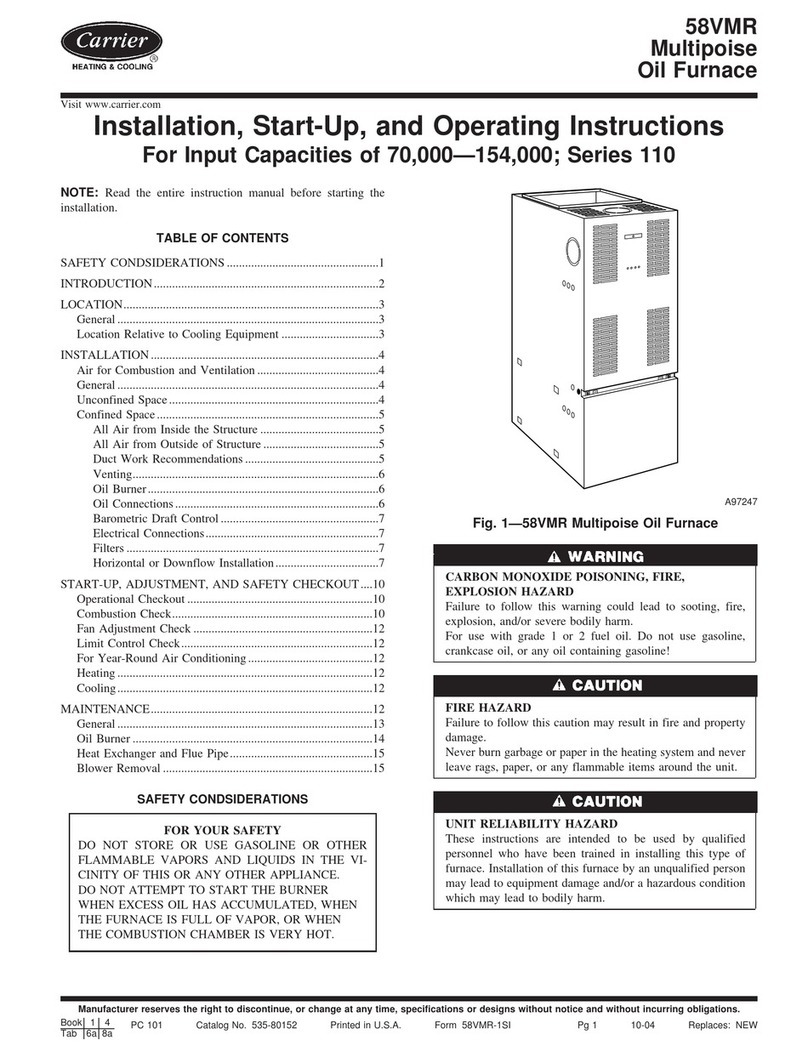

This furnace must be installed with a direct-vent (combustion air

and flue) system and a factory accessory termination kit. In a

direct-vent system, all air for combustion is taken directly from the

outdoor atmosphere and all flue gases are discharged to the

outdoor atmosphere. See furnace and factor,,' accessory vent-air

intake termination kit instructions for proper installation.

This furnace is shipped with the following materials to a,_sist in

proper furnace installation. These materials are shipped in the main

blower compartment.

Installer Packet includes:

Installation, Startup, and Operating Instructions

Service and Maintenance Instructions

User's Information Manual

Warranty Certificate

Loose Parts Bag includes: Quantit

Pressure tube extension 1

Collector Box or condensate trap extension tube t

Inducer housing drain tube 1

l/2qn CPVC street elbow 2

Drain tube coupling 1

Drain tube coupling grommet 1

Vent and combustion-air intake pipe support 2

Condensate trap hole filler plug 3

Vent and combustion-air intake hole filler plug 2

Cornbustioo-air intake pipe podorated disk assembly 1

Vent Pipe Extension 1"

• ONLY supplied with some furnaces.

For accesso_, installation detail, refer to the accessory, installation

instruction.

NOT[:: Remove all shipping materials before operating furnace.

CODES AND STANDARDS

Follow all national and local codes and standards in addition to

these instructions. The installation must comply with regulations

of the serving g_s supplier, local building, heating, plumbing, and

other codes. In absence of local codes, the installation must

comply with the national codes listed below and ,all authorities

having jurisdiction,

In the United States and Canada, follow all codes and standards for

the following:

Step 1--Safety

US: National Fuel Gas Code (NFGC) NFPA 54-1999/ANSI

Z223.1-1999 and the Installation Standards, Warm Air Heating

and Air Conditioning Systems ANSI/NFPA 90B

• CANADA: CSA B149.1-00 National Standard of Canada,

Natural Gas and Propane Installation Code (NSCNGP1C)

Step 2--General Installation

US: current edition of the NFGC and the NFPA 90B. For

copies, contact the National Fire Protection Association Inc.,

Battery, march Park, Quincy, MA 02269: or for only the NFGC

contact the American Gag Association, 400 N. Capitol., N.W.,

Washington DC 20001

• CANADA: NSCNGPIC. For a copy. contact Standard Sales,

CSA International, 178 Rexdale Boulevard. Etobicoke (Tor-

ontoh Ontario, M9W IR3, Canada.

Step 3---Combustion and Ventilation Air

•US: Section 5.3 of the NFGC. Air for Combustion and

Ventilation

• CANADA: part 7 of the NSCNGPIC. Venting Systems and Air

Supply for Appliances

Step 4--Duct Systems

US and CANADA: Air Conditioning Contractors Association

IACCA! Manual D, Sheet Metal and Air Conditioning Con-

tractors National Association (SMACNA), or American Soci

ety of Heating, Refrigeration, and Air Conditioning Engineers

(ASHRAEI 2001 Fundamentals Handbook Chapter 34.

Step 5---Acoustical Lining and Fibrous Glass Duct

US and CANADA: current edition of SMACNA, NFPA 90B as

tested by UL Standard 181 for Class 1 Rigid Air Ducts

Step 6--Gas Piping and Gas Pipe Pressure Testing

• US: NFGC; chapters 2, 3.4, and 9 and national plumbing codes

• CANADA: NSCNGPIC Parts 3.4, 5, A. B, E, G, and H.