This forced air furnace is equipped for use with natural gas at altitudes 0 -10,000 ft (0 -3,050m), except 14,0 size furnaces are only approved for altitudes 0 -7,000 ft.

(0 -2 135m).

An accessory kit supplied by the manufacturer, shall be used to convert to propane gas use or may be required for some natural gas applications.

This furnace is for indoor installation in a building cy,_nstructed on site. This furnace may be installed in a manufactured (mobile) home when stated on rating plate and

using factory authorized kit..

This furnace may be installed on combustible floedng in alcove or closet at Minimum inches Clearance To Combustible Construction as described below.

This fumace requires a special venting system. Refer to the installation instructions for parts list and method of installation. This fumace is for use with schedula40 PVC,

PVC-DWV CPVC or ABS-DWV pipe and must not be vented in common with other gas-fired appliances. Construction through whiclq vent/air intake pipes may be

installed is maximum 24 inches (600 nlm), minimum 3/4 inches (19 mm) thickness (including roofing n_qteriala).

Cette foumaise _ air pula_ est d,quip_e pour utillaation avec gaz naturel et altitudes comprises entre 0 -3,050m (0 -10,000 pi),except6 queles fournaises de 140 taille

sont pour altitudes comprises entre 0 - 2,135m (0 - 7,000pi).

Utiliser une trausse de conversion fournie par le fabricant, pour passer au gaz propane ou pour certaines installations au gaz natarel.

Cette foumaise A air pula6 est pour installation & Hnt6rlaur dans un bAtiment construit sur place. Cette foumalae & air pulse paut 6tre installd, e dens une maison

pr6fabriqu6e (malaon mobile) si prescrit par la plaque signal6tique et si I_on utilise une trousse speclfi6e par la fabrlaant.

Cette foumaise peut 6tre installd, e sur un plancher combustible dens un enfoncement ou un placard en observant les D_gagement Minimum En Pouces Avec

Elements De Construction Combustibles.

Cette fournalae n@cessite un systeme d'6vacuation sp6cial. La n_thede d'installation et la Ilata des pieces nd,cessaires flgurent dens les instructions d'installation. Cette

fournaise doit s'utiliser avec la tayautede des nomenclatures 40 PVC, PVC-DWV, CPVC ou ABS-DWV et ella ne peut pas 6tre ventil_e conjolatment avec d'autres

appareila & gaz. Epaisseur de la construction au travers de laquelle il est possible de faire passer les tuyaux d'a6ration (admlaslan/6vacuation); 24 po (600 mm)

maximum, 3/4 po (19mm) minimum (y compris la toiture).

For upflc_w and cDwnflow applications, furnace must be installed level, or pitched within 1/2" of level. For a M IN 1/4" TO 1/2" MAX

horizontal application, the furnace must be pitahed minimum 1/4" to maximum of 1/Z' forward for propar

drainage. See Installation Manual for IMPORTANT unit support details on horizontal applications.

Pour des applications de flux ascendant et descendant, la fournalae doit (}tre installg_e de niveau ou laclla6e _ T

pas plas de 1/Z' du niveau. Pour une application hodzontale, la fournaise deit (}tre inclin6e entra n-tinimum UPFLOW OR

1/4" et maximum 1/2" du niveau pour le drainage approprid,. En cas d'installatlan en position horizontak_, DOWNFLOW

consulter les renseignementa JMPORTANTS sur le support dens le manuel d'ind_allation. HORIZONTAL

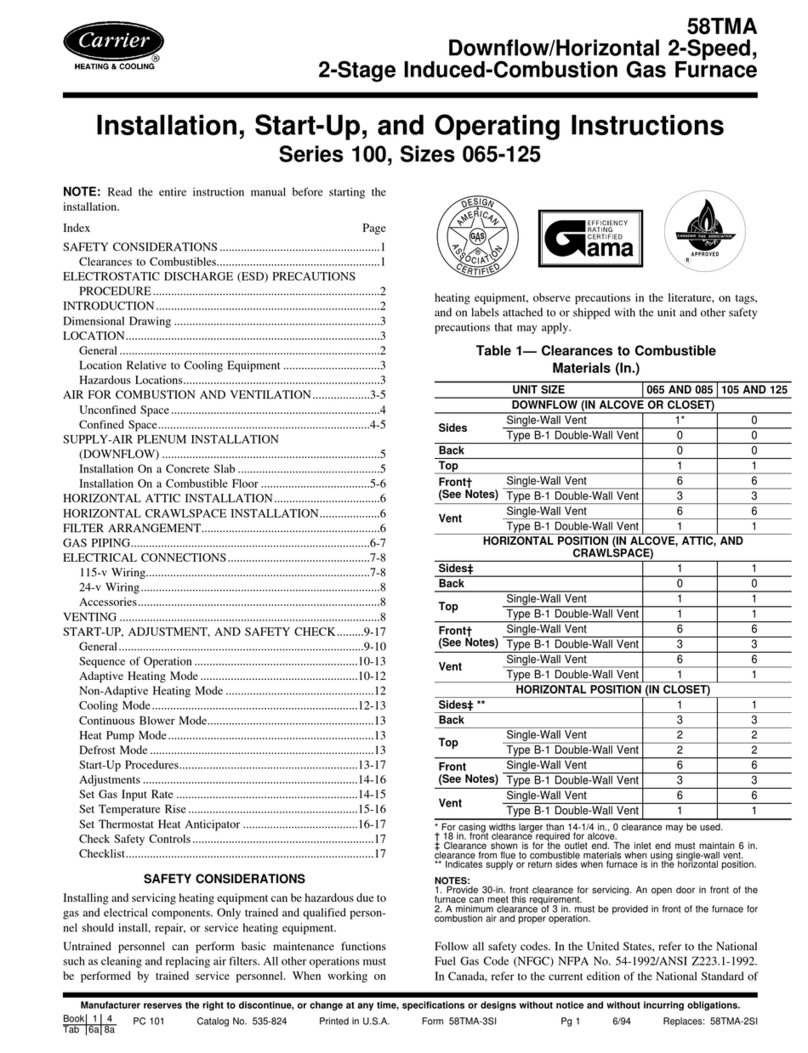

NININUN INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

ALL POSITIONS:

Minimum front clearance for sep,zice 24 inches (610ram).

1 1" 140 size furnaces require 1 inch back clearance to combustible materials.

DOWNFLOW POSITIONS:

1" For installa/Jon on cornbustible floors only when installed on special base No. KGASB0201ALL

Coil Assembly, Part No. CD5 or CKS, or Coil Casing, Part No. KCAKC.

HORIZONTAL POSITIONS:

Line contact is permissible only between lines formed by intersections of top and two sides of

furnace jacket, and building joists, studs, or framing.

§ Clearance shown is for air inlet and air outlet ends.

O 120 and 140 size furnaces require 1 inch bottom clearance to combustible materials.

DEGAGEMENT MINIMUM EN POUCES AVEC ELEMENTS DE CONSTRUCTION COMBUSTIBLES

POUR TOtJS LES POSITIONS:

Degagement avant minimum de 610mm (24 po) pour I'entrelien.

1" 1" Pourles foumaises de 140taille, 1 po(25mm)degagement des mat6riaux combustiblesest

requis au_arriere.

POUR LA POSITION COURANT DESCENDANT:

1" Pour Hnstallalion sur le plancher combustible seulement quand on utilise la base spedale, piece

n ° KGASB0201ALL I'ensernble serpaniin, pi6ce n° CD5 ou CKS, ou le carter de serpentin,

piece n ° KCAKC.

POUR LA POSITION HORIZONTALE:

Le contact n'est permis qOen_-e les lignes formees par les intersectioes du dessus et des

deuxc6tgs de la d:_emise de la foumaise, et des solives, des montanta ou de la d:rarpente du

batirnent

§ La distance indiquee concerne I'extr@mite du tuyau d'arfivee d'air et I'extrernit6 du tuyau de sortie

d'air.

O Pour les fournaises de 120 et 140 taille, 1 po (25mm) degagement des materiaux combusitbles

est requis au dessous.

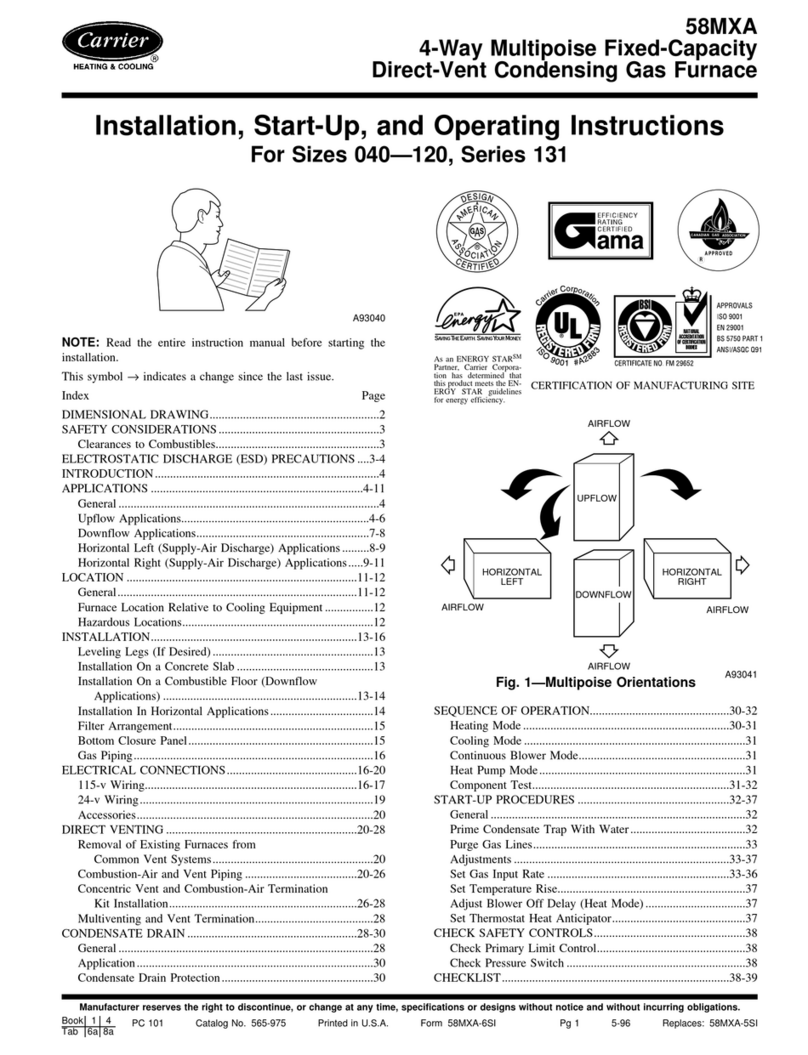

This furnace is approved for UPFLOW, DOW_q FLOW and

HORIZONTAL ins'talla_ns.

Cette fournaise est approuv@e paur Hns[allation HORIZONTALE

et la drculatlan d'air VERS LE HAUT et VERS LE BAS.

Cl_aranoa at-raws

do not change with ne cl]ange pas avec

furnace orlantation, I'otientation de la

g6n6rateur d'ak chaud.

Vent clearance to

combustibles 0".

Clearance in inches 0 (1::o)Dg%Jagement

D_gagement (po). d'@vent avec combustibles.

328066-201 REV. B LIT TOP

Fig. 3--Clearances to Combustibles

ELECTROSTAT{C DISCHARGE {ESD} PRECAUT{ONS 2 Firmly [ouchthe clean, unpaiute& metal surface of the _.m_ace

UNIT DAMAGE HAZARD

Failure to follow this caution may damage furnace compo=

nents,

Electrostatic discharge can affect electronic components

Take precautions during [_urnace installation and servicing to

protect the f_m_ace electronic control. Precautions will pre=

vent electrostatic discharges fi'om personnel and hand tools

which are held during the procedure. These precautions will

help to avoid exposing the control to electrostatic discharge

by putting the furnace, the control, and the person at the same

electrostatic potential.

l, Disconuect all power to the [_urnace Multiple disconnects may

be required DO NOT TOUCH THE CONTROL OR ANY

WIRE CONNECTED TO THE CONTROL PRIOR TO DIS=

CHARGING YOUR BODY' S ELE(TROSTATIC ( HARGE

TO GROUND

4_

5_

d.

chassis which is close to the control Tools held in a person's

haud during grounding will be satisfactorily discharged.

After touching the chassis, you may proceed to service the

control or connecting wires as tong as you do nothing to

recharge your body with static electricity (for example; DO

NOT move or shuffle your feet, do not touch ungrouuded

objects, etc)

If you touch uugrounded ohjects (and recharge your body with

static electricity), firmly touch a clean, uupainted metal

surface of the f_,_mace again befbre touching control or wires.

Use this procedure for installed and uninstalled (ungrounded)

_/fnaces

Betbre removing a new control flora its container, discharge

your body's electrostatic charge to grouud to protect d'*e

control f?om damage If [!_e control is to be installed iu a

f_,u_ace, follow items 1 through 4 bef_._re bringing the control

or yourself in contact with the furnace Put all used and new