Chana M201 2014 Instruction manual

M201 2014.01

2014 M201

Workshop Manual

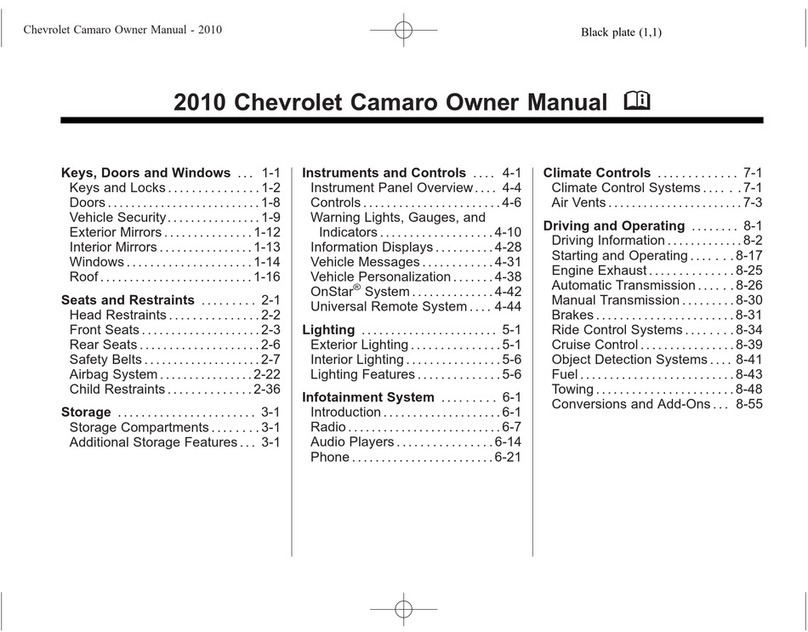

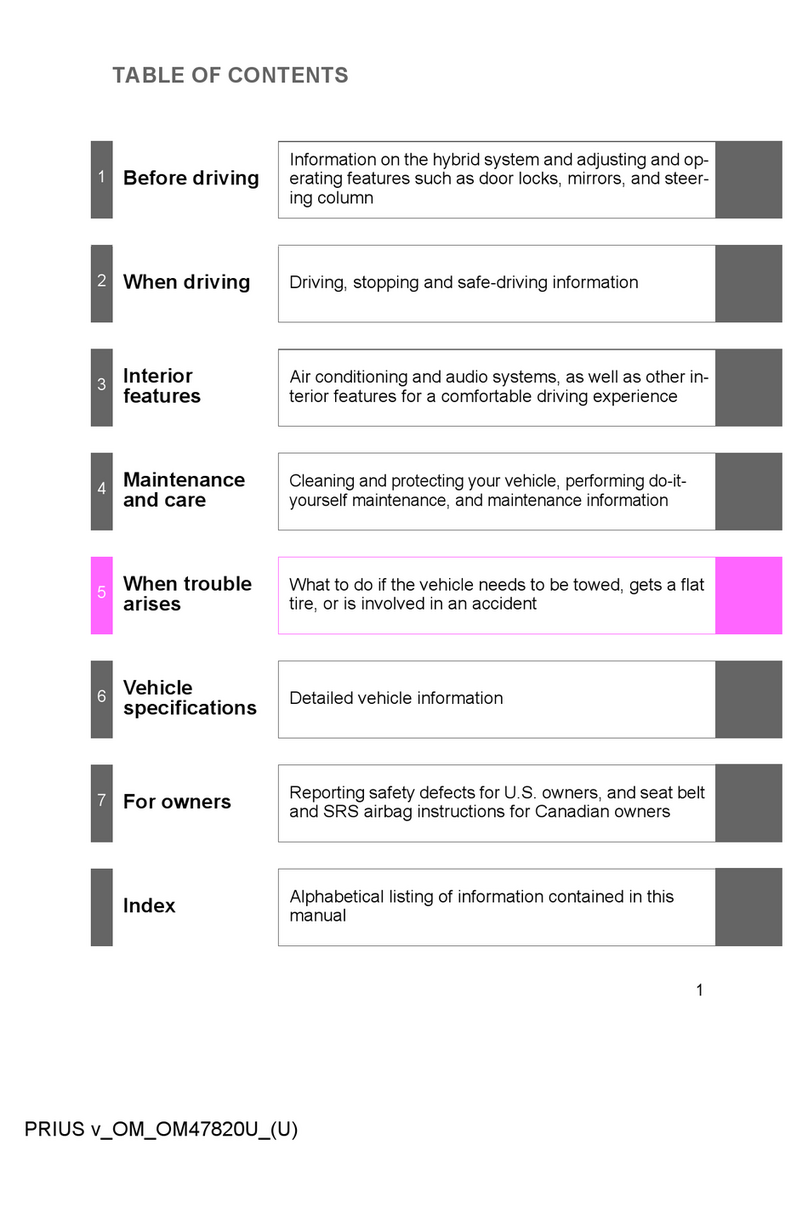

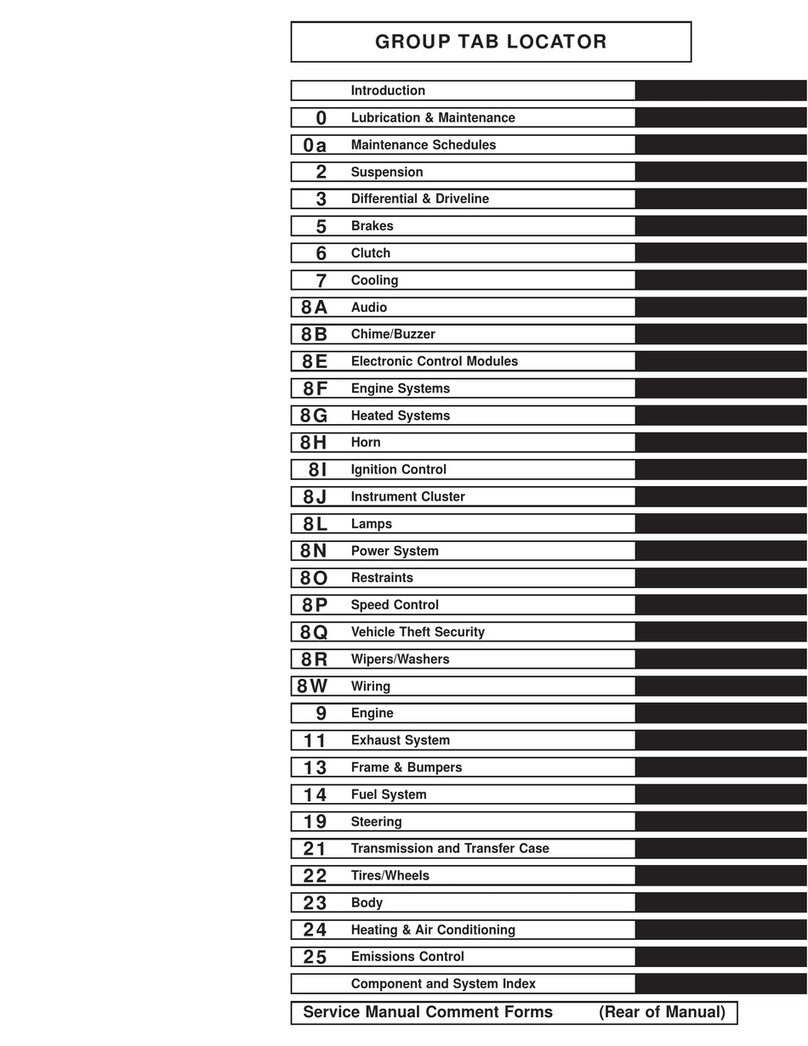

Table of Contents

1.1 Service Information

1.1.1 Overview .......................................1.1.1-1

1.1.2 Identification Codes ......................1.1.2-1

1.1.3 Traction and Lifting........................1.1.3-1

1.1.4 Maintenance Interval.....................1.1.4-1

1.1.5 Noise, Vibration and Harshness....1.1.5-1

2.1 Suspension System

2.1.1 Suspension System - Overview ....2.1.1-1

2.1.2 Front Suspension..........................2.1.2-1

2.1.3 Rear Suspension ..........................2.1.3-1

2.1.4 Wheel and Tire..............................2.1.4-1

2.2 Drive System

2.2.1 Driveline System - Overview.........2.2.1-1

2.2.2 Propeller Shaft ..............................2.2.2-1

2.2.3 Drive Shaft ....................................2.2.3-1

2.2.4 Differential .....................................2.2.4-1

2.3 Brake System

2.3.1 Brake System - Overview..............2.3.1-1

2.3.2 Rear Drum Brake ..........................2.3.2-1

2.3.3 Front Disc Brake ...........................2.3.3-1

2.3.4 Parking Brake and Operation........2.3.4-1

2.3.5 Hydraulic Brake Control ................2.3.5-1

2.3.6 Power Brake .................................2.3.6-1

2.4 Steering System

2.4.1 Steering System - Overview ......... 2.4.1-1

2.4.2 Steering Gear................................ 2.4.2-1

2.4.3 Steering Column ........................... 2.4.3-1

3.1 Engine

3.1.1 Engine System - Overview ........... 3.1.1-1

3.1.2 Mechanical System....................... 3.1.2-1

3.1.3 Lubrication System ....................... 3.1.3-1

3.1.4 Cooling System............................. 3.1.4-1

3.1.5 Air Intake System.......................... 3.1.5-1

3.1.6 Exhaust System............................ 3.1.6-1

3.1.7 Fuel System.................................. 3.1.7-1

3.1.8 Ignition System ............................. 3.1.8-1

3.1.9 Starting System............................. 3.1.9-1

3.1.10 Charging System ...................... 3.1.10-1

3.1.11 Emission Control System.......... 3.1.11-1

3.1.12 Electronic Control

System - M7.............................. 3.1.12-1

3.2 Manual Transmission/Clutch

3.2.1 Manual Transmission/

Clutch - Overview ......................... 3.2.1-1

3.2.2 Clutch..........................................3.2.2-1

3.2.3 Manual Transmission ..................3.2.3-1

3.2.4 Manual Transmission External

Control .......................................... 3.2.4-1

GROUP 1 Overview

GROUP 2 Chassis

GROUP 3 Powertrain

M201 2014.01

4.1 Heating, Ventilation and Air

Conditioning

4.1.1 Heating, Ventilation and

Air Conditioning............................ 4.1.1-1

4.2 Body Electrical

4.2.1 Instrument Panel and

Panel Illumination......................... 4.2.1-1

4.2.2 Instrument Cluster ........................ 4.2.2-1

4.2.3 Horn.............................................. 4.2.3-1

4.2.4 Cigarette Lighter........................... 4.2.4-1

4.2.5 Information and

Entertainment System.................. 4.2.5-1

4.2.6 Lighting System............................ 4.2.6-1

4.2.7 Wiper and Washer........................ 4.2.7-1

4.2.8 Central Door Lock ........................ 4.2.8-1

4.2.9 Power Window ............................. 4.2.9-1

4.2.10 Body Control System................ 4.2.10-1

4.2.11 On-board Network .....................4.2.11-1

5.1 Body and Accessories

5.1.1 Front/Rear Windshield.................. 5.1.1-1

5.1.2 Door.............................................. 5.1.2-1

5.1.3 Seat .............................................. 5.1.3-1

5.1.4 Seat Belt....................................... 5.1.4-1

5.1.5 Rearview Mirror ............................ 5.1.5-1

5.1.6 Instrument Panel and Console..... 5.1.6-1

5.1.7 Bumper......................................... 5.1.7-1

5.1.8 Handles, Locks and Latches ........ 5.1.8-1

5.1.9 Interior Trim Panel

and Ornamentation....................... 5.1.9-1

5.1.10 Exterior Trim............................. 5.1.10-1

5.2 Body Repairs

5.2.1 Body Repairs................................ 5.2.1-1

GROUP 4 Electrical

GROUP 5 Body

M201 2014.01

Overview

1

GROUP

1.1 Service Information

1.1.1 Overview ........................................................................................................................... 1.1.1-1

1.1.2 Identification Codes .......................................................................................................... 1.1.2-1

1.1.3 Traction and Lifting............................................................................................................ 1.1.3-1

1.1.4 Maintenance Interval......................................................................................................... 1.1.4-1

1.1.5 Noise, Vibration and Harshness ....................................................................................... 1.1.5-1

SECTION PAGE

M201 2014.01

Service Information

1.1 Service Information

2014 M201

1.1.1 Overview

Description and Operation ............................................................................................................... 1.1.1-1

About This Manual.................................................................................................................... 1.1.1-1

Health and Safety Precautions ................................................................................................. 1.1.1-2

Standard Workshop Practice .................................................................................................. 1.1.1-12

Solvents, Sealants and Adhesives ......................................................................................... 1.1.1-14

Road/Roller Test ..................................................................................................................... 1.1.1-14

1.1.2 Identification Codes

Description and Operation ............................................................................................................... 1.1.2-1

Vehicle Identification Number ................................................................................................... 1.1.2-1

Nameplate ................................................................................................................................ 1.1.2-2

1.1.3 Traction and Lifting

Description and Operation ............................................................................................................... 1.1.3-1

Traction..................................................................................................................................... 1.1.3-1

Jacking ..................................................................................................................................... 1.1.3-1

Lifting ........................................................................................................................................ 1.1.3-2

1.1.4 Maintenance Interval

Description and Operation ............................................................................................................... 1.1.4-1

Maintenance Items ................................................................................................................... 1.1.4-1

Daily Maintenance Schedule .................................................................................................... 1.1.4-2

1.1.5 Noise, Vibration and Harshness

Description and Operation ............................................................................................................... 1.1.5-1

NVH Meaning in Automotive Engineering ................................................................................ 1.1.5-1

Noise Type in Automotive Engineering..................................................................................... 1.1.5-1

Vibration Process Engineering ................................................................................................. 1.1.5-2

Noise and Vibration on Vehicle................................................................................................. 1.1.5-4

Noise and Vibration Caused By Intake and Exhaust Systems ................................................. 1.1.5-4

Vehicle Body............................................................................................................................. 1.1.5-5

Symptom Diagnosis and Testing...................................................................................................... 1.1.5-6

Inspection and Verification........................................................................................................ 1.1.5-6

Table of Contents Pages

M201 2014.01

1.1.1-1 1.1.1-1Overview

1.1.1 Overview

Description and Operation

About This Manual

Introduction

This manual has been written in a format that is

designed to meet the needs of technicians. This

manual provides general descriptions for

accomplishing service and repair work. Following

them will help assure reliability.

Spare Parts

The parts from Changan Automobile Co., Ltd. are

manufactured according to the original factory

standard. Only the genuine parts from Changan

Automobile Co., Ltd. can be used in repair.

Special Tool

Special tool(s) list provided at the beginning of

each procedure are the special tools required to

carry out the repair. Where possible, illustrations

are provided to assist in identifying the special

tool required. The special tools can be ordered

from Changan Automobile Co., Ltd.

Important Safety Instructions

Appropriate service methods and correct repair

procedures are essential for the safe, reliable

operation on the vehicles as well as the personal

safety.

This manual cannot possibly provide all such

variations and advice or cautions as to each.

Anyone who departs from the instructions

provided in this manual must assure that the

operation methods, tools and components used

neither cause personal injury nor break the

vehicle integrity.

Warnings, Cautions and Notes in This

Manual

As you read through this manual, you will come

across WARNINGS and CAUTIONS.

WARNING: Warnings are used to indicate

that failure to follow a procedure correctly

may result in personal injury.

CAUTION: Cautions are used to indicate

that failure to follow a procedure correctly

may result in damage to the vehicle or

repair tools being used.

Refer to: Notes are used to provide

additional information to

effectively help improve repair

efficiency.

How to Use the Manual

This manual covers the maintenance and repair

service procedures.

This manual is structured into groups and

sections, with specific system sections collected

together under their relevant group. A group

covers a specific portion of the vehicle.

The manual is divided into five groups: Overview,

Chassis, Powertrain, Electrical and Body.

Table of Contents of the manual includes all

sections. Each section has a regular structure:

Specifications, Description and Operation,

General Inspection, Symptom Diagnosis and

Testing, DTC Diagnosis and Testing, Removal

and Installation, Disassembly and Assembly.

All left-hand and right-hand references to the

vehicle are taken from a position sitting in the

driver seat looking forward.

All left-hand and right-hand references to the

engine are taken from a position at the flywheel

looking towards the front camshaft pulley.

Specifications

Specifications mainly describes the material

specifications, component specifications, general

specifications (the contents that can be included

in other specifications) and torque specifications.

The information in the specifications shall use the

metrics except the torque (imperial).

1.1.1-2

M201 2014.01

1.1.1-2Overview

Description and Operation

Description and Operation mainly describes the

system components, functions and principles of

the new systems. The "new systems" refer to the

systems that never used on the previous models

of the manufacturer. The purpose of the brief

introduction is to make the technicians get familiar

with the functions and principles of the systems.

The component location view and components

exploded view are also included in this section.

General Inspection

General Inspection mainly describes the general

inspection steps of the system.

Symptom Diagnosis and Testing

Symptom Diagnosis and Testing section

describes the diagnosis and inspection for the

symptom that cannot be judged from the visual

inspection only, excluding the diagnosis and

inspection using diagnostic tool. The contents

include inspection and verification (visual

inspection chart), symptom chart and symptom

diagnosis procedures.

DTC Diagnosis and Testing

DTC Diagnosis and Testing refers to the

diagnosis and testing for the component or

system using diagnostic tool. It covers engine

control module terminal list, DTC code list, data

flow list, active test list and DTC diagnosis

procedure.

Health and Safety Precautions

Introduction

Many of the procedures associated with vehicle

maintenance and repair involve physical hazards

or other risks to health. This subsection lists,

alphabetically, some of these hazardous

operations and the materials and equipment

associated with them. Precautions necessary to

avoid these hazards are identified.

The list is not exhaustive and all operations and

procedures, and the handling of materials, should

be carried out with health and safety in mind.

Before using any product the Materials Safety

Data Sheet supplied by the manufacturer or

supplier should be consulted.

Acid, Alkali and Metal

• Caustic soda, sulphuric acid.

• Electrolyte and cleaning material.

• Irritable and corrosive substances to skin,

eyes, nose, throat and clothes.

Flammable substance and the substance

able to destroy ordinary protective

clothing.

Avoid splashing such substances to the skin,

eyes and clothes. Wear suitable protective

impervious apron, gloves and goggles. Do not

breathe acid mist. Make sure that the eye wash

bottle, shower and soap are readily available for

splashing accidents.

Place Eye Hazard sign.

Air Conditioning Refrigerant

Refer to: Chemical Materials.

Highly flammable substance - observe No

Smoking policy.

Skin contact may result in frostbite.

Instructions given by the manufacturer must be

followed. Wear suitable protective gloves and

goggles to avoid highlight.

If refrigerant comes into contact with the skin or

eyes, immediately flush the affected areas with

water. Eyes should also be rinsed with an

appropriate irrigation solution and should not be

rubbed. Seek medical assistance if necessary.

Air Conditioning Refrigerant - forbidden items:

• Do not expose the air conditioning

refrigerant in the sunshine or heat it.

• Never put the filling bottle vertically when

filling. The filling opening should be

downward.

• Avoid the frost on the air conditioning

refrigerant bottle.

• Avoid the dropping of air conditioning

refrigerant bottle.

• Do not discharge the air conditioning

refrigerant in the atmosphere in any

circumstance.

• Do not use the mixed refrigerant, such as

Freon R12 and R134a.

M201 2014.01

1.1.1-3 1.1.1-3Overview

Adhesives and Sealants

Refer to: Chemical Materials.

Highly flammable substance - observe No

Smoking policy.

Generally, they should be stored in No Smoking

areas. Cleanliness and tidiness in use should be

observed, for example disposable paper covering

benches; should be dispensed from applicators

where possible; containers, including secondary

containers, should be labeled appropriately.

1. Solvent - based Adhesives/Sealers

Follow manufacturer instructions.

2. Water - based Adhesives/Sealers

Those based on polymer emulsions and

rubber latexes may contain small amounts of

volatile toxic and harmful chemicals. Skin and

eye contact should be avoided and adequate

ventilation provided during use.

3. Hot Melt Adhesives

In the solid state, they are safe. In the molten

state, they may cause burns and health

hazards may arise from the inhalation of toxic

fume.

Use appropriate protective clothing and a

thermostatically controlled heater with a

thermal cut-out and adequate extraction.

4. Resin based Adhesives/Sealers, for example,

Epoxide and Formaldehyde Resin

Mixing should be carried out in well ventilated

areas, as harmful or toxic volatile chemicals

may be released.

Skin will incur dermatitis and inhale toxic or

harmful chemicals if contacting with uncured

resins.

Splashes can damage the eyes. Provide

adequate ventilation and avoid skin and eye

contact.

5. Anaerobic, Cyanoacrylate (super-glues) and

other Acrylic Adhesives

Many are irritant, sensitizing or harmful to the

skin and respiratory tract. Some are eye

irritants. Skin and eye contact should be

avoided and the manufacturers instructions

followed.

Cyanoacrylate adhesives (super - glues)

MUST NOT contact the skin or eyes. If skin or

eye tissue is bonded, cover with a clean moist

pad and SEEK IMMEDIATE MEDICAL

ATTENTION. Do not touch the injured area

with hands. Use in well ventilated areas as

vapor can cause irritation to the nose and

eyes.

6. Isocyanate (Polyurethane) Adhesives /

Sealers

Refer to: Resin-based Adhesives.

Individuals suffering from asthma or

respiratory allergies should not work with or

near these materials as sensitivity reactions

can occur.

Over exposure is irritating to the eyes and

respiratory system. Excessive concentrations

may produce effects on the nervous system

including drowsiness. In extreme cases, loss

of consciousness may result. Long term

exposure to vapor concentrations may result

in adverse health effects.

Prolonged contact with the skin may have a

defeating effect which may lead to skin

irritation and in some cases, dermatitis.

Splashes entering the eye will cause

discomfort and possible damage. Any

spraying should preferably be carried out in

exhaust ventilated booths, removing vapor

and spray droplet from the breathing zone.

Wear appropriate gloves, eye and respiratory

protection.

Antifreeze

Refer to: Inflammables, Solvent.

For example, isopropanol, ethylene glycol and

methanol.

Highly flammable, flammable, combustible.

Used in vehicle coolant systems, screenwash

solutions.

The antifreeze will generate steam when heated.

Avoid inhaling such gas.

1.1.1-4

M201 2014.01

1.1.1-4Overview

The antifreeze or other harmful materials may

enter the human body through the skin. Drinking

the antifreeze accidentally may cause death, so

seek immediate medical assistance.

Do not use any of such substances in the cooling

or industrial water use system related to the food

manufacturing or drinking system.

Electrolyte

Refer to: Acid, Alkali and Metal.

The released gas will cause explosion when

charging the battery. Open fire or spark is

forbidden when charging the battery. Ensure

good ventilation.

Brake Fluid

Refer to: Fire Prevention.

Slight irritability may be caused if the braking fluid

is splashed on skin and eyes. Avoid the braking

fluid touching skin and eyes. Because the steam

pressure is low, the harmful steam cannot be

inhaled at normal temperature.

Braze Welding

Refer to: Welding.

Chemical Materials

Refer to: Legal Aspect.

The chemical materials include solvent, sealer,

adhesive, paint, resin foam, electrolyte,

antifreeze, braking fluid, fuel, oil and grease. Be

careful when using and storing the materials.

They may be noxious, harmful, corrosive, irritable

and inflammable and will generate some harmful

gas and dust.

Long term exposure to the chemical materials

may affect the health to different extents.

1. Chemical Materials - operations to be

performed:

• Read the labels on the dangerous article

container and the corresponding

promotion information and instruction

carefully to obtain the relevant safety

information. The safety and health data

table of the substance can be obtained

from the manufacturer.

• Clean the skin and clothes if being

polluted by the chemical materials.

Replace the severely polluted clothes

and clean them.

• Compile operation instructions, and wear

protective clothes to avoid the substance

polluting skin and eyes and inhaling the

harmful gas, acid mist, dust and smog,

etc. and avoid the combustion and

explosion caused by such substance.

• Wash hands immediately after touching

the substance.

• Keep the working area clean, tidy and no

leakage.

• The chemical materials shall be managed

and stored strictly in accordance with the

national and local regulation.

• Keep the materials away from the

children.

2. Chemical Materials - forbidden operations:

• Do not mix the chemical materials

arbitrarily without following the

manufacturer instructions. Mixing some

chemical materials will generate the

harmful substance; the noxious and

harmful gas will be released or the

explosion may occur.

• Do not spray the chemical materials in

the narrow space with person in the

automobile, especially to spray the

solvent chemicals.

• Do not heat or burn the chemical

materials arbitrarily without following the

manufacturer instruction, because some

chemical materials are combustible, and

some substance will release noxious or

harmful gas when burnt.

• Do not leave the container open, as the

gas emitted from the container may be

toxic to the human body or cause an

explosion. Some gas lighter than air will

accumulate in small sections.

• Do not transport the chemical materials

with containers without label.

• Do not wash hands or clothes with the

chemical materials. The chemical

materials, especially the solvent and fuel,

will make the skin dry, and also irritate the

skin to catch dermatitis, or some noxious

M201 2014.01

1.1.1-5 1.1.1-5Overview

and harmful gas will be absorbed

through the skin.

• Do not store other articles with used

empty tank to store the chemical

materials without special treatment.

• Do not smell the chemical materials. The

gas with sudden high concentration will

cause poisoning or injury.

Clutch Fluid

Refer to: Brake Fluid.

Anti-corrosion Materials

Refer to: Solvent and Fire Prevention.

Highly flammable substance - observe No

Smoking policy.

These materials are miscellaneous and the

manufacturers instructions must be followed.

They may contain solvents, resins or petroleum

products, so skin and eye contact should be

avoided. They should not be sprayed in a

confined space without well ventilation.

Cutting

Refer to: Welding.

Dewaxing

Refer to: Solvent and Fuel (Kerosene).

Dust

Dust may be toxic, harmful and irritant to the skin.

Avoid inhaling the powder chemical material or

other dust. Wear respiratory protection if

ventilation is inadequate.

Fine dusts of combustible materials can present

an explosion hazard. Avoid explosive limits and

fire sources.

Electric Shock

Electric shock can result from the use of faulty

electrical equipment or from the misuse of

equipment in good condition.

Make sure that all electrical equipment is

maintained in good condition and regularly tested.

Faulty equipment should be labeled and

preferably removed from the workstation. Make

sure that wires, cables, plugs and sockets are not

frayed, kinked, cut, cracked or otherwise

damaged. Make sure that the electrical

equipment and wires do not come into contact

with water. Make sure that the electrical

equipment is protected by the correct rated fuse.

Never misuse the electrical equipment and never

use the equipment that is in any way faulty.

Failure to do so could be fatal.

Make sure that the cables of electrical tools do

not get trapped and damaged in a vehicle hoist.

Make sure that the electrical workers are trained

in basic First Aid.

In case of an electric shock:

• Switch off the power supply before

touching the victim.

• If it is impossible to switch off the power

supply, push or drag the victim away from

the power source, using dry non-

conductive material.

• Commence resuscitation if trained to do

so.

• Seek medical assistance.

Engine Oil

Refer to: Lubricants and Grease.

Exhaust Gas

Exhaust gas contains asphyxiating, harmful and

toxic chemicals and particles such as carbon

oxides, nitrogen oxides, aldehydes, lead and

aromatic hydrocarbons. Engine should be run

only under conditions of adequate exhaust

extraction or general ventilation and not in

confined spaces.

Gasoline (Petrol) Engine

There may not be adequate warning of odor or of

irritation before toxic or harmful effects arise.

These may be immediate or delayed.

1.1.1-6

M201 2014.01

1.1.1-6Overview

Noise Insulation Fiber

Refer to: Dust.

Used in noise and sound insulation. The fibrous

nature of surfaces and cut chips can cause skin

irritation. This is usually a physical but not a

chemical effect. Precautions should be taken to

avoid excessive skin contact through careful

organization of work practices and the use of

gloves.

Fire Prevention

Refer to: Welding, Foam and Legal

Aspect.

Many of the materials found on or associated with

the repair of vehicles are highly flammable. Some

give off toxic or harmful fume if burnt. Observe

strict fire safety precautions when storing and

handling flammable substances or solvents,

particularly near electrical equipment or during

welding process. Make sure that there is no fire

hazard present and have a suitable fire

extinguisher available before using welding or

heating equipment.

First Aid

Apart from meeting any legal requirements it is

desirable for someone in the workshop to be

trained in First Aid procedures.

Splashes in the eye should be flushed carefully

with clean water for at least ten minutes.

Soiled skin should be washed with soap and

water. In case of cold burns from alternative fuels,

place affected area in cool to cold water.

Individuals affected by inhalation of gas and fume

should be removed to fresh air immediately. If

effects persist, consult a doctor.

If liquids are swallowed inadvertently, consult a

doctor and give him the information on the

container or label. Do not induce vomiting unless

this action is indicated on the label.

Foams - Polyurethane

Refer to: Fire Prevention.

Used in sound and noise insulation. Cured foams

used in seat and trim cushioning.

Follow manufacturers instructions. Unreacted

components are irritating and may be harmful to

the skin and eyes. Wear gloves and goggles.

Individuals with chronic respiratory diseases,

asthma, bronchial medical problems, or histories

of allergic diseases should not work in or near

uncured materials. Some components, vapor or

spray mist can cause direct irritation, sensitivity

reactions and may be toxic or harmful.

Vapor and spray mist must not be inhaled. These

materials must be applied with adequate

ventilation and respiratory protection. Do not

remove the respirator immediately after spraying;

wait until the vapor/mist has been cleared.

Burning of the uncured components and the

cured foams can generate toxic and harmful

fume. Smoking, naked flames or the use of

electrical equipment during foaming operations

should not be allowed. Any heat cutting of cured

foams or partially cured foams should be

conducted with extraction ventilation.

Refrigerant

Refer to: Air-Conditioning Refrigerant.

Fuel

Refer to: Fire, Solvent and Legal Aspect.

Keep fuel away from skin. Wash with clean water

and soap if stained with fuel.

M201 2014.01

1.1.1-7 1.1.1-7Overview

Gasoline (Petrol)

Highly flammable substance - observe No

Smoking policy.

Swallowing gasoline will stimulate mouth and

throat, and if the gasoline is absorbed by the

stomach, it will cause sleepiness and

unconsciousness. A small quantity of gasoline will

cause death of a child. When the inhaled fluid

reaches the lung, the severe damage will be

caused. Contacting the gasoline for a long time

will make the person skin dry and have the strong

irritability. The gasoline entering eyes will cause

blindness. A great amount of benzene is

contained in the gasoline, which is toxic to

person. The gasoline concentration must be very

low, the over-high concentration will stimulate

eyes, nose and throat and make person vomit,

dizziness and dyspnea, even make person lose

consciousness.

The gasoline shall be transported or used in a

place with air circulation. Operating in confined

spaces is not allowed.

For the cleaning and maintenance of gasoline

storage, there must have special preventive

measures. The gasoline cannot be used as the

cleaning agent and cannot be siphoned with

mouth neither.

Kerosene (Paraffin)

Used also as heating fuel, solvent and cleaning

agent.

Flammable substance - observe No Smoking

policy.

Irritation of the mouth and throat may result from

swallowing. Liquid contact dries the skin and can

cause irritation or dermatitis. Splashes to the eye

may be slightly irritating. In normal circumstances,

the low volatilization does not generate harmful

vapor. Volatilization under high temperature

should be avoided (mist may arise in dewaxing).

Avoid skin and eye contact and make sure there

is adequate ventilation.

High Pressure Gas Cylinder

Refer to: Fire Prevention.

Gases such as oxygen, acetylene, argon and

propane are normally stored in cylinders at

pressures of up to 138 bar (2000 psi). Great care

should be taken in handling these cylinders to

avoid mechanical damage to them or to the valve

gear attached. The contents of each cylinder

should be clearly identified by appropriate

markings.

Cylinders should be stored in well-ventilated

enclosures, and protected from ice and snow, or

direct sunlight. Fuel gas, for example acetylene

and propane, should not be stored in close

proximity to oxygen cylinders.

Care should be exercised to prevent leaks from

gas cylinders and lines, and to avoid fire sources.

Gas

Refer to: High Pressure Gas Cylinder.

General Tool and Equipment

It is essential that all tools and equipment are

maintained in good condition and that the correct

safety equipment is used where required.

Never use tools or equipment for any purpose

other than that for which they were designed.

Never overload equipment such as hoists and

jacks. Damage caused by overloading is not

always immediately apparent and may result in a

fatal failure the next time that the equipment is

used.

Do not use damaged or defective tools or

equipment, particularly high-speed equipment

such as grinding wheels. A damaged grinding

wheel can disintegrate without warning and cause

serious injury.

Wear suitable eye protection when using grinding

wheel, chiseling or sand blasting equipment.

Wear a suitable breathing mask when using

abrasive blasting equipment, working with

asbestos-based materials or using spraying

equipment. Make sure there is adequate

ventilation to control dust, acid mist and fume.

1.1.1-8

M201 2014.01

1.1.1-8Overview

High Pressure Air, Lubricant and Oil

Test Equipment

Refer to: Lubricants and Grease.

Always keep high-pressure equipment in good

condition, and regularly maintained, particularly at

joints and unions.

Never direct a high-pressure nozzle, for example

diesel injector, at the skin as the fluid may

penetrate to the underlying tissue, and cause

serious injury.

Legal Aspect

There are many laws and regulations relating to

health and safety in the use and disposal of

materials and equipment in a workshop.

For a safe working environment and to avoid

environmental pollution, technicians should be

familiar, in detail, with many health and safety

laws and regulations within their country.

Lubricants and Grease

Avoid all prolonged and repeated contact with

mineral oil. All lubricants and grease may be

irritating to eyes and skin.

1. Used Oil

Prolonged and repeated contact with mineral

oil will result in the removal of natural fats

from the skin, leading to dryness, irritation

and dermatitis. In addition, used engine oil

contains potentially harmful contaminants,

which may cause skin cancer. Adequate

means of skin protection and washing

facilities must be provided.

Do not employ used engine oils as lubricants

or for any application where appreciable skin

contact is likely to occur.

2. Health Precautions:

• Avoid long contact with oil, especially the

engine oil.

• Wear protective clothes, including gloves.

• Do not put wiping cloth with oil stains in

pocket.

• Avoid oil polluting clothes.

• Do not wear clothes and shoes seriously

stained with oil. Wash protective clothes

regularly.

• Perform first aid immediately when

injured.

• Protect hands with protective cream

before working.

• Wash with soap and clear water. Do not

wash skin with gasoline, diesel oil,

kerosene, diluents and solvent.

• If skin is abnormal, go to hospital

immediately.

• Degrease liquid first if possible.

• Wear goggles if the liquid may cause

damage to eyes.

3. Environmental Precautions

Burning the used engine oil can be

recommended only for units of approved

design. If in doubt, check with the appropriate

local authority and manufacturer of approved

appliances.

Dispose of the used engine oil through

authorized waste disposal contractors or

licensed waste disposal sites, or to the waste

oil reclamation trade. If in doubt, contact the

relevant local authority for advice on disposal

facilities.

It is illegal to pour the used oil on to the

ground, down sewers or drains, or into

watercourses.

Noise

Some operations may produce high noise levels,

which could, in time, damage hearing. In these

cases, suitable ear protection must be worn.

Sound Insulation Material

Refer to: Foam, Insulation Fiber.

M201 2014.01

1.1.1-9 1.1.1-9Overview

Coating

Refer to: Oil and Chemical Materials.

Flammable substance - observe No Smoking

policy.

1. Monocomponent

It could contain harmful or toxic pigments,

driers and other components as well as

solvents. Spraying should be carried out only

with adequate ventilation.

2. Multicomponent

It could contain harmful and toxic unreacted

resins and resin hardening agents. The

manufacturer instructions should be followed.

Refer to: Resin-based Adhesives.

Spraying should preferably be carried out in

exhausted ventilated booths far from the

crowds. Individuals working in booths should

wear appropriate respiratory protection.

Pressure Equipment

Refer to: High Pressure Gas, Lubricants

and Oil Test Equipment.

Solder

Solders are mixtures of metals such that the

melting point of the mixture is below that of the

constituent metals (normally lead and tin). Solder

application does not normally give rise to toxic

lead fume in welding. Oxy - acetylene flame

should not be used, as they are much hotter to

produce lead fume.

Some fume may be produced by the application

of any flame to surfaces coated with grease, and

inhalation of these should be avoided. Removal of

excess solder should be undertaken with care, to

make sure that fine lead dust, which can give

toxic effects if inhaled, is not produced.

Respiratory protection may be necessary. Solder

spillage and filings should be collected and

removed promptly to prevent general air

contamination by lead. Avoid ingestion of lead or

inhalation of solder dust.

Solvents

Refer to: Chemical Materials, Fuel and Fire

Prevention.

For example acetone, white spirit, toluene,

xylene, trichloroethane. Used in cleaning and

dewaxing materials, paints, plastics, resins and

thinners. Some may be highly flammable or

flammable. Skin contact will degrease the skin

and may result in irritation and dermatitis

following repeated or prolonged contact. Some

can be absorbed through the skin in toxic or

harmful quantities.

Splashes in the eye may cause severe irritation

and could lead to loss of vision. Brief exposure of

high concentrations of vapor or mist will cause

eye and throat irritation, drowsiness, dizziness,

headaches and, in the worst circumstances,

unconsciousness.

Repeated or prolonged exposure of lower

concentrations of solvent will produce vapor or

mist, which there might not be adequate warning

indications, can cause more serious toxic or

harmful effects.

Avoid splashes to the skin, eyes and clothing.

Wear protective gloves, goggles and clothing if

necessary.

Make sure there is good ventilation when in use,

avoid breathing fume, vapor and spray mist and

keep containers tightly sealed. Do not use in a

confined space.

When spraying materials containing solvents, for

example paints, adhesive and coatings, use

extraction ventilation or personal respiratory

protection in the absence of adequate general

ventilation.

Do not apply heat or flame except under specific

and detailed manufacturers guidance.

Suspended Load

WARNING: Never improvise lifting tackle.

There is always a danger when loads are lifted or

suspended. Never work under an unsupported,

suspended or raised load, for example a

suspended engine.

1.1.1-10

M201 2014.01

1.1.1-10Overview

Always make sure that lifting equipment such as

jacks, hoists, axle stands and slings are, in good

condition and regularly maintained.

Underseal

Refer to: Anti-corrosion Material.

Welding

Refer to: Fire Prevention, Electric Shock

and High Pressure Gas Cylinder.

The welding procedures include (resistance

welding) spot welding, arc welding and gas

welding.

1. Resistance Welding

This process may cause particles of molten

metal to be emitted at a high velocity, and the

eyes and skin must be protected.

2. Arc Welding

This process emits a high level of ultra-violet

radiation, which may cause arc-eye, and skin

burns to the operator and to other persons

nearby. Gas - shielded welding processes are

particularly hazardous in this respect.

Personal protection must be worn, and

screens used to shield other people.

CONTACT LENS WEARERS ARE ADVISED

TO REVERT TO ORDINARY SPECTACLES

WHEN ARC WELDING as the arc spectrum

is believed to emit microwaves which dry out

the fluid between the lens and the eye, even

result in blindness. Metal spatter will also

occur, and appropriate eye and skin

protection is necessary.

The heat of the welding arc will produce fume

and gas from the metal molten pool being

welded, when the core or coat are

contaminated. The gas and fume may be

toxic and inhalation of these should be

avoided. The extraction ventilation to remove

the fume from the working area may be

necessary particularly in cases where the

general ventilation is poor, or where

considerable welding work is anticipated. In

extreme cases or confined spaces where

adequate ventilation cannot be provided,

respirators may be necessary.

3. Gas Welding (Gas Cutting)

Oxy acetylene torches may be used for

welding and cutting, and special care must be

taken to prevent gas leakage, with

consequent risk of fire and explosion.

The process will produce metal spatter and

eye and skin protection is necessary. The

flame is bright, and eye protection should be

used, but the ultra-violet emission is much

less than that from arc welding, and lighter

filters may be used.

The process itself produces few toxic fumes,

but such fume and gas may be produced

from coatings on the work, particularly during

cutting off damaged parts. Inhalation of the

fume should be avoided.

In brazing, toxic fume may be produced from

the metals in the brazing rod, and a severe

hazard may arise if brazing rods containing

cadmium are used. In this event, particular

care must be taken to avoid inhalation of

fume and expert advice may be required.

SPECIAL PRECAUTIONS MUST BE TAKEN

BEFORE ANY WELDING OR CUTTING ON

VEHICLES AS COMBUSTIBLE GAS

(VOLATILIZING AND EVAPORATING FROM

FUEL TANK) IS EXISTED.

Warning Signs on Vehicle

Decals showing warning symbols will be found on

various vehicle components. These decals must

not be removed. Owners/operators must attach

great importance to signs.

The most frequently used decals are reproduced

below together with an explanation of the

warnings.

1. Components or assemblies displaying the

caution triangle and open book symbol advise

consultation of the relevant section of the

owner literature before touching or attempting

adjustments of any kind.

M201 2014.01

1.1.1-11 1.1.1-11Overview

2. Components or assemblies displaying the

warning triangle with the "electrified" arrow and

open book symbol give warning of inherent

high voltage. Never touch these with the

engine running or the ignition switched on.

Refer to: Electric Shock.

3. Vehicles and replacement components which

contain asbestos are identified by this symbol.

Refer to: Acid and Alkali Metals.

4. Displaying the caution circle with a deleted

lighted match symbol, cautions against the

use of naked light or flame within the

immediate vicinity due to the presence of

highly flammable or explosive liquid or vapor.

Refer to: Fire Prevention.

5. Displaying this symbol (normally in

conjunction with 5 above) warns of the

presence of potentially explosive matter

within the immediate vicinity.

6. Displaying this symbol warns that children

should not be allowed in the immediate

vicinity unsupervised.

White Spirit

Refer to: Solvent.

M1101001

M1101002

M1101003

M1101004

M1101005

M1101006

1.1.1-12

M201 2014.01

1.1.1-12Overview

Standard Workshop Practice

Vehicle in Workshop

When working on a vehicle in the workshop,

always make sure that:

• The parking brake is applied or the

wheels are securely chocked to prevent

the vehicle moving forwards or

backwards.

• Remove the ignition key before starting

work in front of the vehicle.

• If starting engine, make sure that there is

adequate ventilation, or an extraction

hose to remove exhaust fume.

• There should be adequate room to raise

the vehicle and remove the wheels, if

necessary.

• Fender covers are always fitted if any

work is carried out in the engine

compartment.

• The battery should be disconnected if

working on the engine, underneath the

vehicle, or if the vehicle is raised.

CAUTION: When electric arc welding is

carried out on a vehicle, always

disconnect the alternator wiring,

preventing the possibility of a surge of

current to cause damage to the internal

components of the alternator.

If using welding equipment on the vehicle, a

suitable fire extinguisher is readily available.

Vehicle Towing

WARNING: When the vehicle is being

towed, the ignition switch must be in ACC

(steering lock released and hazard

warning lamp illuminated). Only then will

the turn signal lamps, horn and brake

lamps be operational. Failure to follow

these instructions may result in personal

injury.

CAUTION: The removable towing eye with

left-hand thread must be fully tightened

before towing. When towing is necessary,

the vehicle towing eyes should be used.

The rope must be securely fastened to the

towing eyes and must also be attached to

the other vehicle such that the rope will

not foul the bodywork.

When a vehicle with automatic transmission is

towed, the gear selector must be in position N

(Neutral). Never tow a vehicle with automatic

transmission at a speed greater than 50 km/h or

for a distance greater than 50 km. If it is

necessary to tow the vehicle for a greater

distance, the drive wheels must be lifted off the

ground.

Alternatively the vehicle can be transported on a

low loader or a trailer.

Connecting Another Slave Battery

Using Jumper Cables

WARNING: If the slave battery has just

been charged and is gassing, cover the

vent plug or vent hole with a piece of

damp cloth to reduce the risk of explosion

should arcing occurs when connecting the

jumper cables. Failure to follow these

instructions may result in personal injury.

WARNING: A drained battery condition

may be caused by an electrical short

circuit. If this condition exists, there will

be an apparently live circuit on the vehicle

even when all normal circuits are switched

off. This can cause arcing when the

jumper cables are connected.

WARNING: While it is not recommended

that the vehicle is jump started, it is

recognized that this may occasionally be

the only practical way to mobilize a

vehicle. In such an instance, the drained

battery must be recharged immediately

after jump starting to avoid permanent

damage.

• Always make sure that the jumper cables

are adequate for the task. Heavy duty

cables must be used.

Table of contents