Changhe FREEDOM CH6390 Series 2005 User manual

CHANGHE FREEDOM SERVICE MANUAL FOREWORD

FOREWORD

This manual contains procedures for diagnosis, maintenance, adjustments, minor service

operations, replacement of components (Service) and for disassembly and assembly of major

components.

Applicable model: CHANGHE FREEDOM (CH6390 series) VEHICLE

The contents are classified into sections each of which is given a section number as indicated in

the Table of Contents on following page. And on the first page of each individual section is an index of

that section. This manual should be kept in a handy place for ready reference of the service work.

When replacing parts or servicing by disassembling, it is recommended to use genuine parts, tools

and service materials as specified in each description.

All information, illustrations and specifications contained in this literature are based on the latest

product information available at the time of publication approval. And used as the main subject of

description is the vehicle of standard specifications among others.

Therefore, note that illustrations may differ from the vehicle being actually serviced.

The right is reserved to make changes at any time without notice.

JIANGXI CHANGHE AUTOMOBILE CO., LTD

© COPYRIGHT: JIANGXI CHANGHE AUTOMOBILE CO., LTD

CHANGHE FREEDOM SERVICE MANUAL INTRODUCTION

INTRODUCTION

The CH6390 series auto is a new generation vehicle developed under own R&D center of JIANGXI

CHANGHE AUTOMOBILE CO., LTD. The CH6390 auto structure is compact, flexible, safe and

comfortable, economic and applied, satisfied with statute of collision, emission and noise. It is a

multifunctional automobile that fits for safety and environment.

The CH6390 series auto is equipped with Electronic Fuel Control Injection Engine. Air bags、alnico

wheel and air condition system is optional. Consumers should verify the true equipment status in using

and service. Consumers, please caution: To your safety and the normal use of vehicle, please

don’t make bold to disassemble the air bag and interrelated. If fault occurs, you should take it to

the franchiser and the maintenance man of service station accredited by our company.

The CH6390 series auto may make changes at any time without notice.

For the mend and perfect of the manual, to service more fine, welcome you bring forward

invaluableness advice, editor will thanks a lot. As the editor’s ability is limited, to the misgivings and

discommodious service of work. Please you comment and amend, we will correct in second version.

If you have the manual, you will not worry the service. The manual will be your good assistant.

EDITOR

December 2005

CHANGHE FREEDOM SERVICE MANUAL IMPORTANT

IMPORTANT

WARNING/CAUTION/NOTE

Please read the manual and follow its

instructions carefully. To emphasize special

information, the words WARNING, CAUTION

and NOTE have special meanings. Pay special

attention to the messages highlighted by these

signal words.

WARNING:

For vehicles equipped with a supplemen-

tal Restraint or Air Bag System:

zWARNING:

Service on and around the air bag system

components or wiring must be performed

only by an authorized JIANGXI CHANGHE

AUTOMOBILE CO., LTD. Please observe all

WARNINGS 、CAUTIONS and NOTES under

“On-

V

ehicle Service” in air bag system

section before performing service on or

around the air bag system components or

wiring. Failure to follow WARNINGS could

result in unintentional activation of the

system or could render the system

inoperative. Either of these two conditions

may result in severe injury.

zIf the air bag system and another ve

-hicle system both need repair, JIANGXI

CHANGHE AUTOMOBILE CO., LTD recomme-

nds that the air bag system be repaired first,

to help avoid unintended air bag system

activation.

zDo not modify the steering wheel, in

-strument panel or any other air bag system

component on or around air bag system

components or wiring. Modifications can

adversely affect air bag system performance

and lead to injury.

zIf the vehicle will be exposed to

temperatures over 93°C (200°F), for example,

during a paint baking process, remove the air

bag system components, that is air bag or

inflator modules, SDM and/or seat belt with

pretensioner, before hand to avoid

component damage or unintended activation.

WARNING:

Indicates a potential hazard that

could result in death or in

j

ur

y

.

CAUTION:

Indicates a potential hazard that

could result in vehicle dama

g

e.

NOTE:

Indicates special information to

make maintenance easier or instru-

cttions clearer.

WARNING:

This service manual is intended

for authorized JIANGXI CHANGHE

AUTOMOBILE CO., LTD and qualify-

ed service technicians only. Inexp-

erienced technicians or technicians

without the proper tools and equip-

ment may not be able to properly

perform the services described in

this manual. Improper repair may

result in injury to the technician and

may render the vehicle unsafe for

the driver and passengers.

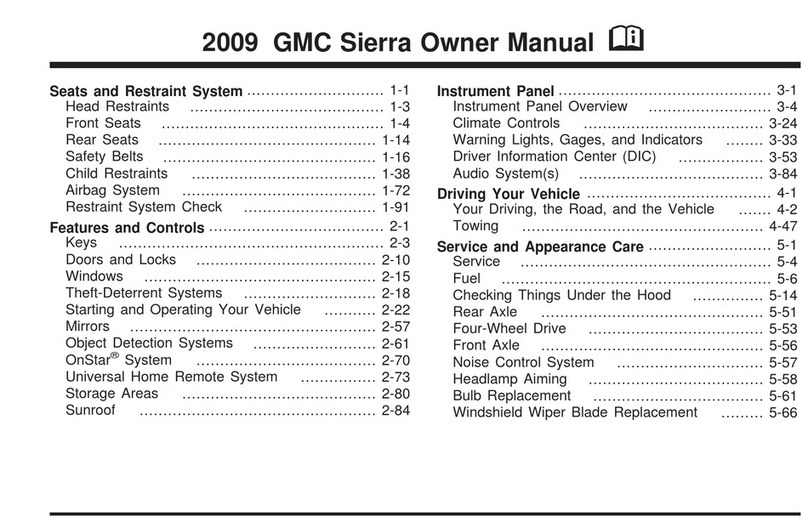

CHANGHE FREEDOM SERVICE MANUAL TABLE OF CONTENTS

TABLE OF CONTENTS

THE FIRST PART GENERAL INFORMATION

SECTION 1 GENERAL INFORMATION

............................................................................. 1

SECTION 2 SCHEDULED MAINTENANCE..................................................................... 22

THE SECOND PART ENGINE

SECTION 3 ENGINE

................................................................................................................. 40

SECTION 4 ENGINE MECHANICAL....................................................................................51

SECTION 5 ENGINE COOLING SYSTEM ........................................................................88

SECTION 6 ENGINE LUBRICATE SYSTEM .................................................................102

SECTION 7 ENGINE MANAGE SYSTEM

...................................................................110

THE THIRD PART CLUTCH TRANSMISSION DIFFERENTIAL

SECTION 8 CLUTCH

...............................................................................................................115

SECTION 9 TRANSMISSION

...............................................................................................124

SECTION 10 GEAR SHIFTING CONTROL

....................................................................161

SECTION 11 PROPELLER SHAFT

...................................................................................171

SECTION 12 DIFFERENTIAL

..............................................................................................177

THE FOURTH PART SUSPENSION STEERING BRAKE

SECTION 13 SUSPENSION ...................................................................................................191

SECTION 14 MANUAL RACK AND PINION ..................................................................214

SECTION 15 BRAKES

.............................................................................................................225

THE FIFTH PART BODY AND ELECTRICAL SERVICE

SECTION 16 ELECTRICAL SYSTEM ................................................................................266

SECTION 17 BODY ELECTRICAL SYSTEM. ................................................................282

SECTION 18 BODY SERVICE ..............................................................................................310

THE SIXTH PART HEATER AND AIR CONDITIONING

SECTION 19 HEATER AND COOLING ............................................................................319

SECTION 20 SEAT BELT AND AIR BAG SYSTEM....................................................330

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

1

THE FIRST PART GENERAL INFORMATION

SECTION 1 GENERAL INFORMATION

CONTENTS

PRECAUTIONS ........................................................................................................................................... 2

Air Bag System Precautions ..................................................................................................................2

General Precautions ................................................................................................................................4

Precautions for Catalytic Converter ..... ................................................................................................6

Precautions for Electrical Circuit Service. . ..........................................................................................6

Intermittent and Poor Connection Inspection ... ..................................................................................7

IDENTIFICATION INFORMATION ........................................................................................................ 8

VIN ........................................................................................................................................................... 8

Engine Identification Number ............................................................................................................... 8

WARNING, CAUTION AND INFORMATION LABELS ................................................................ 9

VEHCILE LIFTING POINTS.................................................................................................................... 10

When Using floor Jack ........................................................................................................................ 10

When Using Frame Contact Hoist ..................................................................................................... 11

FASTENERS STANDARD INFORMAITON .................................................................................... 12

Metric fasteners measurement standard .......................................................................................... 12

Metric fasteners strength identification.... ......................................................................................... 12

Metric fasteners standard tightening torque .................................................................................... 13

SPECIAL TOOLS ........................................................................................................................................ 14

SERVICE AUXILIARY MATERIAL........................................................................................................ 19

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

PRECAUTIONS

AIR BAG SYSTEM PRECAUTIONS

Precautions for Vehicle Equipped with a Supplemental Restrain Air Bag System.

zIf the vehicle will be exposed to temperatures

over 93 °C (200 °F) (for example, during a paint

baking process), remove the air bag system

components before hand to avoid component

damage or unintended air bag system activation.

WARNING:

zThe configuration of air bag system parts are

as shown in the figure. When it is necessary to

service (remove, reinstall and inspect) these parts,

be sure to follow procedures described in section

15. Failure to follow proper procedures could

result in possible air bag system activation,

personal injury, damage to parts or air bag system

being unable to activate when necessary.

zIf the air bag system and another vehicle

system both need repair, we recommend that the

air bag system be repaired first, to help avoid

unintended air bag system activation.

zDo not modify the steering wheel, dashboard,

or any other air bag system components. Modifica-

tions can adversely affect air bag system perfor-

mance and lead to injury.

2

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

SERVICING AND HANDLING

Handle the trouble of air bag, follow the procedure of

removal and installation description in section 15.

WARNING:

zFor handling and storage of a live air bag

(inflator) module, select a place where the

ambient temperature below 65 °C (150 °F),

without high humidity and away from electric

noise.

zWhen carrying a live air bag (inflator)

module, make sure the bag opening is pointed

away from you. In case of an accidental

deployment, the bag will then deploy with

minimal chance of injury. Never carry the air bag

(inflator) module by the wires or connector on

the underside of the module. When placing a live

air bag (inflator) module on a bench or other

surface, always face the bag up, away from the

surface. As the live passenger air bag (inflator)

module must be placed with its bag facing up,

this is necessary so that a free space is provided

to allow the air bag to expand in the unlikely

event of accidental deployment. Otherwise,

personal injury may result.

zThe air bag (inflator) module immediately

after deployment is very hot. Wait for at least half

an hour to cool it off before proceeding the work.

zAfter an air bag (inflator) module has been

deployed, the surface of the air bag may contain

a powdery residue. As with many service

procedures, gloves and safety glasses should be

worn.

3

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

GENERAL PRECAUTIONS

The WARNING and CAUTION below describe some general precautions that you should observe

when servicing a vehicle. These general precautions apply to many of the service procedures described

in this manual, and they will not necessarily be repeated with each procedure to which they apply.

zNew and used engine oil can be hazardous. Children and pets may be harmed by swallowing new or

used oil. Keep new and used oil and used engine oil filters away from children and pets. Continuous contact

with used engine oil has been found to cause [skin] cancer in laboratory animals. Brief contact with used oil

may irritate skin. To minimize your exposure to used engine oil, wear a long-sleeve shirt and moisture-proof

gloves(such as dishwashing gloves) when changing engine oil. If engine oil contacts your skin, wash

thoroughly with soap and water. Launder any clothing or rags if wet with oil, recycle or properly dispose of

used oil and filters.

zWhen it is necessary to do servicing work with the engine running, make sure that the parking brake is

set fully and the transmission is Neutral(for manual transmission vehicles) or Park(for automatic

transmission), Keep hands ,hair, clothing, tools , etc. away from the fan and belts when the engine is running.

zWhen it is necessary to run the engine indoors, make sure that the exhaust gas is forced outdoors.

zDo not perform service work in areas where combustible materials can come in contact with a hot

exhaust system. When working with toxic or flammable materials(such as gasoline and refrigerant), make

sure that the area you work in is well-ventilated.

zTo avoid getting burned, keep away from hot metal parts such as the radiator, exhaust manifold,

tailpipe, muffler, etc.

WARNING:

zWhenever raising a vehicle for service, be sure to follow the instructions under “VEHICLE LIFTING

POINTS” .

CAUTION:

zWhen performing service to electrical parts that does

not require use of battery power, disconnect the negative

cable of the battery。

zWhen removing the battery, be sure to disconnect the

negative cable first and then the positive cable 。When

reconnecting the battery, connect the positive cable first and

then the negative cable, and replace the terminal cover,

zWhen removing parts that are to be reused, be sure to

keep them arranged in an orderly manner so that they may be

reinstalled in the proper order and position.

4

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

zWhenever you use oil seals, gaskets, packing, oil

rings, locking washers, split pins, self-locking nuts, and

certain other parts as specified, be sure to use new ones.

Also, before installing new gaskets, packing, etc., be

sure to remove any residual material form the mating

surfaces.

zMake sure that all parts used in reassembly are

perfectly clean.

zWhen use of a certain type of lubricant, bond or

sealant is specified, be sure to use the specified type.

“A”:Sealant 99000-31150

zBe sure to use special tools when instructed.

Special Tool

(A):09917-98221

(B):09916-58210

zWhen disconnecting vacuum hoses, attach at tag

describing the correct installation positions so that the

hoses can be reinstalled correctly.

zAfter servicing fuel oil , coolant, vacuum, exhaust

or brake systems, check all lines related to the system

for leaks.

zFor vehicle equipped with fuel injection systems,

never disconnect the fuel line between the fuel pump

and injector without first releasing the fuel pressure, or

fuel can be sprayed out under pressure.

5

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

PRECAUTIONS FOR CATALYTIC CONVERTER

Be must to use unleaded gasoline and be careful not

to let a large amount of unburned gasoline enter the

converter or it can be damaged。

zConduct a spark jump test only when necessary.

zConduct engine compression checks within the

shortest possible time。

zAvoid situations which can result in engine misfire

(e.g. starting the engine when the fuel tank is nearly

empty.)

PRECAUTIONS FOR ELECTRICAL CIRCUIT

SERVICE

zWhen disconnecting and connecting coupler, make

sure to turn ignition switch OFF, or electronic parts may

get damaged.

zBe careful not to touch the electrical terminals of

parts which use microcomputers(e.g. electronic control

unit like as ECM,PCM,P/S controllers, etc),The static

electricity from your body can damage these parts.

zNever connect any tester(voltmeter, ohmmeter, or

whatever)to electronic control unit when its coupler is

disconnected. Attempt to do it may cause damage to it.

zNever connect an ohmmeter to electronic control

unit with its coupler connected to it. Attempt to do it may

cause damage to electronic control unit and sensors.

zBe sure to use a specified voltmeter/ohmmeter.

Otherwise, accurate measurements may not be obtained

or personal injury may result.

zWhen taking measurements at electrical

connectors using at tester probe, be sure to insert the

probe from the wire harness side(backside) of the

connector.

zWhen connecting meter probe from terminal side

of coupler because it can’t be connected from harness

side, use extra care not to bend male terminal of coupler

of force its female terminal open for connection。In case

of such coupler as shown connect probe as shown to

avoid opening female terminal. Never connect probe

where male terminal is supposed to fit.

zWhen checking connection of terminals, check its

male half for bend and female half for excessive opening

and bother locking(looseness), corrosion, dust, etc.

6

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

zBefore measuring voltage at each terminal,

check to make sure that battery voltage is 11V or

higher. Such terminal voltage check at low battery

voltage will lead to erroneous diagnosis.

INTERMITTENT AND POOR CONNECTION

Most intermittent are caused by faulty electrical

connections or wiring, although a sticking relay or

solenoid can occasionally be at fault. When checking

it for proper connection, perform careful check of

suspect circuits for:

zPoor mating of connector halves, or terminals

not fully seated in the connector body (backed out).

zDirt or corrosion on the terminals. The

terminals must be clean and free of any foreign

material which could impede proper terminal contact.

However, cleaning the terminal with a sand paper or

the like is prohibited.

zDamaged connector body, exposing the

terminals to moisture and dirt, as well as not

maintaining proper terminal orientation with the

component or mating connector.

zImproperly formed or damaged terminals.

Check each connector terminal in problem

circuits carefully to ensure good contact tension by

using the corresponding mating terminal.

If contact tension is not enough, reform it to

increase contact tension or replace.

zPoor terminal-to-wire connection.

Check each wire harness in problem circuits for

poor connection by shaking it by hand lightly. If any

abnormal condition is found, repair or replace.

zWire insulation which is rubbed through,

causing an intermittent short as the bare area touches

other wiring or parts of the vehicle.

zWiring broken inside the insulation. This

condition could cause continuity check to show a

good circuit, but if only 1 or 2 strands of a

multi-strand-type wire are intact, resistance could be

far too high. If any abnormality is found, repair or

replace.

7

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

BODY IDENTIFICATION INFORMATION

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number is located on the left

front panel in the engine room.

ENGINE IDENTIFICATION INFORMATION

The number is punched on the cylinder block.

8

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

WARNING, CAUTION AND INFORMATION LABELS

The figure below shows main labels among others that are attached to vehicle component parts.

When servicing and handing parts, refer to WARNING /CAUTION instructions printed on labels. If any

WARNING /CAUTION label is found stained or damaged, clean or replace it as necessary.

Engine oil filter, odometer

maintenance label

Fuel indicator

(The side of cap

of fill fuel)

VIN

9

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

VEHICLE LIFTING POINTS

zMake absolutely sure to lock hoist after

vehicle is hoisted up.

zBefore applying hoist to underbody, always

take vehicle balance throughout service into

consideration. Vehicle balance on hoist may

change depending on what part to be removed.

zBefore lifting up the vehicle, check to be

sure that end of hoist arm is not in contact with

brake pipe, fuel pipe, bracket or any other part.

zWhen using frame contact hoist, apply hoist

as shown in figure (right and left at the same

position). Lift up the vehicle till 4 tires are a little

off the ground and make sure that the vehicle will

not fall off by trying to move vehicle body in both

ways. Work can be started only after this

confirmation.

WARNING:

When using floor jack

In raising front or rear vehicle end off the floor by

jacking, be sure to put the jack against the front end of the

engine mounting member or rear axle.

CAUTION:

Never apply jack against suspension parts

(e.g., stabilizer, etc), front bumper or vehicle floor,

otherwise, these parts may get deformed.

To perform service with either front or rear vehicle end

jacked up, be sure to place safety stands under body so

that body is securely supported. And then check to ensure

that body does not slide on safety stands and the vehicle is

held stable for safety's sake.

WARNING:

zIf the vehicle to be jacked up only at the

front or rear end, be sure to block the wheels on

ground in order to ensure safety.

A

fter the vehicle is jacked up, be sure to

support it on stands. It is extremely dangerous to

do any work on the vehicle raised on jack alone.

10

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

When Using Frame Contact Hoist

zBefore lifting up the vehicle, check to

be sure that end of hoist arm is not in

contact with brake pipe, fuel pipe, bracket

or any other part.

zWhen using frame contact hoist,

apply hoist as shown (right and left at the

same position). Lift up the vehicle till 4 tires

are a little off the ground and make sure

that the vehicle will not fall off by trying to

move vehicle body in both ways. Work can

be started only after this confirmation.

zBefore applying hoist to underbody,

always take vehicle balance throughout

service into consideration. Vehicle balance

on hoist may change depending on what

part to be removed.

zMake absolutely sure to lock hoist

after vehicle is hoisted up.

WARNING:

ENGINE CYLINDER NUMBER

CAUTION:

These cylinders of the engine are

identified by numbers (figure 0-9); No.1,

No.2, No.3 and No.4 counted from

crankshaft pulley side to flywheel side.

11

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

FASTENERS STANDARD INFORMAITON

Metric Fasteners Measurement Standard

Most of the fasteners used for this vehicle are metric,

When replacing any fasteners, it is most important that

replacement fasteners be the correct diameter, thread pitch

and strength.

Metric Fasteners Strength Identification

Most commonly used metric fastener strength property

classes are 4T, 6.8, 7T, 8.8 and radial line with the class

identification embossed on the head of each bolt. Some

metric nuts will be marked with punch, 6 or 8 mark strength

identification on the nut face. Left figure shows the different

strength markings.

Nut strength mark

When replacing metric fasteners, be careful to use bolts and nuts of the same strength or greater

than the original fasteners (the same number marking or higher). It is likewise important to select

replacement fasteners of the correct diameter and thread pitch. Correct replacement bolts and nuts are

available through the parts division.

12

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

13

METRIC FASTENERS STANDARD TIGHTENING TORQUE

Each fastener should be tightened to the torque specified in each section of this manual.

If no description or specification is provided, refer to the following tightening torque chart for the

applicable torque for each fastener. When a fastener of greater strength than the original one is used,

however, use the torque specified for the original fastener.

NOTE:

zFor the flanged bolt, flanged nut and self-lock nut of 4T and 7T strength, add 10% to the

tightening torque given in the following chart.

zThe following chart is applicable only where the fastened parts are made of steel light

alloy.

Tightening Torque Table

THREAD

DIAMETER(mm)

STRENGTH

4 5 6 8 10 12 14 16 18

N·m 1.5 3.0 5.5 13 29 45 65 105 160

kg·m 0.15 0.30 0.55 1.3 2.9 4.5 6.5 10.5 16

lb·ft 1.0 2.5 4.0 9.5 21.0 32.5 47.0 76.0 116.0

N·m 2.4 4.7 8.4 20 42 80 125 193 280

kg·m 0.24 0.47 0.84 2.0 4.2 8.0 12.5 19.3 28

l

b·ft 2.0 3.5 6.0 14.5 30.5 58.0 90.5 139.5 202.5

N·m 2.4 4.9 8.8 21 44 84 133 203 298

kg·m 0.24 0.49 0.88 2.1 4.4 8.4 13.3 20.3 29.8

l

b·ft 2.0 3.5 6.5 15.5 32.0 61.0 96.5 147.0 215.5

N·m 2.3 4.5 10 23 50 85 135 210 240

kg·m 0.23 0.45 1.0 2.3 5.0 8.5 13.5 21 24

l

b·ft 2.0 3.5 7.5 17.0 36.5 61.5 98.0 152.0 174.0

N·m 3.1 6.3 11 27 56 105 168 258 373

kg·m 0.31 0.63 1.1 2.7 5.6 10.5 16.8 25.8 37.3

l

b·ft 2.5 4.5 8.0 19.5 40.5 76.0 121.5 187.0 270.0

N·m 3.2 6.5 12 29 59 113 175 270 395

kg·m 0.32 0.65 1.2 2.9 5.9 11.3 17.5 27 39.5

l

b·ft 2.5 5.0 9.0 21.0 43.0 82.0 126.5 195.5 286.0

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

SPECIAL TOOLS

The main function of special tools:1)Improve the quality of work;2)Increase the efficiency of

work;3)Protect parts and components from damage . The special tools use by the model are as

follows:

Mass Storage Facility

14

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

09900-25002

Pocket tester

09900-20803

Thickness rule

09900-06107

Snap ring pliers

(Opening type)

09900-06108

Snap ring pliers

(Closing type)

9913-65135

T

ransmission gear remover

09913-65210

Tie-rod end remover

09913-80112

Bearing installer

09913-75520A:60.5mm

09913-75510A:70.5mm

Differential front and rear

outer race installer

09913-84510

Bearing installer

09913-85210

Wheel hub installer

09913-85230

Differential end Bearing

remover jig

09915-47310

Oil filter wrench

15

CHANGHE FREEDOM SERVICE MANUAL GENERAL INFORMATION

1.09916-14510

Valve lifter

2.09916-48210

Valve lifter attachment

09916-34520

Reamer(7mm)

09915-64510

Air pressure gauge

09915-67310

Vacuum gauge

09915-77310

Vacuum gauge

09916-34541

Reamer handle

09916-37310

Reamer(12mm)

09916-44511

Vacuum gauge

09916-57321

V

alve guide installer handle

09916-77310

Piston ring compressor

09916-84510

Forceps

09917-47910

Vacuum pump gauge

09917-58010

Bearing remover

(

Input shaft use )

09917-88210

Valve guide installer

09917-98210

Valve stem seal installer

09921-20200

pinion bearing remover

16

Table of contents

Popular Automobile manuals by other brands

elddis

elddis Buccaneer 2014 Owner's handbook

Fiat

Fiat TIPO 5DOOR Owner's handbook

Mercedes-Benz

Mercedes-Benz 2011 SL550 Roadster Operator's manual

Mercedes-Benz

Mercedes-Benz 2006 E 320 CDI Operator's manual

RAM

RAM 2011 Chassis Cab owner's manual

Mercedes-Benz

Mercedes-Benz Sprinter 2012 Maintenance booklet