Christ ALPHA 1-2 LDplus User manual

Version 11.2006 – English

Revision 1.2

Operating Manual

Freeze Dryer

ALPHA 1-2 LDplus

Part. No. 101521

Operating Manual Freeze Dryer ALPHA 1-2 LDplus

OPERATING MANUAL

ALPHA 1- 2 LDplus

Order Number:

Serial Number:

In case of inquiries please state the above numbers.

For service:

please use online service request form:

www.martinchrist.de →[Contacts] →[Service request]

Martin Christ Gefriertrocknungsanlagen GmbH

An der Unteren Söse 50, 37520 Osterode (Germany)

Phone +49 (0) 5522 / 5007-8425, Fax +49 (0) 5522 / 5007-9425

eMail: [email protected]

Operating Manual Freeze Dryer ALPHA 1-2 LDplus

Preface

Dear customer

Congratulations on purchasing a CHRIST freeze dryer.

The freeze dryer ALPHA1-2 LDPlus is equipped with a lot of user-

friendly options which make the operation easier for you.

The newly designed ALPHA1-2 LDPlus is a universally usable

CHRIST freeze dryer for laboratories, R&D departments and

scientific institutes. Our well proven range of accessories allows

application-oriented configuration of the equipment for almost all

types of drying processes in round bottom flasks, dishes,

ampoules, injection bottles, etc.

A special advantage is the easy-to-use and self-explaining unit

operation with the new LDplus control system (Lyo-Display-plus):

Graphic LC display with a clear layout showing the most

important process data (ice condenser temperature,

process time, section time and vacuum)

Comfortable and self-explaining menu guidance in

German, English, French, Spanish and Polish

Conversion of product temperature and vacuum according

to the vapour pressure curve for ice

RS-232 communications interface (PC) available as an

option

Retrofitting of a vacuum control system using a pressure

control valve and a vacuum sensor head (both available as

accessories) possible

We can now offer you a freeze dryer combining functionality and

convention utilisation.

We thank you for your confidence and wish you a successful

application of your freeze dryer.

Martin Christ Gefriertrocknungsanlagen GmbH

An der Unteren Söse 50, 37520 Osterode (Germany)

Phone +49 (0) 5522 / 5007-0, Fax +49 (0) 5522 / 5007-12

Operating Manual Freeze Dryer ALPHA 1-2 LDplus Contents •iii

Contents

1. General Information 1

1.1. Introduction ......................................................................................................1

1.2. Applications......................................................................................................2

1.3. Technical Specifications of Freeze Dryer ALPHA 1- 2 LDplus ..........................3

1.4. Standards and Regulations..............................................................................6

1.5. Safety Instructions ...........................................................................................6

1.5.1. CAUTION! Disconnect Mains Plug!....................................................6

1.5.2. CAUTION! Solvents!...........................................................................6

1.5.3. ADVICE! Cleaning and Maintenance of the Unit!...............................6

1.5.4. WARNING! Freezing of Limbs to Surfaces!.......................................6

1.5.5. ADVICE! Transport Instructions! ........................................................7

1.6. Prohibited Freeze Drying Processes...............................................................8

2. General Information on Freeze Drying 9

2.1. General Information on Freeze Drying ............................................................9

2.2. Preparation.....................................................................................................12

2.3. Freezing.........................................................................................................12

2.4. Main Drying....................................................................................................13

2.5. Final Drying....................................................................................................17

2.6. End of Drying and Aeration............................................................................17

2.7. Defrosting.......................................................................................................18

3. Description of the Freeze Drying Processes 19

3.1. Separate Freezing and Drying Outside the Ice Condenser Chamber

(Process B) on Shelves .................................................................................19

3.2. Separate Freezing and Drying Outside the Ice Condenser Chamber

(Process B) with Sealing Device....................................................................20

3.3. Separate Freezing and Drying of Liquids in Flasks (Process B)...................21

3.4. Separate Freezing and Drying of Liquids in Ampoules (Process B)..............22

4. Installation and Commissioning of the Unit 25

4.1. Site of Installation...........................................................................................25

4.2. Mains Electricity.............................................................................................26

4.3. Fuses on Site.................................................................................................26

4.4. Checking the Earth Connection.....................................................................26

4.5. Aeration..........................................................................................................26

4.6. Condensate and Defrosting Water ................................................................26

4.7. Vacuum Pump Exhaust .................................................................................27

4.8. Initial Start-up.................................................................................................27

4.8.1. Functional Components and Control Elements................................28

4.8.2. Connection of vacuum sensor vacuum Pump, and pressure

control valve......................................................................................29

4.8.3. Switching-on.....................................................................................34

5. LDplus Control System 37

5.1. Introduction ....................................................................................................37

5.2. LDplus control panel......................................................................................37

iv •Contents Operating Manual Freeze Dryer ALPHA 1-2 LDplus

5.3. Brief Guide - Handling....................................................................................38

5.4. Visual components of the LDplus control system..........................................39

5.4.1. Main window.....................................................................................39

5.4.2. Status bar .........................................................................................39

5.4.3. Softkey function................................................................................40

5.5. Values window...............................................................................................41

5.6. Mode..............................................................................................................42

5.6.1. Starting a drying process..................................................................42

5.6.2. Changing the phase .........................................................................42

5.6.3. Timer.................................................................................................42

5.7. Main menu .....................................................................................................43

5.7.1. Change set values............................................................................43

5.7.2. Special functions ..............................................................................44

5.7.3. Process and equipment information system ....................................45

5.7.4. Options .............................................................................................45

5.7.5. Tutorial..............................................................................................46

5.8. Process and equipment information system..................................................47

5.8.1. Information status.............................................................................47

5.9. LDplus special functions................................................................................48

5.9.1. Defrost ice condenser (option) .........................................................48

5.9.2. Electrical lifting device (option).........................................................48

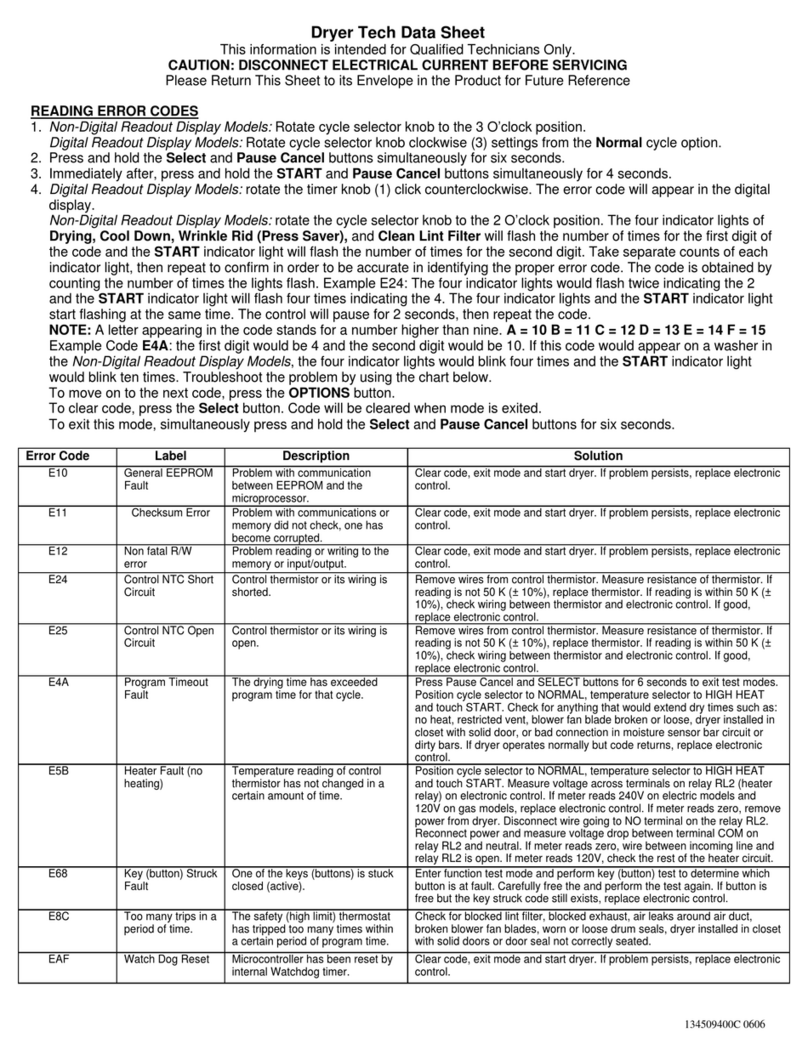

6. Error Correction 49

6.1. Power Failure.................................................................................................49

6.2. Insufficient Vacuum........................................................................................49

6.3. Unit does not function....................................................................................51

6.4. Insufficient Ice Condenser Temperature........................................................51

6.5. Process and Equipment Information System.................................................52

6.5.1. Error Messages ................................................................................52

7. Maintenance 55

7.1. Ice Condenser Chamber................................................................................55

7.2. Heat Exchanger .............................................................................................55

7.3. Adjustment and Maintenance of the Vacuum Sensor VSP62.......................55

7.3.1. Maintenance of the Vacuum Sensor:...............................................55

7.3.2. Replacement and adjustment...........................................................56

7.4. Rubber Valves ...............................................................................................57

7.5. Vacuum Pump ...............................................................................................57

7.6. Exhaust Filter.................................................................................................57

7.7. Cleaning.........................................................................................................58

7.7.1. Cleaning of the Freeze Dryer ...........................................................58

7.7.2. Cleaning of Accessories...................................................................58

7.7.3. Maintenance of the Aeration Valve and the Drain Valve..................58

7.7.4. Disinfection of Drying Chamber, Lid and Accessories .....................59

7.7.5. Checks by Operator..........................................................................59

8. Options 61

8.1. Process Control System LPC-32, Software...................................................61

8.2. Process Control System LPC-32, Software with PC hardware.....................61

8.3. LyoLog LL-1 (Documentation Software)........................................................61

8.4. LDplus Simulation Tool (Training Software)..................................................61

9. Enclosures 63

10. Special functions 79

Operating Manual Freeze Dryer ALPHA 1-2 LDplus General Information •1

1. General Information

1.1. Introduction

What is freeze drying (Lyophilisation)?

Freeze drying means: Extraction of water from frozen material.

The drying process takes place by avoiding the liquid state through

sublimation, i. e. direct conversion from ice to vapour. This

happens under vacuum and the temperature in the product is

normally less than -10°C.

The aim of freeze drying is to obtain an easily water soluble

product which will have the same characteristics as the original

product after addition of water.

As the drying process takes place in frozen state at very low

temperatures it is possible to dry e. g. proteins which will not

denature. Also most of the other chemical compounds will be

qualitatively and quantitatively unchanged.

Through freeze drying the product, mainly of biological origin -

such as tissues, tissue extracts, bacteria, vaccines and sera - is

transformed into a dry product. During this process enzymatic,

bacterial and chemical changes are largely avoided.

Freeze drying (lyophilisation) is the most gentle process for

preserving the biological properties of sensitive tissue and tissue

components.

Lyophilisation is also the best method when drying inorganic

products – e.g. nanoscale dispersions – the particle surfaces of

which should remain unchanged.

2 •General Information Operating Manual Freeze Dryer ALPHA 1-2 LDplus

1.2. Applications

The freeze dryer ALPHA 1-2 LDplus is a high-performance

universal laboratory and pre-production unit for freeze drying of

solid or liquid products in ampoules, vials, glass flasks, plasma

bottles or dishes. All operations necessary for freeze drying can be

realized in one and the same unit:

• Freezing of the products (uncontrolled shelf surface

temperature)1

• Freeze drying (sublimation) of the products at user-

defined temperature limit values and pressure limit

values

• Final drying of the products at user-defined

temperature limit values and high final vacuum for the

removal of capillarily or molecularly bound water.

The freeze dryer ALPHA 1-2 LDplus is suitable for drying of e. g.

bacteria and virus cultures, blood plasma, serum fractions,

antibodies, sera, vaccines and pharmaceutical products such as

chloramphenicol, streptomycin, vitamins, ferments as well as plant

extracts for biochemical tests.

1Normally done separately in a deep-freeze

Operating Manual Freeze Dryer ALPHA 1-2 LDplus General Information •3

1.3. Technical Specifications of Freeze Dryer

ALPHA 1- 2 LDplus

ALPHA 1-2 LDplus

Performance data

Ice condenser capacity max. 2.5kg

Ice condenser

performance1) max. 2kg/24h

Ice condenser

temperature1) approx. –55°C

Shelf or product

temperature during freezing

in the ice condenser

chamber

approx. –25°C

Ice condenser chamber

volume: approx. 3,5l

Max. shelf surface area

when drying outside the ice

condenser chamber

(process B):

3 shelves, Ø200

Atotal 0.092m2

spacing: up to 80mm

with accessory

no. 120893

Max. shelf surface area

when drying in glass vials

with sealing under vacuum

or nitrogen atmosphere

outside the ice condenser

chamber (process B):

2 shelves, Ø200

Atotal 0.054m2

spacing: 25-70mm

with accessory

no. 121015

Drying in round bottom

flasks. Please note that the

max. ice condenser

capacity is 2kg

(process B):

8 pieces, with

accessory no.

121450

4 •General Information Operating Manual Freeze Dryer ALPHA 1-2 LDplus

Physical data (without

vacuum pump):

Dimensions of the unit: width: 315mm

height: 345mm

depth: 460mm

(incl. vacuum flange

connection)

Weight: approx. 28kg

Noise emissions according

to DIN 45635: 49 dB(A)

Electromagnetic

compatibility according to

EN 55011:

class B

Filling quantities:

Refrigerant: see label on the back

of the unit

Connection requirements

with vacuum pump

0.4KVA:

Electrical connection: 230V / 50Hz (others

upon request)

Power consumption: 1,2kVA

Max. current: 5A

Fuse protection: 6,3A

Ambient temperature: +10°C to +25°C

(higher temperatures

upon request)

Operating Manual Freeze Dryer ALPHA 1-2 LDplus General Information •5

Equipment connections:

Vacuum connection: Small flange

connection

DN 25 KF

(ISO 28403,

DIN 2861)

Drain valve and

Aeration valve:: Hose nozzle DN10

(outside diameter

12mm)

1) All machine specifications (especially for temperatures, power

and capacity) refer to the nominal ambient temperature of 20°C.

The scope of delivery includes:

• 1 tube of high-vacuum grease

• 1 litre vacuum pump oil (only in case a pump is

delivered)

• 0.5 m drain hose (silicone 9 x 12 mm)

• 1 operating manual and further detailed technical

documentation

The scope of delivery does not include:

Commissioning of the unit (inside Germany) can be

performed upon request and will be invoiced at cost.

Installation of the exhaust pipe of the vacuum pump (not

necessary when using an exhaust filter).

6 •General Information Operating Manual Freeze Dryer ALPHA 1-2 LDplus

1.4. Standards and Regulations

Please refer to the enclosed EU Declaration of Conformity.

1.5. Safety Instructions

1.5.1. CAUTION! Disconnect Mains Plug!

As current-carrying parts are accessible inside the unit

the mains plug must be disconnected before the side panels are

opened or before the control panel is removed.

For maintenance work the unit must be switched off with the mains

switch.

1.5.2. CAUTION! Solvents!

Acidic products or products with a high solvent

concentration cannot be dried without special protective measures

and devices such as e.g. a cooling trap for protection of the

vacuum pump (if necessary check with our service department).

Besides, the unit may be damaged by corrosion.

Special caution is necessary when using azides because a

dangerous explosive develops in combination with copper or non-

ferrous metals! It is absolutely essential to consult our service

department!

1.5.3. ADVICE! Cleaning and Maintenance of the Unit!

For infectious, toxic, pathogenic and radioactive

substances the corresponding safety regulations must be

observed.

1.5.4. WARNING! Freezing of Limbs to Surfaces!

During operation of the freeze dryer dangerous

situations in the ice condenser chamber may arise. When putting

in the shelves take care that limbs do not come into contact with

the condenser in the ice condenser chamber as the limbs may

Operating Manual Freeze Dryer ALPHA 1-2 LDplus General Information •7

become frozen to the surface. The limb can only be detached from

the surface by applying heat. Liquid should not be used.

1.5.5. ADVICE! Transport Instructions!

Please keep the packaging for possible subsequent

dispatch.

The freeze dryer should be carried by two persons by holding it

underneath on both sides.

WARNING! When transporting or putting down the unit do not hold

the plastic control panel. Please note: When putting the unit down

on a surface there is a danger of squeezing hands or fingers.

WRONG CORRECT

8 •General Information Operating Manual Freeze Dryer ALPHA 1-2 LDplus

1.6. Prohibited Freeze Drying Processes

1. Operation of freeze dryer when not installed correctly.

2. Operation of freeze dryer without panels.

3. Operation of freeze dryer by non-authorised personnel.

4. Operation of freeze dryer with shelves not installed

properly.

5. Operation of freeze dryer with very corrosive

substances (e.g. hydrogen chloride). It is not allowed to

dry these substances, at least special safety measures

have to be observed. The corrosive substances must

not cause damage to material and must not degrade

the mechanical strength of the ice condenser chamber,

the drying chamber, the lid or the accessory

components.

6. Operation of freeze dryer with accessories not allowed

by the manufacturer, except for commercial freeze

drying vessels made of glass or plastic. The user is

explicitly warned not to use poor quality goods.

Breaking glass or bursting vessels can cause

dangerous situations during freeze drying.

7. Operation of freeze dryer in locations with danger of

explosion.

8. During operation the freeze dryer must not be knocked

or moved. Leaning against or resting on the freeze

dryer is not allowed.

9. Do not place potentially dangerous material, e. g. glass

vessels containing liquids, near the freeze dryer.

10. Products which could react to the supply of high energy

during the freeze drying process must not be dried.

11. Do not freeze dry explosive or highly inflammable

substances.

12. Infectious, toxic, pathogenic and radioactive

substances must only be dried in suitable vessels.

Operating Manual Freeze Dryer ALPHA 1-2 LDplus General Information on Freeze Drying •9

2. General Information on Freeze

Drying

2.1. General Information on Freeze Drying

Freeze drying is the most gentle process for drying products. It is

based on the physical phenomenon of sublimation i.e. the direct

conversion from solid to gaseous state. The frozen product is

placed in the vacuum drying chamber for drying. The ice

condenser can also be described as a vapour pump as the

moisture which evaporates under vacuum during drying freezes

onto the ice condenser. Consequently the vacuum pump is only

intended to remove the air from the drying chamber (=gas pump)

but not the vapour. In order to start the sublimation process,

energy must be supplied to the product. This takes place during

drying in round bottom flasks or wide-neck filter bottles etc. due to

the much warmer environment (direct heat contact), on unheated

shelves by means of heat radiation from the environment and

directly by means of the shelves when heatable. Once the “free

water” has been removed from the product, it is also possible to

remove the marginally contained adsorptively bound water by

means of very low vacuum. This part of the drying process is

referred to as final drying (desorption).

The main components of a freeze dryer are :

• Vacuum drying chamber with heating device

a) heatable2and unheatable shelves for drying in

dishes

b) shelves with sealing device for drying in bottles

c) rubber valves for connecting round bottom flasks,

wide-neck filter bottles, etc.

d) manifold for connecting round bottom flasks, wide-,

neck filter bottles, etc.

• Pumps to evacuate air and water vapour

a) vacuum pump to evacuate the drying chamber

(= gas pump)

b) ice condenser with temperatures from -50°C to

-105°C (depending on type of unit) to remove the

2Heatable (controlled) shelves are only possible with an LSC control system.

10 •General Information on Freeze Drying Operating Manual Freeze Dryer ALPHA 1-2 LDplus

water vapour from the chamber

(= vapour pump)

Sublimation

The principle of sublimation is briefly explained using the phase

diagram of water (freeze drying of mainly aqueous solutions, see

vapour pressure curve). If the atmospheric pressure is higher than

6.11 mbar, water passes through all three phases (solid, liquid,

gas) when the temperature is lowered or raised. At 6.11 mbar the

melting pressure curve, vapour pressure curve and sublimation

pressure curve meet in one point called triple point. At this point all

three phases occur in parallel (simultaneously). Below this point,

i.e. the pressure is lower than 6.11 mbar, the ice is converted

directly from a solid to a gaseous phase on reaching the

sublimation pressure curve (vapour pressure curve above ice).

Operating Manual Freeze Dryer ALPHA 1-2 LDplus General Information on Freeze Drying •11

Conversion table "Vapor pressure above ice" (sublimation

curve)

Pressure units: 1mbar = 100Pa

1Pa = 0.01mbar

Temperature units: 273

+

=

tT

273

−

=

Tt

328.1

+

⋅

=

ttF

8.1 32

−

=F

t

t

T = thermodynamic temperatureK (Kelvin)

t = temperature in degree Celsius °C

tF= temperature in degree Fahrenheit °F

°C mbar °C mbar °C mbar °C

mbar

0 6.110 -20 1.030 -40 0.120 -60 0.011

-1 5.620 -21 0.940 -41 0.110 -61 0.009

-2 5.170 -22 0.850 -42 0.100 -62 0.008

-3 4.760 -23 0.770 -43 0.090 -63 0.007

-4 4.370 -24 0.700 -44 0.080 -64 0.006

-5 4.020 -25 0.630 -45 0.070 -65 0.0054

-6 3.690 -26 0.570 -46 0.060 -66 0.0047

-7 3.380 -27 0.520 -47 0.055 -67 0.0041

-8 3.010 -28 0.470 -48 0.050 -68 0.0035

-9 2.840 -29 0.420 -49 0.045 -69 0.0030

-10 2.560 -30 0.370 -50 0.040 -70 0.0026

-11 2.380 -31 0.340 -51 0.035 -71 0.0023

-11 2.170 -32 0.310 -52 0.030 -72 0.0019

-13 1.980 -33 0.280 -53 0.025 -73 0.0017

-14 1.810 -34 0.250 -54 0.024 -74 0.0014

-15 1.650 -35 0.220 -55 0.021 -75 0.0012

-16 1.510 -36 0.200 -56 0.018 -76 0.0010

-17 1.370 -37 0.180 -57 0.016 -77

-18 1.250 -38 0.160 -58 0.014 -78

-19 1.140 -39 0.140 -59 0.012 -79

12 •General Information on Freeze Drying Operating Manual Freeze Dryer ALPHA 1-2 LDplus

2.2. Preparation

In case the unit is equipped with a pressure control valve the

vacuum pump should be warmed up. The operation

temperature should be reached before loading the vacuum pump

with condensable gases. In this way, the service life of the vacuum

pump can be considerably extended.

The vacuum pump can be operated already during the freezing

process when the pressure control valve is closed. The vacuum

pump should be warmed up for at least 15 minutes or it should be

switched on at least 15 minutes before starting the main drying

process.

It may occur that the vacuum in the ice condenser chamber or in

the drying chamber goes up during the main drying process (e.g.

from 0.63 mbar to 0.47 mbar) although the valve to the vacuum

pump is closed. This can be explained physically by the pumping

effect of the ice condenser (“Cryo Pumping Effect”).

2.3. Freezing

Small product quantities are frozen directly inside the ice

condenser chamber of the freeze dryer. Larger quantities are pre-

frozen in a deep-freeze.

If liquids are to be dried in bottles with a layer thickness of more

than 1 cm we recommend that pre-freezing is carried out with a

shell or spin freezing device in a cooling bath (see picture). Due to

the centrifugal force the liquid to be frozen will rise on the wall of

the bottle and freeze. With this freezing process the layer

thickness is reduced and thus the total drying period is shortened

considerably.

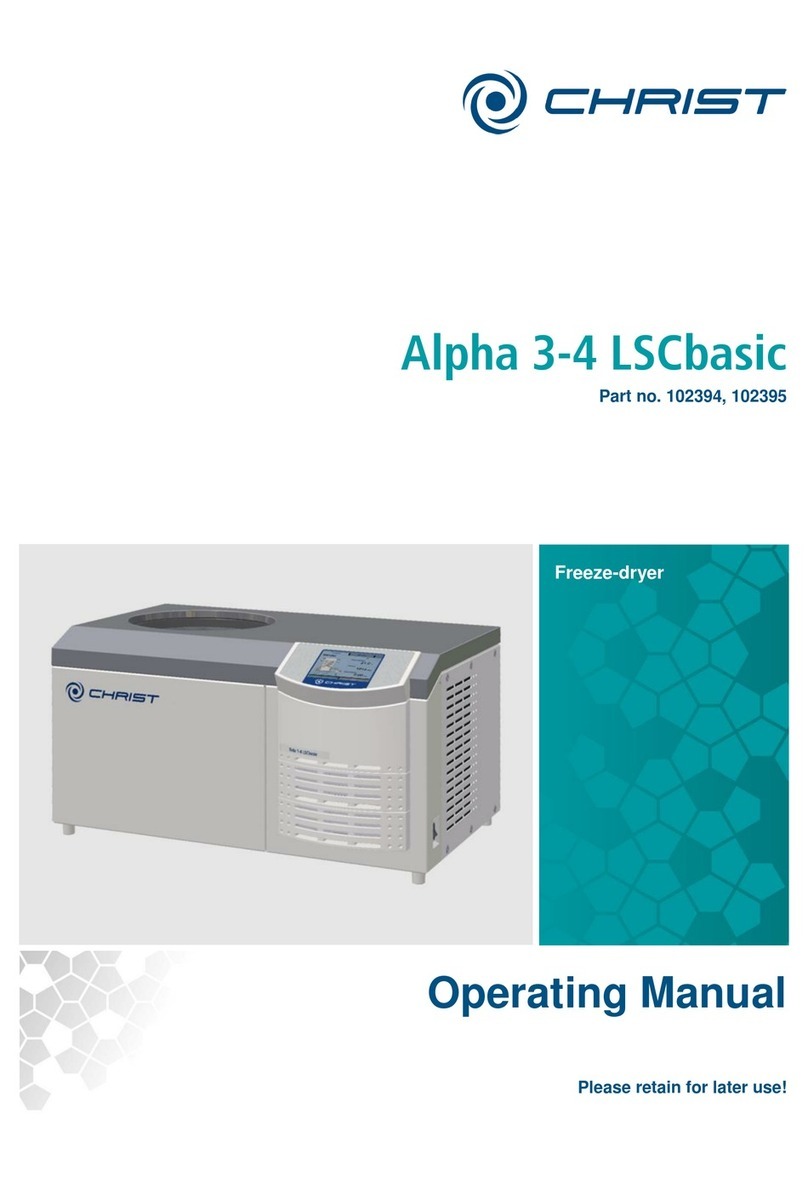

Other manuals for ALPHA 1-2 LDplus

2

Table of contents

Other Christ Dryer manuals

Christ

Christ ALPHA 1-4 LDplus User manual

Christ

Christ Alpha 3-4 LSCbasic User manual

Christ

Christ Alpha 3-4 LSCbasic User manual

Christ

Christ Beta 1-8 LSCplus User manual

Christ

Christ Beta 1-8 LSCbasic User manual

Christ

Christ Delta 1-24 LSCplus User manual

Christ

Christ Alpha 1-4 LSCplus User manual

Christ

Christ ALPHA 1-2 LDplus User manual

Christ

Christ Gamma 1-16 LSCplus User manual

Christ

Christ Delta 1-4 LSCplus User manual